Good day, my dear readers! In my articles I often mention the word heating element, but I haven’t really said anything about them anywhere yet. This defect needs to be corrected!

That’s why I decided to write this article, in which I will give a brief educational program on this (quite extensive) topic.

And in one of the following articles I will tell you how to connect heating elements to an electric boiler.

I will say right away that I do not pretend to be a complete review and will be glad to see your comments and observations, on the basis of which it will be possible to supplement this article. So let's start with the definition.

What is TEN?

What is it?

TEN (short for tubular electric heater) is the simplest electric heating device that has a wide variety of applications:

- Heating - heating elements are used as heaters in electric boilers, electric sauna heaters, oil radiators, and so on.

- Hot water supply - storage and instantaneous water heaters heat water using heating elements. And ordinary household kettles also have a heating element installed.

In general, the scope of application of such devices is very wide.

Wherever you need to heat something, you can think about using one or another type of heating element.

Now let's take a closer look at the main types of tubular electric heaters:

- Heating elements for heating liquids - most often, with the help of such devices, water is heated for certain purposes, but there are exceptions to this rule. For example, there are models designed for heating machine oil or food products.

- Heating elements for heating air - it is clear that such devices heat the air, but there are some nuances here - the presence or absence of blowing and the speed of the blowing air. In addition, air heating elements can be equipped with fins, which increase their surface area.

Purpose of heating elements

Electric heating elements have gained popularity due to their versatility and high efficiency. All the electricity they consume is used for its intended purpose - heating the surrounding space.

The main heating devices where heating elements are used are:

- Portable and stationary oil electric heaters.

- Water heating radiators.

- Bathroom heated towel rails.

- Electric fireplaces.

- Electric convectors.

- Electric boilers.

The specified equipment can be used as a main or additional heating source. It is inexpensive, easy to install and does not require special skills to operate.

You can connect the heating element to a cast iron central heating radiator after disconnecting the common riser. This device can be used for main and additional heating

Heating element device

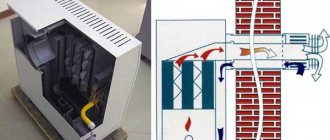

To understand how a tubular electric heater works, look at the figure below:

Water heater heating element device

- The shell is a metal tube. Copper, steel or aluminum tubes of different diameters are used as shells.

- Contact rod - a metal rod with a thread at the end through which the power supply of the heating element is connected.

- The heating element is a spiral made of an alloy with high resistivity.

- Filler - the dielectric periclase (white magnesium oxide powder) is used as a filler.

- Sealing material - protects the filler from external moisture and thereby preserves its properties.

- Contact washers and nuts are needed to secure the terminals.

- Insulator - separates the contact rod and the shell of the heating element. Needed to protect against current leakage to the housing.

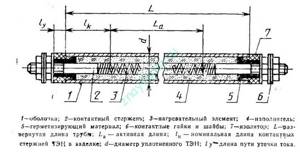

The figure shows the length parameters. Let's decipher their meaning:

- L is the expanded length of the heater. According to GOST, it is equal to the sum of the lengths of straight and curved sections.

- La - active length. Equal to the length of the heating element.

- Lk is the length of the contact rod. The length of the embedment is standardized and indicated in the marking using a letter.

- Ly is the length of the leakage current path. Special standardized value.

- d is the diameter of the heating element.

Additional functions of electric heaters

Above we discussed the simplest designs of devices that do not have any built-in adjustment mechanisms.

The thermoregulation unit can have mechanical or electronic automation. The latter is more accurate, but is demanding on the parameters of the home electrical network

But electric heaters can be equipped with simple automation that provides the device with additional functions.

These include:

- Thermoregulation . Heaters with a built-in thermostat for heating have a temperature sensor that is triggered when the working environment is heated to a certain level. The electric heater is adjusted from the outside of the flange.

- Antifreeze . This function is provided by a simplified thermostat, which operates only when the temperature drops to 0-2°C. It prevents water from freezing in heating pipes, consuming a minimum of electricity.

- Turbo heating , which provides forced heating of the working environment during the initial start-up of equipment. It must be remembered that the electrical wiring of the room must withstand a short-term increase in power.

There are not many devices that support additional functions, because the operation of heating devices as a whole is often regulated using a separate automation unit.

Marking of heating elements: decoding

In order to be able to distinguish some heating elements from others, special markings were developed, fixed by the state standard.

It is applied to the surface using a press and should be located close to the insulator.

Consider, for example, the following marking:

100А13/1.6р220 - 2R30

- The number 100 indicates the unfolded length of the heating element in centimeters.

- The letter “A” in the marking encodes the depth of embedding of the contact rod (I will give the decoding below).

- The number 13 indicates the diameter of the tube in millimeters.

- The number 1.6 indicates the heater power in kW.

- The letter “p” encodes the heated medium (in this case, water and weak solutions of alkalis or acids) and the tube material (carbon steel).

- The number 220 indicates the supply voltage is 220 V.

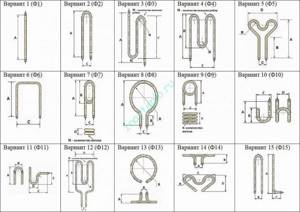

- Number 2 is the number of the heating element shape (in this case it is U-shaped).

- R30 is the bending radius of the heating element in millimeters.

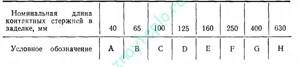

Now let's decipher the length of the contact rods. Look at the picture below:

Designation of heating elements markings

Now let's move on to the second letter in the marking.

Here is a breakdown of the most popular options:

| Letter | Heated medium | Tube material | Maximum specific power, W/cm2 |

| X | Water or weak solutions of alkalis and acids | Copper or brass | 9 |

| P | Water or weak solutions of alkalis and acids | Carbon steel | 15 |

| J | Water or weak solutions of alkalis and acids | Stainless steel | 15 |

| Z | Fats or oils | Carbon steel | 3 |

| O | Air or other gas mixtures (with blowing) | Carbon steel | 5 |

| S | Air or other gas mixtures (without blowing) | Carbon steel | 2,2 |

Everything is deciphered in more detail in GOST 13268-88.

For air heating elements, the presence or absence of airflow and even the required air speed are specified.

If you use heating elements designed for blowing in calm air, they will quickly burn out due to too high power density.

To complete the review, I will add a picture with the forms. This will help you navigate them more easily:

Types of heating elements

Exploitation

Recommendations for operating a heating element with a thermostat:

- It is not recommended to use heating elements in water with a high salt content. In such an environment, sediment forms on the surface. To avoid this, a magnesium anode is installed, which prevents the formation of deposits.

- If the power supply voltage is unstable, it is advisable to install a stabilizer; this will extend the service life of the device.

- The heating element requires significant voltage in the network, so it is recommended to supply a separate power line.

Heating elements for electric heating boilers

Previously, I wrote a separate article on electric boilers, which I also recommend reading.

Well, okay, let's get down to business. Blocks of heating elements are used as heating elements for electric boilers.

They consist of several heaters, which are combined together with a nut.

To make it clearer, look at the picture below:

Heating element block

The nut is available in the following diameters: 1.25 inches, 2 inches and 2.5 inches.

Such a block is sealed using an annular rubber seal (if it is provided structurally) or by winding with thread or FUM tape.

As for the tubes, they can be made of carbon or stainless steel.

Stainless steel is more expensive, but lasts much longer than black steel.

With powers up to 9 kW, units with a supply voltage of 220 V can be installed inside the boilers.

With higher power, units for a three-phase voltage of 380 V are installed in the boilers.

Block heaters

Block options are several tubular-type heaters that are combined into one block and usually have one fastening element

When choosing a particular block heater, you should pay attention to the power ratings and the ability of the boiler equipment and pump to provide effective heat removal

It is recommended to give preference to these types if:

- you need to use a device with high power and heating rate of the environment;

- there is no way to quickly transfer heat energy from the working coil to the medium due to the small area of the heating element shell on the outside.

The advantage of the block solution is the ability to reduce the load on each tube, which simultaneously increases the uniformity of heating of the medium and causes little wear on the heating elements located inside these tubes.

View products

As for power, models can provide from 5 to 10 kilowatts. So, during the installation of equipment with block heating elements, you will have to take care of laying an additional electrical cable.

Heating elements for water heaters

Now let's move on to heating elements for water heaters. They can be made on a threaded nut (most often 1.25 inches in diameter) or on a flange that is clamped with bolts. Look at the picture below:

Heating element for a water heater on a flange

There are also “dry” heating elements. They are isolated from water in special flasks and manufacturers claim that they are safer than regular ones.

Although all their safety advantages can be negated by installing an RCD that will turn off the power if there is a leakage current greater than 30 mA.

"Dry" heating element

Pros and cons of heating elements

To decide which type of water heater to prefer - with a “dry” or “wet” heating element, it is necessary to compare the pros and cons of both elements:

- The advantages of a “wet” heating element

are compatibility with any water heaters designed for this type of working element, quick heating of the liquid, low cost and a huge selection of devices. However, such water heaters will have to be cleaned frequently: a lot of scale settles on open heating elements, which also leads to unpleasant electric shocks when you touch the body. In addition, “wet” heating elements consume a lot of electricity for heating. - The advantages of a “dry” heating element

are the absence of strict requirements for water quality and the ability to maintain liquid temperatures up to +40°C. Such elements do not rust and remain operational for up to 15 years. But water heaters with closed heating elements are expensive, and the variety of such models is relatively small.

How to choose the right device

When choosing, you need to pay attention to the following parameters:

- boiler volume;

- device power;

- desired water heating rate;

- desired electricity consumption.

The larger the tank volume, the more power is needed to obtain the required results.

In order not to make a mistake with your choice, look at the markings on what is installed in your device and purchase a similar one. Water heaters with dry heating elements are especially picky in this regard.

Different manufacturers produce different heating elements for their storage and flow-through designs. When choosing a device, it is important to consider this point.

Termex water heaters

Heating element in a Termex water heater

All models of heating elements from Termex are equipped with a thermostat, and some also have a thermostat, which greatly simplifies boiler control. The maximum heating temperature is 75 degrees. The heater tube can be made of copper or stainless steel.

Termex also produces magnesium anodes made from a special alloy for its devices. It significantly extends the service life of the device.

Ariston water heaters

The average power of Ariston models varies from 1 to 4.5 kW. Here you also have the opportunity to purchase a heating element for water with a thermostat. Maximum temperature 85 degrees.

A design feature of Ariston heaters is the oval shape of the flange, in addition, it is additionally fixed from the outside with a strip. When replacing, you must first unscrew this bar and push the heater inside the tank. The element is replaced in an inclined position.

Electrolux water heaters

Electroluxe prefers closed heating elements. In addition, two elements are usually installed in each heater to speed up heating. The maximum water temperature is 90 degrees.

Nuances of servicing air heating elements

Although manufacturers strive to provide tubular electric heaters with increased technical and physical protection qualities, long-term operation of the devices is only possible if special maintenance measures are taken. At different intervals, depending on operating conditions, it is necessary to clean working surfaces from contamination. If a flexible air heating element is used, then it may be necessary to lubricate the integration site of the element with protective compounds. Also, before the very first session of use, the heating device must be rid of preservative grease, which may interfere with heat transfer.

Replacing the mechanism in a water heater with your own hands

Removing the water heater cover

Replacing a heating device in a boiler with your own hands is quite simple. The main thing is to follow the instructions exactly:

- Disconnect the boiler from the network and from the cold water supply pipe.

- Drain the water tank.

- Remove the outer cover.

- To make sure that power is not supplied to the device, check the voltage at the terminals with a phase meter.

- Unscrew the nuts securing the heater and remove the outlet wires.

- Take out the old heating element.

- Before installing a new one, check the condition of its terminals; they must be completely dry.

- Along with replacing the heating device, the magnesium anode must also be replaced.

- Do not forget to use rubber seals when replacing; they must be of good quality without damage, cuts or dents.

- Install a new heating element and perform all operations in reverse order.

- Now you need to fill the tank with cold water and release the air from the hot water tap, make sure there are no leaks.

- Connect the boiler to electricity.

If the boiler leaks after reassembly, it means the heating element is installed incorrectly. The device needs to be reassembled.

Functionality check

The ability of the device to perform its immediate functions depends on the performance of the heating element. However, sooner or later everything breaks and requires replacement. The average service life of an open heating element is 4 years. If you carry out preventative cleaning of the device once a year, there is a chance to extend this period a little more. But sooner or later it will still fail.

And the main thing here is to understand in time what happened. The first sign of a breakdown is a slowdown in heating or its absence. Also, a breakdown is indicated by the activation of electrical protection. To make sure that it is the heater that is broken, you need to use one of two ways to check its functionality.

- You can check your water heater using a multimeter or tester. You need to measure the resistance of the heating element. In case of breakdown it will be zero.

- If you don’t have a tester or a multimeter at hand, you can use a homemade method of checking. To do this you will need a regular light bulb. It must be connected into a single circuit with the heater using a series connection and electricity must be supplied to this network. If the heating element fails, the light will not light up.

If the check shows that the device is broken, it will need to be replaced.

Prices for heating elements from different manufacturers

Prices for heating elements depend not only on the characteristics, but also on the manufacturer. This is understandable: different companies use different technologies and materials, give different guarantees for their devices, and the service is different for everyone. And one way or another, you have to pay extra for the brand.

On average, the price of a heating element for a water heater with a thermostat is within 1,200 rubles. The most expensive elements are from Ariston, their price starts from 950 rubles, and the ceiling is the same 1200. Electrolux heaters have a similar ceiling, but their lower limit is much less - 500 rubles. The price is within 700 rubles.