In a single-circuit boiler we see one water heating circuit. This circuit can consist of one, two, three heat exchangers. These heat exchangers can be fire tube or tube heat exchangers, but all contain and heat boiler water.

A single-circuit boiler is capable of producing hot water for domestic hot water supply - for this it will need an indirect heating boiler (IBC).

A double-circuit diesel boiler can produce hot water without BKN. For this purpose, the boiler design provides a second circuit in which tap water is heated. This circuit is usually located above the first one, in which the boiler water is heated.

Thus, a diesel hot water boiler better uses the energy of burned diesel fuel - it simultaneously goes to heating water in the CO and heating water in the DHW system.

What is special about heating equipment from Kiturami?

The Kiturami concern produces various types of heating equipment, which includes biofuel and gas installations.

But it was Kiturami’s diesel heating equipment that brought the concern such great fame and a high rating. The name diesel itself speaks about the type of fuel on which it runs. Rice. 1

The most popular model in the line of this manufacturer is the Kiturami Turbo 17 diesel boiler, the purpose of which is hot water supply and heating of industrial and residential premises. Boilers from the manufacturer Kiturami are very convenient for use in country houses, when the need for hot water does not arise daily, and heating is only required when the owners are present there. In addition, with proper operation, repairs of such equipment are very rarely necessary.

The main advantages of Kiturami diesel heating equipment include:

- The Kiturami diesel boiler is easy to use. The control panel allows you to set any control function. The operation of Kiturami using coolant and room temperature is regulated by a thermostat built into the remote control. The boilers are independent of the size of the chimney and the presence of draft due to their turbo-inflating effect, which forces exhaust gases into the chimney;

- diesel Kiturami is highly economical. Thanks to the aerodynamic flow in the combustion chamber, maximum efficiency in the amount of fuel consumed is achieved;

- setting up the equipment is absolutely simple, and you can do it yourself;

- The house has hot water supply all year round. Kiturami brand boilers are also used when the room is not heated;

- The Kiturami diesel boiler has a self-diagnosis system, which on the display informs about its operation and any malfunctions that have arisen, showing the real state of the system. If you constantly monitor the display readings, the need for repairs will be minimal.

The lineup

The development of KSO models was initially carried out as gas-powered equipment. After changing the type of burner and slightly changing the monitoring and control system, it became possible to use other energy sources. Diesel fuel became the main fuel. The turbocyclone burner contributed to 100% fuel combustion and increased efficiency. The advantages of the model are simplicity of design, ease of maintenance and low price.

Biofuel boilers models KRM-30R and KRM -70R with changes made to their design use both diesel fuel and other solid fuels. The transition from one type of fuel to another is carried out quickly. The forced circulation system helps to increase the efficiency of the heater. These models differ only in power.

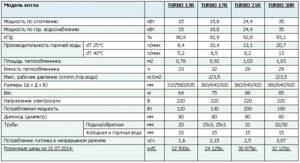

The turbo 13r model produces 13,000 kcal/hour of thermal energy or 15.1 kW, which is enough to heat 150 square meters. m. Heat costs for the preparation of hot water supply are taken into account. With significant regular waste of boiling water, the thermal circuit power is lower.

The turbo 17 model has a thermal power parameter of 19.8 kW, sufficient to heat 180 square meters. m. To increase the upper performance threshold, nozzles on the burner are selected, which can affect fuel consumption.

The turbo 21r model with a capacity of 24.4 kW has increased performance of the DHW circuit. At the same time, the dimensions of the boiler remain unchanged.

The liquid fuel model turbo 30 r has a performance of 34.9 kW, sufficient to heat 350 sq. m. Equipped with torch-shaped burners, the fuel combustion mode is optimal. Due to the low amount of nitrogen oxides, it is a highly environmentally friendly equipment.

Specifications

The Kiturami company was founded in 1962 and began its activities with the production of solid fuel boilers. Gradually increasing production capacity, closely monitoring global market trends and using innovative developments from its own research and development department, the company has become one of the largest manufacturers of heating equipment. Korean devices fully meet stringent international standards, have an ISO-9001 quality certificate and are subject to serious control at all stages of production. Kiturami gas boilers are a complex design of interconnected components and assemblies, the main one of which is a heating element made in the form of a turbocyclone burner. All models are equipped with a system for forced removal of combustion products, which ensures maximum safety for people present in the room and eliminates the risk of exhaust gas entering the room.

Both liquefied and natural gas can be used as fuel for Kiturami boilers. Kiturami boilers are available in a double-circuit version. They provide independent heating of water in two systems - heating and domestic hot water. And if in Russian-made boilers, when heating and hot water are turned on at the same time, the temperature of the coolant drops slightly, then on Korean models, when the hot water supply is turned on, the system automatically switches to heating mode. Thanks to this design feature, the temperature of the water in the network remains stable, moreover, it becomes possible to operate in different temperature conditions for heating and hot water circuits.

The choice of gas boiler power depends on the area of the room that it will heat. Household models with a power of 15.1–34.9 kW are capable of efficiently heating a room with an area of 120 to 340 m², and are the most preferred option for owners of country houses and city apartments. More serious devices have a maximum power of 465 kW. Thanks to the possibility of cascade connection, which can number up to 10 devices, they can easily cope with a huge space of 46,500 m². Such boilers are successfully used for heating shopping centers, warehouses and industrial workshops.

Kiturami devices are characterized by a high speed of water heating: the average productivity of most units is about 33 liters of hot water per minute. This is a very good indicator and allows Korean models to compete on equal terms with well-known Czech and German brands. All heating devices are equipped with a multifunctional room thermostat, which automatically monitors the room temperature and, if necessary, starts or turns off the boiler. Models can easily switch from gas to diesel fuel, which makes them more versatile and significantly expands their scope of application. Korean boilers are equipped with a device status warning system and instantly notify the owner of a problem. In the event of a breakdown, a digital code instantly appears on the display screen, indicating which unit has failed or is not working correctly.

For ease of troubleshooting, there are the following generally accepted error codes:

- 01–03 – the system does not detect fire, which is why the ignition is automatically blocked and the device turns off;

- 04 – temperature sensor failure; in this case, the boiler must be turned off and a specialist must be called immediately;

- 05 – opening of the overheating sensor or activation of the seismic sensor;

- 06 – the boiler has stopped recognizing the blower speed;

- 07 – the fan does not work correctly, which may be due to the accumulation of condensation in the elbow or wind that penetrates the chimney; Before calling a specialist, you should exclude the above reasons and eliminate extraneous influences on the device.

Benefits of Kiturami

Korean boilers, being many times more expensive than their domestic counterparts, enjoy well-deserved respect. Consumers are attracted by their reliability and thoughtful design, which frees the user from the usual troubles associated with the operation of gas equipment. Pros:

- All manufactured modifications have two circuits. A double-circuit boiler provides not only heating, but also hot water supply to the entire house. Domestic analogues have a drawback - when you turn on the water, its temperature quickly decreases. The Koreans have solved this problem - when the tap opens, the automation rebuilds the operation of the system - the water heating mode replaces the heating mode.

- Operation at different temperatures is possible thanks to two independent circulation rings. When the consumer turns off the water, the reverse transition occurs - to heating or waiting.

- Simple controls. Even a child can master it. The user's task is to select and set the temperature. For heating separately, for water – separately. Then the automation does everything without human intervention.

- A gas detection system is provided - if a leak occurs, a shutdown occurs, the flame goes out, and an accident is excluded.

- Energy saving modes. Many Kiturami modifications are equipped with a room thermostat-controller, which allows you to select modes - “absence”, “sleep”, “shower”.

- In winter, when it is frosty outside, the “Koreans” automatically maintain a stable temperature - freezing of the heating system is excluded. If the owner is away for a long time, it is not necessary to turn off the device - just set the “absence” mode.

- The equipment diagnoses problems independently, displaying the appropriate code on the screen. This function allows the user to easily identify and fix the malfunction - the instructions decipher the codes and indicate what to do.

Blitz tips

Diesel single-circuit and double-circuit models have been developed, the latter are more convenient, but more expensive

If you choose the first option, you will need to purchase a boiler and other appliances and accessories, but its cost will still be lower.

It is worth paying attention to the depth of the fuel intake according to the criterion for determining the deep location of the fuel and fuel tank. According to fire safety, fuel tanks must be buried in the ground to an appropriate depth

At low power, the intake depth is higher.

The cost of installing the equipment will include the price of the heater, its installation, startup and commissioning work, maintenance and spare parts for its repair.

Frequent breakdowns and how to fix them

Each model presented in the rating has a large number of advantages, thanks to which, in fact, they made it into the TOP of the best devices. But every future owner of equipment should be prepared for the fact that problems may arise with it for one reason or another. Let's look at the most common problems that occur with each type of unit, as well as options for eliminating them.

- Gas apparatus

With gas boilers, it is not uncommon for the combustion sensor to break down. In this situation, you should turn off the device, turn off the gas supply and let it cool completely.

During the pause, notice if there is a smell of gas in the room. If it is missing, try to restart the equipment; otherwise, urgently call a specialist from the repair service

Overheating is also an equally rare problem. This is facilitated by the breakdown of the automated system; it needs to be replaced. The problem may also lie in a clogged heat exchanger, which will require cleaning.

- Diesel models

Users of diesel models noted that the devices often encounter a problem in the form of loud noise during the operation of the unit. The reason for this is the supply of fuel along with air, water or a breakdown of the nozzle. Also among the possible malfunctions, the pump pressure did not meet the required level. You can't do without a specialist here.

- Pellet units

The most common problems with pellet units include jamming of the fuel supply drive. This does not depend on the manufacturer or the quality of the model, the problem may lie in the fuel itself. First of all, you need to check that the motor is not under voltage in this position. The reasons may be a short circuit, a broken starting capacitor, a worm gear, or a foreign element entering the conveyor.

VIDEO: Kiturami Scheduled Maintenance

Description of Kiturami malfunctions and repairs

The Kiturami diesel boiler belongs to the economy version and has a fairly long service life. But there are also situations when boilers fail prematurely. The reason for the need to repair Kiturami is their untimely maintenance or the use of low quality fuel.

You can carry out simple repairs of Turbo boilers yourself, but it is more rational to contact service organizations in case of malfunctions.

Rice. 3

Below are the main error codes that the Kiturami Turbo 17 diesel boiler most often experiences:

- when the lights flash “01”, “02” or “03” on the display, it means there are problems in the flame detector and ignition does not occur. In this case, the Turbo boiler should be restarted according to the instructions;

- error “04” indicates that the water temperature sensor is faulty in the Kiturami heating system, and repair in this case becomes inevitable;

- error “08” warns that the route between the boiler and the temperature sensor is very long or a wire break has occurred in some place. Repairs will be required to identify the immediate cause of the operational failure;

- error “95” means the pressure in the heating circuit is too low. The Turbo boiler needs to be energized and the entire heating system inspected for possible leaks;

- error “96” - the mechanism that protects the Turbo system from overheating has activated;

- error “98” - indicates that there is a lack of fuel in the supply line.

Of all the errors described above, “01” blinks most often on the display, but this does not pose a great danger to the operation of the equipment. The Kiturami Turbo 17 diesel boiler is characterized by maximum efficiency. Thanks to the control panel, the boiler control functionality is achieved and room heating is possible in any temperature regime.

In Turbo it is possible to regulate temperature parameters step by step from 45 to 75°C. All information about the operation of the diesel Kiturami Turbo is displayed on the thermostat screen by a self-diagnosis mechanism.

Most often, the Kiturami diesel boiler produces error 01. This happens when there is no stable ignition in the Turbo.

The reasons may be as follows:

- when the screw jams, which serves as a fuel level limiter. The repair consists of replacing the locking element or checking the injection motor;

- when the injection motor fails. It is necessary to check the working condition of the Kiturami motor. If the motor is faulty, then the repair consists of replacing it with a new one;

- when there is not enough incoming fuel, then the level in the tank should be checked; repairs in this case will not be necessary;

- when a foreign object accidentally ends up in the screw gate, it must be removed during the repair process;

- when the photosensor fails, the Turbo repair consists of checking this element for its functionality.

When error code “01” periodically appears on the display, in such cases it is necessary to seek help from the appropriate specialists in order to avoid major expensive repairs.

Carrying out regular maintenance and repairs of Kiturami is a guarantee that Turbo boilers will operate efficiently and reliably. If irreparable damage occurs to a diesel boiler during the warranty period, it will be repaired without the need to pay for such work.

The Kiturami Turbo diesel boiler has excellent characteristics, but you must always remember that failure to comply with the established installation diagram, correct settings and basic rules for handling it in many cases ends in total repairs. If all requirements for use and operation are met, modern technologies for the production of heating equipment Kiturami guarantees each user stable operation of the boiler without the need for repairs and a long service life.

Even at the stage of designing heating in a house, you have to operate with the general technical characteristics of the boiler, but in the end you still need to go to the store and choose a very specific model from the huge assortment on the market.

It will be useful to find out in more detail what a Kiturami diesel boiler is, what models are in the line, and how they can be better than other offers on the market.

Advantages and disadvantages of Kiturami boilers

The products of the South Korean concern Kiturami are different:

- high quality;

- modern design;

- functionality;

- reasonable prices.

The most popular models are Kiturami STS diesel boilers. These are powerful devices capable of heating a room up to 190 square meters. The fuel for such models can be kerosene or light petroleum product. If the burner is changed, gas may act as fuel. The advantages of this device include the available security sensors

, which act as a controller of all important processes. They are manufactured using a unique technology for removing combustion products.

The Turbo series includes diesel floor heating boilers that cope with two tasks at once, namely, heating the room and heating water for household needs. At the same time, owners will not need to purchase the necessary equipment

, because this device has a boiler-type system. The undoubted advantages include a high level of protection, which is achieved by working:

- sensors;

- control panel;

- thermostat;

- exhaust gas removal systems.

Installation and operation rules

The boilers are equipped with tanks for storing liquid fuel. These tanks may affect the performance of the equipment. Correct installation of this container is necessary, which must be aligned in all planes.

The tank must have a pipe for draining sediment and a fixing bag. The container must be periodically emptied of fuel and cleaned; it is recommended to use only purified fuel.

Before starting the equipment, the tank is initially filled with diesel fuel, which must sit for at least half an hour. Only after this the unit is started and operating modes are adjusted.

In the presence of power surges, it is advisable to purchase a stabilizer to ensure proper operation of the control and monitoring unit and safety from premature failure.

To maintain the operation of the boiler you need:

- Periodic mechanical cleaning.

- Constant monitoring of equipment performance and checking components and parts for leakage.

It is possible to independently install diesel boilers by carefully studying the diagrams and manufacturer’s recommendations. However, there are many operations that require the presence of highly qualified specialists so that the equipment does not have to be repaired later. The instructions for the exact procedure and principle of installation and the electrical installation diagram serve to illustrate the implementation of these works.

Kiturami boilers are an economical option with a long service life. The reason for premature repairs is untimely maintenance or filling with low-quality fuel.

Error codes:

Reasons for lack of ignition - error code “01”:

- The screw that limits the fuel level is jammed.

It is necessary to replace the shut-off element or check the injection motor; - Failure of the injection motor

- a check of the motor’s performance will be required; - Lack of fuel supply

- you will need to check its level; - Third-party object

in screw gate; - Photosensor failure

- it needs to be checked for functionality.

Diesel single-circuit and double-circuit models have been developed, the latter are more convenient, but more expensive. If you choose the first option, you will need to purchase a boiler and other appliances and accessories, but its cost will still be lower. It is worth paying attention to the depth of the fuel intake according to the criterion for determining the deep location of the fuel and fuel tank. According to fire safety, fuel tanks must be buried in the ground to an appropriate depth. At low power, the intake depth is higher

The cost of installing the equipment will include the price of the heater, its installation, startup and commissioning work, maintenance and spare parts for its repair. Heating a house in the winter is a priority for every homeowner today.

This issue is most relevant for owners of suburban housing. And although modern gas boilers are the most advanced, for many people they are inaccessible due to the constant increase in the price of this type of fuel

Heating a home in winter is a top priority for every homeowner today. This issue is most relevant for owners of suburban housing. And although modern gas boilers are as advanced as possible, they are inaccessible for many people due to the constant increase in the price of this type of fuel.

Therefore, a large number of consumers choose other alternative options, one of which is the Kiturami diesel boiler. Although they are not new on the market, they have not lost their popularity at all. They are able to provide high-quality heating in the house.

Today Kiturami is a well-known South Korean concern, one of the largest manufacturers of heating equipment. The boilers of this company have been repeatedly awarded diplomas for reliability and technical perfection, and due to the presence of certificates that meet all international standards, the Kiturami diesel heating boiler is exported to almost all countries.

Floor standing boilers

Floor-standing gas boilers have high efficiency, so they do an excellent job of heating large rooms.

Models of floor-standing boilers:

- Model KITURAMI KSG. This boiler has high performance and power, which can be 464 kW. This model is usually used for heating apartment buildings and industrial buildings. The coolant is heated from 41 to 75°C. Since this boiler is of a double-circuit type, it has a summer mode, in which the heating function is turned off and only the water heating function remains.

- Model KITURAMI TGB. Double-circuit gas boiler, which is used for industrial and domestic needs. Gas consumption can be significantly reduced since a turbocyclone burner is installed. At the same time, the amount of heat transfer is maintained. Hot water is heated at 20.7 liters per minute. The boiler has a built-in automatic system to prevent gas leakage, overheating of the coolant and fire extinguishing. These boilers have all the necessary modern functions and meet fire safety regulations.

We service all gas boilers, including

- ACV

- Alphatherm

- Ariston

- Baxi

- Beretta

- Bosch

- Buderus

- Dakon

- De Dietrich

- Ferroli

- Electrolux

- Fondital

- Frisquet

- Immergas

- Junkers

- Kiturami

- Mora

- Navien

- Protherm

- Rinnai

- Roca

- Sime

- Siberia

- Thermona

- Thermona

- Vaillant

- Viadrus

- Viessmann

- Westen

- Wolf

- Zhukovsky

- Lemax

Kinds

The Ochag company produces different structural types of boilers:

- Floor-standing. They do not require any special installation as they can be placed directly on the floor. This expands installation options compared to wall-mounted models.

- Wall-mounted. They require hanging installation on strong, preferably load-bearing walls. Temporary or plasterboard partitions are not suitable for this. The specifics of the installation require reducing the weight and reducing the size of the boiler, which affects power and performance.

- Parapet. They can be used both as part of a heating circuit and as an independent heat source.

By functionality:

- Single-circuit. Designed only to supply the heating circuit with hot coolant.

- Dual-circuit. Capable of simultaneous heating of coolant and preparation of hot water (DHW) for domestic needs.

By type of combustion chamber:

- Atmospheric (open). Smoke removal occurs through a common house chimney using a stove-type draft, and combustion air is taken directly from the room.

- Turbocharged (closed). Smoke removal and air supply are carried out by a special turbocharging fan. Possible only on energy-dependent models, but independent ones can also be modified using an external turbo nozzle.

There are many design options for Ochag boilers; the user can choose the most suitable option for his or her purposes.

Features of Kiturami diesel boilers

A distinctive feature of Kiturami devices is electronic control. The boiler has a remote control, with which the user can conveniently interact with the device from a distance.

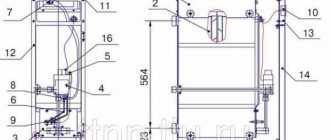

Device

The design of the Kiturami boiler is a combination of external and internal elements.

External parts:

- frame;

- Control block;

- pipes for connecting hot water supply and heating systems;

- chimney hole.

The control unit is responsible for the operation of the boiler. It helps you select parameters and modes. If necessary, the device starts protective functions and self-diagnosis.

Internal elements:

- DHW heat exchanger;

- turbocyclone liquid fuel burner;

- sensors;

- the combustion chamber;

- heat exchange device of the heating system.

Principle of operation

The boiler operates on diesel fuel as follows. The pump pumps the required amount of diesel fuel from the tank into the burner device. The fuel is heated and supplied to the combustion chamber through the nozzle simultaneously with air. The electrodes ignite the mixture, forming a stable torch in the firebox.

Combustion products move through heat exchange channels, heating the water. Exhaust gases are released under pressure into the chimney using a turbulator. The noise level is reduced thanks to the use of special inserts in the smoke channel.

Specifications

The efficiency indicators of Kiturami equipment are superior in many respects to diesel boilers from other manufacturers. A wide range of model parameters allows you to choose the ideal option for both home and industrial enterprise.

General characteristics:

- Efficiency 84–93%;

- service life - 10 years;

- power range 10.5–465.1 kW;

- DHW capacity - from 6 to 100 l/min;

- fuel consumption: 1.5–55.8 kg/hour;

- the cost of devices is from 26,800 to 511,099 rubles.

Fuel consumption

The use of a turbocyclone burner (a Kiturami proprietary invention) allows for efficient use of fuel. The special metal insert heats up to 800 °C, almost completely burning diesel fuel.

Thanks to this type of burner, fuel consumption is 1–1.5 liters to produce 10 kW of heat.

Advantages

Korean-made diesel boilers are distinguished by a successful combination of manufacturability and low cost.

Other advantages:

- Environmentally friendly. The patented burner design burns fuel completely, reducing emissions.

- Efficiency. Three-pass heat exchanger promotes maximum heat transfer.

- Electronic control. Using the display and remote control, the user configures the operation of the equipment to suit his needs.

- Energy saving. Switching operating modes helps save fuel resources.

- Safety. The equipment is equipped with flame, temperature, fuel and water level sensors in the system, as well as frost protection.

- High efficiency. Amounts to 84–91%.

- Versatility. Easy transition to gas by replacing the burner.

- Long service life. They can work uninterruptedly for up to 10 years.

- Modest dimensions. Placement requires 1 sq. m. area.

- Self-diagnosis. In case of malfunctions, information about the state of the system is displayed.

More details about the benefits of the Kiturami boiler delivery kit can be seen in this video.

Flaws

All the disadvantages of liquid fuel boilers are related to the type of fuel used.

Main disadvantages:

- the need to place the boiler room in a separate room;

- high noise level of liquid fuel burners;

- unpleasant smell from diesel fuel;

- the need to install containers with a supply of diesel fuel;

- dependence on the power grid;

- rapid increase in the cost of diesel fuel.

Calculation of the power of a double-circuit boiler for heating and hot water supply

Calculation of the power of a diesel double-circuit boiler using the example of Kiturami Turbo will be as follows:

- The boiler power for heating a house is approximately equal to 1 kW of thermal power for every 10 sq.m. at home with a ceiling height of 2.5-3.0 meters and good insulation of walls and ceilings.

- For the coldest periods of winter, a reserve of 25 percent of the required boiler power is provided.

- The boiler capacity for domestic hot water production is set at 30 percent of the total boiler capacity.

In total, if you have a house of 100 square meters, you need 10 kW of boiler thermal power for heating, 2.5-3 kW is put into reserve and 4-5 kW is put into hot water production.

It turns out that for this situation, you will need a boiler with a power of 18 kW. And this is Kiturami Turbo 17R. The power of the Kiturami Turbo 17R is 19 kW.

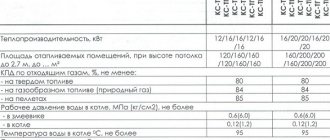

Specifications

The operational characteristics, dimensions and parameters of Turbo series boilers are presented in the table below. It is clearly seen that the series of floor-standing diesel boilers covers a power range from 10 to 35 kW, which is quite enough to heat houses up to 250-275 square meters. Part of the heat will be used to prepare hot water, which must be taken into account in the calculations.

All Kuturami double-circuit boilers and heat exchangers, by the way, are ideally designed specifically for these tasks.

| Boiler model | Unit change | TURBO-9R | TURBO-13R | TURBO-17R | TURBO-21R | TURBO-30R |

| Power | kcal/hour | 9000 | 13000 | 17000 | 21000 | 30000 |

| Power | kW | 10,5 | 15,1 | 19,8 | 24,4 | 34,9 |

| Fuel consumption | liter/hour | 1,13÷1,5 | 1,6÷1,97 | 1,87÷2,15 | 2,28÷2,80 | 3,75÷4,30 |

| Efficiency | % | 92 | 92 | 92.2 | 92.4 | 91.8 |

| DHW consumption | Δt=25ºC | 6,0 | 9,7 | 11,3 | 14,0 | 23,3 |

| Δt=40ºC | 3,8 | 6,1 | 7,1 | 8,7 | 14,6 | |

| Heating supply and return | mm | 25 | 25 | 25 | 25 | 25 |

| Hot water inlet/outlet | mm | 15 | 15 | 15 | 15 | 15 |

| Chimney diameter | mm | 80 | ||||

| Power supply | V/Hz | 220/50(60) | ||||

| Energy consumption | W | 80 | 160 | |||

| External size | w×d×h | 325×600×835 | 365×650×930 | |||

| Weight | kg | 60 | 79 | 85 | 85 | 85 |

Fuel consumption

Fuel consumption is indicated in the table with technical requirements. However, please remember that actual consumption depends on individual settings. Based on the actual power required to heat the house, an appropriate nozzle is selected from the set offered by the manufacturer.

Thermal power, fuel consumption and fuel combustion mode are set. The parameter indicated in the table displays factory presets sufficient to ensure proper performance provided that only high-quality fuel is used, more often this means diesel fuel with winter additives that do not allow it to thicken or separate paraffin in excess of the norm.

In a real situation, for a boiler model with a power of up to 15 kW, you can expect a fuel consumption of 8 liters per day

taking into account the frequency of burner operation and the optimal temperature conditions in the house. However, this is not the limit.

The right approach to choosing a heating mode, as well as installing a controller with variable temperature conditions, for example, depending on the time of day and day of the week, can reduce consumption even more.

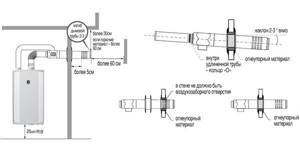

Chimney

Cuturami boilers, gas, diesel, floor-mounted or wall-mounted, are mostly equipped with a closed combustion chamber and, accordingly, a forced exhaust gas removal system. The Turbo series we are currently reviewing is no exception.

The chimney for boilers is coaxial to simultaneously supply fresh air from the street and remove exhaust gases. Since the exhaust temperature after passing through the heat exchangers is no longer high, the requirements for the heat resistance of the chimney are reduced, and the list of acceptable materials is expanded.

In the best case, a steel coaxial chimney is still used, but a ceramic vertical chimney with a group of internal separate channels for supplying air, removing gases from the combustion chamber and ventilating the boiler room can be effectively used in the same capacity.

The size of the chimney is strictly indicated in the boiler specification and operating instructions. For the entire Turbo series it is 80 mm.

If desired, you can make a chimney with a slightly larger diameter, but no more than 50% above the specified value, that is, up to 120 mm.

Under no circumstances should the size and cross-section be reduced.

Even though the removal of combustion products is forced, the resistance of the chimney will greatly affect the combustion mode and the quality of fuel combustion.

Solid fuel

Solid fuel boilers are suitable for use in rural areas. To obtain thermal energy, the units consume biofuel: wood and coal. It is possible to use briquetted and granular materials of various origins.

Features of operation:

- availability of fuel material;

- limited time on one tab;

- the need to constantly manually service the boiler: load new portions of fuel and clean out the ash several times a day;

- the chimney and pipe periodically become clogged with soot deposits.

We recommend: Classification of radiators

Solid fuel boilers come in classic and pyrolysis types. In the first case, the unit has one combustion chamber.

The second option is structurally more complicated. The firebox of such a device is divided into two parts. Fuel is placed in the upper chamber and heated until pyrolysis occurs. The wood gas generated in the process is forced through a nozzle into the lower chamber and burned there.

Pyrolysis boilers are more efficient. Another advantage is their low waste.

Kiturami KF

The series is represented by the KF-35 model with a power of 24 kW. A pyrolysis type boiler is capable of heating rooms up to 240 square meters. m. One full load of fuel allows continuous operation of the unit throughout the day. The heating rate of domestic water is 14.7 l/min. Efficiency - 91.5%.

Design advantages:

- spacious loading chamber for 50 kg;

- stainless heat exchanger;

- a ceramic nozzle between combustion zones 1 and 2 promotes complete combustion of fuel and pyrolysis gases;

- large loading hatch;

- the boost fan maintains a stable fireplace in the firebox;

- the secondary combustion chamber is equipped with a device for removing pyrolytic liquid;

- Ash receptacle in the form of a box.

Kiturami KRP

The KRP line includes pellet boilers that use granulated wood waste. Granule diameter: 6–8 mm, length: 1–3 cm. A full hopper allows the equipment to work without interruption for up to 5 days. The model range consists of 2 sizes: 20A and 50A.

Technical features:

- automatic fuel supply via a screw mechanism;

- built-in expansion tank and circulation pump;

- ash pan in the form of a box;

- pellet burner in the shape of a bowl with an increased ignition area;

- automatic vibration cleaning of grates.

Price range

Gas boilers Kiturami Twin Alpha will cost the buyer an amount in the range of 25-35 thousand rubles, depending on the power of the unit.

This is the average price in Russia; in remote regions it may be increased due to the complexity of delivery or other logistics problems. The boilers are sold in a basic configuration; the usual delivery package includes only the unit itself, packaging, a set of mounting hooks and instructions.

Therefore, when purchasing, you must immediately order the desired type of chimney, as well as purchase a voltage stabilizer and water filters

This is important, since Kiturami Twin Alpha boilers are demanding on the power supply condition

If the voltage supply is unstable, the control board fails, the price of which is about 10-13 thousand rubles.

Excessively hard water is also contraindicated, since it damages the internal pipelines of the boiler.

You should not skimp on warranty service. Some users only increase their expenses, thinking that waiving the warranty will allow them to save money.

Settings

It is better to entrust the initial startup and setup of Kiturami boilers to a specialist who can correctly determine the optimal operating mode, select the desired type of nozzle and check the fuel consumption depending on its characteristics and even the method of connection and location of the fuel tank.

For self-installation, detailed instructions are included with the boiler, according to which you can determine the operating mode closest to the design value.

The main thing is to adhere to the sequence of actions defined in the technical documentation and visual aids for putting the equipment into operation.

Setting up and adjusting the boiler settings should be carried out not only at the first start-up, but also during maintenance before each new season and to switch to summer mode, in which only the DHW circuit will be used.