For many owners of private homes, choosing a heating boiler is a difficult task.

It is necessary to choose the best option that has the most successful set of functions and characteristics.

This is only possible if you have sufficient knowledge about the design and operating principle of gas boilers, understanding their features and advantages.

There are different types of gas units that have their own characteristics and capabilities.

Let's consider one of the groups of such equipment - parapet boilers.

What is a parapet gas boiler?

Parapet gas boilers are heating units that combine the features of atmospheric and turbocharged models. They are completely energy independent, but are equipped with a closed combustion chamber.

A special feature of this design is the use of a coaxial chimney, which is connected to the rear of the unit and vented to the street. Smoke removal and fresh air intake occur as a result of convection processes.

When the boiler is put into operation, no odors are felt in the room; there are not even traces of soot or other combustion products .

In addition, oxygen does not burn out in the room, which allows you to maintain a normal microclimate.

Another feature of parapet boilers is the ability to be used as independent heating elements. There are special holes in the lower part of the case through which hot air escapes.

It circulates in the room and provides it with the desired temperature.

Reviews of domestic parapet boilers: advantages and disadvantages

Despite the fact that such units are still new to most people, there are users who have already tried them and formed their own opinion.

Common reviews from owners of parapet gas boilers:

| Advantages | Flaws |

| budget price - finding an option to suit every taste and budget is not difficult, since prices start from 10,000 rubles | manual control - ignition (piezo) and mode change (mechanical control) is possible only with human participation |

| freedom of communication - versatile connection of pipes reduces the cost of piping the unit and simplifies installation | meager automation - the set consists of a thermocouple that regulates the position of the gas valve and one thermostat |

| replacement of radiators - the holes in the casing themselves provide a good flow of heat, which means that the batteries in the room in which the boiler is installed can be removed | dependence on the weather - if a wind protection is not installed on the chimney, it often happens that the flame simply goes out due to the wind |

| energy independence - almost all models do not require power, but there are also universal ones that work “according to the situation” | inserting a chimney - to remove the pipe you will have to punch a hole in the wall, which is not allowed to be done in all houses |

In connection with the last drawback, one cannot help but note the likelihood of social difficulties also arising: there is no need to formally coordinate the installation with neighbors if technical parameters are observed, but they are unlikely to be happy with the release of carbon monoxide at the level of their windows, because this is also worth thinking about in advance .

What is the difference from the usual?

The main difference between parapet models and conventional boilers is the ability to obtain increased safety from a non-volatile design and no impact on the internal atmosphere of residential premises.

If a conventional atmospheric boiler consumes ambient air, actively burning oxygen and requiring constant ventilation, then parapet models are completely separate and do not disturb the air exchange regime.

Another difference is the ability to independently heat air, making a parapet boiler similar to a stove.

Direct installation of the boiler

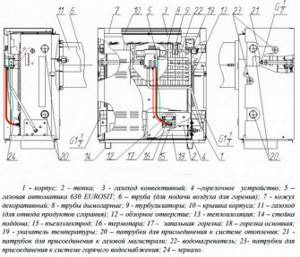

Next, the gas boiler itself is installed (due to the huge variety of boilers on sale, the sequence of steps in each specific case may differ from the one shown) (Fig. 4. Installation diagram of a parapet boiler.).

If the wall where the boiler is installed has a flammable coating, then this coating should be removed at least in an area corresponding to the projection of the gas boiler onto the wall.

In accordance with the chosen location for installing the boiler, a hole is made in the wall for the coaxial pipe. If the hole is drilled with a diamond core bit, it is drilled to size with a slope of approximately 1:100 towards the street. If the hole for the air duct is made with a small-diameter drill and a spatula, then a circle with a diameter equal to the air duct is marked on the wall from the inside of the room and holes are drilled around the circumference at such a pitch that the jumpers between the holes are about a centimeter. Afterwards, these jumpers are knocked out with a spatula. It is quite possible that the inner surface of the hole thus obtained will have to be somewhat trimmed with a spatula.

You should be careful and take into account that the drilled (hollowed out) material may fall; therefore, it is necessary, if the work is not carried out on the first floor, to ensure that there are no strangers in the place where a piece of stone may fall.

Advantages and disadvantages

The advantages of parapet boilers include:

- no electricity consumption;

- no internal air is used, there is no additional load on the ventilation system;

- there is no need to connect to a common chimney;

- low fuel consumption;

- efficiency, practicality, resistance to external loads.

The disadvantages of the models can be considered:

- installation requires making a hole in the wall from 25 to 31 cm in diameter;

- installation is only possible near an external wall;

- it is not possible to provide full-function control and protection of units and parts of the unit (for non-volatile models).

Despite the existing disadvantages, parapet boilers are highly rated by users. The demand for them is constantly growing.

Types, technical characteristics, device and principle of operation

Construction of a Danko parapet gas boiler

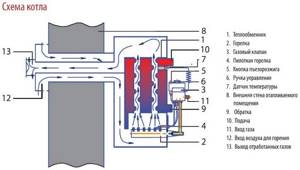

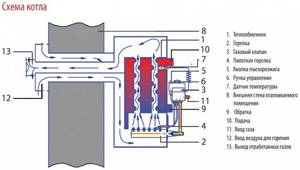

To begin with, let’s determine point by point how a parapet gas boiler works:

- Steel body.

- Closed combustion chamber.

- Gas burner with igniter.

- Coaxial chimney.

- Steel heat exchanger or copper secondary coil.

As well as a protection system: thermometer, thermocouple and draft sensor.

Assembly and installation of this type of boiler can take place anywhere in the building. The only condition is that this place must be near the wall so that it is possible to bring the coaxial chimney out.

Steel structure consisting of a pair of pipes. The one with a smaller diameter is located inside the pipe with a larger diameter. And between the tubes a space is formed through which wall-mounted and floor-standing boilers take in air for gas combustion. Through a small pipe, oxidation products of the energy carrier come out into the street. Coaxial chimney

Thanks to the coaxial chimney, air is not taken from the rooms, which gives a great advantage to gas parapet boilers.

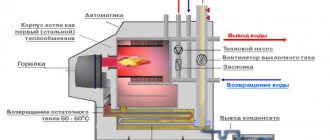

Operation diagram of a parapet gas boiler

In the energy-independent design, operation starts with the piezo ignition button. After pressing, the primary burner of the boiler or igniter begins to burn.

If the equipment is equipped with automation (energy-dependent), then, naturally, it is put into operation automatically. Versatility is what energy-independent boilers are valued for on the domestic market.

How does automation for gas boilers work and what is it responsible for?

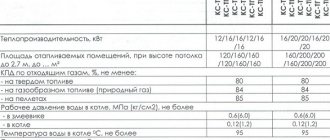

Now we will determine the types of parapet gas boilers. They are all different in:

- functionality;

- price;

- the fuel carrier used;

- type of burner;

- installation location;

- power;

- principle of smoke removal;

- the presence of an automatic control unit;

- dependence on electricity.

But the main difference (on which, in fact, the main parameters of the boiler depend) is the method of installing a parapet gas boiler.

And we can already identify the first typology.

According to the installation method, the following types of parapet gas boilers are distinguished:

- floor;

- wall;

- right-sided;

- left-handed.

Assembling this type of boiler yourself is strictly prohibited. This is done by specialists with the appropriate license and gas service employees.

Floor-standing parapet gas boilers are in no way inferior to similar wall-mounted boilers. The only difference is the strength of the equipment. The greater the power, the correspondingly greater the size and weight of the device.

Based on the presence of automation, they are distinguished:

- non-volatile;

- volatile parapet boilers.

Parapet gas boiler with remote control

With energy dependent people, everything is clear - their work depends on the availability of energy. But the first ones are more often installed in houses where power supply interruptions may occur, which is not uncommon today. Therefore they are quite common.

The advantage of non-volatile boilers is the ability to regulate combustion intensity, service life, and piezo ignition. They have the ability to operate at low gas pressure levels in the system. Some models have a remote control that allows you to control the boiler remotely.

You can read about the features of non-volatile gas boilers on this page.

Read the instructions carefully if you are going to buy a parapet gas boiler. It is on this document that the choice should be based, since it describes information about the power of the device, operating and installation rules.

Based on the number of circuits, they are distinguished:

- single-circuit;

- double-circuit parapet gas boiler.

The single-circuit one is equipped with a conventional heat exchanger and has a plate structure (this allows for faster heat exchange between the coolant and the flame of the heat burner). The heat exchanger is made of steel 3 mm thick. This material makes the equipment durable and ensures rapid exchange of thermal energy. The thicker the steel, the lower the degree of heat exchange between water and the gas burner.

The set of a double-circuit parapet gas boiler includes a copper coil, due to the operation of which water is prepared for the hot water supply circuit of a house or apartment. Water is heated only by flow. It is unrealistic to use the equipment for installation in a standard apartment, since the storage internal capacity will greatly increase its size.

Device

The design of the parapet unit almost completely replicates the design of any non-volatile boiler.

The coolant enters the primary (main) heat exchanger, where it receives a high temperature and enters a three-way valve (mixing unit). In it, colder “return” is mixed into the hot liquid, as a result of which the temperature of the heating agent takes on the parameters specified by the mode.

In double-circuit models, before entering the three-way tap, the coolant passes through a secondary heat exchanger, where DHW is prepared.

The difference lies in the structure of the combustion chamber and chimney, which are not typical for such devices . To exhaust smoke, a coaxial double pipe is used, through the outer cavity of which fresh air enters, and the inner cavity is a chimney.

Air is sucked into the closed combustion chamber and ensures the combustion process. When heated, it expands and displaces smoke and other gases produced when fuel is burned. Some models are equipped with two separate pipes, one of which supplies air and the other exhausts smoke.

This option allows you to enhance convection and stabilize the processes of gas movement.

Varieties in design and material

At the moment, there are various models. Externally, they are not particularly different, except in size and installation method: wall-mounted and floor-mounted. To know which one to choose, you need to understand the filling.

Single and double circuit

There are single-circuit and double-circuit devices. The difference is that the single-circuit heats water only for heating the house; in order to have warm water for domestic use, an additional water heater is installed.

A double-circuit boiler immediately heats water for batteries and household use. This smart device responds to the actions of its owners. While water is needed only for heating, he takes care of it. As soon as you open the tap to wash dishes or take a shower, water begins to flow into the tap using a special valve.

It is necessary to provide the required power of the device. The more people will take a bath or shower, the more powerful the device needed to heat it.

Typically, consumers choose double-circuit boilers. They are more functional, you do not need to buy an additional boiler, but they are also more expensive than single-circuit ones.

Floor and wall mounted

The next difference is the method of installing the boilers. There can be two of them: floor-mounted and wall-mounted.

Mounted ones are more compact, the requirements for their installation are less extensive. They do not need a separate chimney; such elements are installed even in the kitchen; it is enough to simply ensure safety during operation.

Floor-standing ones have large volumes, high power and weight. A separate room must be allocated for them; they require a lot of free space around. It will be necessary to build a separate chimney for a floor-standing boiler, since they produce noise, unlike wall-mounted ones.

For a small house or apartment, a wall-mounted heater will be sufficient. When heating a large house, you need to look after a floor-standing unit. Such models are dependent on constant voltage in the electrical network, so during surges the equipment may fail.

Combustion chamber view

The combustion chambers in these boilers are of open and closed types. The former take oxygen for combustion from the room in which they are located, so they require ventilation. But at the same time, they have a simple design, are more reliable, easier to install and cheaper.

The second type is more modern. These boilers are parapet, they provide safety, but are more expensive and more difficult to install. It is worth considering that these boilers, if properly installed and equipped with an air duct, do not pose a risk of poisoning to residents in the event of a malfunction, which cannot be said about units with an open chamber.

The choice in this case depends on the equipment room. A closed-type boiler is safer and more convenient, but only if it is possible to equip an air duct. If there is a power outage and the ventilation does not work, the heating will also turn off.

Kinds

There are different design options for parapet boilers, which can be divided according to specific characteristics.

By installation method:

- wall-mounted Installed in a hinged manner on an external (load-bearing) wall. According to installation conditions, weight and power are limited;

- floor Installed on the floor. If it is wooden, a non-flammable stand is required. There are no restrictions on weight, dimensions and power.

By power supply method:

- volatile. The design contains components that require the use of electricity - a circulation pump. electronic control board, etc.;

- non-volatile. They work only with mechanical control. A good choice for remote villages and areas with intermittent power supplies.

By feature set:

- single-circuit. Capable only of providing heating of the coolant;

- double-circuit. In parallel with heating, the heating agents are capable of preparing hot water for domestic needs.

NOTE!

Most users prefer single-circuit floor-standing models, which demonstrate the greatest efficiency.

How to choose and what to pay attention to?

When choosing a parapet gas boiler, the buyer should pay attention to a number of related factors.

Initially, you should start from the future location of the device and its technical characteristics. Depending on the space occupied by equipment in homes, there are floor-standing and wall-mounted boilers.

Accordingly, the buyer should focus on the type that is most convenient for him.

An important parameter is also the power characteristic . Gas boilers are divided into two types - single-circuit and double-circuit.

The latter combine two functions at once - space heating and water heating.

Single-circuit ones have the advantage of random switching off and turning on.

If the choice falls on double-circuit boilers, you should pay attention to models with increased power, since the device’s energy reserve is additionally spent on heating water.

You should also carefully choose the appropriate thickness of the walls of the heat exchanger of the boiler you are purchasing, on which the operating life of the unit depends.

However, it is worth remembering that for boilers with walls made of steel whose thickness exceeds 3 mm, efficiency decreases significantly.

Principle of operation

The operation of a parapet boiler differs little from the usual operation of gas convection units.

The burner heats the coolant, which transfers part of the energy to prepare DHW or is discharged into the heating circuit after preparation in a three-way valve.

There are no changes in this. A specific feature is the ability of the boiler to perform the function of a convector, which makes it possible not to install radiators in the room where the unit is located.

In addition, a special method of air supply and smoke exhaust is used. When the burner is ignited, excess air pressure arises in the upper part of the combustion chamber, causing it to be expelled along with the smoke outside.

At the same time, a vacuum is formed in the lower part, creating a suction of fresh flow through the outer part of the coaxial pipe. A pressure difference arises similar to that used in conventional ovens.

This allows the use of a closed combustion chamber without a turbo fan.

IMPORTANT!

In some designs, the chimney and air intake pipe are made separately, but this does not change the principle of operation.

Where you can and where you can’t install a gas boiler

The rules for installing a gas boiler provide the following requirements for installing a HEATING boiler, regardless of whether it also provides DHW or not:

- The boiler must be installed in a separate room - a furnace (boiler room) with an area of at least 4 square meters. m., with a ceiling height of at least 2.5 m. The rules also state that the volume of the room must be at least 8 cubic meters. Based on this, you can find indications that a ceiling of 2 m is acceptable. This is incorrect. 8 cubic meters is the minimum free volume.

- The furnace room must have an opening window, and the width of the door (not the doorway) must be at least 0.8 m.

- Finishing the furnace with flammable materials and the presence of a false ceiling or false floor are unacceptable.

- The combustion chamber must be provided with an air flow through a through, non-closed vent with a cross-section of at least 8 sq.cm. per 1 kW of boiler power.

For any boilers, including wall-mounted hot water boilers, the following general standards must also be met:

- The boiler exhaust must exit into a separate flue (often incorrectly called a chimney); using ventilation ducts for this is unacceptable - life-threatening combustion products can reach neighbors or other rooms.

- The length of the horizontal part of the flue should not exceed 3 m within the combustion chamber and have no more than 3 rotation angles.

- The flue outlet must be vertical and raised above the ridge of the roof or the highest point of the gable on a flat roof by at least 1 m.

- Since combustion products form chemically aggressive substances when cooling, the chimney must be made of heat- and chemically resistant solid materials. Use of layered materials, e.g. asbestos-cement pipes, permissible at a distance of at least 5 m from the edge of the boiler exhaust pipe.

When installing a wall-mounted hot water gas boiler in the kitchen, additional conditions must be met:

- The height of the boiler suspension along the edge of the lowest pipe is not lower than the top of the sink spout, but not less than 800 mm from the floor.

- The space under the boiler must be free.

- A durable fireproof metal sheet 1x1 m should be laid on the floor under the boiler. Gas workers and firefighters do not recognize the strength of asbestos cement - it wears out, and the SES prohibits having anything containing asbestos in the house.

- There should be no cavities in the room in which combustion products or an explosive gas mixture can accumulate.

If the boiler is used for heating, then the gas workers (who, by the way, are not very friendly with the heating network - it always owes them for gas) will also check the condition of the heating system in the apartment/house:

- The slope of horizontal sections of pipes must be positive, but not more than 5 mm per linear meter of water flow.

- An expansion tank and an air valve must be installed at the highest point of the system. It is useless to convince you that you will buy a “cool” boiler that has everything provided for: rules are rules.

- The condition of the heating system must allow it to be pressurized under a pressure of 1.8 atm.

The requirements, as we see, are strict, but justified - gas is gas. Therefore, it is better not to think about a gas boiler, even a water heating one, if:

- You live in a Khrushchev block or other apartment building without a main gas duct.

- If you have a false ceiling in your kitchen that you don’t want to remove, or a permanent mezzanine. On a mezzanine with a bottom made of wood or fiberboard, which in principle can be removed, and then there will be no mezzanine, gas workers turn a blind eye.

- If your apartment is not privatized, you can only rely on a hot water boiler: allocating a room for a furnace means redevelopment, which only the owner can do.

In all other cases, it is possible to install a hot water boiler in an apartment; wall heating is possible, but floor heating is very problematic.

In a private house, you can install any boiler: the rules do not require that the furnace be located directly in the house. If you make an extension to the house from the outside to serve as a furnace room, then the authorities will only have less reason to find fault. You can install a high-power floor-standing gas boiler in it to heat not only the mansion, but also the office premises.

For middle-class private housing, the optimal solution is a wall-mounted boiler; it does not require, as for a floor one, to install a brick or concrete tray with sides of half a meter. Installing a wall-mounted gas boiler in a private house also avoids technical and organizational difficulties: a fireproof closet under the furnace can always be fenced off, at least in the attic.

Rating of TOP 5 parapet gas boilers

Parapet boilers do not have many of the disadvantages of wall-mounted models, so their range is constantly increasing.

Let's look at the most popular models:

Lemax Patriot-12.5

Floor-standing, non-volatile parapet boiler of domestic production. The power of the unit is 12.5 kW . This is suitable for rooms up to 125 square meters. m.

Main characteristics of the unit:

- Efficiency - 87%;

- coolant temperature - 80°;

- system pressure - up to 2 bar;

- gas consumption - 0.75 m3/hour;

- dimensions - 595x740x360 mm;

- weight - 50 kg.

The boiler is single-circuit, but it is possible to connect an external boiler. This will allow you to get a full-fledged hot water supply line.

Lemax Patriot-20

Floor-mounted parapet boiler produced by the Taganrog plant. The power of the unit is 20 kW, so the size of the room should not exceed 200 sq. m. m .

Only the basic task is performed - heating the coolant. If you need to expand the functionality, you should purchase and connect an external storage boiler.

Boiler parameters:

- Efficiency - 87%;

- coolant temperature - 80°;

- system pressure - up to 2 bar;

- gas consumption - 1.2 m3/hour;

- dimensions - 670x790x400 mm;

- weight - 67 kg.

Users and experts note low fuel consumption, which increases the efficiency of the unit and allows for significant savings.

Lemax Patriot-16

Another example of domestic heating technology. Parapet floor-standing boiler with a power of 16 kW , intended for use in rooms up to 160 sq. m.

Like other models of the Patriot series, this is a single-circuit unit with a steel heat exchanger.

Its characteristics:

- Efficiency - 87%;

- coolant temperature - 80°;

- system pressure - up to 2 bar;

- gas consumption - 0.95 m3/hour;

- dimensions - 670x790x400 mm;

- weight - 67 kg.

The Patriot series units with a power of 16 and 20 kW are the same design, only one of the models has artificially reduced performance.

Lemax Patriot-10

A product of engineers from Taganrog. A 10 kW parapet boiler is suitable for a country house or private house with an area of up to 100 square meters. m .

- Efficiency - 87%;

- coolant temperature - 80°;

- system pressure - up to Bar;

- gas consumption - 0.6 m3/hour;

- dimensions - 595x740x360 mm;

- weight - 50 kg.

NOTE!

Reliability and low fuel consumption make Lemax Patriot parapet boilers the best choice for all users.

ATON Compact 12.5E

Gas parapet boiler made in Ukraine. The power of the model is 12.5 kW, and the service area is up to 160 sq. m. Non-volatile unit designed for floor mounting.

Main parameters of the boiler:

- Efficiency - 90%;

- coolant temperature - 90°;

- system pressure - up to 1.5 Bar;

- gas consumption - 1.39 m3/hour;

- dimensions - 630x700x275 mm;

- weight - 50 kg.

The unit is equipped with a stainless steel heat exchanger and has a gas safety valve.

How does a boiler work?

The non-volatile gas boiler is equipped with piezoelectric ignition - for this there is a special button on its body. The wick lights up and ignites the gas burner.

When an automation system is installed in the equipment, the boiler is ignited automatically, depending on the sensor readings. More reliable, versatile and easy to operate are energy-independent models of gas parapet boilers, which is why they are more popular in the domestic market.

Construction of a non-volatile parapet boiler

Parapet gas equipment operates using a simple and understandable technology: the gas burner of the boiler is ignited from the wick and heats the heat exchanger, through which the working fluid moves using a circulation pump or natural current. The gas will burn until the water temperature in the heating system reaches the level set by manual or automatic regulators, after which the gas is automatically turned off by closing the gas valve at the inlet to the boiler. The wick is working at this time and is ready to re-ignite the burner at any time as soon as the water temperature in the system drops below the specified parameters and a command to heat up is received.

The gas boiler safety group consists of the following components and elements:

- Thermocouple, which is installed directly in the burner flame;

- The traction control sensor is installed at the combustion chamber outlet;

- Temperature sensor and thermometer.

Why a thermocouple is needed: under the influence of heat from the burner flame, it generates a small voltage that controls the position of the gas valve. If combustion in the chamber stops, the voltage in the thermocouple disappears and the valve automatically closes, cutting off the flow of gas into the boiler.

In the absence of air draft in the boiler, the heat exchanger quickly heats up to +65°C and above. The signal from the heat exchanger plate is sent to the gas supply valve, it closes and combustion ends. This is how the safety group of a non-volatile boiler works. If the boiler is connected to the electrical network, then all processes are controlled by a control and automation system.

A thermometer paired with a temperature sensor (thermostat) serves to protect the parapet boiler from elevated temperatures. The mechanism works like this: when the thermometer detects a critically high temperature of the working fluid in the system, it sends a command to the thermostat, which closes the gas supply to the boiler burner.

Control automation and sensors

Wall-mounted parapet gas equipment is in even greater demand than conventional floor-standing boilers with a chimney installed in the building due to its versatility and undemanding operating parameters. For example, conventional wall-mounted units react sensitively to changes in gas pressure in the line; because of this, scale appears on the boiler jacket more often; in addition, such units require an uninterrupted supply of electricity.

Parapet gas boilers are less sensitive to pressure changes in gas supply pipes, and non-volatile equipment does not require connection to the electrical network at all. The coaxial type chimney is undemanding in terms of installation conditions: it can be installed both horizontally and vertically, which gives scope for a more convenient location of the boiler in small rooms.

Be sure to carry out preventive maintenance

Which parapet boiler is better to choose?

When choosing any heating boiler model, we focus on its thermal characteristics and additional functions. The performance of the unit, the possibility of heating water for domestic needs, as well as the plant that manufactures the heating equipment are taken into account:

Judging by the reviews, the best manufacturers of gas parapet heating boilers are European and Russian companies. Although the products of the latter are somewhat inferior to their European counterparts in terms of efficiency and degree of automation, they are fully adapted to domestic operating conditions and are sold at an affordable price.