Gas boilers are considered the most convenient and efficient sources of thermal energy.

Several design options have been developed that have remained virtually unchanged for many years.

Manufacturers create only certain variants of basic circuits based on the initially developed design.

All functions of the units are additions to the main type of gas boiler - a single-circuit floor-standing model designed to perform the main task.

Let's take a closer look at them.

Floor-standing single-circuit gas boilers and their features

The design of floor-standing single-circuit gas boilers is economical and simple.

They are capable of performing a single basic function - heating the coolant for the heating system . These units do not perform any additional tasks, therefore the set of units and parts of the unit is limited - only the most necessary elements are involved in the work.

In addition, the floor mounting method allows the use of durable and powerful units with increased weight and capabilities.

This makes the design more powerful and capable of high performance.

Most models are equipped with massive heat exchangers that have a high heat transfer capacity and can accommodate an increased volume of liquid. There are no restrictions on weight or dimensions for floor-standing boilers, so the power can be 100 kW or more.

Many units can be connected in a cascade (usually up to 4 units), creating a high-power thermal station.

Another feature of single-circuit floor-standing boilers is the ability to connect an external storage boiler.

This combination allows you to get not only heating of the house, but also a stable supply of hot water.

Most experts consider this option more preferable than using a double-circuit boiler, since the mode of supply of hot water from the boiler is smooth, without temperature jumps or pauses.

Floor-standing or wall-mounted gas boiler - which is better?

Let's look at the main differences between floor-standing and wall-mounted boilers:

- The efficiency of wall-mounted boilers is 90-94%, lower floor-standing boilers are 88-90%. This means that the lower the efficiency, the higher the energy consumption. Most floor-standing boilers are convection boilers. Their price is lower, they are also inexpensive to repair, but they are also less efficient. Boilers that are attached to the wall can be either convection or condensation. In condensation systems, the heat generated from combustion products and gases passes into the coolant, and not into the atmosphere, i.e. it is used efficiently (this requires the construction of a condensate drain, but this work is simple).

- The service life is affected by the material of the heat exchanger, and not by the number of structural elements and their connection in certain variations. Heavy cast iron is often used - a thick and very durable material that is not afraid of corrosion and is very durable. Such a boiler can operate for at least 20 years, or even 25. Copper or steel are used in suspended structures. Steel is cheaper than copper, but is thin, and will last 12-13 years. Whether it’s copper: units with copper elements last 5-8 years longer and conduct heat better, but they also cost significantly more.

- Fun fact: manufacturers generally prefer to create entire boiler rooms in miniature from wall-mounted boilers, and use floor-standing boilers to a minimum. Regarding dimensions: do not think that the larger and more massive the boiler, the better it works. Most often it happens just the opposite.

- Each region has its own nuances of power supply: a non-volatile boiler will continue to operate even in your area “the lights will be turned off.” Half of all floor-standing boilers on the market are non-volatile, and there are plenty to choose from. But wall-mounted ones require connection to the electrical network, without exception.

- Automation in wall-mounted boilers is better, so these types of models are safer and more convenient to use. They also have overheating protection, self-diagnostics, freeze protection and a lot of other useful functions. Floor-standing ones boast automatic ignition (rarely), overheating protection and gas control.

- Wall-mounted structures cannot work with some coolants, for example, antifreeze on copper and steel heat exchangers has a simply destructive effect. But the same antifreeze is perfect for floor-standing boilers.

- One- or two-stage burners are installed in floor-standing boilers (they can operate either in on/off mode, or with adjustment at 50 or 100% power), in wall-mounted boilers - modeled ones (the indicators can be adjusted by the user himself as he pleases). The situation with chimneys is this: since almost all floor-standing boilers have atmospheric burners and open combustion chambers, the chimney for them must be removed separately . The wall-mounted units have a convenient coaxial chimney.

- Mounted boilers are cheaper and there is more choice than floor-standing boilers. And they are easier to maintain.

From the above, we can draw the following conclusion: the most reliable are floor-standing mini-boilers, since they are unpretentious even with a serious “minus” outside the window and they have a more durable heat exchanger.

Advantages and disadvantages

The advantages of floor-standing single-circuit boilers include::

- simplicity, absence of unnecessary components and parts;

- reliability, stability;

- high power, ability to heat large areas;

- the presence of powerful and efficient heat exchangers with a high heat transfer coefficient;

- the floor mounting method simplifies the installation and connection of the unit;

- management of single-circuit models is simple and accessible to all users;

- There is a large selection of designs that allow you to obtain the most suitable type of boiler for the given conditions.

The disadvantages of floor-standing single-circuit boilers are:

- lack of independent ability to supply hot water;

- the specifics of the work require the allocation of a special room - a boiler room, equipped with window and door openings;

- atmospheric or non-volatile models are connected to the central common house chimney, which determines the location of their installation;

- increased power automatically means increased fuel consumption.

NOTE!

Most floor-standing single-circuit boilers are used in private homes or public spaces, where it is possible to provide all the conditions for the normal operation of the unit. The use of these models in apartments is impractical, since the dimensions and specific features of floor-standing boilers are excessive in such conditions.

Main types of gas floor-standing boilers for heating

As mentioned earlier, there are single-circuit and double-circuit models of heating equipment.

The first ones are represented by one heat exchanger, which allows you to heat the required room. In terms of technical indicators, this version of the device does not differ significantly from the double-circuit one, since it is capable of providing maximum heating of buildings of any size and at the same time gas consumption will be minimal.

The double-circuit version already has a pair of heat exchangers, one of which performs the heating function, and the other for hot water supply. The water in the device heats up very quickly both in flow mode and in storage mode (if there is a built-in boiler). This design is easy to install and further operate. In addition, the operation scheme of the equipment meets the established safety standards.

Tip: For maximum energy efficiency, in small residential buildings, dual-circuit devices should be installed, which simultaneously provide the premises with the necessary heat and hot water.

Operating principle

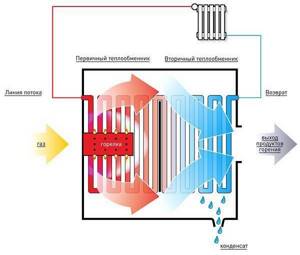

The operation of a single-circuit floor-standing gas boiler consists of flow-through heating of the coolant using thermal energy obtained from fuel combustion.

The liquid enters the heat exchanger, receives the maximum possible heating for a given operating mode and enters a three-way valve . This is a unit where the hot coolant is mixed in a given proportion with the colder return flow.

The more return is added, the lower the temperature of the liquid entering the heating circuit. This is how the room heating mode is adjusted. The coolant moves under the action of a circulation pump, and the air supply and smoke removal are controlled by a turbofan.

The operation of all components is under continuous monitoring of a self-diagnosis system - a network of sensors installed on important components and parts of the boiler.

If abnormal situations occur or any elements fail, the sensors signal to the electronic control board, which immediately generates an error signal.

Some types of malfunctions cause immediate shutdown and blocking of the boiler for safety purposes; the control unit simply notifies the user about minor malfunctions.

IMPORTANT!

All problems that arise must be resolved only by qualified specialists with appropriate clearance. Unauthorized interference with the boiler design is an administrative offense.

Types of floor structures

In suburban buildings, two types of gas units are used:

Convection

There is the concept of two heat of combustion points: the lowest (denotes the thermal energy generated during the combustion of gas in full) and the highest (denotes the totality of energy obtained during the complete combustion of gas and condensation of combustion products).

When designing gas boilers, manufacturers make every effort to ensure that condensation in the heat exchanger is kept to a minimum. In this way, the boilers are protected from the formation of sediment, which can form in the presence of aggressive acids. Unpleasant consequences can render all equipment unusable.

In the photo: convection gas boiler.

The entire operating principle of this type of boiler is based on the absence of condensate in the fuel part. This effect is achieved by installing classically shaped radiators. The length of the heating circuit and the temperature treatment, which must be large, must also be taken into account. Compliance with all rules guarantees the absence of condensation on the heat exchanger.

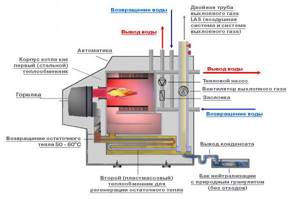

Condensation

They have a built-in economizer responsible for cooling. The temperature during this process promotes the formation of moisture. Due to this, the liquid is heated before entering the heat exchanger.

It is recommended to use boilers of this type in the presence of radiators connected to heated floors, in which the water cools completely.

In the photo: condensing gas boiler.

What are its advantages of energy-dependent species

Non-volatile installations operate only on a mechanical principle, without needing to be connected to the power supply system.

This makes them indispensable in remote villages, in areas with dilapidated or overloaded electrical networks . Frequent shutdowns cause the heating to stop working, which is unacceptable in the Russian winter.

Non-volatile models ensure continuous heating of the house regardless of external conditions. However, such possibilities limit the capabilities of non-volatile boilers. They work only on natural physical processes - circulation of the coolant requires installation of the heating circuit at a slight angle and is based on the rise of warm layers of liquid upward.

Smoke removal occurs under the influence of normal draft in the chimney. It must be taken into account that natural processes occur with minimal intensity and are unstable, so external additional devices are usually installed - a turbo nozzle and a circulation pump.

They make the unit more productive, and operation in non-volatile mode occurs only during a power outage.

If there is no power supply to the house at all, only the basic capabilities of the unit are used.

How to choose the power of a gas boiler?

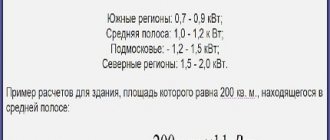

Calculating the boiler power is also not difficult. The ideal is taken to be a normally insulated room with ceilings no more than three meters high, with pressure in the gas pipeline of approximately 14-15 mbar, excluding water heating. In this case, 1 kW is required per 10 square meters.

You should also take into account the region of residence (especially average winter temperatures), how many doors and windows there are in your apartment (house) (the so-called thermal conductivity is of interest here). Remember that the lower the minimum power of the unit, the more economical it will work.

In some cases, a boiler is required whose power is 1.5-1.7 times greater than that required under ideal conditions. Therefore, if you are not sure that you can calculate everything correctly, contact a specialist: he will draw up an individual project, taking into account all the features of your home and the environment.

Kinds

There are several design options for floor-standing single-circuit boilers. They differ from each other in various ways.

By type of combustion chamber:

- atmospheric (open) . The air directly surrounding the boiler is used, and the smoke is removed under the influence of natural draft. Such models are connected only to the central vertical chimney;

- turbocharged (closed) . To supply air and remove smoke, a coaxial type chimney is used (pipe in pipe), or two separate pipelines that perform the functions of intake and supply of air to the boiler and exhaust of flue gases.

According to heat exchanger material:

- steel. The most common option used on inexpensive models.

- copper. The coil-shaped design increases the path of liquid passing through the heating zone. Such units are installed in expensive models from top manufacturers;

- cast iron. Installed on powerful and massive units. Cast iron heat exchangers demonstrate high performance, efficiency, and are capable of developing large units of power. Used for units from 40 kW and above.

By heat transfer method:

- convection Conventional heating of the coolant in the flame of a gas burner;

- parapet. They are able to do without a heating circuit, being a kind of analogue of a conventional stove;

- condensation The coolant is heated in two stages - first in the condensation chamber, from the heat from the condensing flue gases, and then in the usual way.

NOTE!

Condensing boilers are able to fully operate only with low-temperature systems (warm floors), or when the difference in temperature outside and indoors is no more than 20°. These conditions are not suitable for Russia.

Distribution of boilers by ignition type

Gas installations are divided into two groups according to the ignition method:

- Electronic

- Ignites using piezoelectric elements.

In the first case, the boiler igniter works only when the thermostat needs to be turned on, so such units are more profitable and economical.

In the second case, the burner is ignited by a piezoelectric element, which begins to work after turning a special lever or pressing a button. The biggest advantage of these structures is their independence from electricity, that is, the boiler distributes heat regardless of the availability of electricity in the house. Such units consume fuel all day long, and although the costs are small, they are not justified, since only 1/4 of the total volume is required to maintain combustion.

Do you need a boiler?

The need to connect a boiler is dictated by the needs of the room and users

If the unit operates in a private house, then installing a boiler will allow you to organize the supply of hot water in sufficiently large volumes.

However, if there is a connection to a centralized water supply, purchasing an external boiler seems impractical.

What is the difference between non-volatile and conventional boilers?

Conventional (volatile) boilers require an electrical supply, without which they cannot operate. The turbofan, circulation pump, and electronic control board require high-quality and stable power supply.

Particularly capricious are control boards, which immediately fail when the current parameters change. Manufacturers claim the ability to withstand large voltage fluctuations, but in practice this is not observed.

At the same time, volatile units have a set of additional capabilities - they can be controlled remotely, integrated into a smart home system, and programmed for some time in advance..

Non-volatile boilers do not have all these additions. They work exclusively with the help of mechanical components and parts, like a regular gas stove.

The design of such units is devoid of all unnecessary components, it is functional and therefore very reliable. In addition, owners of non-volatile boilers do not face the risk of being left without heating in the event of a sudden power outage.

Dilapidated and overloaded networks are a typical phenomenon for remote villages, so the use of independent heating systems is very valuable for many users.

The most popular manufacturers and their brief descriptions

The leading manufacturers of floor-standing single-circuit boilers are European companies, although domestic designs are optimal for Russian conditions.

The most famous companies are:

- Viessmann. A German company, one of the most famous and reliable companies producing thermal products;

- Protherm. A company from Slovakia that produces a wide range of heating boilers. ALL series are named after animals of different species;

- Buderus . “Daughter” of the world-famous concern Bosh, which fully characterizes the quality and reliability of the products;

- Vaillant. Another German company whose boilers are considered the highest quality and most reliable;

- Lemax. Russian manufacturer of energy-independent floor-standing gas boilers. When developing the project, all the features of working in difficult conditions were taken into account;

- Navien. Korean boilers that successfully combine high quality and affordable prices.

The list of manufacturers can be continued for a very long time. All currently operating companies care about the quality and reliability of their products, trying to surpass competitors and reach the maximum number of users.

Which brand of floor-standing gas boiler is better to choose?

On the consumer market you can find domestic and foreign models from different manufacturers. Russian companies produce simple floor-standing gas boilers for the home. Products from foreign suppliers are convenient, but their prices are higher. The review covers the products of the following companies:

- Lemax - the products of this company are in great demand due to their quality. Modern Italian and German equipment is used in production.

- Protherm - equipment is assembled at factories in Slovakia and Turkey. The first boilers of this company were imported to Russia in 1996.

- Siberia – the brand presents a line of devices with different characteristics. The boilers are made using basalt fiber, which is used to insulate spacecraft.

- Borinskoe - the company supplies heating equipment to regions of Russia and neighboring countries. The range includes more than 30 models of gas equipment for home heating.

- Baxi - today the Italian brand is owned by the BDR Thermea Group corporation. The company produces non-standard heating and hot water supply systems. The quality of the products is confirmed by certificates.

- Ferroli is an Italian company that has been producing heating and air conditioning equipment since 1955. Products are supplied to dozens of European countries. The boilers of this company are durable, reliable and safe.

- Viessmann is a large international concern that supplies equipment for heating and cooling of premises. The main priority is the technological development of the industry and concern for the environment. Products are supplied to 74 countries around the world.

- Buderus , a European manufacturer of heating equipment, began producing the first boilers in 1731. The trademark belongs to Bosch Thermotechnik GmbH. German technology is reliable and efficient.

- Alpenhoff is a German company that produces heating equipment. Production and research centers are located in Germany and Slovakia. The products of this company are imported to 30 countries around the world.

- Atem - the first equipment of this company was released in 1988. Since then, the brand’s products have become popular in Ukraine and other countries. Heating appliances are included in the IQenergy energy saving program.

- Termomax is a Ukrainian company that produces more than 100 thousand products for space heating every year. Simple equipment is in demand among Russian buyers.

- Navien , a Korean brand, has been providing comfort and coziness for 40 years, producing high-quality heating equipment. The main goal of the company is to create favorable conditions for the environment. Products are supplied to 35 countries around the world.

The brands have a long history, good reputation and worldwide fame. Domestic manufacturers are valued no less than foreign ones. In addition, delivery of Russian goods is cheaper.

Rating of TOP 10 best models

| Place | Name | Price |

| TOP 5 best Russian floor-standing single-circuit boilers | ||

| 1 | Lemax Premium-20 | 25 000 ₽ |

| 2 | Lemax Premium-12.5 | 21 000 ₽ |

| 3 | Lemax Leader-35 | 53 000 ₽ |

| 4 | ZhMZ AOGV-17.4-3 Comfort N | 21 000 ₽ |

| 5 | Rostovgazoapparat AOGV | 20 000 ₽ |

| TOP 5 best foreign floor-standing single-circuit boilers | ||

| 1 | Protherm Wolf 16 KSO | 19 000 ₽ |

| 2 | BAXI SLIM 1.230 iN | 55 000 ₽ |

| 3 | MORA-TOP SA 20 G | 30 000 ₽ |

| 4 | MORA-TOP SA 60 | 25 000 ₽ |

| 5 | Protherm Bear 40 KLOM | 57 000 ₽ |

Types of burners

Burners of floor-standing boilers are divided into one-stage, two-stage and modulating. Single-stage systems assume that the device can produce only one power level; with a two-stage system, it is selected from two levels. Modulation regulates the available power. The efficiency of the equipment depends on the type of burners.

Inflatable burners are equipped with turbines for heating. They take air from the room and from the street. They do not require a separate room.

Atmospheric burners are one of the most reliable at an affordable price. Their disadvantage is considered to be air burning and low efficiency.

The best Russian floor-standing single-circuit boilers

Let's look at the most popular models of Russian floor-standing gas boilers:

Lemax Premium-20

Products of the plant of the same name from Taganrog. A non-volatile floor-standing boiler with a power of 20 kW is capable of heating a house of 200 square meters. m.

Its main characteristics:

- Efficiency - 90%;

- coolant temperature (max) - 90°;

- heating system pressure (max) - 3 Bar;

- fuel consumption - 2.4 m3/hour;

- dimensions - 556x961x470 mm;

- weight - 78 kg.

The high demand for Lemax boilers indicates the demand and positive attitude of users towards domestic heating units.

Lemax Premium-12.5

Another representative of the Taganrog plant, designed for work in relatively small spaces. With a power of 12.5 kW, this boiler can heat an area of 125 square meters. m., which is suitable for country houses or country houses.

Unit parameters:

- Efficiency - 90%;

- coolant temperature - 90°;

- heating system pressure (max) - 3 Bar;

- fuel consumption - 1.5 m3/hour;

- dimensions - 416x744x491 mm;

- weight - 60 kg.

The boiler is relatively small, but its capabilities allow you to get the maximum effect.

Lemax Leader-35

Powerful (35 kW) floor-standing boiler, capable of serving a house or public space of 350 square meters. m. The combustion chamber is open type, which requires connection to the central chimney.

Other parameters:

- Efficiency - 90%;

- coolant temperature - 95°;

- heating system pressure (max) - 4 Bar;

- fuel consumption - 4 m3/hour;

- dimensions - 600x856x520 mm;

- weight - 140 kg.

A special feature of this model is a cast iron heat exchanger, which provides high heat transfer and stable heating mode.

ZhMZ AOGV-17.4-3 Comfort N

Product of the Zhukovsky Mechanical Plant. Power 17.4 kW, which is designed to heat 140 sq. m. The non-volatile design makes the unit resistant to all changes in the situation.

Boiler parameters:

- Efficiency - 88%;

- coolant temperature - 90°;

- heating system pressure (max) - 1 Bar;

- fuel consumption - 1.87 m3/hour;

- dimensions - 420x1050x480 mm;

- weight - 49 kg.

If necessary, the boiler can be reconfigured to be powered by liquefied gas, which further increases its autonomy.

Rostovgazoapparat AOGV

A unit from the Rostov plant with a power of 11.6 kW. Designed for heating 125 sq. m. usable area.

Its operating parameters:

- Efficiency - 90%;

- coolant temperature - 95°;

- heating system pressure (max) - 1 Bar;

- fuel consumption - 1.18 m3/hour;

- dimensions - 410x865x410 mm;

- weight - 49 kg.

The unit differs from other models in its cylindrical shape, which looks somewhat old-fashioned. However, this does not affect the quality and parameters of the boiler in any way.

Review of the best single-circuit models

Lemax Leader-25N 25 kW

The stylish boiler is made in red and white colors and does not require a network connection. Has all the necessary programs

protection, reliable and high quality.

The cast iron heat exchanger perfectly maintains the temperature and, thanks to its high heat transfer, warms up the home well. The starting system operates smoothly and the controls are simple.

The temperature regulator is installed on the front panel. The micro-torch burner ignites without problems. Fuel is natural gas.

Specifications:

- Max. thermal power: 25 kW;

- Heated area: 240 m²;

- Dimensions: 515x856x515 mm;

- Efficiency: 90%;

- Max. thermal load: 30 kW.

pros

- automatic Nova;

- gas control;

- overheat protection;

- pressure gauge

Minuses

- very heavy (115 kg).

Lemax Wise 25 25 kW

Ergonomic boiler with low gas consumption (for this level of units) and a set of protective programs, reliable

and relatively inexpensive. There is a convenient display and power indicator.

The installed automation system, made in Italy, is resistant to voltage surges, does not make noise, and allows you to connect additional devices (for example, a turbo nozzle, circulation pump, etc.).

The warranty period is 24 months.

Specifications:

- Max. thermal power 25 kW;

- Efficiency: 90%;

- Weight: 116 kg;

- Dimensions: 515x860x520 mm.

pros

- gas control protection;

- it is possible to connect external control;

- auto diagnostics;

- flame modulation;

- frost protection;

- power-on indication.

Minuses

- heavy weight.

Lemax Premium-20 20 kW

Inexpensive and quite simple, but with a standard set of functions, a boiler for a house with an area of 200 sq.m.

The heat exchanger is made of high-strength steel. Powerful, with good heat dissipation. Gas consumption is economical, the removable panel allows you to clean it yourself.

The model is equipped with automatic ignition. Safe: functionality includes gas control, protection against draft blowing and protection against heat exchanger overheating. It does not take up much space, as it is small in size. Chimney diameter is 130 mm.

Specifications:

- Boiler warranty: no more than 3 years;

- WxHxD: 556x961x470 mm;

- Gas consumption: 2.4 cubic meters m/hour;

- Thermal power (maximum): 20 kW.

pros

- intuitive control panel;

- the boiler is easy to operate;

- affordable price;

- high efficiency.

Minuses

- makes noise.

The best foreign floor-standing single-circuit boilers

Let's look at the most popular models from Western manufacturers:

Protherm Wolf 16 KSO

The brainchild of Slovak engineers, the Volk 16 KSO floor-standing boiler is designed for heating medium-sized private houses. With a power of 16 kW it can heat 160 sq. m.

Main characteristics:

- Efficiency - 92.5%;

- coolant temperature - 80°;

- heating system pressure (max) - 1 Bar;

- fuel consumption - 2.4 m3/hour;

- dimensions - 390x745x460 mm;

- weight - 46.5 kg.

The unit is non-volatile, which is not typical for European models - they prefer fully functional designs. In addition, it is equipped with a two-pass heat exchanger, which increases the performance of the unit.

BAXI SLIM 1.230 iN

Italian boiler from a famous European manufacturer. Its power is 22.1 kW, designed to operate in a room of 220 sq.m.

Boiler characteristics:

- Efficiency - 90.2%;

- coolant temperature - 85°;

- heating system pressure (max) - 3 Bar;

- fuel consumption - 2.59 m3/hour;

- dimensions - 350x850x600 mm;

- weight - 103 kg.

The heat exchanger of this boiler is made of ductile cast iron, the warranty period is 2 years.

MORA-TOP SA 20 G

Czech engineers offer users a 15 kW boiler capable of heating 150 square meters. m. area. A cast iron heat exchanger stabilizes the operation of the system and equalizes the temperature, eliminating sudden jumps.

Boiler parameters:

- Efficiency - 92%;

- coolant temperature - 85°;

- heating system pressure (max) - 3 Bar;

- fuel consumption - 1.6 m3/hour;

- dimensions - 365x845x525 mm;

- weight - 99 kg.

An additional advantage is the non-volatile design, which expands the capabilities of the unit in difficult conditions.

MORA-TOP SA 60

Another Czech boiler with a capacity of 49.9 kW. Suitable for heating a house of 500 square meters. m., as well as for public or commercial premises.

Unit characteristics:

- Efficiency - 92%;

- coolant temperature - 85°;

- heating system pressure (max) - 3 Bar;

- fuel consumption - 5.8 m3/hour;

- dimensions - 700x845x525 mm;

- weight - 208 kg.

The boiler is equipped with a cast iron heat exchanger consisting of 7 sections. Electronic controls provide constant control over the operating mode of the system.

Protherm Bear 40 KLOM

Slovak floor-standing unit with a power of 35 kW. Heating area - 350 sq. m.

- Efficiency - 90%;

- coolant temperature - 85°;

- heating system pressure (max) - 4 Bar;

- fuel consumption - 4.1 m3/hour;

- dimensions - 505x880x600 mm;

- weight - 130 kg.

The features of the boiler include the design of the heat exchanger - it is a cast iron two-pass unit of 5 sections.

Review of the best non-volatile models

Lemax Patriot-10 10 kW

Russian boiler with a closed combustion chamber and an improved protection system. The functionality is simple, but it gets the job done

. For individual heating of a small area, its power is quite enough.

Small steel heat exchanger. It consumes little gas and heats up well. The assembly is good. Mechanical control. The maximum coolant temperature is 80 °C. Weighs 50 kg. Chimney diameter is 250 mm.

Specifications:

- Service life: 3 years;

- Max. thermal power: 10 kW;

- Fuel: natural gas only;

- Dimensions: 595x740x360 mm.

pros

- durable;

- qualitative;

- affordable.

Minuses

- It cannot be used as a gas water heater, only for heating.

Lemax Premium-16 16 kW

Another inexpensive but high-quality model for those who only care about warmth and not “bells and whistles.” Neatly assembled box

covered with an inhibitory anti-corrosion composition and heat-resistant enamel.

Practical and reliable energy-independent model for an area of up to 120 sq.m. Can be installed both in residential and non-residential premises. The temperature sensor is located on the top panel for user convenience. Weight - about 60 kg. Thermal power - 16 kW.

Specifications:

- Allowable heating area: 160 sq.m;

- WxHxD: 416x744x491 mm;

- Warranty period: 3 years.

pros

- easy controls;

- economical model;

- quickly warms up the home;

- convenient to clean.

Minuses

- a bit expensive for boilers of this level;

- volatile

Siberia 17 17.4 kW

A relatively cheap, domestically assembled miniature heating unit with Italian “stuffing”.

The media temperature sensor is located on the control panel. Weighs more than 50 kilograms, the heat exchanger has thick steel walls. Piezo ignition with flame control.

It is not capricious in maintenance, breakdowns (according to customer reviews) occur very rarely. High quality build. The combustion chamber is open. Compact, takes up little space.

Specifications:

- Thermal power: 17.40 kW;

- Area: 200 sq.m;

- Highest carrier temperature: 90 °C.

pros

- attractive design;

- compact;

- automation and burner made in Italy;

- inexpensive;

- high efficiency.

Minuses

- makes noise when ignited.

Types of heat exchanger materials – what to choose?

The heat exchanger is the main component of a gas boiler. The coolant is heated in it, so the parameters and design of this unit are of great importance.

For production use:

- stainless steel . This is a budget option, although the parameters of steel heat exchangers allow you to get quite effective results. Typically, such units are installed on inexpensive medium-power boilers;

- copper tube (coil) . This option is used on expensive models of gas boilers. Copper has a high heat transfer coefficient, so the effect of using such heat exchangers is very high;

- cast iron. It is resistant to mechanical and thermal loads. For the manufacture of heat exchangers, gray ductile metal is used, which is resistant to changes or different values of liquid temperature at individual points. Massive units help equalize the degree of heating and soften sudden temperature changes.

Copper heat exchangers are considered the most preferable, but steel and cast iron units are also quite functional and can provide high-quality heating of the heating agent.

Reviews of domestic gas floor-mounted models: advantages and disadvantages

| Advantages | Flaws |

| High reliability and service life due to the possibility of installing a heavy cast iron heat exchanger and a simpler, more reliable device | Often lower efficiency than wall-mounted models |

| More than half of the models are non-volatile, yet efficient, often with an efficiency of more than 90% | The basic package rarely includes an expansion tank, circulation pump, safety group and other elements of the heating system |

| Offers a wider choice of power ranges when compact wall-mounted designs are limited in performance | Large dimensions and weight, more complex, requiring special skills, installation |

| According to reviews from owners and operating practice, low requirements for coolant and gas | Most often, automation is simpler and less functional, compared to wall-mounted models. |

| Full autonomy of operation, requiring no human intervention | The need for a separate boiler room that meets the requirements |

| Large selection of models, the most budget ones are much cheaper than wall-mounted ones and start from 12-13 thousand rubles | Functional and ultra-efficient models with advanced automation cost more than 80-100 thousand rubles. |

| Requires much less regular cleaning and maintenance than wall-mounted | Budget floor-standing boilers are much less often equipped with modern safety systems (against overheating, freezing, pump blocking), but this does not mean that they are not safe at all. |

Types by combustion chamber type

There are two types of combustion chambers:

- atmospheric (open) . They work on the traditional principle - air is taken directly from the surrounding atmosphere, and smoke is removed using natural draft. For the operation of such boilers, appropriate conditions are required, so they are not in great demand. However, atmospheric units are capable of operating in energy-independent mode;

- turbocharged (closed) . The fully sealed design requires air supply, which is done using a turbofan. This method allows you to regulate the combustion mode and the removal of combustion products. It is considered the most convenient and safe.

The choice of combustion chamber is determined by the design of the boiler - all non-volatile models are atmospheric, and dependent units can be either open or closed.

Turbocharged vehicles are preferred.

Types of boiler ignition methods and which method is the most optimal?

There are three ignition options:

- electronic. The burner is ignited at the touch of a button using a special unit. This option is present on all models of volatile boilers;

- piezoelectric. The principle of operation of such a system is similar to all piezo devices - in order for a spark to appear, you need to press on a special crystal. Used on non-volatile boilers. Many users find this type of ignition inconvenient;

- manual. The flame is ignited with an ordinary lit match (spear). For ignition, you need to have a certain supply of such elongated wooden sticks.

Most users unanimously prefer the electronic type of ignition, but it is not possible on non-volatile units. You have to get used to using a piezoelectric element or ignite the burner with a burning torch.