Boilers may differ in volume, power, and body design, but their structure and operating principle are approximately the same.

In the event of a breakdown, repairing Ariston water heaters with your own hands is difficult, but possible.

A number of faults can be easily repaired; to eliminate others, you need to contact service centers and buy spare parts. And some breakdowns can be avoided, since they are the result of improper connection and operation. Let's start with them.

- Safety valve.

The most common mistake installers make is failing to install the valve. Replacing the safety valve with a non-return valve (which allows fluid to flow only in one direction) is also incorrect - this can lead to increased pressure on the device. As a result, leaks, tank depressurization, and the need to replace gaskets. A working safety valve periodically drips and leaks (especially when the water is very hot when no one is using it). You should be wary of the fact that the valve always remains dry! There is a possibility that it clogged and failed. - Tank orientation.

The second common mistake is installing a horizontal device vertically, and vice versa. Do not rush to purchase a heater until you decide exactly where and how it will hang. Which location is more convenient? If the family moves often, or cannot decide on a location, it is better to immediately purchase a universal boiler. - Electrics

. It is best not to use an outlet that is located in a damp place or where it may be splashed. A prerequisite is a grounding contact. It is desirable to have a separate line with its own machine and through an RCD. Choosing the wrong machine is also a common mistake. It must be bipolar with a value of 16 A if the boiler has a power of up to 3 kW. Three-core copper cable with a cross-section of 2.5 mm2. - Fastening.

You cannot hang a heavy tank (100 liters or more) on a wall or sheathing; they may not be able to support the load. The hole for the dowel should go into the wall to a sufficient depth. Small boilers up to 50 liters can be hung on a plastic dowel. If the volume of the container is larger, it is better not to risk it and use steel anchor bolts. - Water supply.

Of course, installing a flexible plastic pipe is much easier. But if the boiler is planned to be located at a considerable distance from the cold riser (more than 1.5 m), then preference should be given to metal. Rubber hoses should not be used; they wear out too quickly. - Water with impurities.

Hard and dirty water is the main reason for failure of heating elements. The mistake in this case would be to do nothing. If there is a problem, it is worth installing a fine filter at the inlet. It is also important to periodically change the magnesium anode.

Even if this is not the first time you have to install a boiler, read the installation instructions and remind yourself of the basic requirements and principles of connection!

Typical breakdowns of Ariston boilers

The most vulnerable places of Ariston water heaters are their heating elements (heaters), sensors, thermostats and valves.

Problems with tank leakage rarely arise here, since Ariston keeps its brand and makes its containers from stainless steel.

Inspection and testing of the heating element

Heating elements can be called consumables for water heaters - they are their most vulnerable point and break down most often.

Types of faults:

- The scale blocks the transfer of heat, the heater becomes hot and burns out.

- The filament inside the heating element burns out.

- A short circuit occurs to the housing, which can lead to electric shock.

The main cause of breakdowns is hard water and the scale that forms due to it. After 3–5 years of service, if nothing is done, the heating element will fail (in very hard water, even earlier).

To check the heating element, you need to remove the bottom cover of the housing, unscrew the heater and pull it out. The surface of the heating element is cleaned of scale manually or chemically.

Chemical cleaning can be done by placing the heating element in hot water with 70% vinegar, 25 - 50 grams per 1 liter of water.

A visual inspection is carried out. There should be no swelling, cracks, or other defects (if there are any, the heater cannot be repaired; it must be replaced with a new one).

If there is no external damage, the element is tested by a multitester. How to do it:

Resistance measurement. To check, you need to know the power of the heating element. Using this indicator you can calculate resistance.

For this 48400 :P

(power).

48400 is an indicator for a 220 V network.

By connecting the terminals to the contacts of the heating element, you can see the real resistance on the screen.

It should be close to the calculated one. So, for a heater with power:

- 1 kW is 48.4 Ohms;

- 1.5 kW – 32.2 Ohm;

- 2 kW – 24.2 Ohm;

- 2.5 kW – 19.3 Ohm.

If it shows “0”, there is a short circuit.

If “1” or “∞” is a break.

In buzzer mode, a short to body is checked. One terminal remains on the heating element contact, the other on the boiler body. If the buzzer beeps, there is a breakdown in the housing.

In parallel with the heating element, you can check the boiler thermostat for circuit integrity (by also connecting its contacts to the terminals).

If the water heater is operating normally, there is no need to drain the water from it. But if there is a need for repairs, it will have to be done. Read how to drain water from a water heater.

Anode

The protective anode is designed to take the “blow” of scale (the magnesium from which it is made is more active than iron). This is also a consumable, and if you replace the destroyed anode in time, you can keep the heating element operational longer.

Instructions for replacing the boiler anode:

- The device is de-energized.

- The water supply is cut off.

- The container is emptied.

- The bottom panel is removed

- The heating element and the anode are fixed on one flange, which needs to be pulled out.

- The anode is unscrewed and replaced with a new one.

While the device is disassembled, it is better to carry out preventive work: rinse the tank, remove scale from the heating element, call an electrician (heating element, thermostat).

When buying a new anode, remember that it must match the parameters: length, diameter, threaded rod size.

Tank leaking

Ariston boiler tanks are made of stainless steel. On the one hand, this is good; rust does not eat them up like steel ones. But on the other hand, longevity also depends on the quality of the metal.

Problems with Aristons arise due to careless handling of the tank, holes, for example.

There is also a rupture of the container “from time to time,” as people say.

Experts say that the problem appears in cases where owners often set the maximum heating temperature, due to extraneous currents on the body, lack of or incorrect grounding, water characteristics and other factors.

If water appears on the tank body, and not in the safety valve underneath, you must immediately disconnect the unit from the network and do not operate it. Next, the exact location of the leak is determined. If it is any seam, hole or sensor on the sides and top of the device, we can assume that the problem is in the tank. At the bottom you need to remove the lid and see where exactly the water is seeping out. If not from under the flange cover, the problem is the same: depressurization of the container.

Replacing the tank in an existing appliance is equivalent to purchasing a new unit. Due to the peculiarities of the market, Ariston does not widely sell spare tanks for its boilers.

If it leaks from under the flange

If, after removing the bottom cover, you find that the flange (the central round part, the hatch into which the heating element is inserted) is dripping or leaking, you can consider yourself lucky. The problem is easier to fix than replacing the tank. This may be a defect in the rubber gasket, or the alignment is incorrect (perhaps the device was previously repaired, or maybe a factory defect).

Liquid supplied too hot

If the hot water is too hot, the first thing to do is check the thermostat knob.

After making sure that it is in the same position (no one in the household has twisted it by mistake), you need to turn off the power to the device, remove the panel, disconnect the thermal relay wires (it is recommended to mark or photograph them in order to connect them correctly in the future).

The part does not touch water, so there is no need to drain the container.

Each pair of terminals is called.

If a problem is detected, the part is replaced with a new one that matches the parameters of the previous one.

Cold water leaks out

If the device is turned on, but heating does not occur, you need to look for the reason either in the heating element or in the thermostat. Using the same principles as described above, first the thermal relay rings, and then the serviceability of the heating element is checked.

If a breakdown occurs with a thermal relay, heating element, or the anode is destroyed, it’s not so bad, the parts can be easily replaced with new ones.

But if the internal tank leaks, you will most likely have to buy a new water heater.

Why error 104 may occur - Insufficient circulation. Troubleshooting

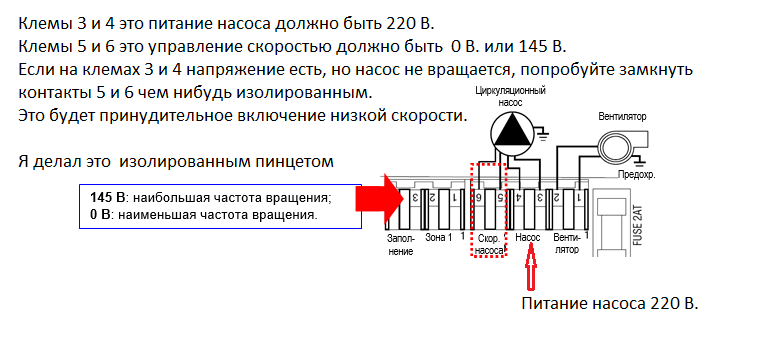

The boiler circulation pump has two rotation speeds in the manual, they are designated as V2 (55 W) and V3 (80 W). The pump speed is naturally controlled by the ECU.

In hot water supply (DHW) mode, the pump operates at V3 speed for better heat transfer.

In central heating (CH) mode, the control unit switches the pump speed depending on the temperature difference at the inlet and outlet of the heating system.

Therefore, the pump is controlled not by one, but by two relays. One supplies 220 V power, and the other controls the speed.

To check these pump power circuits, you will have to turn it on. But you don’t need to light the boiler for this, we don’t want to force it! There is a simple and quick way to turn on the pump without lighting the burner.

It is necessary to switch the boiler to the “Purge” mode. To do this, press the ESC button on the boiler panel and hold it pressed for more than 5 seconds. The purge mode is turned on - During this mode, the circulation pump starts and runs in cycles of 60 seconds. on 30 sec off and so on for 6 minutes. and without igniting the burner. And that's what we need!

This mode is intended to remove air from the heat exchanger and circuit, but we use it to control the operation of the pump. It turns on for 6 minutes, or it can be turned off forcibly by pressing ESC again.

So, we start the “Purge” mode and measure the alternating voltage at the terminals. Let's look at the drawing.

Addition: The voltage is 220 volts, with relay RL 04 (the relay that supplies power to the pump) can be more easily measured at the control points on the board, see the photo below (there are not two relays on the board, they are on the wires to the side) and the points where the probes point and there are the right ones. If they receive 220 Volts, relay 04 is working.

Contacts on the board for measuring voltage with relay RL04

In my case, this was the case; from relay RL 04, 220 V was supplied to contacts 3 and 4. but the pump did not rotate.

The contacts of relay RL03 (pump speed control type relay JQX 118F) when the boiler was turned off, the multimeter rang short, which is the norm for a lower rotation speed, but under load the relay behaved in an unclear way and the pump motor did not spin at all. As soon as I closed terminals 5 and 6 with tweezers, the pump began to work. The output of the relay that controls the pump speed is faulty.

Therefore, until I select a replacement relay, I simply soldered the jumper, i.e. I bridged pins 5 and 6 from the mounting side. In fact, a working relay does almost the same job: it closes this circuit or switches it to another contact, which is how the pump speed is switched. Below are photos to help you avoid mistakes.

Diagram and numbering of the relay location on the board

Photo of the board with explanations for installing a jumper on relay RL03 - pump speed control.

So, the indicated closed contacts, directly on the relay (Points A and B) or on the chip below, which is essentially the same thing, force the pump to turn on low speed.

But let it work at low speed rather than not work at all. This “tricky move” will give you the opportunity and time to calmly find the right relay. By the way, in the comments I have already noted more than once that I was unable to find the relay quickly, and then I didn’t “spit” on it at all, and therefore my boiler on the jumper has already worked for two, or even three seasons. And nothing happened to him, everything is OK.

But still, I finally found an excellent option for replacing this relay, and now, in February 2021. my boiler has regained its usefulness.

Video on the topic

Hot water is a mandatory attribute of comfortable living and creating an individual microclimate in the house. For this reason, any malfunction of the Ariston electric water heater leads people to a state of acute inconvenience. They immediately face the problem of personal hygiene and wet cleaning of premises. In such a situation, it is best to seek help from a specialized service center. But if the culprit behind the breakdown of the Ariston boiler lies in simple things, then it is quite possible to cope with the repair on your own.

The need for urgent repairs and debugging of an electric boiler most often arises during a period of prolonged shutdown of hot water supply. Periodic breakdowns also occur in country houses, where Ariston storage water heaters are used all year round.

Error codes for geysers Arison FAST EVO

The list of possible malfunctions specifically for the Ariston FAST EVO gas dispenser is not long.

Error - 1 flash. Incorrect installation of microswitches

Microswitches are installed incorrectly. Solution: Install the microswitches correctly.

Error - 2 flashes. Malfunction of the DHW temperature sensor

The hot water temperature sensor is faulty. Solution:

- Check the sensor cable.

- Check water pressure (too low).

Error - 3 flashes. No flame

No flame when igniting. Solution: Check the gas valve.

Basic faults

Ariston water heater repair specialists consider several key components to be the most vulnerable:

- magnesium anode;

- thermostat;

- safety valve;

- control board;

- thermostat;

- O-rings, adapters, switches, gaskets.

Regular inspections of heating elements help to promptly identify violations of the integrity of the shell. Read more about the design of different models.

The most common defects of Ariston boilers:

- failure of the heating element;

- thermostat failure;

- reduction in water heating due to scale formation;

- leaks caused by aging gaskets;

- the appearance of corrosion in the storage tank.

Tank leaks in Ariston water heaters occur infrequently. Storage containers are made of stainless steel and covered with protective layers of enamel. The cause of the breakdown may be metal corrosion, errors in connecting equipment or mechanical damage. Ariston service centers rarely manage to repair it - the technicians usually offer a complete replacement of the tank.

Simple repair of Ariston brand water heaters

Regardless of the frequency of operation, each boiler needs periodic cleaning of lime deposits. Ariston technology specialists recommend making simple repairs after 1-1.5 years. The low quality of liquid in the main network forces water heaters to be serviced much more frequently.

The reason for urgent descaling may be negative changes in work:

- the appearance of hissing and other atypical sounds during heating;

- frequent turning on and off of the device;

- increasing heating time.

Instructions:

1. De-energize the house and turn off the equipment by disconnecting the wires from the thermostat.

2. Disconnect the hot water pipe. Instead, choose a drain hose with a smaller diameter, which you lower into the sink or bathtub.

3. Remove the heating element (nut fastening on a metal plate) and pull out the thermostat. To make dismantling easier, it is recommended to press the flange towards the inside of the heater.

4. In the opened hole, lime deposits will be clearly visible on the walls. They are removed by hand and a rag moistened with a solution that neutralizes scale.

5. The dismantled elements are installed in their places. The tank is filled with water and electrical wires are connected.

6. Connection is best done using plastic pipes. They are much more practical and reliable than hoses made of rubber or metal-plastic.

7. In order not to confuse the contacts (phase and zero), technicians advise using an indicator screwdriver. The diagram drawn on the thermostat also helps to avoid errors when connecting.

8. Installing an RCD (residual current device) system in Ariston will protect you from electric shock. Its task is to immediately disconnect from the network at the first sign of a short circuit.

9. Inspect the Ariston boiler for leaks. To do this, fill the tank and leave it unplugged for 1-2 hours. If no leaks are detected during this time, then the water heater can be started.

Ariston storage water heater repair specialists categorically do not recommend cleaning with abrasive materials. This negatively affects the internal surfaces of the unit. The scale dissolving agent can be completely replaced with a solution of citric acid. It is enough to pour it into the Ariston boiler tank and leave it for a day. The heating element can be repaired in the same way. To do this, the heater is immersed in a composition with citric acid overnight. During this time, the main scale dissolves, and the remains can be easily cleaned off with a rag.

How to choose the right mechanism

How to read the designation of the heating element, for example, heating element - 32 A 13 / 1.5 J 220 where:

- TEN – tubular electric heater.

- 32 – expanded length of the heating element along the shell.

- A – designation for sealing the contact rod.

- 13 – diameter of the heating element shell.

- 1.5 – rated power in kW.

- J – designation of the heating medium and heating element material

- 220 – rated voltage in V.

If you follow the markings, you can find the right model quickly and without unnecessary nerves. And for this you don’t need to walk around with a centimeter or carry a broken product with you. It will be enough to compare the data on your heating element and the one you are going to buy.

When choosing a heating element for an Ariston boiler, you should pay attention not only to the price, but also to the design differences. It is also necessary to take into account the operational characteristics of electric heaters

Having a stable voltage and proper operating conditions, a “wet” heating element will last on average 5 years, and a “dry” one – 15.

The company recommends purchasing equipment for replacement in factory-made water heaters and according to the existing model of the unit.

Heating elements with a power of 1.5 kW are more common for Ariston boilers. They are often used in equipment with a volume of both 20 liters and 100.

Engineers categorically do not advise replacing a low-power heating element with a more productive one, since the water in the equipment heats up to 85 degrees and the boiler turns off. And high power disrupts the operation of the device and increases the cost of each water heating.

When choosing a heating element, you should also pay attention to the flange. Threaded - thanks to the existing thread, the heater is attached to the boiler by screwing

The thread diameter is 1 1/4 inches. Clamping ones - come in the following diameters: 62 mm, 72 and 82 mm.

For dry heating elements - they are made of enameled metal, almost always in pairs, and have closely spaced contacts with a “petal” type fastening.

When to contact a specialized service center?

In case of any breakdowns or malfunctions of the boiler during the warranty period, it is recommended to seek help from qualified technicians. Before doing this, you should carefully study the service coupon for Ariston equipment. Usually the repair conditions and the possibility of replacement are specified there. Most often, only individual components and elements are installed free of charge: thermostat, heating element, thermal relay.

During the warranty period for Ariston equipment, it is not recommended to repair or adjust water heaters yourself. Service does not cover breakdowns resulting from mechanical and hydraulic shocks. The thickness of the steel is not very large, so Ariston device repair technicians advise following simple installation rules. If external damage occurs due to the user’s fault, repairs will have to be paid out of your own pocket.

If, after preventive maintenance (for example, cleaning the tank) carried out by specialists, the boiler has become unusable, then you should contact the same service center again. Large trading companies often offer future maintenance services in exchange for installation of Ariston by their craftsmen. In this case, there is no need to save money, because the cost of warranty repairs is already included in the sales price of the unit.

Operation and Maintenance

1. Before purchasing, it is advisable to call the Ariston customer service and ask the specialists which models are most often repaired and for what reason. Advice from experienced specialists will help you decide on the right choice of equipment.

2. In order to prevent increased scale formation in Ariston, it is recommended to set the water heating level to no higher than 60 degrees.

3. If it is not possible to repair the water heater using minimal means and individual elements need to be replaced, then you need to choose only original spare parts.

4. In cases where the boiler is not used constantly, you should decide what to do with the remaining water. If you leave liquid in the tank for a long time, it will stagnate and give off unpleasant odors. When the water is completely drained and the tank is left dry for a long time, there is a risk of rust. The best solution is to periodically run the liquid through the system.

5. In order not to break the tightness of the Ariston connections, you should not touch the tank while it is heating. Operating a leaking container is strictly prohibited.

6. Before installing the boiler, you need to carefully study the technical data sheet. It always indicates which elements of the system should be protected from moisture.

Prices

Approximate cost of repairing Ariston household water heaters with a tank volume of 50 and 80 liters:

If you urgently need to repair the water heater, it will cost the customer 1800-3500 rubles. The cost of spare parts is paid separately.

To provide your apartment with hot water all year round, the best option is to install a water heater. If you choose the Ariston boiler correctly in compliance with the basic conditions and operating requirements, then such a device will serve you for a relatively long time. What to do if there is a malfunction of the device and there is no hot water in the apartment? In this case, of course, you can resort to the services of service centers that repair water heaters, or you can fix the problem yourself.

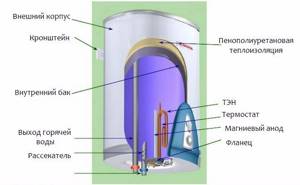

Design and main elements of the Ariston water heater.

Let's consider the second repair option - troubleshooting it yourself.

Before you begin repairing the Ariston water heater, you need to find out the malfunction and the reason for the failure of the device.

Let's get acquainted with the boiler design

To understand how to ensure many years of uninterrupted operation of the purchased unit, you need to at least have a rough idea of its structure. It would also be a good idea to read the instructions for this model. This will allow you to avoid making mistakes when using an electric water heater.

A diagram suitable for most manufactured water heating devices is shown in the picture below:

Schematic design of a storage water heater

All water contains some amount of dissolved salts and minerals. With frequent heating and cooling, these salts crystallize and settle on the inner walls of the tank in the lower part. In 2-3 years, not only the walls are covered with a strong shell, but also the heating element and the copper tube, inside of which the temperature sensor is inserted. To reduce the hardness of the formed slags and to prevent corrosion of the tank body, a magnesium anode is attached to the same flange with the heating element. But it is not designed to last long, so it needs to be changed from time to time.

If you disassemble a boiler that has worked for several years without cleaning, you will see the following picture:

Scale formed due to long-term use of the Ariston boiler

This situation is scary not only because of its appearance. Such a frivolous attitude towards a water heater can lead to the following consequences:

- With such an amount of scale, energy consumption when heating water increases.

- Due to the higher temperature in the operating area of the heating element, the temperature sensor or heating element fails.

- The magnesium anode completely fails and, naturally, requires replacement.

- The risk of corrosion of the tank body increases many times over, causing water leakage. In this case, replacing the device with a new one is inevitable.

In order not to take matters to such an extreme, almost all companies that produce electric water heaters recommend maintenance of devices once every one to two years. What is it? It is necessary to disassemble the water heater, replace the magnesium anode with a new one, check and, if necessary, clean the heating element, clean and rinse the inner surface of the tank with water. If such an event is carried out regularly, the service life of the boiler can at least double.

Ariston water heater malfunctions

Scheme of connecting a storage water heater to communication systems.

Since the boilers are connected to two communication systems, a water supply system and an electrical supply system, all problems can be divided into 2 groups. The first group includes faults associated with water leakage, failure of the tank, check valve and connection elements to the water supply system. The second group includes malfunctions of electrical equipment included in the Ariston boiler systems.

Preparatory work

Before repairing water heaters, you need to prepare tools and accessories. To eliminate mechanical problems associated with water leakage, you will need:

- adjustable wrench;

- adapter kit;

- known-good check valve;

- welding machine when the water heater tank fails.

For electrical faults, in addition to tools, you will need a measuring device, tester or ohmmeter. Preparatory work also includes work during which water is drained from the water heater tank and the electrical part is disconnected from the apartment power supply network.

Repair and troubleshooting for Ariston water heaters

The cause of poor heating may be a poor electrical connection between the heating element and the thermostat.

Let's look at several of the most likely malfunctions that are identified when performing repairs and adjustments of Ariston water heaters, associated with a malfunction in the water supply system and heating the water to the required temperature.

One of the main malfunctions is water leakage from the boiler tank. First of all, it is necessary to visually inspect the water supply and drainage hoses. If they are in good working order, proceed to inspect the lower part of the storage tank. To do this, after turning off the power to the Ariston boiler, remove the bottom cover that covers the electric heater and thermostat. If necessary, you can remove the insulation from the bottom of the tank. If a leak is detected at the connection points, additional seals and sealant can be installed. If the storage tank fails, more complex work is required - welding. Of course, you can use so-called cold welding, but this will not give the desired result for a sufficiently long period of time.

If the tank in the water heater leaks, additional seals and sealant are installed at the connection points.

The second most common malfunction of Ariston water heaters is the lack of heating of water in the storage tank. In case of such a malfunction, repair of water heaters is referred to as repair of the electrical part of the heating device. First of all, when repairing water heaters, the presence of 220 V mains voltage in the apartment power supply network is checked. If there is no voltage, check the input circuit breakers for the apartment or house as a whole. If voltage is present, they gradually approach the main element - the thermal electric heater (TEH). Using an ohmmeter or tester, check the serviceability of the cable with which the boiler is connected. If the cable is in good condition, the direct current resistance of the heating element is measured, which for a serviceable element should be several Ohms and tend to zero.

If there are no readings from the device, they are convinced of the failure of the heating element and begin to disassemble the water heater. Before disassembling the boiler, make sure that the cold water supply system is shut off and use a hose to drain the water from the storage tank.

When identifying a malfunction of the heating element of an Ariston water heater, you can make a mistake, since water heating may not be possible if the thermostat is faulty. If the measuring device shows a resistance value corresponding to the operating state of the heating element, you should check the serviceability of the thermostat and sensors for monitoring the temperature of the water in the container. When repairing water heaters, you may encounter a lack of water heating even if the heater is working properly. In this case, the thermostat is considered to be a faulty element and needs to be replaced.

Features of Ariston gas boilers

The popularity of equipment under the Hotpoint/Ariston brand is associated not only with the low price of all products. The functionality of this equipment is often close in its characteristics to the flagship models of well-known manufacturers.

So, for gas appliances from this developer, the following functions are considered the norm:

- Automatically maintains the outlet water temperature regardless of any changes in the environment, as well as fluctuations in the temperature of the water itself and changes in its pressure. The flame intensity is adjusted without user intervention;

- Automatic pumping of air from the heating system, which creates safe conditions for the operation of the device;

- In the event of emergency situations, the operation of the circulation pumps is blocked.

Rice. 1

All protective systems, like the flame maintenance and regulation unit, operate via an electronic board. This allows you to organize not only a convenient panel with control buttons, but also an indication of the current operating mode, and, if necessary, error codes indicating the suspected cause of the problem.

The decoding of these codes is usually presented in the operating instructions. The owner of the equipment can independently understand the situation and, to the extent he has the skills, also eliminate the cause. But in most cases, such information is useful only to determine whether it will be enough to simply restart the boiler or whether it’s time to call a repairman to your home.

Post-repair work

Regardless of what malfunction was eliminated when repairing the water heater, it is recommended to clean it of scale and debris. Before connecting to the power supply network, you must ensure that the individual elements are completely dry so as not to cause a short circuit. When connecting the Ariston boiler, also do not forget to ground the storage tank. Before filling the tank with water, make sure that the mechanical connections and fastenings of the brackets for hanging the boiler on the wall are secure.

Repairing an Ariston water heater is not very difficult, and even a non-professional in the field of plumbing and electricity can handle it.

The most popular blog articles of the week

Do-it-yourself repair of an Ariston 80-liter water heater is possible if you know how the device is folded and what problems may arise in it.

Quality and weaknesses

Ariston water heaters have a stylish modern design, excellent functionality, and differ from analogues from other manufacturers at a reasonable price

Developers pay careful attention to the safety of products during operation: the units are equipped with various protections for all occasions, turning off the product in the event of a power failure, overheating, or lack of water supply

But this reliable equipment suffers from the hardness of our water and quite frequent changes and surges in voltage. The weakest points, according to experienced craftsmen, are tubular-type heating elements, a magnesium anode and a check valve. These very simple breakdowns can be fixed with your own hands if you have the necessary minimum tools. The design of the product has a standard design, so prevention and repairs are not difficult.

Features of the Ariston water heater 80 liters

This water heater is considered the best in its range for use in a family apartment. It is medium in size and easy to install. The device is horizontal in shape. Therefore, it can be installed directly under the ceiling.

The main disadvantage of the boiler is the frequent malfunction of the display. However, its operation does not affect the functioning of the water heater itself.

Such a boiler can break down when the remaining water in it freezes. It is necessary to drain all the water completely, even though the manufacturer claims that the device is resistant to freezing.

The maximum water heating temperature is 80 degrees. But if you use such heating constantly, the boiler will quickly fail. The optimal heating temperature is considered to be 60 degrees.

Features of replacing a faulty heating element

If the boiler stops heating the water to the required temperatures, then the heating element should be replaced. To do this, you need to perform the following procedure:

- Disconnect the device from the electrical network.

- Stop supplying water to the container.

- Connect a hose to the drain valve and drain all the water into the sewer.

- Remove the protective box by removing 2 screws.

- Remove the return valve from the pipe.

- Drain the remaining water from the tank.

- Using a wrench, unscrew the nut that secures the flange.

- Carefully remove the old heating element without damaging the flange.

- Clean the walls of the container from accumulated dirt. If the inside walls have a special protective enamel, then there is no need to remove scale. You may simply damage the protective film. This layer of scale will protect the walls of the vessel from rust formation.

- The magnesium anode is removed and repaired if required.

- A new heating element is being installed. You need to do exactly the opposite of all the work.

- Checking operation after final assembly of all parts. The tank should not leak. Otherwise, you need to put in new gaskets.

Weaknesses of the water heater

The Ariston brand is considered one of the most reliable. But despite this, these boilers have their drawbacks. Very quickly after purchasing the device and starting its operation, the display indicating the main parameters of the boiler’s operation breaks down. However, it is intended for the convenience of the user. A broken display does not affect the operation of the boiler in any way.

Although the manufacturer indicates that the device is frost-resistant, the water from it must be completely drained during downtime. Frozen residues may damage the device.

The temperature maximum of the Ariston boiler is 80 degrees. But it is not recommended to use it. The boiler will fail very quickly in this case. It is best to heat up to 60 degrees.

If all these disadvantages are taken into account during operation of the device, then it will last for many years.

Do-it-yourself Ariston water heater repair in the video below:

Additional Information:

- Repairing Termex water heaters with your own hands helps you quickly and efficiently get rid of the problem without calling a technician to your home. Certain knowledge in...

- How to drain water from a water heater in order to periodically clean the device tank? This question is often asked by people when faced with a service...

- How to install an electric storage water heater yourself is of interest to people who do not want to spend money on paying for the services of a professional technician. This work...

2017-02-01 Yulia Chizhikova

During operation of the Ariston storage water heater, the following problems may arise:

- The unit does not turn on.

- Cold water flows from the water tap.

- Slightly warm or too hot water flows from the tap

- Water is dripping from the safety valve.

- Tank leaking.

Each of these situations requires diagnosis and repair; most of the repairs can be done with your own hands, having some skills. First make sure that the apartment or house has a supply of water and electricity.

Nomenclature

Champion model – classic round body, bioglass porcelain coating. A high-quality and inexpensive model – it is very popular and has good reviews.

Presented in the following modifications:

- Water heater Thermex ER 50 V

Thermex ER 50 V; - Thermex ER 80 V;

- Thermex ER 100 V;

- Thermex ER 150 V;

- Thermex ER 200 V;

- Thermex ER 300 V;

- Thermex ER 80 H;

- Thermex ER 100 H.

Champion slim - Small diameter - only 36cm. Bioglass porcelain coating. An ideal solution for small apartments.

Modifications of this model:

- Water heater Thermex ES 50 H

Thermex ES 30 V; - Thermex ES 40 V;

- Thermex ES 50 V;

- Thermex ES 60 V;

- Thermex ES 70 V;

- Thermex ES 80 V;

- Thermex ES 50 H.

Termex flat plus - impeccable design, flat body, snow-white color scheme and electronic control with an LCD display.

The model is presented in the following modifications:

- Water heater Flat Plus IF 50 H

Thermex IF 30 V; - Thermex IF 50 V;

- Thermex IF 80 V;

- Thermex IF 100 V;

- Thermex IF 30 H;

- Thermex IF 50 H;

- Thermex IF 80 H.

Termex round plus – classic style water heaters. 7-year trouble-free operation guarantee.

Modifications presented in the line:

- Water heater Thermex IR 100 V

Thermex IR 10 V; - Thermex IR 15 V;

- Thermex IR 80 V;

- Thermex IR 100 V;

- Thermex IR 150 V;

- Thermex IR 200 V;

- Thermex IS 30 V;

- Thermex IS 50 V.

Thermo power – The most powerful and most modern model. Double area of heating elements, and power 2.5 kW. Double guarantee, double efficiency. Stainless steel heating elements and the ubiquitous bioglass porcelain.

Water heater Thermex ES 50 V

Models:

- Thermex ERS 80 V(Thermo);

- Thermex ERS 100 V(Thermo);

- Thermex ESS 30 V(Thermo);

- Thermex ESS 50 V(Thermo);

- Thermex ESS 80 V(Thermo).

You may be interested in an article about Termex instantaneous water heaters.

Read the article about instantaneous electric water heaters for taps here.

Hit – The most compact model. Ideal for small apartments. Bioglass porcelain and plastic body. Designed for mounting above the sink.

Presented in the following modifications:

- Thermex H 10 O;

- Thermex H 15 O;

- Thermex H 30 O;

- Thermex H 10 U;

- Thermex H 15 U.

Thermex Praktik – classic round shape and stainless steel tank. Guaranteed quality and durability.

Water heater Thermex Round Praktik IRP 80 V

Modifications:

- Thermex IRP 30 V;

- Thermex IRP 50 V;

- Thermex IRP 80 V;

- Thermex IRP 120 V;

- Thermex ISP 30 V;

- Thermex IRP 50 V.

Thermex light - A miniature body of an unusual design, made of plastic, similar to a children's balloon. Combination of characteristics of flow and storage heaters. The tank capacity of up to 30 liters allows you to quickly heat water. Convenient for summer cottages.

There are three modifications of this line on the market:

- Thermex Light MS 10;

- Thermex Light MS 15;

- Thermex Light MS 30.

Thermex Combi is a new direction in the field of combined type water heaters, with an indirect heating boiler.

It works both from internal heating elements and from external heat sources: central or gas heating. It has a huge advantage in saving energy.

Water heater THERMEX ER 80 V (combi)

The model is presented in the following forms:

- Thermex ER 80V;

- Thermex ER 100V;

- Thermex ER 120V;

- Thermex ER 200V;

- Thermex ER 300V.

All Thermex electric heaters are certified for compliance with GOST requirements.

You may also be interested in an article on how to clean a Termex water heater.

Read the article about installing and connecting a Termex water heater here.

After reading this article, you will learn about the nuances of repairing a Termex water heater with your own hands.

Boiler does not turn on

First of all, check the power supply to your storage water heater. Pay attention to the condition of the outlet, whether it is burnt or melted; this can happen due to inappropriate parameters of the outlet and the power of the device.

Test the wire with a tester or an indicator screwdriver; the wire may be broken. In a working wire, the indicator lights up only on the “phase”; there is no signal on “zero” and “ground”. Check the contacts connecting the wire and the water heater; over time, the contacts oxidize and “boil.”

If this happens, unscrew the wire, clean the contacts, then reconnect the power cable. Check the serviceability of the RCD by pressing the “Test” button; if the device turns off, this indicates that the RCD is serviceable. Check whether the wires on the electrical panel are securely connected; if the wire is unscrewed or loose, tighten it.

The reason may be that the fuse switches off during power surges or when the wire does not correspond to the parameters declared by the manufacturer. For Ariston 80 l, the cable must be marked H05VV-F 3 * 1.5 sq. mm, with a diameter of 8.5 mm, this should be taken into account in case of replacing a faulty cable.

Ariston boiler electronic board

If everything is in order with the heating and water supply circuits, then an error in the electronic display board of the Ariston boiler is possible.

Error Code 301 - Display Board Program Error

- There is no contact between the main board and the display board.

- Check that the EEPROM key is installed correctly on the main board.

- Check contacts. If necessary, replace the display board.

Error Code 302 - Communication error between main board and display board

- There is no contact between the main board and the display board.

- Check contacts. If necessary, replace the display board.

Error Code 303 - Main Board Failure

- Poor contact between main board and control board.

- Check if the main board is working properly.

Error Code 304 - More than 5 resets performed within 15 minutes

Switch off and start the boiler using the ON/OFF button.

Error code 305, 306, 307 - ECU operation error

Internal error in ECU operation.

Cold or insufficiently hot water flows from the boiler

You can find out complete information on the selection, operation and maintenance of boilers (water heaters) from all manufacturers if you go.

In addition to specific information on the site, you can also study specific problems from other people on this topic who have already purchased a boiler (storage water heater) and thus avoid them. You will find a regularly updated list of such problems and their solutions.

The cause of a malfunction of this nature may be a breakdown of the heating element, thermostat and a large layer of scale on these devices. Before determining the cause of the malfunction of the Ariston 80-liter water heater and doing the repair yourself, you should turn off the power supply and drain the water.

Then, using a 13 mm wrench and a Phillips screwdriver, remove the protective box and unscrew the bolts on the mounting plate. Carefully remove the flange on which the heating element and thermostat are attached. Now you need to descale these 2 devices.

Boiler protective cover

The thermostat should be unscrewed, cleaning the attachment points to the flange from sediment, then carefully, using a screwdriver, free the thermostat from scale. You can check the functionality using a tester; the absence of a signal on its contacts indicates a malfunction and the need for replacement, since the thermostat cannot be repaired.

You can also check the heating element for functionality using a tester by connecting the ends of the tester to the contacts of the heating element. If there is voltage, the heating element is working, but it needs to be cleaned. The heating element can be cleaned using a screwdriver, carefully removing pieces of deposits.

Then you need to prepare a solution of citric acid - 100 g per 1 liter of water and immerse the heating element in the solution. The effect of the solution on the device will be indicated by air bubbles that appear as a result of the reaction. If this action is not enough for complete cleansing, you can put the vessel with the solution and heating element on low heat.

After cleaning the heating element, you need to descale the tank. Be careful not to damage the inner surface of the tank. If it is possible to remove the heater from the wall, cleaning can be done using a solution of citric acid, pouring it into the tank.

There may be a lot of debris in the tank

After these manipulations, assemble all the parts in the order in which they were disassembled and carefully insert and secure the flange. Make sure that during assembly there are no distortions of parts, do not overtighten the bolts, change the gasket between the body of your storage boiler and the flange, since the flange gasket was also exposed to salts.

Descaling

Hard tap water inevitably provokes the appearance of salt deposits or simply scale on the heating element and the walls of the housing. If you do not remove deposits, a number of problems may arise over time: deterioration in water heating, loud boiler noise, overheating relay operation, and even breakdown of the heating element. To prevent these malfunctions and, as a result, save on repairs, regularly - at least once a year - clean the Termex water heater.

Descaling is carried out in three stages: