Hardware problems that can lead to error 104

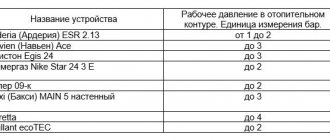

Fault code 104, according to the manufacturer's instructions, indicates poor circulation or insufficient coolant.

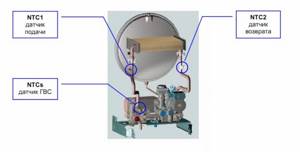

Ariston boilers have an automatic system for checking the circulation and heating of the coolant at the moment of release from the heat exchanger, which protects the device from overheating.

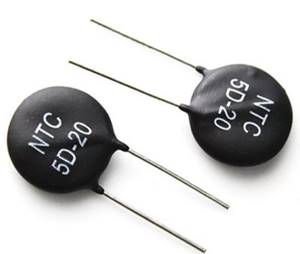

Control is performed by temperature sensors NTC1 (supply to the central heating circuit) and NTC2 (input from the central heating circuit). NTC devices are thermistors, the resistance of which decreases with increasing degree of heat of the coolant.

When the rate of increase in readings on NTC1 or NTC2 is more than 20 degrees per second, and fault code 104 occurs.

In real life, this breakdown looks like this: after switching on, the burner ignites, after a few seconds the gas boiler makes the characteristic crackling sounds of rapidly evaporating water, then the boiler clicks, the installation turns off and switches to emergency mode with error code 104.

In models BS 24 ff, cf the red light 90 gr is on. together with the indicator (crossed out flame), this indicates overheating of the equipment. When the yellow indicator (chimney) in the 24 ff heater flashes simultaneously with the 40 or 50 g indicators, this means a lack of coolant or insufficient circulation.

When trouble code 104 appears, the manufacturer recommends that you first reboot the equipment to make sure that it is not a system self-diagnosis failure.

Let's find out how to enable restart - to do this, press the "Reset" or "Reset" button on the control panel.

If after a reset the boiler does not function normally, then the self-diagnosis indicates a real defect.

The most likely causes of equipment damage: either problems in the heating pipes, or problems in the device itself - clogged coarse filter, damage to the pump, electronic board, sensors, heat exchanger.

Problems with the heating system

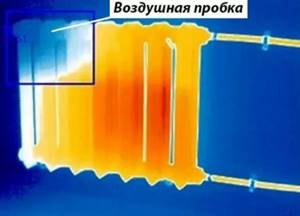

If the pressure meter transmits inflated data, or heat transfer decreases, this demonstrates problems in the heating structure: blockage in the pipeline, the formation of air locks, a violation of the tightness.

Blockages appear due to the penetration of dirt into the pipes, layers of rust and scale. Detecting the location of a blockage is a very labor-intensive task; for this, methods of measuring the heat of pipes and an acoustic method are used, in which the pipeline is tapped and listened to.

To flush pipes, a hydraulic method is used, or the blockage is broken through using a wire with a brush attached to the end.

Air jams are formed as a result of air entering the pipeline for the following reasons: when water is heated, air dissolved in it creates air bubbles; air accumulation occurs due to a decrease in pressure, leaks, and repair processes.

After finding the plug by tapping (the sound increases in the problem area), the air space is eliminated using air collectors or air bleed valves.

Air locks also lead to a decrease in pressure in the heat exchanger, which will result in error code 108.

In most cases, leaks occur due to corrosion, which leads to both leaks and complete rupture. If you do not have the skills to properly install heating pipes, you should contact a specialist.

Coarse filter clogged

Ariston CLAS, GENUS, ALTEAS models have a built-in mesh filter. It is advisable to monitor its condition on a regular basis; if it becomes clogged, the bearings quickly wear out and cooling deteriorates.

To verify the cause of the breakdown, you should perform several manipulations:

- Turn off the power supply; you must completely remove the power, since after pressing the on/off button, the mechanism continues to function for some time; you will have to wait several minutes to stop completely.

- Let's see what pressure the built-in pressure gauge shows.

- Turn on the power and note the pressure gauge readings with the device in operation. If the pressure drop exceeds 0.2 bar, the structure is clogged.

- We open the front cover, fold out the control panel with the board and find the mechanism we need. It is located at the coolant inlet from the central heating circuit (bottom right), and a pressure gauge capillary is connected to it.

- Having previously shut off the heater, drain the water and remove the clamps.

- We first take out the capillary, and then the part we need, prying it off with a screwdriver.

- We wash the device and clean it of deposits, then install all the elements in the reverse order.

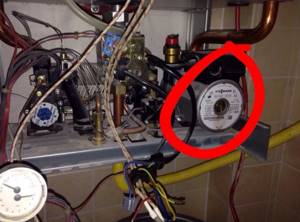

Pump failure

To check the circulation mechanism, unscrew the release screw on it, after placing rags or rags under it to prevent moisture from getting on the board. This will make it possible to see whether the shaft rotates after starting the equipment.

You can also turn off the power and try to turn the shaft manually with a screwdriver by inserting it into a special wide slot. If the shaft rotates manually but does not start when the device is turned on, check the supply voltage of the mechanism. If there is 220 watts on the chip, most likely the cause of the heater defect is damage to the part.

Ariston installs 2 types of pumps, with modulation and two-speed WILO: if the modulated one has become unusable, then only replacing the element will help, but the two-speed one can be repaired by changing the rotor and impeller assembly. A rotor from WILO RS25/6 is suitable for these purposes.

Electrical part of the pump

The circulation pump has two rotation speeds: V2 (55 W) – central heating mode and V3 (80 W) – hot water supply mode. Consequently, it is activated by 2 relays, the first supplies 220 V power, the second regulates the speed of rotation of the shaft.

To check the functioning of both relays, the heater should be started in the “Purge” mode; this mode is configured by pressing the ESC button for more than 5 seconds. Next, we measure the alternating voltage: at the 3rd and 4th terminals there should be 220 V, and at the 5th and 6th - 0 V or 145 V. If the required voltage is not available, the corresponding relay should be replaced. When there is voltage at the 3rd and 4th terminals, but the unit does not turn on, try making a jumper between pins 5 and 6.

If power is supplied to all terminals, a possible cause of the defect may be an interturn short circuit. This problem can only be eliminated by completely replacing the component part.

Useful video on the topic:

Failure of the electronic board

Also, heater failure may be associated with the control board itself. You can try to measure the voltage output to the pump.

To do this, remove the connector, set the tester to measure voltage, turn on the device, reset the error by pressing the Reset button. If there is no voltage, the device is broken and does not supply voltage to the pump, but the heater comes into action and boils. A new board needs to be installed.

Failure of sensors

NTC sensors may be faulty. In models BS 24 ff, cf, when they break down, the yellow indicator light (chimney) lights up simultaneously with the 60, 70 or 80 g indicators.

To check their serviceability:

- Go to the menu and look at the characteristics of NTC devices.

- Make sure that the burner fires, then error sp3 occurs, otherwise it looks like an Ariston boiler error 501.

- Measure the resistance of devices by first turning off the power.

- If the values differ, the sensor is changed.

Heat exchanger

The operation of even pure coolant in the heating pipeline over time serves as a source of clogging of the heat exchanger. Corrosion on its internal part leads to a narrowing of the pipe cross-section and reduces the thermal conductivity of the metal.

The manufacturer recommends cleaning the heat exchanger at least once every 3-4 years.

Signs of clogging of the mechanism appear as:

- reduction in heating performance;

- increased gas consumption;

- increased noise;

- increased activity of gas equipment.

To clean the unit, it is recommended to rinse it with special chemical solutions and then perform mechanical cleaning.

Cleaning the heat exchanger yourself is most often ineffective. It is best to entrust servicing of the part to a service workshop. Date: April 1, 2021

What you need to know before connecting an Ariston geyser

Ariston water heating devices are quite economical and have low gas consumption. At the same time, the boiler has a wide range of operational capabilities.

Before you start using the Ariston gas water heater, you must do the following:

- make sure that the apartment (house) has good ventilation;

- check the water pressure - if the pressure mark is below 0.3 atm, then care should be taken to additionally recharge the circuit;

- if there is often a decrease in water pressure in the apartment, you need to make sure that there is no leakage of liquid from the system itself.

It is important to know that identified faults such as low water pressure should only be repaired by a specialist.

Modern Ariston geysers are universal and quite easy to use. To activate them, you just need to press a button. The required temperature on the brand’s gas equipment is set using special control buttons - to supply hot water, it is enough to set 36-56 degrees.

It is also important to know that the water heater starts working immediately after opening the hot water tap. As soon as the user closes the tap, the column stops heating water. If the device needs to be completely turned off, then turn the external switch to the maximum and turn off the gas supply.