Despite the reliability of modern gas heating equipment, minor malfunctions occur during its long-term operation. If a gas boiler breaks down, every owner wonders whether it is possible to repair the boiler on their own; I do not turn to the services of specialists. Indeed, every owner of a heating system can cope with some faults, but there are a number of repairs that should only be carried out by specialists.

Among the most common breakdowns are:

Before you repair a gas boiler yourself, you need to accurately determine the cause of the breakdown . It is possible that you simply cannot do without calling a specialist.

The fact is that each model is individual and different from other similar models. It is unlikely that you will find two identical units that have an identical layout of working units. Some devices have interchangeable working units, others do not.

Gas boiler design

Installation of a gas heating boiler

According to experts, the operation of the entire system without risks to the life and health of people in a house with an autonomous heating system depends on the boiler safety team.

The failure of even a small link in this chain can lead to the most unpredictable consequences - in particular, a gas leak.

The gas boiler safety group consists of:

- limit thermostat that controls the boiling of water inside the boiler. If it boils, the sensor will shut off the gas supply to the burner;

- monostat (in turbo boilers), responsible for protecting the boiler from the accumulation of smoke inside the combustion chamber. As a rule, this happens when the heat exchanger or chimney is clogged;

- a burst valve that controls the pressure in the system. When the reading exceeds 3 bar, the sensor causes the boiler to reduce pressure; ionization electrode that controls the burner flame. If the boiler operates without a flame, it will lead to an explosion;

- a draft sensor, which can be used to determine how combustion products are selected, whether the chimney system is operating normally, and whether exhaust products are being ejected correctly.

It is known that the safety of boiler operation and the quality of fuel combustion directly depend on the draft in the chimney. Experts recommend installing an audible gas alarm to the draft sensor.

Automation

A modern boiler is an automated system that requires periodic inspection and maintenance.

Automation for gas heating boilers is a serious matter. To maintain and repair automation, you will need a set of special tools, knowledge in the subject area and experience, so do not try to fix it yourself.

UPS and control board

To ensure continuous operation of an automatic boiler, electricity is required, which ensures the operation of the electronic control system, the functioning of the pumps and the ignition of the burner.

Power outages or voltage drops in the network lead to stoppage of the boiler, system failures and other malfunctions.

To prevent force majeure situations, it is necessary to provide the boiler with uninterrupted power supply.

A UPS is a fairly complex device. It must be repaired by a highly qualified specialist using special equipment. Self-repair in the absence of skills and knowledge can lead not only to the final breakdown of the boiler, but also to its explosion.

Expert advice on control board repair.

After the repair has been made, you should not immediately apply full voltage to the board, as it may simply burn out. If this happens, you will need to completely replace the burnt-out automation, which will cost you a significant amount.

Checking the circulation pump

A common cause of poor circulation in closed heating systems is a faulty circulation pump. This device has two parts - electrical and mechanical. The electrical part is a plastic box in which the starting capacitor is located. The main characteristic of a capacitor is its capacity. In most circulation pumps of wall-mounted gas boilers, the capacitance of the condenser is 2-2.5 microfarads (the exact value is indicated on the capacitor itself). Therefore, you should first check this value using a tester. If the capacity is significantly lower than the nominal value, you will need to buy a capacitor and replace it.

For example, an Ariston Clas boiler with a Wilo pump worked unstably and gave error 104 with a capacity of 0.15 microfarads, and an Ariston Egis boiler worked normally with a capacity of 1.15 microfarads. Therefore, in each specific case the situation may be different and depend on the parameters of the heating system as a whole. It is advisable to buy a starting capacitor for a gas boiler with exactly the same characteristics and rating as was installed; an error may affect the service life of the pump.

To check the mechanical part, the pump will have to be removed. But keep in mind that this may require sealing. After dismantling the pump, it is inspected for mechanical damage, the presence of deposits - check how freely the impeller rotates. It is better to entrust this process to a qualified specialist. It is not always possible to repair the circulation pump.

What to consider when repairing a boiler yourself

If there is smoke in the house or there is a clear smell of gas, first of all you need to turn off the boiler and open the doors and windows.

In some cases, you can deal with the breakdown yourself, without replacing parts. For example, if the combustion sensor fails, you need to completely turn off the boiler, disconnect it from the gas supply, let it cool, check for draft and restart. If there is no draft, then it is strictly forbidden to turn on the boiler and it is recommended to immediately call a technician.

The main reason for boiler overheating is contamination of the heat exchanger.

To eliminate this malfunction, it will be enough to clean the heat exchanger, which is the most effective measure. But sometimes the cause of overheating can be improper operation of the automation. In this case, you cannot do without calling a specialist. If the fuel supply pipe becomes clogged, it is enough to disconnect the pipe from the system, clean and rinse it, dry it and reconnect it.

If the flame, which is constantly burning in standby mode, dies out, you need to find the instructions for the boiler and, following the recommendations, check the unit for clogging of the column.

To check the presence of draft in the chimney, be sure to make sure that there is no smell of gas in the room. Then hold a thin strip of newspaper near the chimney. If there is no traction, the newspaper will remain motionless.

Description of a device for remote control of a heating boiler, use cases.

In this article, we will not touch upon issues related to the choice of gas equipment. We will assume that this choice has already been made and we need to calculate the consumption of liquefied gas and its cost for a specific boiler.

3 comments

Thanks for the informative article! The boiler broke down, it’s good that it’s summer and I’m not freezing at home) Unfortunately, I don’t have time to do the repairs myself, so I want to contact zzz. According to reviews, the company is good, and thanks to your article I know what to check in their work, thank you!

Tell me, I notice a green flame in the burner of the gas boiler, is this normal?

Hello. The article is very useful. Could you help me? I have this problem. Water is not pumped when the make-up tap is open (heating boiler). The pressure does not rise or fall, while the pressure in the expansion tank is 1.2 bar. I tried to drain the water from the boiler with the supply to the boiler closed and the pumping open through the hot water tap. Doesn't merge. I bleed and pump air from the expansion tank - the pressure sensor changes readings, which means it’s working. I flushed the boiler with a booster, but it didn’t help. I suspect the pump valve is clogged. If so, how to remove it? I tried it, it didn’t work, I was afraid to break it. Maybe I should have pulled it harder? Please help me figure it out. I will be very glad for your answer. Thank you.

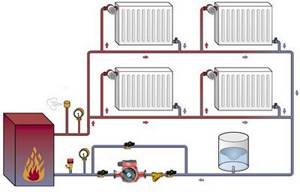

Principle of operation

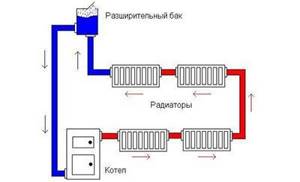

Schematically, the OS heating circuit can be represented as a long vertical ring. One side of the ring

- with hot water (supply riser from the boiler to the boiler),

the other side

- with cold water (riser with return from the radiators). The density of a hot coolant is less than that of a cold fluid - water expands when heated.

Consequently, the weight of water and the pressure of the water column in the cold part of the circuit will be higher than the weight of water and the pressure of the column in the hot leg.

According to the law of communicating vessels, the liquid will tend to balance the pressures - to move from the cold branch to the hot one.

Since the circuit is such a closed ring, circulation or gravity flow of the coolant occurs.

- The supply riser is maximally insulated along its entire height.

- The boiler is located as far down as possible from the last radiator.

- The circuit has a container for releasing the excess volume of heated coolant

- an expansion tank (to ensure a reduced density and low pressure of the water column in the heated branch).

With natural circulation

During natural circulation, the coolant moves under the influence of the circulation pressure Pн

(in mm water column):

Pn=H x (cold - phot).

- H

- height difference between the boiler and the last radiator, m; - phol

- density of water in the cold return riser,

kg/m³

; - phot

- density of water in the hot supply riser,

kg/m³

.

During circulation along the circuit, the coolant spends part of the pressure to overcome the hydraulic resistance of pipes, radiators, and shut-off valves. Therefore, when designing an operating system, materials with low hydraulic resistance

so that their total does not exceed the design pressure

Pn

(do not block the system).

Important! The OS coolant contains air, which is mixed in the expansion tank. To remove air, pipes are made with a slope of at least 3-5 mm per p.

m. pipes.

With circulation from a pump

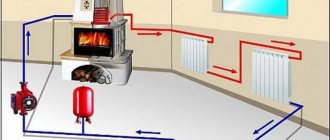

To increase the natural pressure, a circulation pump is included in the OS circuit.

There are two pump insertion points

to existing OS:

- On the return pipe in front of the boiler.

The expansion tank is reconnected to the return pipe in front of the pump (in the suction zone). - On the upper supply pipe

immediately after the expansion tank connection point.

Reference!

The pump insertion point is equipped

with a bypass

with a reed check valve.

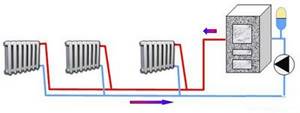

Single-pipe

A single-pipe system with natural circulation is made only with upper coolant distribution.

All radiators in the riser of a single-pipe OS are connected in series - the output of one battery is connected to the input of another.

- Small number of pipes.

- Easy to install.

- The system is unbalanced

- the top batteries are hot, the bottom batteries are cold. To equalize the temperature regime, lower radiators are installed with a large number of sections. - Impossibility of thermoregulation

due to high resistance of control valves.

1.When turned on, the boiler does not work at all

There can be several ways to eliminate this gas boiler malfunction. The simplest one is to check whether the boiler is plugged in or whether the machine has been knocked out . If this does not help, you need to remove the boiler casing and inspect its insides for a short circuit. Perhaps there is some smell or something has leaked. You need to check whether all wires and sensors are in their places. If everything is in order, then you need to move on to inspecting the fuses on the electronic board. Once you are sure that the fuse has blown, you just need to replace it with a new one. If the new fuse immediately burns out, then you need to call a technician, as this means some kind of serious breakdown that is unlikely to be corrected on your own. A specialist should also be called if all the fuses are normal. This indicates that the problem is not with them.

Pay attention to the varistor. It is designed to protect the boiler from voltage surges. If there was some kind of difference, then the varistor will be blown up and only a small part of it will remain. Because of this, the boiler may also not turn on. The solution to this boiler malfunction is to simply re-solder the varistor.

gas boiler varistor

Heating devices

In systems with natural circulation, you can use only radiators, as well as thick pipes as radiators (they have less hydraulic resistance).

But, alas, you cannot use convectors - natural circulation simply will not flow through them.

To summarize the above, an open system is a thing of the past. Slow heating, high inertia of the system, a large amount of soluble air, bulky pipes, and low efficiency make it unattractive for modern heating systems. So it is used in extreme cases - for example, in areas where electricity is often cut off.

The most popular now are closed systems with forced circulation of coolant, two-pipe or collector-beam.

Let's analyze the situation when water boils in a heating boiler, and it turns off in emergency mode due to overheating of the coolant. Let's look at several types of boilers and the common causes of this problem in them.

The boiler also does not turn on, but that is not the problem

This may be due to a clogged filter under the boiler. You need to find it and close both filter taps, unscrew the nut and pull out the mesh from there, which you need to rinse with water and put back. When cleaning the filter, as when performing any other actions, be sure to turn off the boiler.

Coarse filter

The reason may also be the pump, which does not supply heat for two reasons:

- due to air accumulation;

- The rotor is jammed.

Useful video on the topic:

Doesn't turn off

If the electric boiler does not turn off when it overheats, the problem is in the thermostat. It does not open the contact, although it reaches critical temperatures.

You can check this like this:

- Unsolder it from the board.

- Heat with a soldering iron or over a gas stove.

- Now test with a multimeter.

If the contact is still there, it is broken and needs to be replaced. Often the problem occurs with boilers for heating private houses .

They are much more powerful than apartment ones and the thermostat breaks down faster.

Makes noises

There will always be a slight background sound - this indicates normal operation of the pump. It’s bad when the noise becomes unnatural, loud and occurs after several years of using the boiler.

This indicates limescale deposits inside the heat exchanger. Treatment: washing with special solutions. If you can already hear a crackling sound, then it is unlikely that you can save the heat exchanger - only replace it.

Another thing is a violation of the connection diagram of the electric boiler to the heating system . It is possible that water is not flowing from the expansion tank and the pump is running idle.

By the way, this is also one of the answers to the question: “ why does the boiler turn off for no reason?”

How to repair boiler fault codes?

Boiler overheating error

Gas boiler malfunction in the form of overheating can occur due to lack of circulation. In this case, you need to check the pump and filter. The overheating thermostat may also be broken.

Low system pressure

If the pressure does not rise when the boiler warms up, then the tightness of the system may simply be broken and you need to tighten the connections, and then add a little pressure. If this problem arose almost immediately after installing the boiler, then you just need to remove the air through an automatic air vent and add a little water.

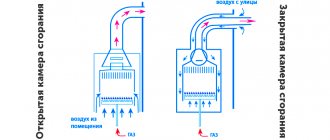

There is no draft of the gas boiler

If the boiler has an open combustion chamber, just check to see if it is clogged with anything. If the combustion chamber is closed, then condensate drips from the outer pipe, entering the inner one and freezing in the winter, turning into an icicle, blocking the access of air to the boiler. To eliminate this problem, you need to pour hot water over the resulting icicle. Another foreign object may also get into the chimney.

The boiler does not light a flame when ignited

This indicates a malfunction of the gas valve in the boiler. To verify this, you can unscrew the hose and see if gas is supplied. If there is gas, then you should call a specialist who will replace this valve.

The boiler lights up, but the flame goes out immediately

In this case, the panel may show a malfunction of the gas boiler in the form of a lack of ionization current. You need to check this by turning on the boiler again, turning the plug over, thereby changing the phases. If nothing has changed, then the operation of the ionization current may be disrupted due to some electrical work in the house. If the boiler periodically extinguishes the flame, then this is due to power surges and a stabilizer is needed.

The panel displays incorrect errors

Sometimes electronic board errors may occur. This happens due to poor electricity and poor quality power supply. This causes some parasitic charges to appear on the boards, which is why such errors are observed. To eliminate this, you need to disconnect the boiler from the network and let it stand for about 30 minutes. During this time, the capacitors will discharge and these unnecessary charges will disappear. After this, the boiler should work well.

In general, that's all. If the material was useful, do not forget to share it by clicking on the social media buttons below this text.

Also find out how to choose the right gas boiler so that there are no problems in the future:

First steps

Ariston boilers are reliable, and testing the equipment will take a lot of time. Considering that error 104 can be caused by a problem in the heating system, it is more logical to start looking for the cause there.

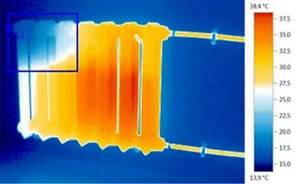

A drop in flow velocity is the result of a narrowing of the circulation channel. This is caused by sediment in the cavities of the devices, deposits on the walls or the accumulation of air bubbles in the coolant. Gas formation becomes more intense the longer the Ariston boiler operates at elevated modes - a common occurrence at low temperatures outside.

How to proceed. Walk around the house, check by touch the degree of heating of pipes and radiators: the problem area is colder. Depending on the characteristics of the circuit (circuit), it is easy to make a decision - bleed the air, service the device. It is necessary to check the filters mounted in the system. They can also trigger an Ariston boiler error with code 104.

Checking the air lock in the radiator with a thermal imager

Advice . Automatic valves installed on radiators require regular maintenance. If the heating line is made of steel pipes, water treatment is not carried out, and the liquid is of high hardness - more often than recommended by the manufacturer. A clogged channel, a defective spring are the probable causes of error 104, and the Ariston boiler has nothing to do with it.