Gas boilers are excellent for heating apartments, houses, cottages, industrial, administrative or commercial premises. When choosing a gas fuel boiler, it is important to decide on the type of combustion chamber.

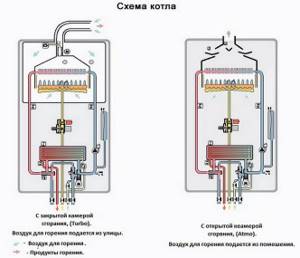

Fuel is burned in the combustion chamber. It can be open or closed. This design element of the heating unit affects smoke removal, noise level and room requirements for the boiler.

Gas boilers with an open combustion chamber

The design of these boilers is quite simple. The heat exchanger is located directly above the atmospheric burner.

Due to the simplicity of the design, boilers with an open combustion chamber:

- easy to maintain;

- more reliable;

- have a lower cost (compared to analogues with a closed chamber);

- lower gas consumption when operating at partial power compared to a closed chamber;

- produce less noise during operation.

A conventional vertical chimney is used to remove combustion products.

Gas fuel boilers with an open chamber take the air necessary for gas combustion directly from the room in which they are located. Therefore, they are very demanding on the quality of ventilation and require an equipped boiler room.

The disadvantages of boilers with an open chamber include:

- difficulties in designing a chimney (if mistakes are made, there may be problems with draft and smoke removal, including the possibility of reverse draft when gusts of wind on the street can blow out the flame in the boiler);

- atmospheric burners are subject to accelerated clogging and require more frequent cleaning;

- boilers with an open combustion chamber are inferior in efficiency to their analogues with a closed chamber, they have lower efficiency, and worse environmental performance.

The best boilers with an open combustion chamber in 2021

- Gas floor-standing boiler Protherm Bear 30 KLOM Ver.17 (26 kW)

- Gas floor-standing boiler Protherm Bear 40 KLOM Ver.17 (35 kW)

- Gas wall-mounted boiler Protherm Panther 25 KOV

- Gas wall-mounted boiler BAXI ECO-4S 24

- Gas wall-mounted boiler BAXI LUNA-3 240 i

- Gas wall-mounted boiler BAXI NUVOLA-3 Comfort 280 i with built-in 60 l boiler

- Gas floor-standing boiler Vaillant atmoVIT VK INT 484/1-5

- Gas wall-mounted boiler BAXI LUNA-3 Comfort 1.240 i

- Gas wall-mounted boiler Vaillant atmoTEC plus VU INT 280/5-5

- Gas wall-mounted boiler Vaillant ecoTEC pro VUW INT IV 346/5-3 H

Design features and operating principle

…

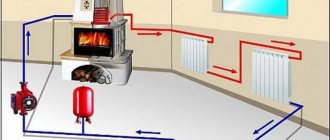

To understand that the failure is a single-circuit gas boiler with an open combustion chamber , you need to imagine an open flame source above which a heat exchanger is installed. The operating principle of this unit is simple: the thermal energy generated by burning gas heats the walls of the heat exchanger through which running water circulates. In other words, the simplest gas boiler is a flow-through heater designed to create and maintain the required temperature of the coolant circulating in the heating system.

The combustion chamber

The vast majority of domestic consumers usually find it difficult to determine what an open combustion chamber of a gas boiler means ? We will try to answer this question as clearly as possible.

As you know, oxygen is needed to maintain the combustion process.

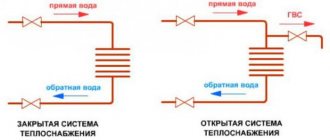

Air supply to the heat generator can be forced or natural. In installations with an open combustion chamber, draft is created in the chimney, and the air mixture is taken directly from the room in which the boiler unit is installed. All exhaust gases are discharged into the atmosphere through the chimney. You should know! Draft, without the use of blowing devices, appears due to the difference in the density of hot and cold air. Combustion products have a high temperature and, therefore, lower density than the surrounding air. Based on this, the pressure of the gas column in the chimney will also be less than in the room. The pressure difference creates draft: the air from the room pushes out lighter exhaust gases and itself participates in the process of fuel combustion.

Heat exchanger

A single-circuit gas boiler with an open combustion chamber is equipped with one heat exchanger, which can be made of:

…

- Of stainless steel. This material has good durability. The disadvantages are low thermal conductivity and high cost. Boilers with such a heat exchanger have a fairly low efficiency.

- Galvanized steel. The most inexpensive and short-lived type of coil.

- Copper. Good thermal conductivity at relatively low cost. Boilers with a copper heat exchanger have high efficiency, which makes them the most economical in terms of fuel consumption.

In double-circuit gas boilers with an open combustion chamber, two types of heat exchangers are used:

- Modular. Structurally, this heat exchanger consists of two modules: the primary one, made in the form of a finned coil, heats the coolant for the heating system; the secondary one, made in the form of a set of plates, is responsible for creating the domestic hot water supply at home.

You should know! Despite the fact that such a heat exchanger is considered one part, the modules are located in different places of the heat generator. The primary one is installed above the burner, the secondary one is installed at the bottom of the gas boiler.

- Bithermic. Structurally, this type of heat exchanger is designed like a pipe within a pipe. In the cavity, between the walls of the outer and inner tubes, a coolant circulates, which heats the water for hot water circulating through the inner tube of the coil.

Tip: heating running water is associated with the formation of scale. In a modular heat exchanger, a plate heat exchanger is responsible for the process of creating DHW, which, if necessary, can be easily replaced. If scale forms in the inner tube of a bithermic heat exchanger, the entire part will have to be replaced, which significantly increases the cost of repair work.

Atmospheric burner

Gas burners, which differ in the way they control the flame, are responsible for the process of heating the coolant in boiler equipment with an open combustion chamber.

- Single stage.

- Two-stage.

- Modulated.

The operation algorithm of burners of the first type is as follows: on - off. To set and maintain the required coolant temperature, the burner is ignited; Once reached, it turns off. Frequent switching on/off of the boiler unit creates conditions under which its resource is exhausted much faster.

In two-stage, there are two operating modes: 100 and 50% productivity. Power control is carried out through automation. Burners of this type are more economical and allow you to more accurately maintain the required coolant temperature.

In modulating burners, automation allows you to set productivity in the range from 10 to 100%. Today, this is the most economical and most expensive type of burner.

Heat generator performance

Correct determination of the required power is one of the key points in choosing a boiler installation. In order to correctly determine the power of a gas boiler, you need to calculate the heat loss through the building envelope, roof, floor, geographic location, etc.

Accurate calculations can be ordered from the design organization of your locality. You can take a simpler route. With an average degree of thermal insulation of a room with a ceiling height of 2.5 m, the following calculation algorithm is suitable: to heat 10 m2 you need 1 kW of heat generator power.

Gas boilers with a closed combustion chamber

Boilers with a closed chamber are more technologically advanced and complex, so their cost is often higher than that of boilers with an open chamber. Combustion of gas fuel occurs in an isolated closed chamber; air is pumped in and combustion products are removed using a fan (turbine). The gas combustion process is regulated automatically, which allows optimizing fuel consumption.

Air intake and smoke exhaust can be done either through a separate or through a coaxial chimney (side, through the wall). It is designed according to the “pipe-in-pipe” principle. This option is the safest to use. Air is not taken from the room, so boilers with a closed chamber can be installed in the kitchen or other suitable room.

Obvious advantages of boilers with a closed chamber:

- higher efficiency indicators (efficiency, environmental friendliness, safety) in comparison with atmospheric models;

- a coaxial chimney is easier to install than a classic one;

- stability of traction without the risk of being blown by the wind;

- there are no strict ventilation requirements;

- can be installed not only in the boiler room, but also in other suitable rooms.

The disadvantages include:

- higher cost (10-30% more expensive than atmospheric);

- energy dependence;

- higher gas consumption when operating at partial power compared to an open chamber;

- the risk of chimney icing, however, you can buy a special coaxial chimney with anti-icing protection;

- slightly increased noise level from the operation of the turbine (fan), but this is almost imperceptible.

The best boilers with a closed combustion chamber in 2021

- Vaillant turboFIT VUW 242/5-2, 24 kW

- Vaillant turboTEC pro VUW INT 242/5-3

- Vaillant ecoVIT VKK 286/4

- Protherm Cheetah 23 MTV

- Protherm Jaguar 24 JTV

- Protherm Lynx K 25 MKO

- BAXI ECO Nova 18 F

- BAXI ECO Nova 24 F

- BAXI LUNA-3 240 Fi

- BAXI SLIM 1.300 FiN 5E

Comparison

The main difference between an open chamber and a closed chamber in gas boilers is that the first element of the unit’s design operates due to natural draft and involves the removal of gas combustion products through a traditional chimney installed in a special room. Preferably located at a distance from living rooms.

The second type of chamber in gas boilers involves directing air from the atmosphere into the unit using a fan, and also provides for the removal of the resulting smoke. As a result, combustion products can be removed through a coaxial chimney. It has a less complex design, as a result of which the boiler of this type can be installed in residential premises.

Having determined what the difference is between an open and a closed chamber in gas boilers, we will reflect the conclusions in a small table.

Which combustion chamber to choose: open or closed? Which is better?

If you are buying a boiler to replace an old one, you already have a ready-made boiler room with good ventilation and a well-installed chimney - you can consider atmospheric models with an open combustion chamber. This will save you some money. An atmospheric boiler also helps to save money if the heating unit most often does not operate at full capacity. However, this is not very economical in general (the efficiency drops); it is wiser to choose a less powerful model.

If you need a boiler for a new house, or even more so for an apartment, then you should consider more modern models with a closed chamber. This option is also suitable if there is no classic vertical chimney and no opportunity to equip it. If there is no boiler room or room for its arrangement, the best choice would also be a boiler with a closed combustion chamber; it is easier to choose a suitable place for it.

Single-circuit and double-circuit boilers

Single-circuit models have one function - heating the house. The double-circuit model supplies the household with hot water in addition to heating. The main advantage of single-circuit boilers is their significantly lower price. You can purchase additional equipment to obtain hot water, but in this case the cost of additional equipment and the boiler, the complexity of installation, balances or even exceeds the cost of double-circuit boilers. Additional equipment is included in the harness and becomes part of it.

Single-circuit boiler:

Pros:

- Independence from water pressure;

- Constant supply of hot water;

- There are no restrictions on the amount of hot water consumed in all taps.

Double-circuit boiler

Pros:

- The cost of a double-circuit one is lower than a single-circuit one with a boiler;

- Takes up very little space, compact;

- There is no need to purchase additional equipment;

- Easy installation;

- Economical - only the amount of water required is heated.

Minuses:

- Inconsistency of hot water temperature. When the valve opens, the water begins to heat up. Since the water is running, heating occurs gradually from cold to hot. The water temperature is affected by the pressure in the water pipes. The lower it is, the colder the water flows from the tap;

- The water temperature immediately drops if several taps are open at the same time;

- The farther the tap is from the boiler, the longer you have to wait for the water to get hot. Consequently, flowing water is simply poured down the drain until it is heated to the desired temperature;

- The second circuit is turned on only when the water flow is significant. Otherwise, the second circuit may not turn on with a small stream. Because of this feature of dual-circuit modules, it is difficult to save water.

Devices with a storage tank of up to 60 liters or a layer-by-layer heating boiler do not have this disadvantage. They supply water at a constant temperature regardless of the pressure in the water supply.

Comparison of popular boilers with open and closed combustion chambers

Let's look at the differences between two types of boilers from the same series using the example of popular wall-mounted double-circuit gas models with a power of 23 kW (for a heated area of up to 230 m2): Protherm Gepard 23 MTV and Protherm Gepard 23 MOV.

| Protherm Cheetah 23 MTV | Protherm Cheetah 23 MOV | |

| The combustion chamber | closed | open |

| Efficiency | 93,20% | 90,30% |

| Max. gas consumption in heating mode (G20) | 2.9 m3/hour | 2.7 m3/hour |

| Boiler weight | 34 kg | 31 kg |

| Dimensions (H x W x D) | 740x410x310 mm | 740x410x310 mm |

| Price | 61640 rubles | 58698 rubles |

Price of floor-standing gas boilers

To create a high-quality heating system for premises for various purposes, floor-standing boilers are often used. The total price of each device depends on the power it produces, as well as on the additional capabilities of the device and the options purchased. Thus, a budget model can cost an average of 18-19 thousand rubles, and a programmable high-performance industrial boiler will cost several million. Our company organizes the delivery of gas boilers throughout Moscow and Russia, and will also help with installation, commissioning and regular maintenance.