Connecting an electric boiler and safety rules

Connecting an electric boiler to the electrical network must follow safety rules. Here are the basic recommendations that you need to follow when performing electrical work:

- The electric boiler must be connected when the power is turned off.

- Its installation must take place at a certain distance from other objects:

- Leave 5 cm of space between the wall and the boiler.

- The front panel must be accessible to open. 60 cm is enough for this.

- The distance from the ceiling should be 75 cm.

- If the device is of a suspended type, then at least 50 cm must be left from the floor.

- The distance to the nearest pipes should be about 60 cm.

- The electric boiler must be connected to a three-phase network. If a single-phase network is installed in your house, then it simply will not withstand the load. Subsequently, a short circuit may occur.

- Wire connections must be sealed. They must be reliably protected from moisture. Also, when laying wiring for an electric boiler, experts recommend using a corrugated pipe. It will provide reliable protection and easy access to the cable. Also, if the wiring catches fire, a corrugated pipe can prevent the spread of fire.

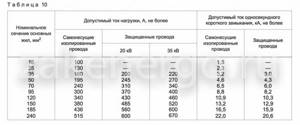

Wire cross-section for closed and open wiring

Another consideration is the type of electrical installation you plan to use. Open electrical wiring is mounted on surfaces or in pipes fixed on top. Hidden electrical wiring is laid in ceiling voids, in channels or grooves cut into walls, in insulating and steel pipes inside structural elements.

With closed wiring, the requirements for the cable cross-section are slightly higher than with open wiring, since without air access the cable heats up more under load.

Knowing the design current, the type of cable and wiring, you can proceed to calculating the cross-section of the wires. Two parameters are taken into account: permissible long-term current load and voltage loss in the wires connecting the consumer to the current source. The longer the wire, the greater the loss in throughput it incurs (then the cross-sectional diameter of the current-carrying conductor is increased).

For individual rooms or devices that do not require high power, the second indicator can be ignored (voltage losses will be too small).

ELECTRICAL WIRING FOR ELECTRIC BOILER

Now that the required power of the boiler for heating the house has been determined and a specific model has been selected, we make electrical wiring for it.

To do this, we will use the data from the article “Diagram for connecting an electric boiler to the electrical network,” which shows in detail all the main diagrams for connecting any electric boilers to electricity, and also provides recommendations for choosing the cable cross-section and circuit breaker.

Our boiler “ZOTA - 12” is three-phase, designed to operate in a network with a voltage of 380 V, this information is reflected in the documentation for the boiler, in addition, the power consumption indirectly indicates this; 220 V boilers are rarely more than 8 kW.

In addition, you can look at the number of installed heating elements (tubular electric heaters) and their connection diagram. 380 V boilers usually have at least three installed.

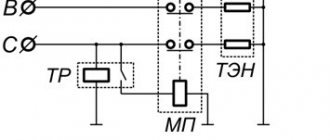

There are at least two possible schemes for connecting the boiler to a three-phase network. one is used when heating elements are designed for 220 V and connected in a “star”, and the other is used in cases where heating elements of an electric boiler are designed for a voltage of 380 V and connected in a “delta”.

There are several ways to determine which connection diagram is suitable for your boiler. The easiest way is to refer to the diagram in the documentation; for the ZOTA - 12 boiler it is located on the back of the control panel and looks like this:

As you can see, this boiler has a “Star” connection diagram, which means the heating elements are designed for a voltage of 220 V. This is also confirmed by direct inspection of the contacts for connecting wires to the heating elements; they are also prepared for star connection. Their contacts for connecting the neutral conductor are connected by a jumper; phases will be connected to the free contacts one by one, each with its own phase.

It follows that we are suitable for connecting a three-phase electric boiler to electricity with 220 V heating elements, a star connection.

All that remains is to select the required cable cross-section for the electric boiler in terms of power and the rating of the circuit breaker. To do this, look at the table from the article:

It follows that with a route length of up to 50 meters, we will need to install a three-phase electric boiler with a power of 12 kW. five-core cable VVGngLS with a core cross-section of 4 sq. mm. (VVGngLS 5×4 sq.mm.) and install a 25A differential circuit breaker. or a combination of an automatic circuit breaker (AB) designed for 25 amperes - C25 and a residual current device (RCD) for 32A.

Now, having selected an electric boiler and decided on the connection diagram and wiring parameters, you can install it, after which we will continue connecting to electricity.

Connecting the ZOTA electric boiler to the electrical network is described in the next part of the article - HERE!

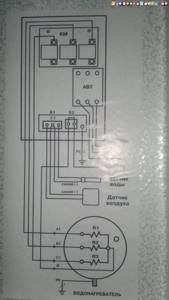

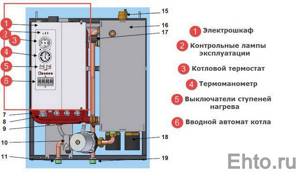

Electrical boiler cabinet

The electric heating boiler has its own built-in electrical cabinet. It is equipped with metering devices, an introductory boiler circuit breaker, connection blocks, control and mode switching devices.

Heating boiler electrical cabinet

The electrical cable for the boiler power supply is inserted into this electrical panel and connected to the boiler input circuit breaker.

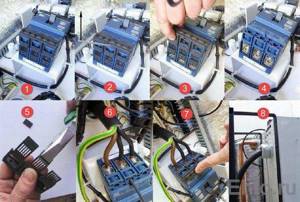

Steps to connect a heating boiler

Features of calculating boiler performance for apartments

Calculation of boiler power for heating apartments is calculated according to the same norm: 1 kW of heat per 10 square meters. But the correction is taking place according to other parameters. The first thing that needs to be taken into account is the presence or absence of an unheated room above and below.

- if there is another heated apartment below/above, a coefficient of 0.7 is applied;

- if the room below/at the top is unheated, we do not make any changes;

- heated basement/attic - coefficient 0.9.

When making calculations, it is also worth taking into account the number of walls facing the street. Corner apartments require more heat:

- if there is one external wall - 1.1;

- two walls face the street - 1.2;

- three external ones - 1.3.

You need to take into account the number of external walls

These are the main areas through which heat escapes. It is imperative to take them into account. You can also take into account the quality of the windows. If these are double-glazed windows, adjustments need not be made. If there are old wooden windows, the found figure must be multiplied by 1.2.

You can also take into account factors such as the location of the apartment. In the same way, you need to increase the power if you want to buy a double-circuit boiler (for heating hot water).

Calculation by volume

In the case of determining the power of a heating boiler for an apartment, you can use another method, which is based on SNiP standards. They stipulate standards for heating buildings:

- heating one cubic meter in a panel house requires 41 W of heat;

- to compensate for heat loss in a brick building - 34 W.

To use this method, you need to know the total volume of the premises. In principle, this approach is more correct, since it immediately takes into account the height of the ceilings. A slight difficulty may arise here: usually we know the area of our apartment. The volume will have to be calculated. To do this, we multiply the total heated area by the height of the ceilings. We get the required volume.

Heating boiler calculations for apartments can be done according to standards

An example of calculating the power of a boiler for heating an apartment. Let the apartment be on the third floor of a five-story brick building. Its total area is 87 sq. m, ceiling height 2.8 m.

- Finding the volume. 87 * 2.7 = 234.9 cu. m.

- Round up - 235 cubic meters. m.

- We calculate the required power: 235 cubic meters. m * 34 W = 7990 W or 7.99 kW.

- Round up, we get 8 kW.

- Since there are heated apartments at the top and bottom, we apply a coefficient of 0.7. 8 kW * 0.7 = 5.6 kW.

- Round up: 6 kW.

- The boiler will also heat water for domestic needs. We will give a reserve of 25% for this. 6 kW * 1.25 = 7.5 kW.

- The windows in the apartment have not been replaced; they are old, wooden. Therefore, we use a multiplying factor of 1.2: 7.5 kW * 1.2 = 9 kW.

- Two walls in the apartment are external, so once again we multiply the found figure by 1.2: 9 kW * 1.2 = 10.8 kW.

- Round up: 11 kW.

In general, here is this technique for you. In principle, it can also be used to calculate the power of a boiler for a brick house. For other types of building materials, standards are not prescribed, and a panel private house is a rarity.

Calculation of heating boiler power by area

For a rough estimate of the required performance of a heating unit, the area of the premises is sufficient. In the simplest version for central Russia, it is believed that 1 kW of power can heat 10 m 2 of area. If you have a house with an area of 160 m2, the boiler power for heating it is 16 kW.

These calculations are approximate, because neither ceiling height nor climate are taken into account. For this purpose, there are coefficients derived experimentally, with the help of which appropriate adjustments are made.

The specified norm is 1 kW per 10 m2, suitable for ceilings of 2.5-2.7 m. If you have higher ceilings in the room, you need to calculate the coefficients and recalculate. To do this, divide the height of your premises by the standard 2.7 m and obtain a correction factor.

Calculating the power of a heating boiler by area is the easiest way

For example, the ceiling height is 3.2 m. We calculate the coefficient: 3.2m/2.7m=1.18, round it up, we get 1.2. It turns out that to heat a room of 160 m 2 with a ceiling height of 3.2 m, a heating boiler with a capacity of 16 kW * 1.2 = 19.2 kW is required. They usually round up, so 20 kW.

To take into account climatic features, there are ready-made coefficients. For Russia they are:

- 1.5-2.0 for northern regions;

- 1.2-1.5 for Moscow region regions;

- 1.0-1.2 for the middle band;

- 0.7-0.9 for the southern regions.

If the house is located in the middle zone, just south of Moscow, a coefficient of 1.2 is used (20 kW * 1.2 = 24 kW), if in the south of Russia in the Krasnodar Territory, for example, the coefficient is 0.8, that is, less power is required (20 kW * 0 ,8=16kW).

Heating calculations and boiler selection are an important step. Find the power incorrectly and you can get the following result...

These are the main factors that need to be taken into account. But the values found are valid if the boiler operates only for heating. If you also need to heat water, you need to add 20-25% of the calculated figure. Then you need to add a “reserve” for peak winter temperatures. That's another 10%. In total we get:

- For heating a house and hot water in the middle zone 24 kW + 20% = 28.8 kW. Then the reserve for cold weather is 28.8 kW + 10% = 31.68 kW. We round up and get 32 kW. If we compare it with the original figure of 16 kW, the difference is twofold.

- House in Krasnodar region. We add power to heat hot water: 16 kW + 20% = 19.2 kW. Now the “reserve” for cold weather is 19.2+10%=21.12 kW. Round up: 22 kW. The difference is not so striking, but still quite significant.

From the examples it is clear that at least these values must be taken into account. But it is obvious that when calculating the boiler power for a house and an apartment, there should be a difference. You can go the same way and use coefficients for each factor. But there is an easier way that allows you to make corrections in one go.

When calculating a heating boiler for a home, a coefficient of 1.5 is used. It takes into account the presence of heat loss through the roof, floor, and foundation. Valid for an average (normal) degree of wall insulation - masonry with two bricks or building materials with similar characteristics.

For apartments, different coefficients apply. If there is a heated room on top (another apartment) the coefficient is 0.7, if there is a heated attic - 0.9, if there is an unheated attic - 1.0. You need to multiply the boiler power found using the method described above by one of these coefficients and get a fairly reliable value.

To demonstrate the progress of the calculations, we will calculate the power of a gas heating boiler for an apartment of 65 m2 with 3 m ceilings, which is located in central Russia.

- We determine the required power by area: 65m 2 /10m 2 = 6.5 kW.

- We make an adjustment for the region: 6.5 kW * 1.2 = 7.8 kW.

- The boiler will heat the water, so we add 25% (we like it hot) 7.8 kW * 1.25 = 9.75 kW.

- Add 10% for cold weather: 7.95 kW * 1.1 = 10.725 kW.

Now we round the result and get: 11KW.

This algorithm is valid for selecting heating boilers using any type of fuel. Calculating the power of an electric heating boiler will be no different from calculating a solid fuel, gas or liquid fuel boiler. The main thing is the productivity and efficiency of the boiler, and heat loss does not change depending on the type of boiler. The whole question is how to spend less energy. And this is the area of insulation.

how many kilowatts is this? 22 answers

15 kilowatts 3 phases how many amperes

In the Construction and Repair section, the question is 380 volts and 50 amperes: how many kilowatts is this? the best answer given by the author Yolava Filippov is Regardless of the delta or star connection, the total power for the three phases of the consumer is equal to: P = 3 * Uph * Iph The same for 1 phase P = Uph * Iph That is, in your case, P = 3 * 220 *50=33kW. BUT you need to look at the project. The maximum permitted power is indicated there. And in meters they usually write, for example, 10 (50) A. This means that the peak current is 50A. Here I have a meter of 10 (100) A, but the power according to the project is 6 kW.

Hello! Here is a selection of topics with answers to your question: 380 volts and 50 amperes: how many kilowatts is this?

Answer from Lech Bezfamilny To find out the power allocated to you, you need to know which input machine was installed for you to begin with.

Reply from *** That's right. Three phases are three wires of 220V each. Have you seen the voltage sine wave? When in one wire it decreases, in another it rises, in the third it is at a minimum. That. It is possible to have voltage at some level. More precisely, 220V * root of three = 380V. Power is current (A) multiplied by voltage (V). 380V * 50A = 19 kW. Approximately 6.3 kW per phase will be needed. Now about the wiring. In high-rise buildings they do exactly as you wrote - the phases are released along the risers of the apartments, and the zero is common to all. If you do the wiring, carefully calculate the load, do not load everything on one phase wire. And be sure to make a protective grounding (fifth wire). Details are set out in the PUE (Electrical Installation Rules)

Answer from Yoarkasm This is what they usually do. Between phases there is 380V, and between phase and zero - 220. It happens the other way around. But these are not Spanish. for household needs. A 50A and 380 V - This is 380 times 50 = this is 19 kilowatts. But the meter does not consume such power - it will simply be able to withstand a current of less than 50 amperes (but no more - it will burn out), and the power will be as much as you yourself demand from the network, if you demand more, you will damage the meter (but for this purpose they install automatic circuit breakers 3 x 15 A - (total current - 45 A - they will not allow a large current to flow through your meter. But I strongly doubt that to you have 3 phases installed. Only by risers. One apartment cannot have more than 1 phase.

Answer from Ilya Kalmykov Watt = Ampere * Volt, or Ampere = Watts / Volts, that is, 50 * 380 = 19,000 watts or 19,000/380 = 50!

Answer from 1: Don't mislead people. A 50 amp machine with three phases is 50 amps for each phase. This means 220V (single phase) * 50 A = 11000 W = 11 kW 11 kW * 3 phase = 33 kW

Answer from Yra M vayUmnogo you will know!

Hello! Here are more topics with the answers you need:

what is the required wire cross-section for 3 kW

What wire cross-section is needed for 3 kW

In the Other services section, to the question How to determine what the wire cross-section should be for a 3.5 kW water heater? asked by Kochegar2 the best answer is The cable usually consists of 2-4 cores. The cross-section (more precisely, the cross-sectional area) of the core is determined by its diameter. Based on practical considerations, at low current values, the cross-section of the copper conductor is taken to be at least 1 mm2, and for the aluminum conductor – 2 mm². At sufficiently high currents, the wire cross-section is selected according to the connected power.

Simply put, if you have a 3.5 kW instantaneous water heater, then you need to connect it with a wire rated at least 15.9 A, and for a copper wire the cross-section should be at least 2.5 mm².

The cross-section of aluminum wires should be one step higher, since their conductivity is approximately 62% of the conductivity of copper wires. For example, if according to calculations for copper a cross-sectional value of 2.5 m⊃m is required; 2, then for aluminum you should take 4 mmI, if for copper you need 4 mmI, then for aluminum - 6 mmI, etc.

In general, it is better to choose a larger cross-section than according to calculations - what if you need to connect something else? In addition, it is necessary to check whether the cross-section of the wires is consistent with the maximum actual load, as well as with the current of the protective fuses or circuit breaker, which are usually located next to the meter.

Come here

Reply from 22 replies Hello! Here is a selection of topics with answers to your question: How to determine what the wire cross-section should be for a 3.5 kW water heater? What rating should I install a 4-pole circuit breaker on a 380V socket? Tell me for a 5.5 kW welding inverter Which extension cord on the reel should I choose, with what cross-section? tags: Equipment What cable cross-section is needed for a 6 kW EVN. 380 V copper cable. We know the CROSS SECTION of the wire and VOLT, how to calculate how many WATT the wire will withstand? for example, cross section 0.75, 12 volts tags: Experienced Dedovsk

Reply from Koshak

take 6*3 you won't go wrong

Answer from Iuslan Globazh

take with a reserve of more than 20a

Reply from Ololosh

Well, consider the student, divide the power by the voltage, we get a current strength of 15.9 amperes at a voltage of 220 volts, and then 4mm * 2, I think that’s enough because suddenly there will be short-term interference

Reply from Bosston

for 4 kW we take the cross-section of the copper core 4 sq. mm, the rated current of the protection device is 31.5 Amperes.

And you can determine it from the table of rated protection currents and cross-section of supply wires

Reply from Alrisha

It’s very easy to determine :) - 3*2.5

By the way, don’t forget that the water heater must be plugged into a grounded outlet, i.e. into the outlet from the washing machine (if there is one :)), if not, then buy a 16-amp machine (see what it looks like next to the meter) and a waterproof outlet with grounding and call an electrician - he will connect everything.

Reply from 2 replies Hello! Here are more topics with the necessary answers: in the bathroom there is a boiler and a washing machine, a 2.5 mm copper wire, there is a 16A machine on the panel. Is it worth changing to 25A tags: Equipment Areas of Van Will VVG 4x16 withstand a load of 50 kW? or do you need to select a VVG 4x25 cable??? tags: Equipment Cable production Can any knowledgeable electricians tell you how cables are supplied to the meter in Khrushchev-era buildings?! tags: Khrushchev technology What is the current and voltage in ordinary Russian sockets? tags: Equipment

https://youtube.com/watch?v=0o9x-5mPCuY

Connection diagram of the electric boiler to the electrical network

An electric boiler installed in a heating system is often the most energy-intensive device in the entire house; moreover, its power consumption is often higher than that of all other electrical equipment in the premises combined.

And this is not surprising, because even the unspoken rule for choosing a boiler for a home states that 1 kW (kilowatt) of power is required to heat 10 square meters of a house. Following it, for heating a relatively small (by modern standards) house of 100 sq.m. you will need an electric boiler with a power of 10 kW.

Of course, this is a general rule; in real conditions, when choosing the power of a boiler, many factors are taken into account, but in general, the rule reflects the approximate, average requirements for the boiler correctly.

Therefore, for such a “gluttonous” consumer of electricity as an electric boiler, on whose stable operation in winter a lot depends, it is important to make the correct electrical wiring, select reliable automatic protection and make the connection correctly. To better understand the principle of connecting a boiler, you need to know what it usually consists of and how it works

We will talk about the most common heating element boilers, the heart of which is Tubular Electric Heaters (TEH)

To better understand the principle of connecting a boiler, you need to know what it usually consists of and how it works. We will talk about the most common heating element boilers, the heart of which is Tubular Electric Heaters (TEH).

An electric current passing through the heating element heats it up; this process is controlled by an electronic unit that monitors important indicators of the boiler’s operation using various sensors. The electric boiler may also include a circulation pump, control panel, etc.

Depending on the power consumption, electric boilers designed for a supply voltage of 220 V - single-phase or 380 V - three-phase are usually used in everyday life.

The difference between them is simple; 220V boilers are rarely more powerful than 8 kW. Most often, heating systems use devices of no more than 2-5 kW, this is due to limitations on the allocated power in single-phase supply lines of houses.

Accordingly, 380V electric boilers are more powerful and can effectively heat large houses. Connection diagrams, rules for choosing cables and automatic protective equipment for 220V and 380V boilers are different, so we will consider them separately, starting with single-phase ones.

Which cable to connect a 6 and 9 kW electric boiler

Content

According to PUE-7, the permissible load on a standard outlet should not exceed 3 kW.

That is, an electric boiler with a power of 3 kW seems to be able to be connected via an outlet. However, it is strictly not recommended to do this, since the electric boiler must have its own cable, and always through a separate circuit breaker. Many people also argue about whether it is possible to connect electric boilers with an aluminum cable. In fact, it is possible, although it is recommended, to connect electrical equipment with a power of 1.5 kW or more through copper conductors. In any case, it won't get any worse.

Advantages and scope of products

Electric boilers are often used to heat the premises of a summer house or private home. This was due to many factors. The main factor is that they have a low price and the installation process does not take much time.

Connecting the boiler to the electrical network also has a number of advantages. The main ones include:

- Completely safe design. The design does not provide for an open flame and that is why it is the safest.

- The operation of the electric boiler will not be affected, even if its water heaters are turned off for about a year.

- It has small design dimensions. That is why it can be mounted almost anywhere.

- Today you can find a huge number of varieties of the system. They can differ significantly in their power and type of device.

- When heating water, soot will not appear, which can harm humans.

Cable marking

Cables are marked with letters and numbers. The letters indicate the aluminum core—core insulation material—cable sheath—cable property

- VVG – cable in vinyl insulation, vinyl sheath with flexible copper conductors;

- AVVGA - the same thing, only with aluminum conductors.

- VVGng is a copper cable with the “flame retardant” characteristic.

- NUM is an excellent imported cable with triple insulation. Very hard, making installation difficult.

- PVA cable (connecting wire) with stranded cores is best not used in stationary electrical installations.

I recommend using the VVGng cable to power the electric boiler.

CHOOSING AN ELECTRIC BOILER FOR YOUR HOME

To choose the right electric boiler for heating your home, you need to consider many factors. including the material and thickness of the walls, glazing area, outdoor air temperature in winter in your region, ceiling height and many others.

Often, such calculations are entrusted to specialists who make a home heating project that takes into account all the necessary characteristics of the system, including the type and power of the electric boiler; often they even offer a specific model or several to choose from.

When independently choosing the required power of an electric boiler for heating, it is usually customary to use the following formula: 1 kW of power is required to heat 10 sq.m. Houses.

The rule is relevant for single-circuit boilers used only for heating rooms, but if there are two circuits, one of which is used to heat water in the hot water supply system, the calculation must be changed, the same should be done if the ceiling height is higher than the standard 2.5-2.7 m and in some other cases.

So, in our example, the area of the house is 120 sq.m. Therefore, an electric boiler with a power of 12 kW was chosen. model ZOTA - 12 series "Econom".

After all the theoretical calculations, we will determine whether this boiler is suitable for the permitted (allocated) power for the house. For us it is 15 kW, with a three-phase input, so a 12 kW boiler is suitable for us in terms of power.

Of course, if the electric boiler operates at its maximum capabilities, only 3 kW of the permitted amount will remain for the remaining consumers of the house, which is quite small. But since the boiler will be a backup one and will only turn on when the main gas boiler is faulty, this decision was made acceptable.

No wires, just cables?

The first question, which usually remains “behind the scenes,” is why you need to use a cable and not separate wires to connect an electric boiler?

In the theory of electrical installations and regulations, there are no prohibitions on using wires selected according to the cross-section and protected according to all rules to power electrical installations.

Another thing is that doing electrical wiring with wires is more difficult, or rather more inconvenient, than with a cable. Wires cannot be laid without protection. To lay them, it is imperative to use metal or electrical plastic pipes. Tightening wires into pipes requires some skills and special tools.

Unlike wires, cable lines can be laid: PUE 2.3.33: openly, in boxes or pipes, including pipes laid in floors and ceilings, ... and double floors.

On the other hand, my house is not an industrial production and for the fire safety of a wooden house, I would protect the cable with a metal pipe, especially if the boiler has a high power.

Electric boilers electric boilers

Let's start with the fact that there are several serious reasons limiting the spread of electric boilers:

- not all areas have the opportunity to allocate the electrical power required for heating a house (remember that for a house with an area of 200 sq. m. this is approximately 20 kW),

- relatively high cost of electricity,

- power outages.

On the other hand, if the problems described above do not exist in your case, then an electric boiler may well be an ideal option for heating. This type of boiler really has a lot of advantages. Among them:

- relatively low price of an electric boiler,

- ease of installation of the electric boiler,

- lightweight and compact, they can be hung on the wall, which saves space,

- safety (no open flame),

- electric boilers are easy to use,

- electric boilers do not require a separate room (boiler room),

- do not require installation of a chimney,

- do not require special care,

- electric boilers are silent,

- electric boilers are environmentally friendly, there are no harmful emissions or foreign odors.

In addition, in cases where power outages are possible, an electric boiler is often used in conjunction with a backup solid fuel boiler. The same option is also used to save energy (first the house is heated using cheap solid fuel, and then the temperature is automatically maintained using an electric boiler).

It is worth noting that when installed in large cities with strict environmental regulations and coordination problems, electric boilers also often outperform all other types of boilers (including gas boilers).

Briefly about the design and configuration of electric boilers. An electric boiler is a fairly simple device. The main elements of an electric boiler are a heat exchanger, consisting of a tank with electric heaters (heating elements) mounted in it, and a control and regulation unit. Electric boilers from some companies are supplied already equipped with a circulation pump, programmer, expansion tank, safety valve and filter.

It is important to note that low-power electric boilers come in two different versions - single-phase (220 V) and three-phase (380 V). Electric boilers with a power of more than 12 kW are usually produced only three-phase

The vast majority of electric boilers with a power of more than 6 kW are produced in multi-stage versions, which allows rational use of electricity and not turning on the boiler at full power during transition periods - in spring and autumn.

When using electric boilers, rational use of energy is most important. Significant energy savings can be achieved by installing remote programmers that maintain the room temperature according to a schedule you preset. It is worth keeping in mind that the cost of such programmers is not at all high and usually ranges from 50 to 150 euros. In addition to saving energy, programmers significantly increase the comfort and ease of use of heating equipment.

If you decide to purchase an electric boiler, then the following tables will be useful to you with approximate values of the cable cross-section for the electrical connection of the boiler (Table No. 1) and the current values of the safety circuit breakers depending on the power of the boiler (Table No. 2)

Table No. 1 Approximate values of cable cross-section for connecting an electric boiler

| Boiler power | Cable cross-section for single-phase electric boilers | Cable cross-section for three-phase electric boilers |

| up to 4 kW | 4.0 mm2 | |

| up to 6 kW | 6.0 mm2 | |

| up to 10 kW | 10.0 mm2 | |

| up to 12 kW | 16.0 mm2 | 2.5 mm2 |

| up to 16 kW | 4.0 mm2 | |

| up to 22 kW | 6.0 mm2 | |

| up to 27 kW | 10 mm2 | |

| up to 30 kW | 16 mm2 | |

| Up to 45 kW | 25 mm2 | |

| Up to 60 kW | 35 mm2 |

Table No. 2 Current values of safety circuit breakers depending on the power of the electric boiler

| Boiler power | For single-phase electric boilers | For three-phase electric boilers |

| 4 kW | 25 A | 10 A |

| 6 kW | 32 A | 16 A |

| 8 kW | 40 A | 16 A |

| 10 kW | 50 A | 20 A |

| 12 kW | 63 A | 25 A |

| 14 kW | 25 A | |

| 16 kW | 32 A | |

| 18 kW | 32 A | |

| 22 kW | 40 A | |

| 27 kW | 50 A | |

| 30 kW | 63 A | |

| 45 kW | 80 A | |

| 52 kW | 100 A |

Among the most notable brands of electric boilers on the Russian market are: RusNIT and EVAN (Russia), ACV (Belgium), Bosch (Germany), Dakon (Czech Republic), Eleko (Slovakia), Kospel (Poland), Protherm (Slovakia), Roca ( Spain), Wattek (Czech Republic), Wespe Heizung (Germany).

| Manufacturers of gas boilers | MILeev Leonid [email protected] tel.: 8-926-22-760-99 |

Cable for an electric boiler - which one is better?

When choosing the type of power cable to connect an electric boiler, first of all, attention should be paid to the conditions for its installation, which depend on the installation location of the boiler itself.

Typically, the boiler room is located in one of the rooms of a residential building; in this case, you can choose any installation cable designed for installing internal wiring. As for the material of current-carrying conductors, it is better to give preference to copper. This is a general rule - the advantages of copper over aluminum are obvious. The boiler is powered by a separate line from the main distribution board. To do this, you can use the most common brands of installation cables VVG or NYM. Both types of cables have double polyvinyl chloride insulation; the insulation cover is colored to mark the cores. The wiring can be open or hidden; it is important to comply with the requirements of the PUE.

To understand the nuances of the difference between NYM and VVGng, we recommend reading our article “NYM or VVGng - what is the difference?”

Much less often, an electric boiler room is placed in a separate building. In this case, the cable for powering the boiler must be connected to this room. In this case, the boiler is not connected directly; a distribution board must be installed in the boiler room, since in addition to the boiler there must be at least lighting there.

Direct connection of the electric boiler from the switchboard inside the boiler room can also be done using a VVG or NYM cable. As for the cable connecting the main distribution board and the boiler room, its type is also determined by the installation method. For overhead installation, it is best to use a self-supporting insulated wire, although the minimum cross-section of the SIP is 16 mm2, which corresponds to the power of a three-phase boiler of about 25 kW. An aerial laying of the VVG or NYM cable with fastening to a supporting cable can also be used, but in this case additional protection must be provided using a corrugated hose made of metal or UV-resistant plastic.

To increase fire safety in the case of group installation, it is better to use a cable with the index “ng”. A cable without special indexes is also suitable for single installation.

Do you want to understand the nuances of fire-resistant and non-flammable cables? Read the blog section Fire-resistant cables"

The required number of cable cores depends on the type of boiler, which can be single-phase or three-phase. In addition to the phase wires and the working neutral wire, the cable must have a core connected to the protective zero. Thus, a single-phase boiler is connected with a 3-wire cable (L, N, PE), and a three-phase boiler with a 5-wire cable (L1, L2, L3, N, PE).

How many kilowatts will SIP withstand?

While browsing the internet for electrical installations, I found a thread on one forum discussing “whether a 4x16 sip can withstand 15 kW.” The question arises because 15 kW 380 volts are allocated for connecting a private house. Well, people are wondering if it’s not enough to lay 16 square meters on a branch from the overhead line? I first looked into the PUE, but for some reason I didn’t find anything there on the topic of SIP power.

There is only plate 1.3.29 “Permissible long-term current for non-insulated wires according to GOST 839-80.” And it shows that the maximum permissible current for the cross section is 16 kV. mm. wire type AC, ASKS, ASK outdoors is 111 amperes. Well, at least something to start with.

How many kilowatts can a 4x16 SIP withstand?

But there is GOST 31943-2012 “Self-supporting insulated and protected wires for overhead power lines.” At the end of the standard, in paragraph 10 of the operating instructions, there is a sign

How many kilowatts can SIP withstand - table:

| SIP 4x16 | 62 kW | 22 kW |

| SIP 4x25 | 80 kW | 29 kW |

| SIP 4x35 | 99 kW | 35 kW |

| SIP 4x50 | 121 kW | 43 kW |

| SIP 4x70 | 149 kW | 53 kW |

| SIP 4x95 | 186 kW | 66 kW |

| SIP 4x120 | 211 kW | 75 kW |

| SIP 4x150 | 236 kW | 84 kW |

| SIP 4x185 | 270 kW | 96 kW |

| SIP 4x240 | 320 kW | 113 kW |

Calculation method (update from 02/19/2018)

We take plate 10 and from it we find that one core is 16 sq. mm. withstands - 100 amperes. Next, we take the following calculation formulas:

for single-phase load 220V P=U*I

for three-phase load 380V P=(I1+I2+I3)\3*cos φ*1.732*0.38

update from 02/19/2018 Regarding the calculation of power for a three-phase load, you need to understand that a lot depends on the type of consumers (more precisely, what kind of load they provide active or reactive, it depends on what cos φ should be substituted into the formula, in this case for calculations it is equal to 0.95 )

Dear visitors to the site, I might not have noticed your caustic but technically correct comments on the article if just today a person called me with the question: “what kind of sip do I need for 120 kW?” According to the sign, a SIP with a cross section of 50 mm square would be perfect for him. Even if we omit the fact that the length of the line affects the voltage drop (it has 150 meters), we should not forget that the load on the phases can vary, as can be seen from the formula - it takes the average value for three phases. Here you just need to understand that the phase current can exceed the maximum permissible values for a given wire cross-section.

Therefore, if the value of the load you need is closer than 10% to the table, you should choose a larger section of the vulture from the list. Let me explain with the example of 120 kW. According to the table, for this three-phase load, a SIP with a conductor cross-section of 50 mm is suitable, but this is less than 10%. That is, 121 kW * 0.9 = 109 kW. Accordingly, you need to choose SIP 3x70+1x54.6.

At the beginning of the topic, the question was raised: “will a 4x16 15kW sip handle it?” Therefore, for a private house we multiply 220Vx100A = 22 kW per phase. But don’t forget that we have three phases. And this is already 66 kilowatts in total for a residential building. Which is a 4-fold margin relative to the issued technical conditions.

General points

In order for the house to be warm, the heating system must replenish all existing heat losses in full. Heat escapes through walls, windows, floors, and roofs. That is, when calculating the boiler power, it is necessary to take into account the degree of insulation of all these parts of the apartment or house. With a serious approach, they order a calculation of the building’s heat loss from specialists, and based on the results, they select the boiler and all other parameters of the heating system. This task is not to say that it is very difficult, but it is necessary to take into account what the walls, floor, ceiling are made of, their thickness and the degree of insulation. They also take into account the cost of windows and doors, whether there is a supply ventilation system and what its performance is. In general, a long process.

There is a second way to determine heat loss. You can actually determine the amount of heat that a house/room loses using a thermal imager. This is a small device that displays the actual picture of heat loss on the screen. At the same time, you can see where the outflow of heat is greater and take measures to eliminate leaks.

Determining actual heat loss - an easier way

Now let’s talk about whether it’s worth taking a boiler with a power reserve. In general, constant operation of equipment at the limit of its capabilities negatively affects its service life. Therefore, it is advisable to have a performance reserve. Small, about 15-20% of the calculated value. It is quite enough to ensure that the equipment does not work at the limit of its capabilities.

Too much stock is not economically profitable: the more powerful the equipment, the more expensive it is. Moreover, the price difference is significant. So, if you are not considering the possibility of increasing the heated area, you should not take a boiler with a large power reserve.

Installation of the unit

To begin, you will need to install your electric boiler indoors. This process is the simplest. The unit can be installed both on the floor and on the wall. If it is installed on the floor, then you will definitely need to make a special stand.

If the electric boiler will be installed on the wall, then you will need special anchors. First you need to make markings on the wall. Remember that your holes must be placed evenly on the wall. Next you need to drill holes and insert anchors. Once the anchor is firmly placed in the wall, you can hang the boiler.