Network and make-up pumps for a boiler room - purpose, design

For work in boiler rooms, network pumps for the boiler room are often used. Such products perform the function of pumping hot water in a heating network system. The temperature of the network water, which such a pump for a boiler room can drive through pipes, reaches +180 degrees. At the same time, the device and design of network pumps are relatively simple, and at the same time, the devices show a high level of performance along with reliability.

Features of connecting pumping equipment

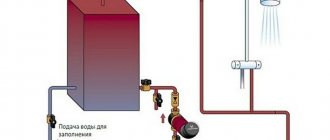

If a forced circulation system is used to service the house, then when the electrical power is turned off, the boiler pump must continue to operate, receiving energy from a backup source. In this regard, it is best to equip the heating system with a UPS, which will maintain the operation of the structure for several more hours. External batteries connected to it will help extend the life of the backup source.

When connecting the pump, you must avoid the possibility of condensation and moisture getting into the terminals. If the coolant heats up to more than 90 °C, then a heat-resistant cable is used for connection. You will also need to avoid contact of the pipe walls and power cable with the motor and pump housing. The power cable is connected to the terminal box on the right or left side by changing the location of the plug. In the case of a side-mounted terminal box, the cable must be routed only from the bottom. A prerequisite is that grounding must be connected to the pump.

Mains pumps are often used in boiler rooms. Such products perform the function of pumping hot water in a heating network system. The temperature of the network water, which the installed unit is capable of driving through the pipes, reaches +180 degrees.

At the same time, the device and design of network pumps are relatively simple, and at the same time, the devices show a high level of performance along with reliability.

Scope and characteristics

Characteristic features of network pumping devices are ease of installation and low maintenance. Materials such as high-quality steel and gray cast iron, from which such equipment is made, help to increase the safety margin and durability of the pump. The technical characteristics of network pumps allow them to work with predominantly clean water, which should not contain solid parts with a diameter greater than 0.2 mm, as well as more than 5 mg/l of mechanical impurities.

Most often, network pumping devices are used to create water circulation in heating networks, as well as to service a boiler (heating) network installation. Such units are manufactured both with one gear and in a 2-stage version. The drive operates using electric power units (motors). They look like horizontal pumps.

The units also include in their device:

- housing with horizontal connector;

- impeller with double-sided water inlet;

- bearings, shaft and end sealing elements;

- chambers for end seals and flanges for mounting bearings installed in the housing;

- rolling bearings that support the rotor;

- roller or ball support bearing for drive;

- bearing for the radial axis.

The average water supply of devices for boiler houses is 450-500 cubic meters per hour, the pressure is around 50-70 m, and such a parameter as inlet pressure varies within 16 kilograms per square centimeter. Pumps whose purpose is to circulate hot water in small heating systems have lower power and performance indicators, but they also cost an order of magnitude cheaper.

The scope of application of network products is not limited only to heating systems, in particular boiler rooms. This equipment is successfully used for supplying fuels and lubricants to bases, warehouses and industrial enterprises, for pumping reagents into water treatment plants, as well as in water treatment systems designed for pumping water into water supply systems when the pressure level in pipes drops. At the same time, such equipment is also used for cleaning tanks contaminated with sludge, as well as storage facilities for substances such as fuel oil.

Why do you need a circulation pump?

Heating systems with natural circulation of coolant have been popular for quite a long time, but today they can still be found in individual houses - there is no booster pump for heating. In such a system, the coolant moves thanks to the elementary laws of physics. The circulation is based on different densities and masses of hot and cold coolant. In addition, the slight slope of the system pipes also facilitates movement.

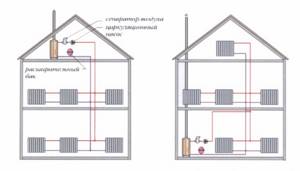

Heating system with circulation pump

However, even small errors made during installation of the system can lead to the fact that the quality of space heating will be significantly lower. To prevent this from happening, the system is supplemented with a circulation pump. An electric pump for heating a house easily eliminates all the disadvantages of a system with natural coolant circulation. Namely:

- the system does not require a pipe slope, which is considered necessary when the coolant moves spontaneously;

- there are no strict rules for the cross-section of pipes - they can have a smaller diameter;

- Due to the temperature difference, plugs are not created in the system that impede the circulation of the coolant;

- heating of the room occurs more evenly, since the coolant moves through the pipes at a certain, always the same speed;

- the temperature difference at the inlet and outlet is minimal - flow-through heating pumps allow you to save some amount of fuel.

Stable temperature of the coolant in the system allows you to save not only fuel, but also significantly extends the performance of the heating boiler. Indeed, under such conditions, the pump for boosting the heating system always operates with a certain power - there are no conditions for the element to overheat.

In particular, such a system allows the use of temperature controllers. Located on each radiator, they allow you to adjust the level of its heating. Thus, you yourself can choose which temperature will be most comfortable for you. In addition, the use of such regulators somewhat reduces the level of water heating, which leads to fuel savings.

In addition, the circulation booster pump for heating allows, due to the active movement of the coolant, to maintain a stable and comfortable temperature in the rooms even if the operation of the boiler is temporarily stopped. An additional advantage of a system with a circulation pump is that it can use less coolant than in a system with natural circulation.

In addition, certain pump models are made in such a way that even during the non-heating season, the pump to feed the heating system is turned on once a day in order to drive the coolant through the pipes. This helps maintain the normal operation of the system. However, you may need an additional pump in the heating system. In particular, this could be a pump for filling the heating system - a special device that is required to fill water. Air heat pumps for heating constitute a separate category of heating systems used in modern times.

What boiler room pumps are used?

Network pumps for a boiler room are most often centrifugal, equipped with an electric motor. By type they can be divided into: condensate, network, make-up, intended for raw water. You can also find this type of pump as a nutrient pump.

In water supply boiler systems, it is customary to install several devices at once that have the same characteristics. The pumps are connected in parallel, with one of them being the main one, and the second being a backup and starting as needed when the first one fails. However, it is also possible to operate two devices at once. In this case, the water pressure in the pipes remains the same as when operating one installation, but the water supply increases, the level of which becomes equal to the sum of the supply of each of the devices.

For boiler houses, the best option would be to install a centrifugal 1-stage pump type KM, a 1-stage unit type D with 2-way suction, or a multi-stage product type TsNSG. In addition, many professionals recommend installing condensate type KS units in the boiler room. In this case, the final choice depends on the specific requirements of the buyer, which, as a rule, are determined by the operating conditions of the future equipment.

Selecting a device and calculating the required pressure

Pumps for a boiler room are selected strictly based on the requirements of the heating system, or more precisely, on the required pressure. To understand what pressure is needed for optimal operation of your system, you can refer to the formula created for this purpose.

Calculation of the pressure level that is necessary for the proper functioning of the heating system can be calculated using the following formula: H=(Lsum*Rsp+r)/(Pt*g).

The formula at first glance does not look the simplest, but when studying each value, calculating the required pressure is not difficult. The symbols in the formula by which you can calculate the required pressure mean:

- H – the required pressure value in meters of water column;

- Ltotal is the total length of the circuits, taking into account the return and supply pipes. If you use a heated floor, you need to take into account the length of the pipes laid under the floor in the calculation;

- Rsp is the specific resistance level of the system pipes. Taking into account the reserve, take 150 Pa per 1 linear meter;

- r is the total resistance value of the system pipeline;

- Pt – specific density of the coolant;

- G is a constant that is equal to 9.8 meters per square centimeter, or the unit of acceleration due to gravity.

It is often difficult to calculate the total resistance of system elements. However, in this case, you can simplify the general formula by replacing the coefficient k, which is a correction factor, instead of this sum. Thus, the correction factor of a system in which any thermostats are installed will be equal to 1.7.

For a conventional system with standard fittings and taps that do not have elements for thermostatic regulation, the correction factor is 1.3. A system that has many branches and highly saturated shut-off and control valves has this coefficient at 2.2. The calculation using the final formula, in the case of a correction factor, will have the following form: H=(Lsum*Rud*k)/(Pt*g).

By calculating using this formula, you will be able to understand what parameters and characteristics the pump you need to purchase has. We emphasize that it is recommended to choose a pump for boiler rooms whose power will not exceed that necessary to create the required pressure. If you buy a pump with more power than is needed to provide the desired pressure, you will simply be wasting your money.

Installation of a boiler room in a private house (video)

Source

Purpose of the circulation pump

Open heating systems with a natural type of fluid circulation have been used for many years, even now they can be seen in some homes. They function due to the influence of physical laws. In addition, the pipes in such systems are installed with a certain slope. Those consumers who are just considering options do not always know whether a circulation pump is needed for this type of heating.

It is worth noting that in case of proper installation, an open heating system with natural ventilation is quite functional and efficient. However, minor flaws during the assembly process can affect its productivity. The circulation pump allows you to compensate for all shortcomings and provide the house with heat when needed.

Using a circulation pump, you can bypass such important heating conditions with natural ventilation as:

- the presence of a mandatory pipe slope when using a pump for steam heating becomes irrelevant - the equipment will cope with pumping the coolant;

- the cross-section of the pipes may be slightly smaller than necessary for spontaneous circulation;

- coolant circulation is not blocked by plugs formed due to differences in water temperature;

- due to always the same speed of water circulation, the system warms up much faster and more evenly;

- Due to the slight difference in water temperature, some fuel savings are achieved in the circuit.

It is worth noting that maintaining a stable water temperature in the heating circuit not only implies fuel savings, but also allows you to operate the boiler in a gentle mode, thereby extending its service life. The heat exchanger does not overheat, since the liquid always moves at the same speed.

Thus, those heating systems that have a circulation pump use fuel more efficiently and economically.

Types of pumps for boiler rooms and how to choose them

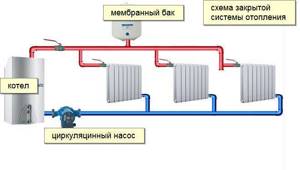

Large heating systems cannot exist without pipeline systems: air, water, condensate, fuel oil pipelines. Sometimes they have long sections with high hydraulic resistance, which various pumps help overcome.

In a boiler room of medium power, up to two dozen similar units of different functionality, designs and dimensions are installed. The network pump for the boiler room has the largest dimensions and performance.

It is installed in the boiler room and serves to pump the main coolant from 1 t/h for small heating areas to several thousand t/h for large cities.

The Wilo network pump for the boiler room takes water from the return network pipeline, drives it through the network heating unit (boiler room), where several water-water or steam-water network water heaters are compactly located, in which the heating circuit coolant is heated according to a schedule depending on the outside air temperature. The heating medium is steam or hot water at the outlet of the boiler.

To overcome all resistance, the German unit must provide a pressure drop of up to 3 atm. Incorrectly selected or installed equipment, as well as violations of the operating requirements of heating networks, will cause a failure of the operating mode or an emergency stop of the equipment of the thermal energy production system.

Types of pumps in a boiler room (5 photos)

Details Section: Heat supply Category: Boiler installations Created 03/04/2015 19:28 Pumps are devices for pressure movement of mainly liquids and imparting energy to them.

Network pump for heating and ventilation systems. This pump serves to circulate water in the heating network. It is selected according to the flow of network water based on the thermal scheme. Network pumps are installed on the return line of the heating network, where the temperature of the network water does not exceed 70 °C.

Recirculation (boiler, anti-condensation, anti-condensation) pumps are installed in boiler rooms with hot water boilers to partially supply hot network water to the pipeline supplying water to the hot water boiler.

In accordance with SNiP I-35-76 (clause 9.23), the installation of recirculation pumps is carried out if the manufacturers of hot water boilers require a constant water temperature at the inlet or outlet of the boiler. As a rule, it is necessary to provide common recirculation pumps for all hot water boilers. The number of pumps must be at least two. The performance of the recirculation pump is determined from the balance equation of the mixing flows of network water in the return line and hot water at the outlet of the hot water boiler. Regulation of the temperature of the water entering the hot water boiler and the temperature of the water supplied to consumers is carried out as follows. The amount of water supplied by the recirculation pump is adjusted to obtain the required water temperature at the inlet to the hot water boiler. However, the temperature of the water leaving the boiler may be higher than the temperature required by consumers. To maintain the set temperature of water supplied to consumers, part of the water from the return line is directed through a jumper into the forward line. The amount of water taken from the return line into the forward line is regulated by the network water temperature regulator.

Make-up pump. Designed to replenish water leaks from the heating system, the amount of water required to cover the leaks is determined in the calculation of the thermal circuit. The capacity of the make-up pumps is selected equal to twice the amount of water received to replenish possible emergency make-up.

The required pressure of the make-up pumps is determined by the water pressure in the return line and the resistance of the pipelines and fittings in the make-up line; the number of make-up pumps must be at least 2, one of which is a reserve one.

DHW circulation pump. Serves to supply the required flow rate and provide the required hot water pressure to the consumer. It is selected based on hot water consumption and required pressure.

Raw water pump. Serves to ensure the required pressure of raw water before the chemical treatment plant and the supply of chemicals. purified water into the deaerator, as well as supplying raw water to the hot water tank.

Random materials:

- Rotary disc shutter (4 photos) - 03/11/2015 20:18 - Read 2847 times

- Boilers burning wood, chips and wood waste (6 photos) - 05/14/2015 19:41 - Read 4318 times

- Safety relief valve (2 photos) - 03/11/2017 03:16 - Read 3639 times

- Membrane pressure meter showing NMP-52 (3 photos) - 05/28/2015 11:01 - Read 4300 times

- Chimneys of a boiler room on a supporting structure (6 photos) - 02/24/2015 13:11 - Read 6050 times

- < Back

- Forward >

Boiler pump types

Network units are among the largest pumping equipment in a boiler room, although they are not the only pumping mechanisms.

There are the following types of pumps used in boiler installations:

- nutrient steam and water;

- make-up;

- raw water;

- network circulation pumps;

- liquid fuel recycling;

- fuel oil;

- condensate

All units are carefully pre-calculated and selected in the relevant sections of the boiler installation project. This is due to particularly high requirements for the reliability of the equipment used to ensure the production of thermal energy.

The main purpose of all pumps is to circulate and supply the medium to the distribution point. At the same time, they must work continuously for a long time.

How are pumps controlled?

In modern boiler houses, pump control is one of the functions of complex automation. However, this does not exclude the possibility of manual control performed by operating personnel in emergency situations.

In all directions of process fluid movement, there is backup equipment; the same requirement is imposed for the availability of backup power supply.

For large thermal circuits, this must be an independent source of electricity, for example, from another transformer substation, and for devices of low and medium power, there must be autonomous power sources, for example, diesel generators.

To reduce emergency situations, especially in heating networks due to water hammer, a frequency converter (FC) system has recently been used, which contributes to:

- energy savings up to 20%;

- reduced water consumption due to reduced leakage by up to 5%;

- reducing the cost of repairing heating systems, since due to changes in frequency, the service life of a group of pumps increases 1.5 times;

- reduction of fuel consumption for heating network water.

Circulation pumps for heating systems

Circulation pump

KINDS

- Horizontal.

They are used in air conditioning and central hot water supply systems. - Console.

Used in air conditioning systems and small heating systems. - Centrifugal

. They are used in hot water supply systems of public and residential buildings.

Circulation pump for heating how to choose

The circulation pump is the main element in heating systems with forced circulation and forces the coolant to move within the system, which is especially important for houses with more than one floor with an extensive pipe distribution system. The circulation pump helps the coolant overcome resistance in the pipe. The thicker the pipe, the lower the resistance and the lower the required pump power. Circulation pumps create a certain pressure drop at the installation site. The pressure difference serves to overcome the sum of all hydraulic losses due to friction in pipelines, that is, due to it, the liquid is maintained in constant motion. To determine the actual pressure, the pressure drop is added to the static pressure.

ADDITIONAL FEATURES

Circulation pumps can be used not only for heating systems, but also for “warm floors”. To create them, you will need a unit of greater power than for organizing hot water supply. Each room must be equipped with its own control system.

Circulation pumps for heating private houses

ADVANTAGES OF CIRCULATION PUMPS

- Efficiency.

Circulation pumps significantly improve heat transfer, thereby significantly increasing the efficiency of heating systems. With proper installation and operation, heating costs can be reduced by up to 60%. - Ease of installation.

The circulation pump takes up little space. It is installed directly on the pipeline using union nuts or flanges. - Easy to use.

Most models of circulation pumps are equipped with an electrical cable with a Euro plug; to get started, you just need to plug them into a power outlet. After this, you only need to adjust it once; no ongoing maintenance is required. - Low noise level.

When properly assembled and installed, circulation pumps operate almost silently, which allows them to be used in heating systems of residential buildings.

Circulation pump for heating price

Circulation pumps for heating systems - you can buy wholesale and retail at Teplodoma-msk

How to choose a pump: calculation

To select a unit, take into account the performance, pumping medium and calculate the required pressure. It shows the difference in the medium difference when the unit is turned off and on, measured in m.v.s., it is calculated using the formula:

H=(L xR xZ)/(ρ xg),

L – total length of the pipeline in two directions, m. R – losses in pipes per 1 m are 150 Pa; ρ – specific water density 1000.0 kg/m3; g – 9.80 m/s2. Z – correction factor.

Calculation: 2000Х150Х1.3/1000Х9.8 = 39.79 m or 4 atm.

Source

What pumps are used for boiler rooms?

Network pumps for boiler houses are most often centrifugal, equipped with an electric motor. By type they can be divided into: condensate, network, make-up, intended for raw water. You can also find this type of pump as a nutrient pump.

In water supply boiler systems, it is customary to install several devices at once that have the same characteristics . The pumps are connected in parallel, with one of them being the main one, and the second being a backup and starting as needed when the first one fails. However, it is also possible to operate two devices at once. In this case, the water pressure in the pipes remains the same as when operating one installation, but the water supply increases, the level of which becomes equal to the sum of the supply of each of the devices.

Pumps for boiler rooms can have enormous weight and dimensions

For boiler houses, the best option would be to install a centrifugal 1-stage pump type KM, a 1-stage unit type D with 2-way suction, or a multi-stage product type TsNSG. In addition, many professionals recommend installing condensate type KS units in the boiler room. In this case, the final choice depends on the specific requirements of the buyer, which, as a rule, are determined by the operating conditions of the future equipment.

Network pump and its purpose

This unit must pump the heating fluid in the supply pipeline at the optimal speed and pressure according to a temperature schedule of 150-70 C, depending on the outside air temperature. Their feature is the proximity of the cooling system circuit to its seals.

How to choose a circulation pump for heating?

To select equipment taking into account the most suitable parameters, you must use certain formulas . However, only specialists know which formulas need to be used in each specific case. And if the device is selected by an unknowing person, then you should use the following recommendations:

- Marking of the circulation pump . For example, Grundfos UPS 25-50 equipment, where the first two digits indicate the thread diameter of the nuts - 25 millimeters (1 inch), which are supplied with the device. There are also pumps with nut diameters of 32 millimeters (1.25 inches). The second two digits are the maximum height of coolant rise in the heating system - 5 meters, that is, using a circulation pump, an excess pressure of no more than 0.5 atmospheres can be created. There are also pumps in which the lift height is 3, 4, 6 and 8 meters.

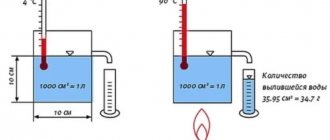

- Unit performance . It is the main parameter that determines the operation of the unit. Represented by the volume of coolant pumped using a pump. The formula used for calculation is: Q=N:(t2-t1),

- where N is the power of the heat source. This could be a boiler or a gas water heater;

- t 1 – shows the temperature of the water in the return pipe. As a rule, it is +65-700С;

- t 2 - shows the temperature of the water that is in the supply pipeline (coming out of the boiler or geyser). Often the boiler maintains +90-950С.

- Calculation of the heating system and its losses is carried out in order to correctly select the design parameters of the unit that is able to cope with the resistance in the heating system.

Mass-produced equipment has average characteristics. Therefore, it is necessary to take into account the individuality of each heating system.

Note! A suitable pump should be selected taking into account the ability of the unit to operate in several modes, and its power should exceed the design power by 5-10 percent.

Network pump design and principle of operation

SE type pumps have a horizontal design. These are units that operate thanks to centrifugal force. For this purpose, an impeller with two-way motion is installed in a spiral casing with a horizontal split. The rotor rests on external-type rolling bearings with forced or ring lubrication. The drawing of the network pump forces you to pay attention to the mechanical seals of the shaft seal. They are supplied with a locking and cooling fluid; this “jacket” is mandatory for units of any power.

The working shaft of the network unit is located horizontally, this is typical for all SE models. The casing connector is also located in a horizontal plane, which provides easy access to pump parts and their quick replacement in the event of an accident or scheduled repair. These pumps are available in single-stage and multi-stage types.

The slot seals of the units are made of corrosive alloys; chromium steel is used for the impeller. The body and covers are cast from gray cast iron, which allows the equipment to be used in the climatic conditions of the Far North.

Structure of the network pump symbol

SEN 1250-140 UHL3

- C – network;

- E – electric;

- N – pump;

- 1250 – nominal flow, m 3 ;

- 140 – nominal pressure, m;

- UHL3 – climatic version.

Types of circulation pumps and their design

The body of any heating circulation pump is made of stainless metal or alloy. The body can be steel, cast iron, aluminum, brass or bronze. Inside the housing there is a steel or ceramic rotor, on the shaft of which a bladed impeller wheel is mounted. The equipment operates from a single-phase or three-phase electric motor. Depending on whether the rotor is in contact with water or not, pumps are usually divided into “wet” and “dry”.

Wet rotor pumps

A “wet” circulation pump is characterized by the fact that its impeller and rotor interact with the coolant (hot water). At the same time, water lubricates and cools the moving parts of the device. The rotor and stator of this type of circulation pump are separated by the walls of a metal cup. As a result, this design solution ensures a hermetically sealed location of the stator of the electric motor under voltage.

Wet-type pumping equipment can be operated for a long time without any maintenance. Repairing these products, as well as setting them up, is not particularly difficult. The devices are compact, lightweight, energy-efficient, and silent, which allows them to be installed directly in the home. The design of circulation pumps with a wet rotor provides for the presence of threaded or flanged connections that facilitate the installation of products in the home heating system.

This is what a model of a circulation pump looks like for a water heating system in a private house or cottage. The pump rotor is in contact with the coolant

The pump is installed in the heating system in such a way that the axis of its shaft must be located in a strictly horizontal plane. It is this arrangement that will allow the coolant to continuously wash the bearings, while ensuring their lubrication. If this requirement is ignored, the pump may break down due to increased wear of moving parts due to a lack of lubricant.

One of the possible schemes for connecting a “wet” type circulation pump to the heating system of a country house with forced circulation of coolant

The main disadvantage of “wet” pumps lies in the low efficiency value, amounting to only 50%. This fact must be taken into account when choosing, since this equipment makes sense to install only in water heating systems with a short pipeline length. Such models are recommended to be used to ensure forced circulation of coolant in the heating system of a small private house.

Dry rotor pumps

The design of the “dry” circulation pump is designed in such a way that the rotor of the device does not come into contact with the water circulating through the pipes. The working part and the electric motor of this type of pump are hermetically separated from each other by special seals. There are three subtypes of dry rotor circulation pumps:

- block;

- vertical;

- horizontal (console).

Pumping equipment of this type is characterized by high efficiency, reaching 80%, as well as increased noise levels

Therefore, it is recommended to install a “dry” type circulation pump in a separate utility room, while paying special attention to its sound insulation

Scope and characteristics

Characteristic features of network pumping devices are ease of installation and low maintenance. Materials such as high-quality steel and gray cast iron, from which such equipment is made, help to increase the safety margin and durability of the pump. The technical characteristics of network pumps allow them to work with predominantly clean water, which should not contain solid parts with a diameter greater than 0.2 mm, as well as more than 5 mg/l of mechanical impurities.

Most often, network pumping devices are used to create water circulation in heating networks, as well as to service a boiler (heating) network installation. Such units are manufactured both with one gear and in a 2-stage version. The drive operates using electric power units (motors). They look like horizontal pumps.

The units also include in their device:

- housing with horizontal connector;

- impeller with double-sided water inlet;

- bearings, shaft and end sealing elements;

- chambers for end seals and flanges for mounting bearings installed in the housing;

- rolling bearings that support the rotor;

- roller or ball support bearing for drive;

- bearing for the radial axis.

In boiler houses, several identical pumps are installed in parallel.

The average water supply of devices for boiler houses is 450-500 cubic meters per hour, the pressure is in the region of 50-70 m, and such a parameter as inlet pressure varies within 16 kilograms per square centimeter. Pumps whose purpose is to circulate hot water in small heating systems have lower power and performance indicators, but they also cost an order of magnitude cheaper.

The scope of application of network products is not limited only to heating systems, in particular boiler rooms. This equipment is successfully used for supplying fuels and lubricants to bases, warehouses and industrial enterprises, for pumping reagents into water treatment plants, as well as in water treatment systems designed for pumping water into water supply systems when the pressure level in pipes drops. At the same time, such equipment is also used for cleaning tanks contaminated with sludge, as well as storage facilities for substances such as fuel oil.

Is an additional pump needed for a Navien double-circuit boiler?

After installing a double-circuit condensing boiler, many users consider installing an additional pump in the heating system of a country house.

The need to use an additional pumping device is explained by the uneven heating of the living spaces of a two-story house with sufficient power of the boiler equipment. Advice! If the temperature differences of the coolant in the supply and return pipelines exceed 20 degrees, it is necessary to switch the circulation pump to a higher speed or get rid of air pockets.

Installing another pump is necessary in the following cases:

- When installing heating in a private house with an additional circuit, or in cases where the length of the pipes is more than 80 meters.

- For uniform supply of coolant through the heating system.

There is no need to install an additional pump if the heating is balanced using special valves. Therefore, before purchasing pumping equipment, bleed the air from the heating radiators and add water, check the circuit for leaks using a manual pressure test pump. If after such procedures the autonomous heating of a private house works normally, then another pump will not be needed.

- Why do you need a hydraulic arrow?

- Installation nuances

Why do you need a hydraulic arrow?

If several pumps are installed in the heating system of a summer house or cottage, a hydraulic separator or hydraulic arrow must be included in the circuit. This device can be used together with a single-circuit diesel boiler or solid fuel unit. In the latter case, the device regulates the supply of coolant in different phases (fuel ignition, combustion phase and attenuation). Installing a hydraulic arrow allows you to balance the operation of the heating system. The main tasks of the hydraulic separator are:

- Automatic removal of accumulated air;

- Catching dirt from coolant flows.

Important! The hydraulic arrow in heating allows you to balance the operation of the system, protects it from airing, and prevents the accumulation of dirt in the pipelines. Such a device must be installed without fail if there are several booster units

Installation nuances

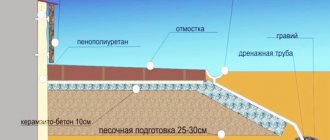

When installing turnkey heating, a master plumber installs a circulation pump with a wet rotor. Such a device does not create much noise; its rotor rotates without lubrication. Coolant is used here as a coolant and lubricant. When installing pumping equipment, you need to take into account the following nuances:

- The shaft of the pressure-injecting device is positioned horizontally relative to the floor plane.

- Carry out installation in such a way that the direction of water coincides with the arrow on the device body.

- Install the device with the terminal box facing up, which will prevent water from entering the electronics.

Important! Experts recommend installing the pump on the return pipeline of the heating system of a single-story or multi-story residential building. Despite the fact that such equipment is designed to operate in hot water with temperatures up to 110 degrees, warmer liquid in the return pipeline will only extend the service life

Installation of the unit is carried out only after draining the water from the system. If there is a power outage, the pump will not be able to pump the coolant, so it is connected through a bypass, and a mesh filter is installed in front of the inlet pipe to prevent scale and debris from getting onto the impeller. In addition, shut-off valves are provided at the input and output of the device for possible replacement and repair of the device.

As we can see, installing a circulation pump requires certain skills, so the installation of this equipment must be carried out by a professional. To order a service, you can leave a request on the website or call the number