It would seem what secrets there could be in such an ordinary task as chopping wood. However, this work is not as simple as it might seem at first glance; it is quite dangerous, labor-intensive, requiring well-developed skills and good physical fitness, attentiveness and compliance with safety precautions.

Wood chopping process

Before sending firewood to the woodshed, it must be prepared for storage. If whole logs have been purchased or prepared, they must be cleared of branches and protruding twigs, and then cut into logs ranging from 40 centimeters to half a meter in length. It is very important that the logs are approximately the same length, then the firewood will lie neatly in the woodpile. In addition, the uniformity of drying of the firewood will depend on such evenness and accuracy.

The logs are measured using a wooden plank, which has a certain length and is called a measure. It is applied to a long log and the number of logs that can be obtained from a given round timber is marked with notches using a regular hacksaw. The log is cut with a two-handed saw or with a chainsaw, placing it on stands called “goats”.

Wood chopping

When the logs are prepared, you can start chopping them into logs. You can chop wood with an ax, or you can use a wood splitter specially designed for this purpose. This device will greatly facilitate and speed up the work, since chopping wood with an ax is not an easy task. If the house is heated only with firewood and you have to make preparations every year, then it is better to purchase or make your own wood splitter. But until it is acquired, it is worth learning how to chop wood with an ax correctly, since this is a rather dangerous activity, especially if there is no experience and skill in this work.

How to chop wood correctly

The place and tools for the work were prepared. Now a little about firewood. It is best to chop dry or frozen firewood. Freshly cut ones “go” hard. If possible, let the logs dry out or freeze. This will make your work much easier.

The size of the firewood is chosen based on the size of the furnace firebox: its length should be approximately ¾ of the length of the firebox, and its width should be about 6-10 cm. With such dimensions, the fuel will burn for a long time and evenly, soot will form in minimal quantities.

How to properly chop wood: the correct stance

Now the process itself. A block of wood is placed on the deck. If there is a crack on it, turn the crack towards you and try to hit it with a cleaver. If there is no crack, but there are knots, try to get between them or along one of them. If you're lucky, the log will split. If not, the cleaver will get stuck. Then you need to either hit the butt with a sledgehammer, or pick up the cleaver with a block of wood, turn it around and hit the deck with the butt. But the second option is not available to everyone: swinging a cleaver is no longer easy, and if there is also a deck hanging on it...

How to split wood correctly: the cleaver is stuck in a block of wood, unwrap it and use the butt to reach the length of the log

The stance when chopping wood is very important: feet shoulder-width apart, knees slightly soft. They can be springy, increasing the impact force. Raise the cleaver in front of you and sharply lower it down. A good technique for chopping wood is demonstrated in this video.

How many parts should the log be divided into? Depends on its size: very small ones can be two or four, larger ones – eight or more. In principle, the scheme is the same: first in half, then into quarters, if necessary - quarters or even in half, or into three parts.

If the log is of a very large diameter, it is more convenient not to try to break it into halves, but to chop off logs of the required size from the edges, having “cut” it in a circle, the rest can already be split in half.

How to properly chop wood. It’s easier to chip off pieces from the edges of a large block of wood

Splitting with an ax

Firewood, the old fashioned way, can be chopped with an ax

For the convenience of splitting firewood, a large wooden block of wood, about half a meter in diameter and height, is used. This size is necessary for the stability of this stand and the ability to place a block of approximately the same or smaller diameter on top of it.

Modern ax on a stand-deck

For such a stand deck, carefully select a fragment from a thick wood log. It should have as many knots as possible, which will serve as a binder for the rest of the wood in the log and make it denser. This is necessary to make it difficult to split, since when chopping logs you cannot avoid hitting the deck. If branches of fairly large branches come out of it, then some of them can be left protruding to a length of 12-15 centimeters. They can serve as handles when carrying the deck from one place to another.

In addition to the physical strength to split wood, you need to understand that heating efficiency depends on some other factors that need to be taken into account when preparing fuel. For example, on the type of wood, the thickness and length of the logs, as well as their shape.

The logs should not be very thick, otherwise they will burn poorly and slowly, and also, if the firewood is not dried enough, they simply will not burn out completely, leaving behind unnecessary firebrands. Therefore, even such a seemingly simple task as chopping wood needs to be approached with skill.

You should try on the blow with outstretched straight arms - at such a distance, safety will be maintained, and there is less chance of breaking the ax handle due to inexperience. Smooth, non-knotty logs are split along natural end cracks. Knotty ones - if possible, avoid knots. If there are too many knots or they are very large, then you need to prick from the butt side along the largest knots.

Thin logs are placed on a block and split with an ax. The optimal diameter is about 12-15 centimeters; four logs will come out of such a log. If the log has a large diameter, sometimes you will have to resort to the help of a cleaver and wedges made of metal or hardwood. Woodcutters who have many years of experience in this occupation usually cope with the work with one ax, without resorting to auxiliary tools.

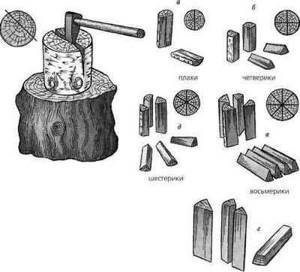

Schemes for splitting logs

The figure shows diagrams for splitting a block of wood, depending on its diameter. So, you can chop on blocks, fours, sixes, eights.

General points

To ensure normal storage of firewood in the woodshed, it should be properly prepared. Wood is stored in the form of logs, which are obtained from split logs. If you purchased timber in the form of long logs, which is very profitable, then in order to be able to store the wood, they should be cleared of branches and twigs, sawn into logs, and then split into more or less uniform logs.

The optimal length of logs is considered to be 40-50 centimeters. If you are working with dense and hard wood, it is better to make them a little smaller; for soft wood species this is not so important.

At the same time, it is necessary to cut the logs into logs of the same length so that they not only fit in the barn, oven, but also stacked in a neat stack. In a well-assembled woodpile, the wood dries better because it is well ventilated.

During cutting, the easiest way is to prepare a wooden stick, a branch and use it to check the size of the next log, or use a chainsaw to prepare firewood to mark the entire log using a tape measure at once, and then start cutting. For the convenience of cutting logs, you should prepare trestles and stands of the original type, since sawing wood on the ground is inconvenient.

Previously, two-handed saws were used to cut logs on trestles.

After the logs of approximately the same size are prepared, you can start chopping them. Classical splitting of firewood involves the use of an ax or cleaver, but there is also an alternative, mechanical option, when firewood is split by a special machine, a wood splitter. It is worth noting that working with an ax is very labor-intensive, so using a special machine not only speeds up, but also makes the work easier.

If you live in a house that is heated exclusively with wood, if you have a bathhouse, then to simplify and facilitate the process of collecting firewood, you should definitely consider purchasing a wood splitter. This device will facilitate the annual winter wood harvesting activities for the following year. By the way, the system is so simple that you can easily do it yourself.

Good to know: Burning temperature of firewood from different types of wood in the furnace firebox

If there is no wood splitter, you will have to chop the wood into logs using an ax. If you also don’t have experience and skill in this matter, then this activity will be very dangerous for you, so we decided to give some recommendations for such work.

Splitting with a wood splitter

Today, urban and rural owners of private sector houses that are heated with wood generally do not split firewood themselves, but prefer to buy already chopped logs or invite a craftsman to do this work.

Chopped firewood costs an order of magnitude more than round logs, and the invited woodcutter will also want to receive a decent amount for his hard work, but many are willing to overpay, just not to have to do this, for some, unbearable work.

But not everyone who needs firewood knows that it is possible to split logs by adhering to certain standards and without making much effort. This is what a special mechanized installation is designed for - a wood splitter. The main working tool in it is a special cone with a thread cut into it. Rotation is transmitted to it using a belt drive from an electric or gasoline engine.

This wood splitter will be a good helper around the house.

This design itself is very simple. The main thing is to find all the elements necessary for it. Typically, metal parts such as a cone are ordered from a good turner. By the way, special dimensional accuracy is not required when sharpening it, and therefore the master must make the part quickly enough.

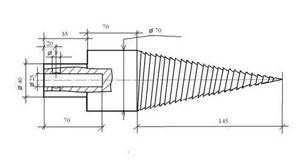

The main working tool of a mechanical wood splitter is a cone or “carrot”

If you have the skills to work with a grinder, then you can try to make a cone yourself. To do this, you need to prepare a suitable metal blank and remove excess metal from it, reducing the workpiece to the desired shape. For convenience, such a blank is installed in the place where the cone should be installed, i.e. so that it rotates, then the metal will be removed evenly. Then a thread is cut on the cone in increments of five to seven millimeters and a depth of two to three millimeters.

A good turner can easily make it to these dimensions

To operate such a wood splitter, an electric motor or one running on gasoline is used. The last of them, of course, is more economical and practical, since it is not tied to the availability of electricity and can be used anywhere, but selecting, installing and debugging it is more troublesome. The engine power to operate this device must be at least three kilowatts.

When making a transmission for rotating the cone of a wood splitter made by yourself, it should be taken into account that the optimal angular speed should be from 400 to 600 rpm. If you set the speed too low, the work will have to be done much longer, as the productivity of the installation will decrease. Too high a speed - there will be a high risk of jamming or even injury. For safety reasons, the chain or belt drive (gearbox) must be covered with a metal casing.

Sometimes the engine is placed directly on the workbench area

For stability, supports from the driveshaft of domestic Zhiguli cars are installed on the table panel, which in this case will serve as a support for the bearings in which the cone shaft is installed and rotates.

This mechanized wood splitter works according to a simple and understandable principle. The log is manually placed against a rotating cone, which is screwed into the wood and splits it. If you need to split one of the resulting parts into two or three more logs, this will also quickly help you make a wood splitter, you just need to put the log in the right place on it. The process of working with this device can be clearly seen and studied in the video below.

It is best to install this device next to the woodshed so that you can immediately stack the split firewood under the roof.

Video: work of a home mechanical wood splitter

It must be said that such an installation greatly facilitates preparation for winter, since you do not need to put in a lot of effort in order to prepare the required amount of fuel. You just need to put the log on a stand and press it with a fairly slight force against the rotating cone - that’s practically all that is required of the “woodcutter”. In a short time, you can chop a large amount of firewood in this way.

And another important advantage of this method is its safety, compared to splitting firewood with an ax.

There are also more modern powerful wood splitting machines that work on a different principle - a mechanical drive strongly presses the log of wood against the splitting knives, which split it into ready-made logs. Depending on the power of such a unit and the thickness of the logs used, the output is 4, 8, 16 or even more logs.