An automatic coal boiler requires less maintenance than a classic one. Fuel loading and ash removal are carried out once every 7 days. Due to the large number of components and systems, high demands are placed on their reliability, therefore it is necessary to pay special attention to the choice of manufacturer.

Description of coal boilers with automatic feed

Fuel continuously enters the firebox in small portions . A similar principle is implemented in pellet boilers. The feed rate is regulated by a microprocessor controller taking into account the temperature of the coolant or air in the room (thermal sensors are connected).

The scheme has the following advantages:

- user participation is required less often;

- coal burns completely (efficiency 90%);

- power is regulated (up to 30% of the nominal);

- there is no inertia - productivity can be sharply reduced to zero.

Due to their ability to operate for a long time on one load of fuel, units of this type are called long-burning boilers. The ability to change heat transfer over a wide range allows them to be used in low-temperature mode, which is necessary in the off-season or for floor heating.

Due to the lack of inertia, the heater turns off at any time. This prevents boiler water from boiling and excessive consumption of coal.

Pellets

Pellets have become widespread. They are granules whose size does not exceed a few centimeters. For their production, waste of various wood species is used.

One of the disadvantages of pellets is the need for special long-burning boilers to burn them. In classical equipment with uncontrolled access of oxygen, they will burn out very quickly and are unlikely to bring the expected benefits and benefits.

Representing hexagonal cylinders, Pini&Kay heating briquettes are the most technologically advanced among the above varieties. They have a round hole in the center. Thanks to the additional distribution of air flows inside it, it was possible to achieve uniform combustion.

Pini&Kay briquettes are widely used for burning in fireplaces. They have the most beautiful aesthetic appearance, being a source of beautiful and even fire.

Video review of Pini Kay

The average cost is approximately 8,000 rubles. per ton

The most common are RUF briquettes. They can be made from small particles and even dust, which are pressed into rectangular or square shapes.

RUF briquettes have many advantages, including:

- Ease of use

- Easy to stack and store

- High thermal conductivity

- No harmful binding additives in the composition

Briquettes of this shape and structure are able to smolder the longest in classic solid-state boilers. Due to their high density, they can be stored in high humidity conditions for an unlimited period of time. Even despite their higher cost compared to other types, their price per unit of heat is lower. Average price 6,000 rubles per ton

NESTRO fuel briquettes, unlike other varieties, are made exclusively from large sawdust, which is tightly pressed mechanically. They are the cheapest among the varieties considered, as they do not require the use of special equipment during the production process.

Among the shortcomings are noted:

- Easily disintegrates if improperly transported

- Burn out quickly

- Can only be stored in low humidity areas

Video of the combustion process

NESTRO briquettes may be similar in appearance to Pini&Kay and have a similar hole in the center. However, during the manufacturing process they are not treated with high temperatures, as a result of which they do not allow for an even fire over a long period of time.

The average cost is approximately 7,500 rubles. per ton

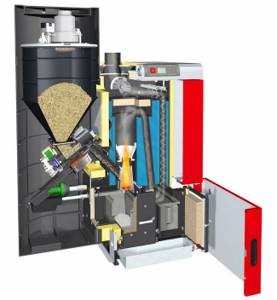

Design and principle of operation

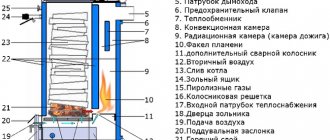

The solid fuel automatic machine is designed on the basis of a classic boiler: in the body there is a combustion chamber with a heat exchanger, below there is an ash pan.

The following components have been added to the design:

- Fuel bunker.

- Electric feeder.

- Special burner with ignition mechanism.

- Rotary grate.

- Electronic automation.

- Fans for air supply. When burning coal, large amounts of oxygen are consumed. Natural draft is not able to provide such a volume; the fuel will not burn completely.

The user pours coal into the container and turns on the control unit. He activates the feeder motor and commands the burner to ignite the incoming portion of fuel. Ignition is carried out by an electric arc. If the fuel extinguishes in the future, the automatic system will generate a spark again based on a signal from the flame sensor.

By controlling the feeder motor, the controller regulates the supply of coal. The grate bars rotate periodically to dump the ash into the box. There are models with the function of removing soot from the walls of broken smoke channels. It is cleaned by springs, then dumped into the ash pan by a rotating auger.

If necessary, automatic coal boilers are switched off, stopping the supply of fuel and air. The heat exchanger located away from the burner does not receive energy from the smoldering coal. After the water in the pipes has cooled, the temperature sensor signals the controller to resume air injection. Fuel ignites; The smoke entrained by the fan is directed to the heat exchanger and heats the working environment.

Advantages and disadvantages of pellet boilers

Pellet automatic boilers are deservedly very popular all over the world. They are widely used in private households and in production. Among the main advantages of such heat generators are:

- High operating efficiency - up to 90%. In comparison with other types of solid fuel boilers, they compare favorably in this indicator.

- Fully automated process, including fuel supply, ignition, oxygen injection. The boiler requires human attention, as a rule, no more than 1-2 times a week.

- Environmentally friendly and maintaining cleanliness in the room where the boiler is installed.

- Eliminating the danger of coolant overheating.

- Almost complete absence of inertia. If the supply of fuel and air mixture is stopped, the flame in the firebox goes out almost instantly.

Pellet boilers have much fewer disadvantages than advantages. And yet, for some users, warning factors may include:

- Relatively high price of equipment and service.

- Energy dependence. A solid fuel boiler with automatic fuel supply will not be able to function without being connected to the electrical network. In addition, automation is extremely sensitive to voltage changes and can easily fail.

- The need to comply with special storage conditions for granules. The storage area must be dry, otherwise the biofuel granules will become damp and crumble.

Coal hopper design

The container is a steel box with a flange for connection to the feeder.

Installed inside:

- crusher;

- fuel disintegrant (prevents large caked lumps from jamming the mechanism).

Bunkers are available that do not require connection to a feeder.

The product is located above the burner and is a horizontally rotating drum with a rectangular hole in the wall. With each revolution, a portion of coal is poured into an even layer onto the grate.

This solution has two disadvantages:

- danger of fuel ignition in the bunker;

- inability to load fuel manually (necessity arises during power outages).

The owner of such a device is recommended to acquire a low-power diesel generator for backup power.

Advantages of pellet construction

An automatic boiler has a number of advantages:

- high efficiency, reaching 93%;

- environmental safety. Harmful substances are released in minimal quantities;

- high automation;

- safety during operation;

- long burning time on one tab;

- You can connect remote temperature controllers indoors and outdoors to the system;

- you can use mobile applications for your smartphone to control the heating device;

- Wood and pellets are used for heating. When using wood, the burner is removed and the fan is attached to the mounting plate. Firewood is loaded into the combustion chamber. The automatic control system does not need to be further configured. It is adapted to work with conventional firewood.

Varieties by type of fuel bunker

Reservoirs differ in volume and location . There are two types.

Built-in

It is part of the boiler, attached to the body.

Advantages:

- quick installation;

- there is no need to allocate an adjacent room for storage.

Disadvantage: small volume. Coal reserves last for 3-7 days.

Mechanized

A spacious bunker installed in an adjacent room. It must be separated from the boiler room by a wall made of non-combustible material.

The advantage is large volume. Loads only once per heating season.

Disadvantage: installation takes 2-3 days.

Automatic fuel delivery options

There are two types of feeders.

Feeding by pneumatic conveyor

The device consists of the following parts:

- compressor;

- receiver;

- dispenser with piston drive.

Once every 24 hours, air with excess pressure is pumped into the storage tank, after which the system goes into a non-volatile mode.

Automatic feeding is carried out due to the action of compressed gas on the pistons, so power outages lasting less than a day do not affect it in any way.

Conveyors of this type have two disadvantages:

- relatively high energy consumption (compressor engine power is 1.5-2 kW);

- make a loud noise.

Therefore, they are used only in conditions of unstable power supply.

Screw transmission

The mechanism resembles a meat grinder. The spiral turns of the auger move the coal forward as they rotate.

The feeder operates silently and consumes relatively little electricity (motor power is 130-180 W).

The disadvantages of the mechanism are as follows:

- energy dependence;

- with a length of more than 2 m, the coal has time to crumble during the journey.

Most household units are equipped with such feeders.

Automatic vacuum feeding system

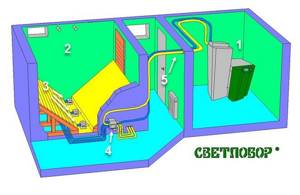

Svetlobor automatic vacuum supply system

The Svetlobor boiler has a vacuum pellet supply system, which eliminates the need for daily manual loading of pellets.

For complete automation and autonomous operation, we offer a pellet supply system from an external warehouse. If such a system is available, the Svetlobor boiler will be automatically replenished from an external warehouse.

The system consists of a Svetlobor pellet boiler (1) and an external pellet warehouse (Warehouse 2), where intake devices (Mushrooms 3) and an automatic switch (4) are installed, connected by vacuum hoses (5).

Principle of operation:

- A closed room for storing pellets is organized at a distance of up to 15 m from the boiler. The warehouse can be either a permanent structure or any container that ensures there is no direct contact of pellets with water. For example, you can use used shipping containers or bury a plastic container on the site like a septic tank. No heating is required in the warehouse. The height difference between the base of the warehouse and the boiler is up to 3 meters. The boiler can be equipped with a second vacuum pump, then the length of the route increases to 20 meters, the difference to 5 meters.

- Fungi and inclined slides are installed in the warehouse. The warehouse is filled with pellets to a height of up to 2 meters. (For ease of loading, it is advisable to provide hatches in the roof of the warehouse or purchase a ready-made solution based on Svetlobor modular boiler houses) Each fungus collects pellets from an area one meter by meter and, accordingly, is installed at a distance of a meter from another fungus. When using inclined slides, one fungus can load 3 tons of pellets.

- The boiler is connected to the fungi with vacuum hoses, through a patented, automatic switch. Standardly, the switch switches 6 fungi, i.e. provides loading of more than 18 tons of pellets. The Svetloborovsky patented fungus ensures the intake of pellets with a productivity of 10-15 kg/min. With a vacuum pump life of 800 hours, this corresponds to 700 tons of pellets. There is virtually no pellet crushing, which is especially important for soft husk pellets.

System Features:

- with a productivity of 10-15 kg/min, this scheme is effective not only for cottage boilers, but also for industrial boilers of 300-500 kW;

- efficient use of space in non-standard premises;

- low power consumption;

- There is practically no crushing of pellets;

- high stability of the system; if a fungus becomes clogged (for example, a plastic bag gets caught), or if the pellets run out in a given place, the switch automatically switches to another fungus.

Our company will supply you with a Svetlobor pellet boiler, an automatic switch and fungi; the work on arranging the warehouse is carried out by the customer independently. Ready-made solutions in the form of modular boiler rooms Svetlobor

| Receiving device (Mushroom) | 6000 rub. |

| Automatic switch | 40,000 rub. |

Which coal is suitable for heating automatic coal boilers?

Fractional fuel of the Eco-pea variety is used. The grain size is determined by the design of the feeder and is given in the product data sheet. In most cases it is 5-50 mm. It is advisable to use fractions of no more than 25 mm, since large pieces do not burn completely.

Requirements for coal quality depend on the type of burner.

There are two of them:

- Retort.

- AKM.

The first option is designed for clean fuel that does not contain coal (coal chips less than 5 mm in size). It is obtained by sifting on sorting sieves, packed in bags and sold at a relatively high cost.

The second type is unpretentious in terms of fuel quality . The share of shtyba is allowed up to 60%. Such fuel is obtained from cheap assorted fuel using a built-in crusher. This generates a large amount of dust, which is a significant drawback.

Operating principle

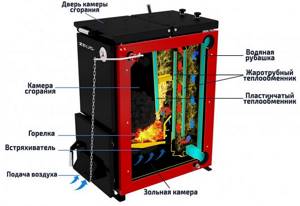

Pellet heating devices include the following mechanisms:

- boiler;

- burner;

- conveyor, with the help of which the granules are supplied;

- fuel bunker.

They are fed into the boiler using a screw conveyor. Pellet combustion occurs in the combustion chamber. As a result, the temperature of the coolant increases. In the combustion chamber, the upper layers burn out first. The process occurs much slower than in classic boilers. In them, the wood ignites from below and gradually the fire moves upward.

The pellet design includes a special burner. Through its nozzle, the heated air flow is delivered to the combustion zone. As a result of such a device, it becomes possible to control the combustion of fuel material. The fire gradually moves from top to bottom.

Heated air masses contribute to complete combustion of fuel. The amount of ash and soot generated is minimal. At the same time, the efficiency value increases significantly. It can reach 96%.

A pellet boiler with automatic fuel supply increases the duration of continuous operation of the heating unit. Without refilling, the house is heated for more than 24 hours. This is especially convenient for domestic heating systems. The operation of the boiler device is controlled fully automatically.

Requirements for arrangement in a private house

The room in which the boiler is supposed to be placed must meet the following conditions:

- Minimum area - 7 sq. m.

- There is at least one opening window.

- Provides fresh air. The quantity depends on the heater power.

- There is a separate entrance from the street for fuel delivery.

According to the standards, for natural ventilation the total area of the inlet openings is determined at the rate of 8 square meters. cm per 1 kW of boiler rated output. These can be open transoms or valves or channels in the walls.

If it is not technically possible to provide the required area with inlet openings, forced ventilation is used.

Choosing an installation location

The boiler is placed in a separate room.

The installation location must meet the following conditions:

- The minimum distance from the device to the wall is 50 cm.

- The floor is made of non-combustible material (ceramic tiles, concrete).

- For a unit with a power of over 50 kW, a separate foundation is erected on the ground, not connected to the building structures and screed.

The wooden floor is protected with a sheet of tin on a fireproof heat-insulating substrate. It is recommended to use basalt cardboard for this purpose - the material is inexpensive and environmentally friendly. Previously used asbestos was recognized as a carcinogen.

On the sides and rear, the flooring protrudes beyond the boiler by 50 cm, from the side of the combustion door - by 1 m.

If the heater is installed near a wooden wall, it is also protected with a tin screen with a backing or covered with vermiculite plaster.

Requirements for installation of an automatic solid fuel boiler

Despite a lot of advantages, solid fuel boiler systems have important disadvantages. These include insufficient fire safety, since sparks are released during fuel combustion, and the surrounding air in the room becomes very hot.

Photo source: barrakuda.com.ua

To reduce the risk of fire, it is necessary to take into account a number of requirements for installing an automatic unit:

- For any boiler operating on solid fuel, you need to equip a special room - a combustion chamber with an area of at least 7 m².

- It is necessary to provide a powerful ventilation system in the boiler room, because... For uninterrupted operation of equipment, large volumes of oxygen are needed. Experts recommend that the diameter of the exhaust and inlet openings in the ventilation shaft be at least 100 mm.

- To finish walls, flooring and ceilings, you need to use non-combustible materials (cement, tiles, plaster).

- It is better to install the boiler unit in such a place in the combustion chamber that there is at least 50 cm of free area around it. In this case, you can conveniently maintain and configure the system.

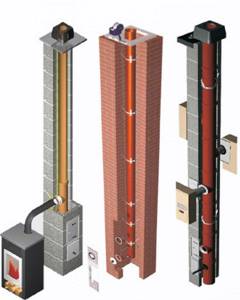

Which chimney is better to install?

The exhaust from a coal boiler is characterized by:

- high temperature - 650 ˚С versus 300 ˚С for wood;

- a large amount of sulfur and other elements that form a caustic mixture of acids when moisture condenses.

In such conditions, special requirements are placed on the chimney. In the case of using a sandwich type structure, the internal (working) part must be made of heat-resistant and acid-resistant steel. Ceramic chimneys have similar properties. Brick ones need to be lined.

The cross-section of the smoke exhaust duct is selected in accordance with the rated power of the heat generator. The manufacturer provides it in the instructions. You can focus on the smoke exhaust pipe: the diameter of the channel should be the same or exceed it.

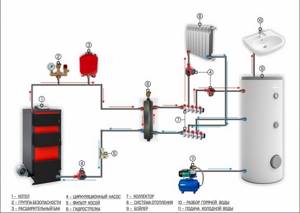

Which heating system to choose

The preferred option is with forced coolant circulation.

Its advantages:

- heat is distributed throughout the house evenly;

- the boiler operates in a gentle mode (the difference between the thermometer readings at the flow and return is small);

- Low temperature mode and connection of heated floors are possible.

The system is designed so that in the event of a power outage or pump failure, the coolant circulates naturally.

For this:

- use pipes of increased diameter;

- install them with a slope of 3 mm/m;

- the supply pipe from the boiler begins with a vertical section (acceleration manifold);

- the pump is installed on the bypass.

A two-pipe scheme is optimal.

User manual

The user is required to comply with the following rules:

- In the same room with the boiler, it is allowed to store a supply of coal for no more than 24 hours of operation. The rest of the fuel is contained in an adjacent room behind a wall made of non-combustible material.

- The chimney and internal surfaces of the boiler should be cleaned of soot every year before the heating season. Otherwise, it may ignite, which can lead to a fire and shorten the service life of the pipe.

- Liquid removed from the condensate collector must not be drained into an autonomous sewer system. This will cause the death of bacteria in the drive. Condensate is disposed of separately.

During operation of the automatic fuel supply system, coal dust is generated. In concentrated form, it can ignite and even lead to an explosion. To avoid this, you should equip the boiler room with dust collectors and regularly perform wet cleaning.

Device for automatically loading firewood into a solid fuel boiler

The invention relates to thermal power engineering, namely to a device for automatically loading firewood into a solid fuel boiler. A device for automatically loading firewood into a solid fuel boiler contains a hopper for solid fuel, a controller, a temperature sensor, an electric drive, and a rotating element equipped with a mechanism for converting the rotational movement of the engine shaft into rotation of this element. The device is additionally equipped with sleeves for grouping individual logs, the rotating element is made in the form of a rotating capsule located under the mouth of the hopper, moving cartridges with firewood, the rotating capsule is made with an upper segment cut along the axis, and is connected to pushing firewood into the solid fuel boiler from the sleeve and removing empty cartridges from a rotating capsule with a rod equipped with an asynchronous motor installed with the possibility of horizontal movement. The technical result is the automation of the operation of a solid fuel heating boiler using wood for small buildings. 3 ill.

A device for automatically loading firewood into a solid fuel boiler relates to thermal power engineering and can be used in automated solid fuel boilers used for heating individual houses, as well as small industrial and public buildings.

A device is known for automatically loading fuel into a solid fuel boiler. For automatic fuel supply, screw conveyors are used, located at a slight angle and having a loading funnel at the end. The hopper from which the fuel is supplied has rotating blades that mix the fuel to ensure an even supply of fuel to the conveyor [(access date: 07/22/14)].

This device has large dimensions, which prevents its use in small buildings, and also has limited functionality of the device, which excludes the possibility of using firewood as fuel.

A device for automatically loading fuel into a solid fuel boiler is known. The turbine sucks pellets from the hopper through a feed auger into the storage tank. The control system ensures automatic loading of the drive thanks to the set filling time. With the help of a fill level sensor, the pneumatic turbine is switched off when the storage tank is full. Through the dosing drum, which, thanks to its all-steel construction, is 100% fireproof, pellets enter in equal quantities into the feed auger, from where they are transported to the boiler [https://granuly.ru/tag/avtomaticheskaya-zagruzka (access date: 07.22.14 ].

This device is structurally complex, has large dimensions, which prevents its use in small buildings, the functionality of the device is limited, since it excludes the possibility of using logs of firewood as fuel.

The closest technical solution is the device “Automated solid fuel boiler” according to patent RU 140631 dated November 5, 2013, publ. 05/20/2014, MPK51 F 24 H 1/00, containing a hopper for solid fuel, devices for supplying fuel to the firebox, a control unit containing a controller, parameter sensors, and an electric drive.

This device is structurally complex and has large dimensions, since before automatic supply of coal to a solid fuel boiler, the coal must be ground in a crusher to the required fraction before feeding, and only then the coal is fed into the combustion chamber by a screw auger, so it is impossible to use it in small buildings and premises.

The objective of the proposed technical solution is to reduce to a minimum human participation in the operation of a solid fuel wood-fired boiler, intended for use in heating small greenhouses, individual houses, small industrial and public buildings.

The problem is solved by a device for automatically loading firewood into a solid fuel boiler, including a hopper for solid fuel, a controller, a temperature sensor, an electric drive, a rotating element, equipped with a mechanism for converting the rotational movement of the engine shaft into rotation of this element, characterized in that the device is additionally equipped sleeves for grouping individual logs, the rotating element is made in the form of a rotating capsule located under the mouth of the hopper, moving the sleeves with firewood; the rotating capsule is made with an upper segment cut along the axis and is connected to a rod that pushes firewood into the solid fuel boiler from the sleeve and removes empty cartridges from the rotary capsule, equipped with an asynchronous motor installed with the possibility of horizontal movement.

Equipping the device with additional sleeves for grouping individual logs, making a rotating element in the form of a rotating capsule located under the mouth of the hopper that moves the sleeves with firewood; making a rotating capsule with an upper segment cut along the axis and connecting it with a rod that pushes firewood into the solid fuel boiler from the sleeve and removes empty cartridges from the rotary capsule, equipped with an asynchronous motor installed with the possibility of horizontal movement, allowing the solid fuel boiler to operate on wood without their prior processing, do not burden the design with additional devices for preliminary, for example wood chips, chopping firewood and forming, for example, pellets, ensure minimal dimensions for the entire device, and also allow the entire cycle to function automatically, reducing human participation to a minimum, which is preferable for use in heating greenhouses, individual houses, small industrial and public buildings.

The technical result is the automation of the operation of a solid fuel heating boiler using wood for small buildings.

A device for automatically loading firewood into a solid fuel boiler is illustrated in drawings, where Fig. 1 shows a diagram of a device for automatically loading a solid fuel boiler; Fig. 2 shows a perspective view of the sleeve and the rotating capsule, in FIG. Figure 3 shows a perspective view of a device for automatically loading firewood into a solid fuel boiler.

Figures 1, 2, 3 show a hopper 1, sleeves 2, a rotating capsule 3, a screw rod 4, an asynchronous motor 5, a slide 6, a solid fuel boiler 7, a temperature sensor 8, a container for empty sleeves 9, a boiler door 10, a controller 11 , driven gear 12, drive gear 13, water jacket 14, firewood 15, hopper mouth 16.

The device for automatically loading firewood into a solid fuel boiler is designed as follows.

Bunker 1, into which firewood 15 is stored, is a prefabricated metal structure. The bottom sheets of the hopper are inclined to the mouth 16 at an angle of 45 degrees, for better unloading of cartridges 2 with firewood 15 from hopper 1. The mouth of the hopper 16 is a narrow slotted hole for passing cartridges 2 into the rotary capsule one by one. The small distance between the mouth 16 of the hopper and the rotating capsule 3 makes it possible to prevent the uncontrolled loss of cartridges 2 when turning the rotating capsule 3 around its axis.

The mechanism for supplying firewood to a solid fuel boiler consists of a rotating capsule 3, a screw rod 4 that pushes firewood 15 out of the sleeve 2, and an asynchronous motor 5 that rotates the rod 4.

The rotary capsule 3 is made in the form of a metal cylinder with an upper segment cut along the axis, allowing for the unhindered placement of a sleeve 2 with firewood 15 coming from the hopper 1 and removal of the sleeve 2 after supplying firewood to the solid fuel boiler.

To prevent the sleeve 2 itself from falling together with the firewood into the solid fuel boiler, limit screws are provided at the end of the rotating capsule 3. The rotary capsule 3 is held on the body of the container 9 for empty cartridges located underneath it. Used sleeves 2 are removed when the rod 4 is returned to its original position.

The rotary capsule rotates around its axis 360 degrees using a gear, throwing the cartridge case 2 into the container 9, intended for empty cartridges.

On the inner surface of the blind end of the rotary capsule 3, a driven gear 12 is rigidly fixed, which meshes with the drive gear 13 located at the end of the screw rod 4.

To push firewood from the sleeve 2 into the solid fuel boiler 7, the screw rod 4 is attached to the shaft of the asynchronous motor 5, the mounting legs of which are located in the slide 6, for the reciprocating movement of the screw rod 4 together with the asynchronous motor 5, which rotates the screw rod 4, moves with it in the sled 6 towards the solid fuel boiler 7 and, in reverse operation, away from the solid fuel boiler 7.

Temperature sensor 8 is mounted in the upper part of the boiler at the location of the water jacket 14.

In fig. 2 are shown in perspective: sleeve 2 and rotary capsule 3. In FIG. 3 are shown in perspective: hopper 1, rotary capsule 3, asynchronous motor 5 and container for empty cartridges 9.

A device for automatically loading firewood into a solid fuel boiler works as follows.

Before the start of operation of the solid fuel boiler 7, firewood is manually placed in the sleeves 2, after which the sleeves 2 are placed in the hopper 1. The operation of the solid fuel boiler 7 begins with loading fuel into it. To do this, controller 11 switches the operation of the firewood loading device to manual mode. In manual mode, firewood is supplied by pressing the button on the controller 11 to supply firewood to the solid fuel boiler 7. Then, after reaching the water temperature in the water jacket 14, previously set in the controller 11, the installation begins to operate in automatic mode. The automatic mode is carried out when the controller 11 constantly polls the temperature sensor 8. When the water temperature in the water jacket 14 drops below the set value, the controller 11 sends a signal to turn on the asynchronous motor 5. The asynchronous motor 5 rotates the screw rod 4, which pushes the firewood out of the sleeve 2 into the solid fuel boiler 7. Firewood enters the solid fuel boiler 7 through the boiler door 10, which opens inward under the influence of moving firewood. The controller 11 sets the time during which the screw rod 4 will push the firewood from the sleeve 2 into the solid fuel boiler 7. At the end of this time, a signal is sent from the controller 11 to the asynchronous motor 5, which begins reverse rotation, as a result of which the screw rod 4 returns to its original position . While the screw rod 4 returns to its original position, the drive gear 13 engages with the driven gear 12 as a result of which the rotary capsule 3 rotates around its axis by 360 degrees. The empty cartridge 2, as a result of turning the capsule 3, falls into the container for empty cartridges 9. The rotary capsule 3, having returned to its original position, stops exactly above (under) the mouth of the hopper 1 due to the closure of the contact pair. The new sleeve 2 falls from hopper 1 into the rotating capsule 3. When the water temperature in the water jacket 14 drops below the set value, the automatic cycle is repeated.

The advantages of the claimed device for loading fuel into a solid fuel boiler are that it makes it possible to automatically load firewood into a solid fuel boiler and, due to its small dimensions, allows it to be used in small buildings and premises.

Compared to other boilers of this type, the proposed device has a full automatic cycle, providing:

— automatic unloading of firewood from the bunker;

— automatic loading of firewood into the boiler;

— automatic removal of empty cartridges.

A device for automatically loading firewood into a solid fuel boiler, including a hopper for solid fuel, a controller, a temperature sensor, an electric drive, a rotating element equipped with a mechanism for converting the rotational movement of the engine shaft into rotation of this element, characterized in that the device is additionally equipped with sleeves for grouping individual logs; the rotating element is made in the form of a rotating capsule located under the mouth of the hopper, moving cartridges with firewood; the rotating capsule is made with an upper segment cut along the axis and is connected to a rod that pushes firewood into the solid fuel boiler from the sleeve and removes empty cartridges from the rotary capsule, equipped with an asynchronous motor installed with the possibility of horizontal movement.

Criteria for choosing heating equipment

When purchasing a heat generator, pay attention to the following:

Rated power.

- Bunker volume. It is selected so that at maximum productivity the fuel reserve is enough for 3-4 days.

- Functionality.

- There are two varieties: one works only for the heating system, the other is also capable of heating water for household needs.

- Control.

- Automation type.

The first criterion is the main one. The rated power is equal to the heat loss of the heated object in the coldest period. The exact value is determined using a complex calculation. The methodology is set out in SNiP “Heating, ventilation, air conditioning”.

A simplified version of the calculation allows you to approximately estimate the power.

The procedure depends on the ceiling height:

- Up to 3 m. Heat loss is assumed to be 100 W per square meter. m area.

- More than 3 m. Calculate the volume in cubic meters. m and multiply it by 40 W.

Boilers with the function of preparing hot water are divided into two types:

- Dual-circuit. They operate in flow heating mode. They are compact, but with low power they serve only one water point.

- With the ability to connect an indirect heating boiler. The storage tank takes up a lot of space, but even with minimal heater power, any number of water points can be serviced simultaneously.

Based on the control method, there are three types of devices:

- Simple. There are only keys on the front panel of the boiler.

- With remote control.

- With GSM module. Receive commands over a cellular network from anywhere in the country.

There are 3 types of automation installed on heaters:

- Simple. Thermal sensors are attached to the pipes. The system supports user-specified temperature conditions, for example, 90/80 (flow/return).

- Room thermostat. Sensors are installed indoors. The boiler maintains the temperature in the room set by the user, choosing the optimal mode (90/80, 70/60, etc.).

- Weather-sensitive. Sensors are located indoors and outdoors. The heater receives information about warming or cooling and manages to promptly adjust the operating mode in order to maintain a stable temperature in the room.

Rating of the best manufacturers

Due to the complexity of the design, the likelihood of an automatic boiler breaking down is higher than a classic one. Taking into account the fact that such an event complicates the operation of the unit and threatens the destruction of the heating system due to freezing of the coolant, the issue of choosing the brand of the unit deserves special attention.

Users consider boilers from the following companies to be the most reliable:

- “Thermorobot”, “Zota Stakhanov”, KAZ Kordi, TIS Eko, Altep, Faci (Russia).

- Roda, Buderus (Germany).

- Metal-Fach (Czech Republic).

- Pereko, Galmet, Heiztechnick, Defro, Stalmark (Poland).

- Vulkan (Ukraine).

- Termodinamic, Emtas (Türkiye).

High-quality boilers with a drum hopper (without feeder):

- "Auto-30".

- "Ugleavtomat"

- "Master."

- "Prometheus".

- Carborobot (Hungary).

Russian boilers, which are not inferior in quality to imported ones, are more profitable to purchase due to their cost and speed of repair.

The best manufacturers of automatic pellet boilers

It is generally accepted that the best examples of automatic boilers are manufactured abroad, although over the past few years the quality of domestic products has improved so much that it already allows them to compete on equal terms with recognized leaders in world production. Customer reviews and sales volumes in Russia allow us to create a rating of automated boilers by manufacturing country, which will help you choose a truly high-quality device:

- Germany. Recognized leader of the global market. The highest quality products, automation that works without failures - these are the distinctive features of German boilers. Long-burning automatic solid fuel boilers from Germany are the most expensive on the market today, but they are worth it. The most popular models are the Heiztechnik and ThermoFLUX brands.

- Japan. Japanese products are traditionally characterized by a high degree of automation. Their boilers with automatic feeding are equipped with a lot of additional functions that significantly increase ease of use. Among the most famous manufacturers is Kentatsu.

- Türkiye. Turkish solid fuel heating systems belong to the middle price segment. In terms of their parameters, boilers from Emtas, Caldera Caltherm or Termodinamik are comparable to their domestic counterparts, although they are inferior in quality.

- China. Products from this country are traditionally not distinguished by high quality and reliability. Only a few models that have good functionality and convenient equipment are worthy of attention. These are solid fuel boilers from the Termal company.

- Serbia. Solid fuel boilers from Serbia are still little known to Russian consumers. Meanwhile, Radijator devices deserve the closest attention. They are manufactured in accordance with EU standards and undergo mandatory quality checks.

- Russia. Over the past 5 years, our country has made a real breakthrough in the production of automatic solid fuel boilers. Coal boilers with automatic fuel supply, pellet models and universal devices are presented in the widest variety. Automation at the highest level, high-quality assembly, attractive appearance, excellent characteristics - all this allows samples from Obshchemmash Peresvet, Obshchemmash Valdai, Pereko, Danko to be in stable demand.

Domestic solid fuel boiler Pereko