When arranging a cottage or summer house, homeowners, as a rule, prefer to install their own heating system. This need is determined by the lack of ability to connect to general communication networks or the desire not to depend on failures in their operation. The heating equipment market today offers various models of devices with various characteristics and parameters. When choosing the optimal model, special attention must be paid to the type of fuel on which the boiler will operate:

- gas,

- electricity,

- diesel,

- solid fuel (coke, coal or wood).

There are various boiler models with different characteristics and parameters on the heating equipment market.

When choosing, special attention should be paid to the type of fuel on which the boiler will operate. The latter are in greatest demand among consumers - solid fuel heating boilers.

Wood-burning equipment is characterized by its simple design and ease of operation.

It is installed in boiler rooms, outbuildings or directly in the house. Models of solid fuel boilers differ in size and configuration and are made from different materials, which allows each buyer to choose the boiler that is most suitable for him.

Description and characteristics

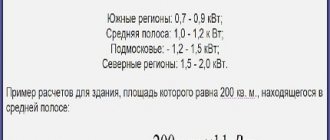

Zota Topol-M boilers are a whole series of heating equipment. It is available in models with a power of 14, 20, 30, 42 and 60 kW. The manufacturer of heating equipment is the domestic enterprise LLC TPK Krasnoyarskenergokomplekt. The main advantage of the products is their affordability. For example, the younger model costs about 30 thousand rubles, and the older one costs about 60 thousand rubles.

Let's look at other features and advantages of Zota Topol-M boilers:

- High burning time;

- Easy soot removal;

- Possibility of installing a block of heating elements;

- High heat transfer efficiency due to a three-pass heat exchanger.

The equipment does not require connection to the mains and can operate autonomously.

Piping the boiler with a water heating circuit

Energy efficiency and safety of the boiler room are problems that can be solved when choosing the correct connection diagram for the unit to the pipeline. At the same time, the location of process equipment (pumps, valves, air vents, measuring instruments) affects the accuracy of parameter control and the correct operation of protection devices.

Gravity type system

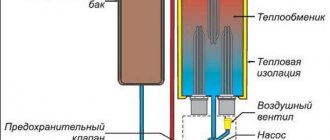

Depending on the design, the circuits are open or closed. The first option involves installing an expander in the attic, the second - a membrane tank located at the level of the boiler with the mandatory equipping of the system with a safety group.

The gravity-type system operates thanks to the circulation of water.

With natural circulation

No pressure equipment is provided. The movement of the coolant is ensured by the location of the boiler at the lower level of the building. The minimum slope angle observed when laying pipelines is 0.5°. The speed of water movement in the system is 0.1-0.25 m/s.

With forced

The liquid circulates in the circuit under the action of a pump located on the return line. It is selected according to the pressure and volume of the pumped coolant based on the heated area and circuit configuration. It is possible to use an open or closed circuit.

ZOTA Topol M 20 reviews:

Do you want to buy ZOTA Topol M 20? Read reviews written by site visitors. The site administration is not responsible for the possibly harsh content of reviews of ZOTA Topol M 20.

Articles from OZYV24.ru

07.05.2021 12:42

211

Anna (24review.ru)

Earlier, there were rumors that Nubia is preparing to launch a new Z series phone called Nubia Z30. Recent reports have revealed renders and key specs of the Z30. Today co-founder

Read more…

22.04.2021 08:38

350

Anna (24review.ru)

Yesterday, a Vivo phone with model number V2050 was spotted on testing platform Geekbench, powered by Dimensity 800U. It is speculated that this phone may hit the market as Vivo V21 5G.

Read more…

08.04.2021 10:47

550

Anna (24review.ru)

Realme has announced three new C-series smartphones: Realme C20, Realme C21 and Realme C25. The new C series phones range from $94 to $148. Realme C25 features a 6.5-inch

Read more…

The information is not a public offer. Trademarks belong to their respective owners.

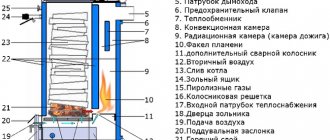

Combustion structure and stages

A solid fuel boiler is a device assembled in a steel casing and consisting of the following components:

- heat exchanger (coil);

- cleaning hatch and combustion chamber equipped with a door;

- grates (grid);

- thermostat.

The principle of operation is to burn fuel: first it is dried, then it is oxidized and wood gas is released, everything is burned, turning into ash. Once in the chamber, the fuel is distributed on grates, which are located obliquely.

All moisture that is in the fuel evaporates during interaction with the chamber lining and from combustion energy. All combustion is carried out by forced air. Afterburning occurs in the firebox at a temperature of 95°C in the part where air enters from the layer between the lining and the lining.

After combustion, the heat exchanger transfers energy to the coolant. The heat exchanger is a simple device - it is a barrel, a vessel through which pipes go: hot air passes through the pipes and heats the water inside the barrel. Water moves in the coolant automatically using a pump. To regulate the volume of coolant, an inlet and outlet manifold with a temperature sensor are used.

Zota Carbon (Zota Carbon).

Solid fuel boilers Zota Carbon (Zota Carbon) are real leaders on the Russian market. Due to their high efficiency and excellent engineering solutions, the boilers quickly gained popularity among users. The main feature of the units is the ability to precisely regulate the air supplied to the firebox. This allows you to significantly increase the combustion process of solid fuel, and as a result, the maximum frequency of heat exchange surfaces is maintained.

Zota Carbon are welded analogs of boilers that are perfect for autonomous heating systems. A full load of fuel allows you to maintain combustion for 5-7 hours, while the unit is able to withstand sudden pressure changes. Safety, high efficiency, quality and the ability to further modify models with block heating elements are the main advantages of this product line. So that the consumer can get a truly useful and modern device, the developers have improved their boilers:

- Top fuel loading.

- Easy cleaning of the heat exchanger.

- The combustion chamber capacity has been increased.

- High gas density.

- Three-way flue.

- Thermal manometer on the front of the boiler.

- High operating pressure.

- Adjustable chimney pipe.

- The efficiency of the boilers has been increased - the ash pans are located on the water-cooling surface.

- Movable grate – greatly simplifies the process of cleaning the boiler.

It is worth noting that the Zota Carbon line of solid fuel boilers allows the buyer to use any type of solid fuel. High quality, affordable price and excellent economic performance of the unit are the characteristics of an effective boiler for your home.

The site presents the following positions:

Fuel: what do we use?

When figuring out how to choose a long-burning solid fuel boiler, it is worth taking a closer look at the different options for raw materials from which the system generates energy. As fuel, you can use firewood or coal, wood processing waste formed into briquettes (shavings), as well as special pellets. In the product passport, the manufacturer records what type of fuel is required for the system to operate adequately.

Many appliances are designed to handle different types and forms of raw materials: briquettes, wood and coal. It should be remembered that briquettes are the most expensive, but it is this fuel that does not burn longer and provides more heat. As experts say, briquettes are the best offer on the market.

Combination boilers may be of interest to those who do not have the opportunity to purchase firewood. When deciding which solid fuel long-burning combined type boiler to choose, you should pay attention to the operating conditions and power of different devices. They waste electricity or fuel, which means that even if there is an interruption in the supply of any raw materials, the house will still be warm at any time of the day or night.

Boilers designed primarily for burning pellets are primarily universal. Their design has a special bunker into which fine-grained raw materials are loaded. Such material burns for a long time, so the efficiency of the system as a whole becomes higher. At the same time, the boiler can handle coal and can be heated with briquettes or wood.

Zota Lava.

Functionality and design features

- new for 2021;

- Models 13, 17 and 26 kW;

- fuel: coal, firewood or fuel briquettes;

- large volume of loaded fuel (32 and 36 kg, respectively);

- efficiency 75%;

- water-filled grates;

- The boiler body is thermally insulated and gas-tight;

- loading fuel through an inclined combustion door, closed with a lock;

- firebox depth 500 and 600 mm respectively;

- the volumetric firebox is ideal for stacking firewood;

- a screwing mechanism made of AISI321 stainless steel for cleaning grates allows the use of caking coals and coals with high ash content;

- large ash drawer (12.5 and 15 l respectively).

Burning duration

- long-term operation on one load of coal for up to 20 hours;

Additional devices

- it is possible to install a heating element unit with a control panel (optional);

- it is possible to install the TurboSet kit.

The site presents the following positions:

How to choose a boiler.

The choice of a solid fuel boiler depends on your needs and capabilities. Indeed, in our time, solid fuel boilers are very diverse both in functionality and in materials and, accordingly, price.

All solid fuel boilers can be divided according to the following criteria:

- — purpose of the boiler (single-circuit, double-circuit);

- — heat exchanger material (steel, cast iron);

- — method of air supply (with additional draft, with natural draft);

- — method of loading fuel (manual, semi-automatic, automatic).

Let's start with the first one

. If you don’t need anything from the boiler other than heat in the house, buy a single-circuit solid fuel boiler, but if you want it to also provide you with hot water, you need a double-circuit one. If you dream of heated floors, you need to buy a boiler with three circuits, but only gas or electric.

Second

. Solid fuel boilers are made of steel and cast iron. Cast iron boilers have higher efficiency, a longer service life, and a cast iron heat exchanger can be repaired in sections of which it actually consists. This is one of the advantages, but the disadvantage of a cast iron boiler is that it is afraid of temperature changes and mechanical stress. A steel heat exchanger, on the contrary, will withstand shocks and temperature changes very well, but will last about 6 years, after which it must be completely replaced. If you compare the prices of cast iron and steel boilers, then cast iron will be much more expensive.

Zota MIX (Zota Mix).

The Zota Mix boiler is an offer specially designed for residential premises, allowing you to regulate the comfortable temperature in your home as rationally and simply as possible. These boilers are suitable for home use, providing high efficiency and the ability to heat the house using any raw material.

Why is it worth buying Zota Mix solid fuel boilers?

The main advantage of such equipment is the use of various types of raw materials that you currently have at hand. I have an opportunity? Heat your house with gas. No? Electricity or even solid fuel is used. Despite this multifunctionality, the boilers are small in size, they are quite easy to operate and do not require careful handling.

buy a Zota Mix boiler in Moscow in our online store, choosing a model to fit the dimensions you are interested in. A wide range allows you to give preference to the optimally suitable option so that the boiler does not run idle, providing the temperature regime you need.

Another reason to order Zota Mix is the maximum safety of such equipment, which is resistant to strong pressure drops, protected from fires and explosions. Special heat treatment of the boiler ensures low heat losses and guaranteed fire safety. The presence of a flap door allows you to minimize draft and use this equipment in a residential area without fear.

The affordable price for the Zota Mix boiler in the TeploHydroInvest online store is another obvious advantage of purchasing from us. You can place an order right now to enjoy comfort and warmth in your home at minimal cost!

Represented by the following positions:

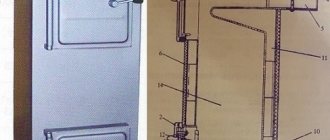

Design features

A traditional solid fuel boiler is essentially any stove with a built-in container and a water circulation circuit connected to it. This design has long been used in private homes and in small stoking rooms of enterprises. It must be said that homemade solid fuel boilers using coal and firewood are often used and work quite well. In other words, the principle is this: heating water in a heat exchanger (the lower part of the circulation circuit), achieved by burning solid fuel. Moreover, the shape and size of the heat exchanger itself can be varied, and they are usually made of steel or cast iron. The latter are more fragile, but more durable and efficient - after all, cast iron is more inertial than steel.

As a rule, there should be an open expansion tank in the circulation circuit. This is due to the fact that most traditional solid fuel boilers use natural circulation of water in the circuit. Sometimes the circuit is modified - a pump is installed in it to maintain pressure and better water circulation.

Today, the production of solid fuel boilers has been put into production. Boilers are produced in various capacities, shapes and sizes. Industrial boilers usually have the form of a metal cylinder or rectangle , in front of which there is a combustion door, controls and a temperature (mode) and pressure sensor, at the back or on top there are heating circuit terminals, a chimney and terminals for the electrical network. There are a number of universal models that, in addition to solid fuel, can also operate on other types of fuel - electricity and gas.

Pyrolysis (gas generator) boilers require a separate discussion, so we will consider them in a separate article.

in the ability to cook food on them during manufacture Also, most stove models are designed for local heating - they are not designed to connect a heating circuit. There are also stoves with two chimneys: for summer mode and for winter mode. Many companies offer long-burning stoves - they operate using the pyrolysis combustion method.

For better and complete combustion of fuel, these stoves are equipped with forced ventilation. Some boilers can be installed separately, others are designed to be built into brick lining. It should be noted that the location of the boiler in brick or stone masonry increases the heating inertia of the room itself in which it is installed - the stone takes longer to heat up, but also takes longer to cool down. Of course, this rarely matters, because a heating circuit is connected to the boiler and all rooms are well heated, and the boiler itself is usually installed in a small utility or special room.

Most solid fuel boilers are afraid of overheating , so they often require more careful care during operation. This is due to the impossibility of stopping them instantly and their great inertia. Boilers are often equipped with overheating protection elements. It can be of two types. The first type boils down to adding cold water to the heat exchanger through a thermal valve that receives a signal from a temperature sensor. The second type comes down to installing a so-called “buffer” tank at the outlet of the boiler (it can be built into the boiler), where superheated water is mixed with water of lower temperature. There is another type of protection, but it is rarely used - organizing the draining of overheated liquid from the system . This type largely protects the heating system itself, rather than the boiler.

Advantages of solid fuel boilers of the ZOTA “Master X” series

- line power range from 12 to 32 kW;

- fuel: coal, firewood;

- work in autonomous heating systems with operating pressure up to 3 atmospheres;

- boilers are equipped with a cast iron stove with burners (except for Master X -14/20 models);

- high degree of gas density;

- thermal insulation made of basalt cardboard;

- adjustable flow of primary air into the combustion chamber (the air damper is equipped with a screw with a handle);

- secondary air duct supply system;

- thermometer for measuring water supply temperature.

- Master X-14/20 models are suitable for installing a gas burner.

- it is possible to install the TurboSet kit for 14/20 kW models;

- On the Master X-14/20 model you can install a Fox pellet burner. If a pellet burner is installed, the manual boiler will become automatic.

This series of boilers is presented on the website by the following positions:

Kind of work

How to choose a solid fuel boiler? It is necessary to consider different options for the type of fuel combustion. There is quite a high demand for pyrolysis systems, the operation of which is based on the decomposition of incoming raw materials into waste and gas. There are long-burning systems, devices that operate using natural draft and are supplemented with a standard thermostat. There are also heating systems in which a fan is installed, providing additional traction power.

Many believe that long-burning boilers are the most reliable and profitable option. There are very inexpensive systems that are safe to use, and there are expensive models that can heat large houses. Even small heating boilers are designed with a built-in automatic control system, which means you have to spend a minimum of time and effort monitoring the operation of the device.

Zota Box (Zota Box).

.

The ZOTA “Box” boiler began its production in 2016. The smallest solid fuel boiler Zota. This boiler operates on coal, wood, briquettes and electricity.

Distinctive features of the Box boiler:

- The special design of the boiler casing creates convective flows of warm air sufficient to heat 15 m² near the boiler ( Attention! This does not make the boiler an air heating stove!)

- Multifunctional ash scoop box.

- The variable geometry of the chimney outlet makes it possible to connect to the chimney, both horizontally and vertically.

- Cast iron burner.

- Standard thermometer.

- The blower door for working with the draft regulator is located at the rear of the boiler (the draft regulator is included additionally)

This series of boilers is presented on the website with the following position:

What does a boiler heat exchanger consist of?

The most popular materials for the manufacture of such an obviously important functional part of a solid fuel boiler as a heat exchanger are two - cast iron and steel.

It is these devices that should be discussed in more detail:

- Cast iron units are characterized by high performance if they run on coal fuel, since the use of firewood can negatively affect the power of the equipment. The main advantages of products made of cast iron are their affordable price, the versatility of the fuel used for operation, as well as the ability to repair them quickly and without problems for the entire system. However, this technique also has disadvantages, the main of which are a small efficiency coefficient (about 65 - 75%), the need for regular cleaning of the heat exchanger, as well as high inertia rates.

- In steel mechanisms, the main fuel is firewood or briquettes created by processing wood waste (pro

Types of hot water boilers

The design of hot water boilers is distinguished by design, type of fuel used and outlet water temperature.

Low-temperature boilers, in which water is heated to a temperature of 115 degrees, are highly economical during operation. However, the cost of the units themselves is quite high, since quite high demands are placed on the material used to manufacture all boiler elements.

High-temperature boilers produce superheated water with a temperature of 150 degrees and are characterized by a long service life and the reliability of all components and elements. In addition, such a boiler is quickly installed and has simple controls. But such installations consume much more fuel.