Installing a solid fuel boiler is the first step towards efficiently and economically maintaining heat in the house. The next steps are to regularly add firewood or other types of solid fuel. It is also necessary to maintain the temperature of the heating system coolant within operating limits at night. And even when the house is visited only on weekends, maintaining a minimum temperature is required to avoid moisture condensation on the internal surfaces of the room.

If the presence of condensation is not critical, then when leaving after the weekend, you need to wait until the boiler stops and drain the water from the heating system to avoid freezing of the system. If water is drained, all metal elements corrode upon contact with air.

There is no need to drain the coolant if antifreeze is used instead of water. However, when using antifreeze, due to its high fluidity, high demands are placed on threaded seals and shut-off valves.

The most common solution for maintaining the temperature in the heating circuit is to install an electric boiler together with a solid fuel one. The minimum amount of additional equipment will allow the electric boiler to automatically take over the heating functions, and the solid fuel boiler to turn off, without the risk of boiling. Also, the use of an electric boiler eliminates the need to carry out any manipulations with the heating system, leaving the country house until the next weekend. To monitor emergency situations and remote control of the electric boiler, there is a GSM module that controls the operating mode of the heating equipment.

Types of electric boilers

When choosing an electric boiler for installation in addition to a solid fuel one, it is enough to quickly familiarize yourself with the basics of heating water using electric current, so as not to get caught in the network of marketers. Electric boilers operate with an efficiency of about 95%. You should not use your heating system to check the veracity of the manufacturer’s assurances about the incomparably high efficiency of their devices - this may cost extra money, and it will not pay off soon. There are three main types of boilers:

1. Heating element boilers.

Heating in them is carried out by an electric heating element (heating element), which is immersed directly in the coolant. Both water and antifreeze can circulate in the circuit of such a boiler. It is unpretentious in operation, but periodically requires replacement of the heating element due to the formation of scale, which reduces heat transfer.

2. Electrode boilers.

The coolant in them is water. Heating occurs due to the energy released when electric current flows through the coolant in the boiler between the electrodes that are located inside. Can work without an electric pump in the circuit. Provides smooth heating of water in the system. Over time, as a result of electrolytic reactions, the electrodes dissolve and require replacement.

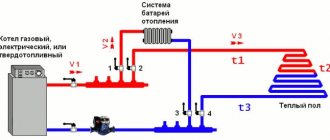

Connection diagram for two manually controlled boilers

Nothing is required here except shut-off valves. Switching between boilers is carried out by manually opening/closing two taps located on the coolant. And not four, in order to completely cut off the idle boiler from the system. Both boilers most often have built-in expansion tanks and it is more profitable to use both of them at the same time, because the volume of the heating system very often exceeds the capabilities of one expansion tank taken separately. To avoid the useless installation of an additional (external) expansion tank, there is no need to completely isolate the boilers from the system. It is necessary to block them according to the movement of the coolant and leave them simultaneously included in the expansion system.

Features of the purchase and installation of electric boilers

When installing electric heating equipment, a number of nuances should be taken into account:

- In order to properly connect the electric boiler to the electricity and heating system, it is necessary to resort to the services of employees of organizations engaged in this type of work on a professional basis.

- The device itself should be purchased from specialized retail outlets, where the relevant documents are attached to it. The equipment must have original packaging, which should preferably be opened in the presence of a specialist from the service department. Together with it, the boiler is inspected to ensure that there are no mechanical damage or other defects on the surface.

- Before installing the electric boiler, you need to remove the plugs from the pipes and make sure that there is no dirt in them and the communications. With this electric boiler connection scheme, sealing materials and gaskets are used.

- When choosing a place to install a thermal electric boiler, it is advisable to give preference to non-residential premises. The best option is the kitchen (see photo). The device should be positioned so that it is convenient not only to use, but also to carry out its maintenance. In accordance with the standards, the gap between the sides of the boiler and the walls should be 5 centimeters. The free space in front of the appliance cannot be less than 70 centimeters, above it - at least 80 centimeters, and below the boiler - at least 50 centimeters.

- Heating equipment must be installed on a wall made of non-combustible material. To install the device, use a special fastening element - a mounting plate. Usually it is included in the basic package of an electric boiler. The plank is secured to the wall using 4 dowels.

Important connection details

For the system to function effectively, it is necessary to make preliminary calculations. First of all, you should find out whether it is possible in principle to install such equipment in a given building. Low or unstable voltage in private homes is not uncommon. Under such circumstances, installing an electric boiler may be completely useless.

Important! When choosing an electric boiler, it is necessary to take into account the state of the electrical wiring in a particular house, as well as the total power of all electrical appliances in it, otherwise, when the heater is turned on, a short circuit may occur or the circuit breaker will constantly turn off.

The correct choice of hydraulic pumps is of great importance. When purchasing, you need to pay attention to their parameters. Low-power devices will not be able to provide the necessary circulation of liquid. Accurate calculations should be made taking into account the diameter and length of the pipelines.

For more economical operation of the system, a heat accumulator is often built into it. This is, as a rule, a container in which water for domestic hot water is accumulated. It prevents the cooled liquid from directly entering the solid fuel boiler.

Completion of the heating system installation

At the stage when the connection of the electric boiler to the heating system and electrical network is completed, perform the following actions:

- check the serviceability of the pipeline fittings located in front of the device. To do this, it is switched from the “closed” to “open” position and back;

- The pipeline fittings of a heat generator powered by electricity are moved to the “closed” position. In the same mode, the fittings of water supply and heating systems should be installed;

- On the pipelines supplying cold water to the heating boiler, it is necessary to open the shut-off valves. When using an electric heating system, do not use non-freezing coolant fluids, as they will negatively affect the functioning of the equipment. They contain components that over time lead to wear of the rubber elements. For the heating system, water with a minimum hardness level should be used;

- before entering the device on the return pipeline, it is necessary to install a sump filter or a filter or both of these parts;

- After filling the heating system with coolant, you need to check its tightness.

What to consider

Since one heating boiler replaces another during force majeure, reservation should be carried out without intervention by the owner, that is, automatically.

And for this you need to have a good understanding of many issues. And above all, how to properly wire heating units. Several factors are taken into account here, otherwise uneven heating, water hammer and a number of other negative consequences cannot be avoided. After all, it is necessary to take into account the characteristics of individual elements of the circuit; the same expansion tank (or GA); The control units most purchased for the private sector and their prices can be found here.

The conclusion is not difficult to draw - if we are talking about a heating system with a combination of two different types of boilers, then it is better to contact a specialist. As practice shows, independent calculations and purchase of equipment do not give the expected result. The result is complete disappointment in the purchase and additional costs. That is, such savings on professional consultation are ephemeral and irrational.

"ALFATEP" is ready to provide practical assistance to residents of the Moscow region in organizing complex heating of buildings using solid fuel and electric boilers. The company has been working in this service sector for several years; its warehouses have everything you need, and its staff includes highly qualified engineers. You just need to call her contact number 8

, and the employees, having clarified certain points, will give competent advice. Upon mutual agreement, specialists will go to the site, based on the results of the survey, develop a design for the heating system, select everything necessary for it, deliver it, install it and test it for operation. In this case, all concerns regarding service support of the equipment will be taken over.

Connecting an electric boiler to a TT boiler

If it is necessary to provide heat supply to a country house, experts believe that the most reliable and profitable way is to connect an electric boiler to a solid fuel boiler. A device operating, for example, on wood will be a backup non-volatile heat source.

Most often, the electric + solid fuel boiler design is installed in houses with an area of 100 to 200 square meters, when there is no main gas pipeline in the locality. The main thing is that the necessary electrical power is supplied to the building.

This page shows connection diagrams for a solid fuel boiler along with various equipment: an electric boiler, an indirect heating boiler, a heat accumulator, a gravity circuit, etc.

When are solid fuel and electric boilers combined in one system?

An electric boiler and a solid fuel boiler are installed in the same system so that the first smooths out the inconvenience of using the second. As a rule, with this combination, the solid fuel boiler is the main one, and the electric one is the auxiliary one. The opposite happens, but rarely.

What are the benefits of adding an electric boiler to the system?

It is no secret that the combustion time of solid fuel is limited by fuel combustion. If you go to bed in the evening in a warm house, you can wake up in the morning in a cold one. Then you will have to get out from under the blanket, like jumping into cold water. This is where an electric boiler will help, which, turning on at a given time before we wake up, will raise the temperature in the house.

The presence of an electric boiler will allow the owners to go on vacation, for a weekend or on a business trip even in winter without fear that the pipes and radiators will freeze and burst. The same can be said about houses with temporary residence. The electric boiler will turn on according to a signal from the room thermostat and maintain a positive temperature in the house.

An electric boiler can be heated in the off-season - in autumn and spring, when it makes no sense to heat it too much, but only to maintain a normal living temperature.

Schemes: TT boiler

This is the simplest wiring diagram for a solid fuel boiler. It can only be used if a boiler control unit is used, which provides control of the circulation pump to prevent condensation.

This is a common budget piping scheme for a solid fuel boiler. It includes protection against condensation formation - a three-way valve. Read more.

Wiring diagram for a solid fuel boiler with an emergency gravity circuit. Of the existing safety elements, the emergency gravity circuit is the most reliable, in my opinion. Read more.

This diagram shows the piping of a wood-burning boiler with a four-way emergency mixing valve. I do not recommend it for boilers with a cast iron heat exchanger.

With this type of piping, you additionally need to install a heating element into the boiler.

This option is for boilers with a fan. A separate pump is installed on the boiler. An automatic system is required with a function to control the boiler pump, with a function to turn off the pumps when the temperature drops below the condensation point. A heating element is also installed in the boiler.

Electric boiler with solid fuel boiler: simplified diagram

As usual, let's start with a general diagram to give a general idea:

In this scheme, each boiler can operate either independently or simultaneously with the second.

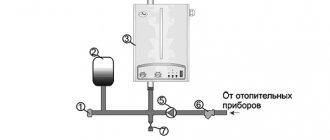

In the diagram, the electric boiler is the simplest: without built-in automation and without a circulation pump, but the actual tank with welded pipes and heating elements inside. Therefore, in the diagram the pump is outside. Maybe you'll buy a different model, something like this:

It's all-inclusive, all that remains is to connect the pipes. Well, supply and return valves in front of the boiler are required.

How to choose a combi boiler

The choice of heating boilers for wood and electricity is limited, since they are all very similar floor-mounted designs with a steel heat exchanger. When choosing, you should pay attention only to:

- Number of circuits . Single-circuit models are used only for heating. Double-circuit systems also heat water in the DHW circuit, the sanitary water of which does not mix with technical water in the heating circuit. Double-circuit models are 10-30% more expensive, but this is still the cheapest way to organize hot water supply.

- Burnt fuel . Typically, such boilers are designed to burn not only wood, but also coal, peat, pellets - this information is always indicated in the product description or operating instructions. However, there are exclusively dual-fuel models (wood-burning with built-in electric heaters) that are not designed to burn coal.

- Operating pressure . Due to the steel heat exchanger, many models are characterized by a maximum permissible operating pressure of only 1 bar. This means that they can only be used in an open heating system with natural circulation, since in closed systems the operating pressure is usually within 1.5-2 bar.

- Efficiency . Despite the fact that this is an efficiency indicator, in this case it can be paid attention only as a last resort, since it very much depends on the quality of the fuel. The 75% declared by the manufacturer can turn into 60 or even 50% when using too damp wood or ash-based, non-calorific coal. However, an excellent indicator is 80% or more, indicating a successful and efficient boiler design.

Minimum required power

For a standard uninsulated or weakly insulated house in the climatic zone of the Moscow region, with 2 bricks and a ceiling height of 2.7 m, the minimum required power is calculated using a simple formula: 1 kW for every 10 m2 of area. We also recommend setting aside a power reserve of 20-30%.

For example, for the average house described above with an area of 120 m2, the minimum required heating capacity of heating equipment is 120/10 * 1.2 (20% reserve) = 14.4 kW, that is, 15 kW.

If the boiler is double-circuit, it is advisable to add another 10-15% reserve so that heating the water does not affect the heating. If the house is located in the south or north of the country, is well insulated, has high ceilings or a large glass area, correction factors are taken into account, changing the result by 5-30% up or down.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

How to achieve joint operation of electric and solid fuel units

If you are faced with a choice of which individual heating option to give preference to - a solid fuel boiler, an autonomous electric unit or a combination of these two devices, the latter option has advantages. To install the circuit, you will need a connection diagram for both units, similar to a gas-solid fuel heating system. Properly done equipment piping is a guarantee of the efficiency and safety of operation of this equipment.

The proposed video describes in detail how and in what way to connect solid fuel heating devices together with electric heating elements

What you need to pay attention to during installation:

- both devices must have a reasonable power ratio, the coal or wood heating device is the main source of heat, so its power must be twice the power of the electric boiler;

- both units are connected in parallel, which makes the operation of one independent from the other;

- the solid fuel unit is the main one and is connected to the large circuit, while the electric boiler is responsible for the temperature in the small circuit;

- the main heating unit is equipped with a three-way valve;

- to save energy resources and ensure heating safety, installation of a heat accumulator is mandatory;

- each heating device is set to a certain heating temperature - for solid fuel equipment the operating temperature should be 60-70 0 C, while on an electric unit the temperature value is set to 40-50 0 C, since due to the presence of a heat accumulator the water for heating will cool slower, and the electric boiler will start with a delay.

Basic wiring diagram.

The pressure gauge, air vent and valve are mounted on a single manifold made of stainless steel. It allows you to reduce the pressure in the system automatically.

When choosing a method for connecting a solid fuel boiler to the heating system, special attention should be paid to the installation of the mixing unit, as well as the safety group. The latter is the first element of the system encountered on the path of the heated coolant. The security group includes:

- a pressure gauge that monitors the pressure in the system;

- safety valve - discharge of excess coolant and steam;

- an air vent that eliminates the occurrence of air jams;

Such equipment is presented in the “Related Products” section of our online store under the name “Security Group”. Its main purpose is to ensure trouble-free operation of the heating system. The pressure gauge, air vent and valve are mounted on a single manifold made of stainless steel. It allows you to reduce the pressure in the system automatically.

Additional mixing unit.

An additional mixing unit is mounted in the area between the buffer tank and the heating radiators. This element of the system connects the return and supply circuits and allows you to avoid strong temperature differences when the coolant almost begins to boil at the peak of the boiler operation.

By the way, for solid fuel boilers “Kupper” with an automatic pellet burner, an additional mixing unit is not needed and when installing them, you can safely limit yourself to the most primitive piping scheme.

In the Kupper OVK 10 model, an automatic pellet burner (APG) is installed in place of the ash door of the boiler, and the container into which pellets are loaded and the built-in control panel are installed on the boiler itself, which saves space in the room. Before starting the work process, the operating parameters of the heating system are set on the remote control. Using an automatic remote control, you can control the ignition, combustion process and maintain a balanced temperature of the coolant without the participation of additional mixing units that complicate installation. Another advantage of this model is that the ash is partially removed under the influence of a built-in high-power fan.

This boiler is suitable for installation in rooms up to 100 m² and can be used in a residential building, country house, garage, and other places. The equipment can be easily integrated into different types of heating systems. A nice bonus is the presence of a stove with a hob.

This boiler is suitable for installation in a residential building, country house, or garage.