Here you will learn:

Electric boilers are in demand among owners of country houses, residential cottages and other non-gasified buildings.

They are characterized by good functionality and allow you to heat any buildings that are not connected to gas mains. Their typical representative is the Proterm electric boiler - this is a device from a well-known manufacturer, characterized by high build quality and decent characteristics. We decided to devote this review to Protherm electric boilers. In it we will tell you:

- About the Skat model range;

- About the technical characteristics of the equipment;

- About popular models;

- About user reviews.

Equipment from such a renowned manufacturer really deserves special mention, so we will tell you everything we know about Proterm boilers.

Features of Proterm electric boilers

By installing such an electric unit in your home, you are making an excellent choice. Rather than buying equipment from dubious brands, it is better to overpay a little and take a really worthwhile item from a well-known manufacturer - the performance of the entire system depends on the quality of the boiler used . Moreover, the Protherm company has extensive experience in the production of electric heating equipment.

There is only one model range - Skat.

Heating a home not connected to gas mains is always a big problem. Electric boilers existing on the market are either high cost or cannot boast of sufficient functionality. In this case, you always pay attention to small-sized and neat gas models that operate automatically and do not clutter up the space. The Protherm company is ready to offer owners of country houses similar solutions, but powered by the electrical network.

Protherm electric boilers are a unique solution that is economical. They are installed in both residential and non-residential buildings, regularly generating heat. They are presented in a single model range called Skat - customers can choose from samples with thermal power from 6 to 28 kW. Thanks to this, they can heat rooms up to 280 square meters. m.

- Simple single-circuit design - if you like simple and reliable equipment, you will definitely like the products of this brand;

- Wide power range – it is possible to choose a device that is suitable in terms of power and price;

- High efficiency - efficiency, according to the manufacturer, is 99.5% . This means that almost all of the expended electricity is converted into heat, without significant losses;

- Absolutely silent operation - even if the equipment is in the bedroom, it will not interfere with a good night's sleep;

- Precise temperature control – create a comfortable and cozy atmosphere in your home;

- Availability of universal models - they can operate from single-phase and three-phase networks with a voltage of 220 or 380 V;

- Easy installation - you can handle the installation yourself, without the help of specialists.

Prices range from 37,900 to 47,000 rubles - this is the official price from the manufacturer as of April 2016. In some other stores it may differ up or down (usually more). But nothing will stop you from buying a Proterm electric boiler in the official online store - this is the most economical and reliable option.

Types of Proterm boilers

The Proterm line of boilers includes models running on gas, electricity and solid fuel

Protherm heating equipment is a device that runs on various types of fuel: gas, electricity, coal. They are designed for heating apartments, private houses, office and commercial premises. The company's factories produce boilers for floor and wall mounting, as well as high-power units. All products undergo strict quality control. Before being put into production, models are tested in the laboratory.

Electrical

The Skat series is an alternative to gas equipment; it includes 8 models with a power from 6 to 28 kW. The electric boiler is designed for connection to a 220 or 380 V network. The equipment heats the coolant to 85°C, the installation efficiency is 99%. Among the advantages of electric boilers:

- No connection to a chimney is required, the equipment does not emit combustion products.

- The compact boiler fits into any interior.

- High performance.

- Possibility of programming control of heating medium heating temperature.

- When installing electrical equipment, fewer requirements are imposed than when installing gas boilers.

Electric wall-mounted boiler Proterm Skat - economical, does not emit combustion products

The unit is manufactured with wall mounting. Its functions include:

- Diagnosis of breakdowns using error codes.

- Pump and valve blockage protection.

- Protection against freezing, pressure drop.

Gas

The equipment heats water for heating and domestic needs of house residents. Several series are offered, differing in the method of installation and heating. The product line includes:

- Single-circuit installations - heat water in the heating system. They are designed for houses up to 350 sq.m.

- Double-circuit models - in parallel with heating the premises, the boiler provides the owners with hot water.

Floor-standing gas boilers differ in the design of the combustion chamber - open and closed

According to the type of combustion chambers, the equipment is presented in two types:

- Open - with a chimney and natural draft.

- Closed - a fan is used to force smoke out.

The equipment runs on main and liquefied gas. A distinctive feature of the units is the expanded functionality of the settings. Some models can be connected to the “smart home” system; it is possible to install low-temperature operation for heated floors.

Solid fuel

The units operate on coal and wood and are designed to heat rooms up to 500 sq. m

The Bober series are cast iron boilers for heating residential and industrial premises. A special feature of the equipment is the large area of the heat exchanger covering the entire firebox. Pros of the series:

- energy independence;

- durability;

- ease of operation;

- safety.

The unit runs on coal and wood. Its disadvantage is the need to add fuel every 2-4 hours. Non-volatile floor-mounted boilers. Their power ranges from 19 to 48 kW. They are designed for heating rooms ranging from 190 to 480 square meters. m.

Technical characteristics and appearance

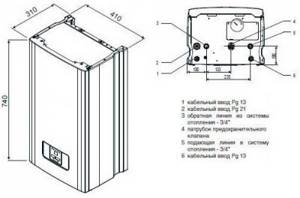

The Proterm electric boiler will fit into any interior due to its small size and wall placement.

As befits good equipment from a well-known brand, Proterm electric boilers are housed in neat, compact housings. Thanks to this, they can fit into any interior , even the most sophisticated. Case dimensions – height 740 mm, depth – 310 mm, width – 410 mm (dimensions are identical for the entire Skat model range). Inside we will find everything you need for the heating system to work:

- Circulation pump;

- Automatic air vent;

- Expansion tank 7 liters.

There is no need to worry about installing the piping - just connect the pipes and radiators, fill the system with coolant, after which you can start testing.

Models with a power of 6 kW and 9 kW can operate from both single-phase and three-phase networks. More powerful ones are three-phase. The equipment is not afraid of power surges and does not cause overloads on the network - a stepwise increase in power is provided here. The maximum current in the circuit when the heating elements are operating is up to 50 A. The maximum coolant pressure in the system is 3 atm, the temperature is up to +85 degrees.

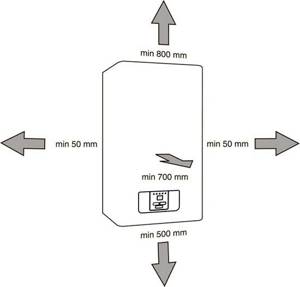

Layout of inlets for Proterm electric boilers, as well as their dimensions.

Protherm electric boilers are equipped with convenient control panels. They contain LED indicators and liquid crystal displays. Self-diagnosis systems are provided - error codes are displayed on built-in screens. Thermostats are used to create a comfortable atmosphere. Safety systems include an overheating sensor, frost protection, a pressure sensor, a safety valve and an anti-blocking system for the circulation pump.

Heater installation instructions

Electric water heating boilers of all types are designed for wall mounting and are equipped with mounting brackets or clamps. There is no point in explaining the marking and driving of dowels - every homeowner knows how this is done.

For reference. Universal electric wood-burning and coal-fired boilers, described in our other material, are sold in a floor-standing version.

Another question is how to choose the right room and specific location for installing the electric boiler. On the one hand, regulatory documents do not prohibit installing a heat generator in any room. On the other hand, there are rules for the use of electrical installations (PUE), which impose restrictions on the placement of high-power thermal power devices.

The wall version can be hung even in the corridor, but all communications will have to be pulled there

We will give some general recommendations on how to properly install an electric boiler in a private home:

- Considering the high current in the circuit of operating electric heaters, it is better to install the devices in a separate technical room, for example, a furnace room or garage. The goal is to limit access to power electrical equipment and protect devices from moisture.

- New heating elements can be placed in the kitchen or hallway. But keep in mind an important nuance: you will have to pull the main line of the heating system and a powerful power cable there. It is unlikely that these communications will fit harmoniously into the interior, unless the pipes are sealed into the wall.

- When installing the heat generator on a wooden wall or other combustible partition, comply with the requirements for wall-hung gas boilers. Place a sheet of roofing steel or basalt cardboard under the back of the body adjacent to the wood, as shown in the photo.

- Provide approach and access to the heater for ease of connection and maintenance. Install induction and electrode boilers in such a way that an expansion tank and pump are placed nearby. Place the control cabinet at a height of 1.5–1.8 m from the floor.

Recommended clearances to the Proterm Skat boiler unit specified in the instructions - Lay the cables above heating and sewer pipelines so that they are not flooded with water in the event of a breakthrough.

- Heating pipes should not load the connecting fittings of the unit with their weight.

Important! Be sure to connect the body of the electric boiler to the grounding bus. If there is none, make a grounding loop outside and lay it in the boiler room. Find detailed instructions below.

As a rule, an electric heat generator acts as a backup device for the main solid fuel or gas boiler. This means that heat generators and auxiliary equipment need to be configured correctly to ensure a minimum of pipeline crossings. Think and draw a diagram in advance.

Popular models

The electric boiler Protherm Skat 9 KR 13 is the most popular. Used to heat rooms up to 90 square meters. m.

As we have already said, electric boilers from Protherm are represented by the only Skat line. Therefore, all equipment has similar characteristics, differing in electrical power and current consumption - all other data is identical, down to dimensions and weight. As for the most popular models, they are designs with a power of 9 kW, 12 kW and 21 kW .

Reviews

User reviews of Proterm Skat electric boilers are positive. But not everyone can understand all the features of electric heating equipment, expecting more from it. You will find detailed information in the reviews.

When we bought a summer cottage, we didn’t even suspect that we would want to live on it almost permanently. We often come here in winter, so last year we decided to install normal heating in the house. Having installed a Protherm electric boiler, we spent a lot of money, but we received the long-awaited warmth. What can we say? It heats properly, we don’t even touch it, there are no leaks or breakdowns, nothing rattles, stinks or rattles. Yes, the bills for electricity turn out to be substantial, but this is the only way to heat the dacha, the nearest gas pipe from which is 10 km away. But it is simply impossible to heat with wood and diesel fuel - the system will freeze while we are in the city.

I work as a sales consultant in a store and sell heating equipment. There are many small settlements near our city that still do not have gas. Therefore, the sale of Protherm electric boilers brings the store good money. Why Protherm? Yes, because this company makes really excellent devices, and not poor crafts in the form of metal pipes with wires. Excellent layout, built-in automation, excellent appearance - what more does the consumer need? Yes, the price is a little steep, especially due to the unstable dollar exchange rate, but this is the only solution for those who do not want to bother with heating, but just want to warm up in their country house.

When I was choosing an electric boiler, I wanted to take a simple Russian model. The devil pulled me to buy a Proterm boiler. I didn’t see the vaunted efficiency, but I spent a lot of money for the equipment. The good news is that I didn’t have to buy a harness, at least I saved on it. So, electricity bills turn out to be astronomical, despite the fact that the winter this year was relatively warm. What will happen then in the cold winter? No, there are no complaints about the equipment itself, it works well. But why do the manufacturer and sellers talk about some mythical efficiency? Here are the gas ones - yes, economical. But what I saw in the bills for electricity was pure horror.

Where gas heating is not possible for safety reasons or due to the lack of a gas main, it is advisable to use electric heating. This is especially useful in places where there is cheap electricity. One of the best in its field is the Proterm electric boiler.

Features of electric boilers Proterm Skat

A Protherm electric boiler of any modification is equipped with a detailed and understandable control panel, as well as a display that displays all the main indicators from pressure to ambient temperature and coolant.

The diagnostic system is working properly: in case of any malfunctions or deviations from the norm, an error code is displayed on the display. For safe operation, the boiler is equipped with excellent automation and a whole system of sensors and fuses. All this protects the device from overheating, excess pressure, freezing and pump blocking.

Electric boiler Protherm (Proterm) SKAT 21K

Electric boilers Protherm SKAT (Slovakia) are wall-mounted single-circuit electric heating boilers used in systems with forced water circulation. Protherm SKAT electric boilers have eight power modifications, from 6 to 28 kW (6 kW, 9, 12, 15, 18, 21, 24 and 28 kW).

Single-circuit wall-mounted electric heating boilers are intended mainly for use in residential premises. Therefore, not only technical stability and excellent performance are important to them, but also design. Protherm electric boilers are boilers with increased comfort, are easy to use and maintain, and create almost no noise.

All boilers can operate from a 380 V network, and models 6K and 9K can be connected to a network voltage of both 220 V and 380 V.

This version of the SKAT v.13 boiler has a liquid crystal display for indicating temperature, operating modes and other parameters, as well as displaying fault codes.

| Boiler | Heating elements, kW | Individual power stages, kW | |||||||||||

| Protherm 6K | 3+3 | 1 | 2 | 3 | 4 | 5 | 6 | ||||||

| Protherm 9K | 6+3 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |||

| Protherm 12K | 6+6 | 2 | 4 | 6 | 8 | 10 | 12 | ||||||

| Protherm 14K | 7+7 | 2,3 | 4,7 | 7 | 9,3 | 11,7 | 14 | ||||||

| Protherm 18K | 6+6+6 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | |||

| Protherm 21K | 7+7+7 | 2,3 | 4,7 | 7 | 9,3 | 11,7 | 14 | 16,3 | 18,7 | 21 | |||

| Protherm 24K | 6+6+6+6 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| Protherm 28K | 7+7+7+7 | 2,3 | 4,7 | 7 | 9,3 | 11,7 | 14 | 16,3 | 18,7 | 21 | 23,3 | 25,7 | 28 |

- Single-circuit electric boilers;

- 8 power modifications from 6.0 to 28.0 kW;

- Possibility of setting up to 4 power levels;

- Stepped power switching with a time delay to protect against sudden power surges in the network;

- Overvoltage control;

- Possibility of working with weather-dependent automation;

- Pump run-out;

- Possibility of cascade connection of boilers;

- Built-in 10-liter expansion tank;

- Built-in circulation pump with automatic air vent;

- Possibility of working in a 220V network (models 6K and 9K).

Specifications:

Electrical voltage 3 x 230 V / 400 V, 50 Hz., 220 V (only Skat 6K and Skat 9K); Maximum operating pressure - 3 atm; Minimum operating pressure - 0.8 atm; Recommended operating pressure - 1-2 atm.; Efficiency 99.5% Maximum operating coolant temperature - 85ºC; The maximum pressure of the circulation pump is 50 kPa; Degree el. protection IP 40; Supply/return connection - ¾", drain - ½"

Documentation

The price of the product is indicated at a discount

The manufacturing company reserves the right to change the configuration and place of production of the product without notifying dealers!

The information provided is not a public offer

Advantages

The Proterm electric boiler has a number of positive features that distinguish it from devices from other manufacturers:

- High quality components and good assembly.

- Reliable and durable design.

- A wide range with different power options for units for any room.

- Reliable security system.

- High efficiency (up to 99%).

- The ability to be equipped with additional modules, acquiring new options and the ability to perform new tasks.

- The manufacturer has a good reputation among Russian users.

The Protherm electric boiler also has some negative properties:

- Quite a high price (starts from 35,000 rubles).*

- Antifreeze liquid is prohibited for use as a heating system filler.

- The device does not include a compact thermostat for use in a room.

- Despite the wide range of models, there is no factory modification that would provide for heating water for household purposes using a boiler method.

Technical characteristics of electric boilers Proterm Skat

The main products of this company are boilers of the Proterm Skat model of various capacities. They all have similar technical characteristics. Overall dimensions are: height - 74 cm, width - 41 cm, depth - 31 cm. The device operates from both three-phase and single-phase networks. The maximum permissible current in them is 50 amperes. The highest pressure in the system is up to three atmospheres, the coolant temperature is about 85 degrees.

Important! When connecting heating systems to the network, their power consumption must be taken into account and suitable wires must be used. This will protect them from melting and burning out, increasing their service life and ensuring safety.

Advantages and disadvantages

Advantages:

- single-circuit models are simple and do not have unnecessary additions. This increases their reliability and durability;

- wide choice of parameters. There are power options that are optimally suited for a given room;

- high efficiency of units (99.5%);

- during operation, the equipment does not make any sounds and does not disturb the peace of the residents of the house;

- regulation and setting of room temperature are accurate and stable;

- there are models capable of operating from both three-phase and single-phase power supply networks (power 6 and 9 kW);

- installation is possible without the involvement of specialists.

Flaws:

- excessively high cost;

- high energy consumption;

- boilers create a load on the power supply system.

The disadvantages of the units are not considered critical. This confirms the constantly growing demand for all models of Protherm Skat electric boilers.

Construction of electric boilers

The Skat boiler is equipped with all the necessary modules to ensure a complete heating process:

- Cylindrical heat exchanger made of copper.

- Also copper heating elements. Their power is different to create a multi-stage heating system.

- Expansion tank, volume 7 liters. Performs the function of compensating for the expansion of coolant in the system.

- To carry out forced circulation of coolant in the system, the design has a special pump with three speeds.

- The air accumulated in the system is automatically removed through a special air vent.

- The hydraulic group also has a pressure relief valve to maintain a maximum pressure of 3 atmospheres.

- Thermostat.

- A group of sensors that protect the device from freezing, overheating, and blocking the circulation pump.

Main models

The Skat model range is quite wide due to the different boiler capacities. Such a spread is necessary to fully meet the heating needs of any premises: from small rooms to large industrial premises.

Wall-mounted options are mainly single-circuit devices (but there are also double-circuit ones with the possibility of supplying hot water), created for heating apartments and residential buildings. They are simple and easy to use and install.

Important! Power ranges from 6 to 24 kW. Wall mounting eliminates the need to equip an additional room for a heating system.

Scat 6 kW

A boiler with a production capacity of 6 kW, with proper configuration and a well-thought-out heating system, is capable of heating a house with an area of up to 60 square meters. The power is divided between two blocks of heating elements of 3 kW each. The multi-stage adjustment step is 1 kW. The mass of the modification is 34 kilograms. This makes it possible to install the boiler directly on the wall. Operating voltage 220 or 380 V (works from three-phase and single-phase networks). The equipment has its own simple software, which makes it possible to independently regulate the heating of the coolant.

Electric boiler skat 9 kW

In terms of power supply, this model is also universal: it can be powered from a single-phase network with a voltage of 220 V or from a three-phase network of 380 V. The power of 9 kW between two blocks of heating elements is not divided into equal parts: one of them is 6 kW, the second takes on the remaining 3 kW .

In proportion to the power, the possible area for heating also increases - for this modification it is already 90 square meters. A display is installed on the boiler panel. Which displays basic data about the system and the condition of the coolant.

12 kW

This option operates exclusively on power from a three-phase 380 V network and has two separate blocks of heating elements, each 6 kW.

This boiler provides heating for a home up to 120 square meters. Despite its fairly high power, it is a wall-mounted model.

24 kW

Power mode - from a network with a voltage of 380 V. Heating is provided by four blocks of heating elements of 6 kW each. The largest heating area is 240 square meters. Equipped with a display on the front panel, which displays detailed data on the status of the heating system and the environment. The boiler is also equipped with sensitive step-by-step power adjustment. This allows you not only to select the appropriate temperature regime, but also to ensure significant energy savings.

It is possible to connect an additional circuit for heating DHW to devices of any power and model. For equipment of any modification, the manufacturer provides a warranty period of one year.

Important! To save money on electricity bills, it is recommended to purchase two electric meters for night and day tariffs (if separate payment is provided)

Post navigation

But, given the fact that the average price per kilowatt in Russia is 4.5 rubles, the heating season lasts seven months, the amount will be substantial. The control panel is equipped with a function for storing parameters and adjusting the boiler power.

Liquid fuel. In this case, a gas double-circuit boiler is a more preferable option, since water heating for hot water supply and heating occurs in one device, and connecting additional devices is not required.

The cable cross-section, the power of circuit breakers and RCDs must be selected taking into account the power of the boiler and circulation pump. Operating instructions for Proterm electric boilers Using an electric Proterm heating boiler to heat rooms for various purposes is not so difficult, because the regulation and control system for an electric boiler is quite simple.

There are four heating elements in the heat exchanger with a power of 7 kW each. Automation allows the use of an electric boiler in conjunction with a load relay.

Instructions for PROTHERM Skat

A very high efficiency indicator indicates the rational use of thermal energy and the elimination of heat loss. This is how the Protherm Skat 14K electric boiler impressed me in practice. If you need to stop the operation of the Protherm boiler for a long time, you need to disconnect it from the power supply and turn off the taps. Experts recommend using a voltage stabilizer to ensure normal operating conditions for the Protherm Skat boiler.

Many people note the perfectly designed design of the boiler, which fits well into any room interior. To heat a specific room, an electric boiler is selected primarily based on power. In addition, an NTS temperature sensor is installed on the heating circuit line, as well as an emergency sensor that protects the unit from overheating.

Advantages and disadvantages of electric boilers Protherm Skat

So what to do if gas is not supplied to the site in the foreseeable future? To do this, it is enough to change the switching scheme. Electric boilers are superior to both solid and liquid fuels in terms of comfort. Starting the heating system. Do-it-yourself heating (ch6)

Connection and operation instructions

When installing and connecting equipment, you must use protective equipment and follow safety regulations. When choosing an installation location, pay attention to:

- For the dryness of a specific place and the room as a whole.

- Structures that could easily catch fire should be kept away.

- Devices must not be installed in such a way that they interfere with access to emergency exits.

- Large household electrical appliances cannot be located nearby. This is especially true for air conditioners.

- Installation is strictly prohibited where there is a possibility of water and other liquids getting into the boiler.

You must also follow the rules:

- To protect the boiler and users, grounding must be done.

- It is necessary to take into account the weight of the equipment and select appropriate fastenings when installing wall structures.

- When installing additional modules, you must strictly follow the attached instructions.

- When installing the wiring on the electrical panel, separate circuit breakers are installed to power the boiler.

- Heating pipes must be laid so that there are no distortions.

User reviews about electric boilers Proterm Skat

Oleg, 41 years old: “Before purchasing the dacha, we didn’t think that we would appear on it so often and in winter too. Since there are severe frosts in winter, it was decided to purchase a boiler for heating there. There is no gas main there, and installing gas or solid fuel boilers in a small dacha area is not very convenient. The solution was an electric boiler of the Proterm brand. It took a lot of money, but it was worth it. It has been working for several years, properly heating the home. There have never been any breakdowns or leaks. It is very simple and convenient to operate. The only downside is the high electricity bills.”

Roman, 30 years old: “When choosing a boiler, the first thought was to purchase any domestic gas model, but still settled on the Proterm electric boiler. In terms of efficiency, it still loses to gas equipment, and the bills for paying for electricity turn out to be very, very impressive. There is nothing to complain about in the operation of the boiler itself: it performs its functions properly, operating without leaks or breakdowns. But still, if it is possible to purchase a gas appliance, then it is better to choose it to save money in the future.”

Important! The Proterm electric boiler is high-quality, but expensive equipment. Before purchasing, you should definitely calculate all possible options, calculating their cost and paying for the energy or gas consumed.

If there is no possibility of connecting to the gas network, and solid fuel heating is not available, then an electric boiler becomes an alternative way to provide heat to the house. This article will introduce readers to Proterm Skat electric boilers, and also provide instructions on how to start them up.

Assembly elements, installation and connection of the Skat Protherm electric boiler

Boiler components Skat Protherm

Manufacturer – Wilo Power supply – 230V/50 Hz Number of speed stages – 2 1st stage, rpm – 2500 2nd stage, rpm – 2600

Before filling and putting the Proterm Skat electric boiler into operation, you must perform the following steps:

– Loosen the pump air valve cap.

– Loosen and unscrew the rotor shaft cap and use a flat-head screwdriver to rotate the shaft.

– If quite noticeable resistance is felt when rotating the shaft, it is necessary to dismantle the motor part of the pump.

– After this, clean the entire pump stator or rotor of any dirt.

Before removing the Wilo pump, make sure that the following conditions have been met:

– The water temperature in the boiler unit has reached a safe value (40°C).

– The boiler has been switched off via the main switch.

– The heating water inlets and outlets were closed.

– The remaining water in the boiler was drained.

Wilo pump dismantling work:

– Disconnect the connecting cable connecting the pump to the control board.

– Remove the heating water pipe leading from the pump to the heat exchanger.

– Disconnect the pipe leading to the expansion tank.

– Pull out the safety clip.

– Loosen and unscrew the pump safety screws located at the bottom of the boiler.

– Turn the pump slightly clockwise and remove it.

If the maximum permissible pressure value in the Proterm Skat boiler is exceeded, excess water will be drained through the safety valve. The valve response pressure is 3 bar. The outlet of the safety valve must be equipped with a suitable drain.

If it is necessary to remove the safety valve, do the following:

– Wait until the water has cooled to a temperature of approximately 40 °C.

– Disconnect the Skat Protherm boiler from the electrical network.

– Close all valves located under the boiler system.

– Disconnect the drain pipe from the safety valve.

– Release the water from the boiler system using the drain valve.

– Remove the safety valve retaining clip.

Heating water temperature sensors

Temperature sensors - If replacement is necessary, remove the sensor together with the retainer and pull out both two connectors.

Emergency thermostat - 100 °C causes the boiler to stop working - error code F20 (unlock manually). The emergency thermostat of the heating circuit is located at the water outlet from the boiler heat exchanger.

To replace it, unscrew the screws located on the thermostat holder, remove the thermostat along with the holder and disconnect both connectors.

The pressure sensor is used to determine the water pressure in the boiler (heating system). If there is a lack of heating agent in the boiler, the pressure sensor will transmit information to the control board, which will give a command to stop it.

As the water pressure increases, the volume of the membrane carrying the magnet will increase. Opposite the magnet there is a Gall sensor, which changes the incoming voltage on the Proterm Skat boiler control board depending on changes in the magnetic field parameters. The change in the magnetic field parameters depends on the change in the distance of the Gall sensor relative to the position of the magnet.

Before removing the pressure sensor, it is necessary to close the heating water supply and then drain the water from the unit using the drain valve. Pull slightly to remove the pressure sensor connector. Using a flathead screwdriver, remove the pressure sensor safety clamp. Remove the pressure sensor by pulling it towards you.

Dismantling the heating water circuit heat exchanger

Heat exchanger dismantling work:

– Remove the front cover, side panels and top cover of the boiler unit.

– Disconnect the wires of the heating elements from the control board of the Skat Protherm electric boiler and the terminal box and disconnect the grounding conductor.

– Disconnect the heating water supply pipe at the bottom of the heat exchanger.

– Remove the heating water drain pipe at the top of the heat exchanger.

– Loosen and then unscrew the bolts located at the top.

– Pull up slightly and remove the heat exchanger from the boiler.

Removing the heating coils

Dismantling operations:

– Remove the front panel of the boiler and its top or bottom cover (depending on which element needs to be replaced).

– Disconnect the appropriate heating element wires from the control board and terminal block, as well as the grounding conductor.

– Using a wrench of appropriate size, unscrew the heating element from the heat exchanger housing in a counterclockwise direction.

Expansion tank

The expansion tank serves to equalize the pressure of heating water, the volume of which increases when heated. The expansion tank of the Proterm Skat electric boiler is designed for a maximum amount of water in the heating system - 90 liters (at a temperature of 75 °C). The expansion tank is located at the rear of the unit.

Before filling the heating system with water, check the pressure in the expansion tank. The initial pressure in it should be 0.2 bar greater than the static height of the water column in the heating system.

Fill the heating system with water. The filling pressure should be 0.2 - 0.3 bar higher than the water pressure in the expansion tank. The water pressure when filling the system is checked using a pressure gauge on the water supply side, in a cold state and after removing air from the system.

The valve for filling the expansion tank is located in its upper part. If water flows out of the expansion tank fill valve, this means that its membrane is damaged. In this case, the expansion tank must be replaced.

Work on removing the expansion tank:

– Loosen and unscrew the screws located on the top of the boiler frame.

– Loosen and unscrew the nut of the inlet pipe leading to the expansion tank.

– Pull upward to remove the expansion tank.

– When reinstalling, new gaskets must be provided.

Recommendations for installing the Skat Protherm boiler

Skat Protherm electric boilers do not have their own bypass, so it is recommended to install it directly in heating systems.

The boiler connection terminals must not be subject to loads from the heating system pipes. To do this, it is necessary to accurately observe the dimensions of the ends of all connected pipes, both in terms of height and relative to the distances from the wall and the relative position of the individual inputs and outputs in relation to each other.

It is recommended to connect the electric boiler to the heating system in such a way that, if it is necessary to repair the boiler, heating water can only be discharged from it. During reconstruction, unfavorable layout, etc. The boiler can be connected to the heating system using flexible hoses intended exclusively for this purpose.

Electric boilers Proterm Skat

This single-circuit equipment is made in a wall-mounted version. It is possible to connect a water heater. Most models require a three-phase connection to the network , but models with a power of 6 kW and 9 kW can operate from a 220 V network. The required level of hot water and heating temperature is selected using a display, which, by adjusting, helps control the operation of the equipment. Control is also carried out using a thermostat or outside temperature sensor.

To create a specific level of heat, the parameters are adjusted individually. Electricity supply is controlled remotely from the tariff meter. For domestic needs, you can install 24 kW and 28 kW units in a cascade.

Protherm Skat has:

- two-way pump;

- expansion tank;

- safety valve;

- automatic air valve.

The Protherm boiler can also be connected via a voltage stabilizer. An electric boiler in operation is characterized by a slow start , that is, within two minutes it “accelerates” and its power is minimal. The heating elements are protected from overload, their operation is uniform, this is achieved by being able to adjust the rhythm (1.2 or 2.3 kW).

Electric boilers Protherm Skat are distinguished by their low weight (only 34 kg) and convenient dimensions, making it possible to install them in almost any area. The operation of the boiler is reliably protected by several functions:

- protection against pump blocking;

- a pressure sensor that monitors the water pressure level;

- frost protection;

- protection against valve blocking and water heater freezing (when connecting a boiler).

If errors occur in the operation of the boiler, automatic diagnostics occurs, ending with the results being displayed in the form of a code. The decoding of the codes is given in the product operating instructions.

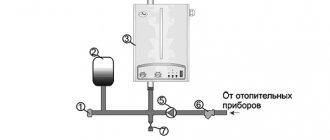

Connecting an electric boiler to a heating system

Wall-mounted mini-boiler rooms with a built-in expansion tank, pump and safety group are operated in closed heating systems with forced circulation, operating under pressure. The connection is extremely simple and does not require display in the form of a diagram: the supply and return pipelines are connected to the corresponding pipes of the electric boiler.

Note. The automation of such heat generators monitors the pressure in the heating network using a sensor. If the coolant pressure is below the set threshold (usually 1 Bar), the device will not turn on.

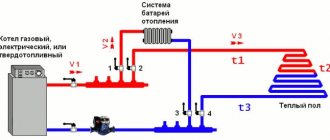

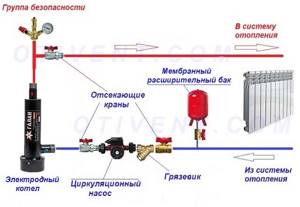

Next, we would like to present typical diagrams for connecting electric boilers to heating systems for the following cases:

- when you need to install a unit that is not equipped with its own pump and expansion tank;

- parallel operation in tandem with a solid fuel or gas boiler;

- piping with buffer tank;

- connecting the dual-circuit version of the unit to the heating and hot water mains;

- connection to an indirect heating boiler.

The first diagram illustrates the connection of an electrode or induction boiler to a closed-type heating network with a membrane expansion tank. A safety group is installed on the direct outlet section of the supply pipe, followed by a shut-off ball valve. The pump and filter - sump filter are equally well placed on the supply or return side.

Note. This and subsequent diagrams do not conventionally show the make-up pipeline. It should be inserted into the heating return line.

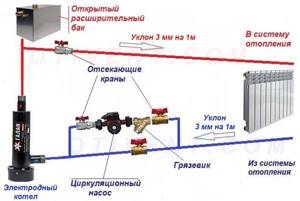

The heating element version of the electric boiler, which is not equipped with an expansion tank, safety group and pump, is connected in a similar way. If it is necessary to organize a connection to an open-type gravity (gravity) heating system, then the pipelines are laid with a slope of 3 mm per linear meter, and the circulation pump is mounted on the bypass.

The ability to work by gravity does not give the circuit a big advantage - without electricity, the boiler will still turn off

An open expansion tank is located at the top point of the network. To ensure stable gravity flow, the manufacturer of electrode boilers “Galan” recommends maintaining the height of the vertical section between the heater and the tank at 2 meters. Accordingly, the tank is placed in the attic of a private house.

Comment. Installing a wall-mounted electric boiler, whose pipes face downwards, will not allow the coolant to circulate naturally due to convection. An example is units of the Evan or Proterm brand. Heaters with side and top fittings - “Galan”, “VIN” and the like - are suitable for gravity systems.

Connection with other boilers and heat storage tank

To connect an electric heat generator together with a solid fuel boiler, use a circuit with two check valves, a surface-mounted thermostat and a room temperature controller. This connection option provides automatic “pickup” of the cooling system by the electric boiler after the firewood load burns out.

Check valves prevent the coolant from flowing into the adjacent circuit and moving in the opposite direction

The algorithm of the circuit looks like this:

- The TT boiler acts as the main one, the electrical apparatus is in standby mode.

- When a portion of firewood or coal burns, the air temperature in the building begins to decrease. When cooling reaches a user-set threshold, the room thermostat turns on the electric heater.

- An overhead thermostat detects a drop in temperature in the return of a solid fuel boiler and turns off its pump.

- After loading firewood into the firebox, heating is resumed and the thermostat starts forced circulation. Using its own sensor, the electric boiler “sees” the heated coolant and does not start working until the next command from the thermostat. The expert explains the operating principle in more detail in the following video:

Note. The piping method is also suitable for other types of boilers - gas, diesel, and so on. Please note one nuance: the electric heater is used here as a backup heat source.

Connecting to a buffer tank, shown in the next diagram, also allows you to combine several heat sources and accumulate a sufficient amount of energy in the tank. The heat accumulator is very useful in a situation where the electric heater operates at night, taking advantage of a cheap tariff. During the day, the device is inactive, and the building is heated with heat from a buffer tank.

In this scheme, you can organize the operation of the electric heater according to a schedule using a timer

The task of the mixing unit with a three-way valve is to supply the radiators with water at the required temperature, because the heat accumulator is “charged” to 80-90 °C. If the rooms have underfloor heating water circuits, a second mixing unit is made for them, preparing the coolant at a temperature of 35-45 °C (maximum - 50 °C).

Schemes with hot water supply

There are two ways to get hot water from an electric boiler for household needs:

- purchase and install a double-circuit heating unit;

- connect an indirect heating boiler to a single-circuit boiler.

In the first case, the device is connected according to the standard diagram shown in the picture. There are a minimum of difficulties here; the main thing is to correctly install the shut-off valves.

For ease of cleaning, the mud pans should be in a horizontal position.

The connection with the indirect heating boiler is carried out through a three-way switching type solenoid valve. At the command of the thermostat built into the storage tank, the element switches the coolant flow to heat water for hot water supply or heating radiators. Loading the boiler is a priority: until the tank warms up to the set temperature, the radiator network will not receive heat.

In the case of an induction or electrode unit, the immersion thermostat is connected to the contacts of the thermal relay

Important point. For this reason, the selection of heat generator power plays an important role. If it is not enough, the heating of the tank will take a long time, and the room air will have time to cool down. For more information about how the system works, watch the training video.

Although the plot talks about connecting a storage water heater to a wall-mounted gas boiler, the essence does not change - an electric heater is connected in the same way.

Advantages and disadvantages of electric boilers Protherm Skat

Proterm Skat has a number of advantages over other types of heating:

- does not produce harmful emissions into the atmosphere, since it has no combustion products , so this type of heating can be called environmentally friendly;

- An electric boiler is an affordable type of heating. It is used where it is not possible to connect to mains gas or can become an alternative form of heating;

- does not require systematic maintenance, unlike, for example, gas or solid fuel models;

- silent operation;

- there is a heat level regulator;

- able to adapt to domestic water of poor quality;

- resistant to voltage surges;

- equipped with several types of protection.

Along with the advantages, there are some disadvantages:

- electric boiler Protherm Skat needs to be connected through a stabilizer;

- is unable to perform its work during a power outage.

Consumer Reviews

Consumers note that Protherm Skat provided an opportunity where gas connection was problematic or completely impossible. When the power grid is stable, many people refuse to connect to gas, saving considerable amounts of money. In addition, an electric boiler is used in parallel with a gas unit, connecting them to a single heating system. This find allows you to significantly save money on resources by alternating them with each other during the heating season.

If you connect a water heater to Protherm Skat, consumers have the prospect of using hot water. Many people note the perfectly designed design of the boiler, which fits well into any room interior. It can be successfully installed in living rooms; thanks to its silent operation, it will not cause increased attention.

The disadvantages are that when using only a boiler that runs on electricity, there are no alternative heating options when it turns off. Therefore, before purchasing a Protherm electric boiler, you should make sure that there are no problems with electricity. Experts recommend using a voltage stabilizer to ensure normal operating conditions for the Protherm Skat boiler.

In addition, the increased energy consumption of an electric boiler causes negative emotions among the population, since paying bills takes a toll. If we compare the costs of gas and electric heating, the Protherm electric boiler is a little more expensive, with identical heating parameters. From the above, we can conclude that this electrical equipment is chosen by those who do not have the opportunity to connect to network gas, as well as by those who care about the environment and see it as a source of environmental consumption.

How to make grounding

Laying a grounding loop near a private house is a simple matter and very useful from the point of view of electrical safety. For installation, find 3 steel rods Ø16 mm 2 m long and a strip with a cross-section of 40 x 5 mm.

Stepping 3 m away from the wall of the building, arrange grounding according to the step-by-step instructions:

- Mark a triangle with sides of 2 m on the ground and dig a pit to a depth of 50 cm.

- Sharpen the ends of the rods with sandpaper or a grinder, install them at the vertices of the triangle and drive them into the ground to their full length.

A bunch of grounding conductors (on the left in the photo) and laying a busbar into the house (on the right) - In the pit, securely connect the protruding ends of the rods with a strip by welding.

- Make a supply bus from a strip, welding it to the circuit and securing it to the base. Grab a bolt to it, screw on the copper busbar and conduct the grounding conductor inside the house, connecting it to the metal body of the electrical panel.

Upon completion, treat the welding seams and the above-ground section of the strip with bitumen and bury the hole. For more information about the grounding device for an electric boiler and home appliances, watch the video:

How to put the Protherm Skat boiler into operation?

To start the boiler, you must follow the instructions below.

- The electric boiler is installed by a specialist in accordance with the design documentation.

- Before starting the equipment, a professional provides instructions on the principles of operation of the electric boiler.

- Before turning on the boiler, you should connect to the network , open the taps on the heating circuit and note the pressure level (1 or 2 bar).

- The display shows the settings options.

- The required temperature of the heating system, when connecting a boiler - water supply circuit, and power is set by the consumer himself.

When the pressure is low, the “bar” light starts flashing on the display. To correct the situation, add water to the system. If in this case the pressure decreases, then you need to contact a specialist.

If you need to stop the operation of the Protherm boiler for a long time, you need to disconnect it from the power supply and turn off the taps. If shutdown is necessary in winter, the system must be drained to prevent freezing.

How to care for a Protherm electric boiler? Do not use abrasives or chemicals. It is better to wipe the surface of the case with a damp cloth, and then dry the surface.

Any malfunctions are indicated on the display by an error code. The code numbers are located and deciphered in the product passport.

If serious problems occur, for example, the heat exchanger is frozen or water is dripping from it, the electric boiler must not be connected to the power supply. You need to wait for a specialist who will diagnose and carry out high-quality repairs. Replacement of parts is carried out only using original spare parts.

So, dear readers, you have become acquainted with the alternative type of heating Protherm Skat. When gas and solid fuel are out of reach or you are a stickler for cleanliness, an electric boiler can be a good help.

- Author: Maria Sukhorukikh

Rate this article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!

Installation and startup of Protherm equipment

Due to the fact that electric boilers do not require a smoke exhaust system to operate, they can be installed in almost any convenient place. The main condition is the availability of a power supply of 220 or 380 volts and the possibility of organizing grounding.

https://youtube.com/watch?v=1_SniMbfpiY

Tips for startup and maintenance:

- Only a qualified specialist should install and perform an initial check of the operation of Protherm devices. Before start-up, equipment owners must be instructed on the principles of boiler operation.

- After installing the unit in the chosen location, it is connected to the network, the taps on the heating circuit are opened and the pressure in the system is checked, which should be 1 or 2 bar.

- After the display shows the settings, you must select the required power, the temperature of the heating system and, if a boiler is connected, the temperature of the water supply circuit.

- If the “bar” light flashes on the display, it means that the pressure in the structure has decreased and you need to add water.

- When stopping equipment for a long time, it is necessary to turn off all taps and disconnect it from the network.

It should be borne in mind that if the device breaks down, parts of the Protherm boiler can only be replaced with original spare parts.

Efficient, reliable and high-tech electric boilers Proterm are well adapted to the weather conditions of the unpredictable Russian climate, therefore they are widely used for heating apartments, cottages and private houses.