Selection of the optimal heating scheme

To heat a home, the following schemes are most often used on how to install a heating boiler in a private house:

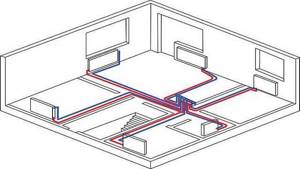

- Single-pipe. One manifold supplies all radiators. It plays the role of both supply and return, as it is laid in a closed loop next to all the batteries.

- Two-pipe. In this case, separate return and supply are used.

To choose the most optimal installation scheme for a heating boiler in a private home, it is recommended to consult a specialist. However, in any case, a two-pipe system is a more progressive solution to the question of which heating scheme is better for a private home. Although at first glance it may seem that a single-pipe system allows you to save on material, practice shows that such systems are both more expensive and more complex.

It is important to understand that inside a single-pipe system, water cools much faster: as a result, radiators further away have to be equipped with a larger number of sections. Also, the distribution manifold must have a sufficient diameter that exceeds the two-pipe distribution lines

In addition, in this scheme there is a serious difficulty in organizing automatic control due to the influence of the radiators on each other.

Small buildings such as dachas, where the number of radiators does not exceed 5, can be safely equipped with a single-pipe horizontal heating system for a private house with your own hands (it is also called “Leningradka”). If the number of batteries is increased, there will be malfunctions in its functioning. Another application of such an interchange is single-pipe vertical risers in two-story cottages. Such schemes are quite common and work without failure.

The two-pipe decoupling ensures that the coolant is delivered to all batteries at the same temperature. This allows you to avoid building up sections. The presence of supply and return pipes creates optimal conditions for the implementation of automatic control of radiators, for which thermostatic valves are used. In this case, you can take pipes of smaller diameter and simpler designs.

What are the heating schemes for a private two-pipe type house:

- Dead-end. In this case, the pipeline consists of separate branches, inside of which counter movement of the coolant is used.

- Associated two-pipe. Here the return serves as a continuation of the supply, which ensures an annular movement of the coolant inside the circuit.

- Radiation. The most expensive schemes are those where each radiator has a separately laid hidden line (in the floor) from the collector.

If, when laying horizontal pipelines of large diameter, a slope of 3-5 mm/m is used, then a gravitational method of operation of the system will be achieved, and circulation pumps may not be used. Thanks to this, complete energy independence of the system is achieved. This principle can be applied to both one-pipe and two-pipe schemes: the main thing is to create conditions for gravity circulation of the coolant.

In open heating systems, an expansion tank will be required at the highest point: this approach is mandatory when arranging gravity circuits. However, the return pipe next to the boiler can be equipped with a membrane expander, which will make the system closed, operating under overpressure conditions. This approach is considered more modern and is most often used in forced-type systems.

Warm floors deserve special mention when researching which heating scheme to choose for a private home. Such a system is quite expensive, since it requires laying several hundred meters of pipeline in a screed: this makes it possible to provide each room with a separate heating water circuit. The pipes are connected to a distribution manifold, which has a mixing unit and its own circulation pump. As a result, the rooms are heated very evenly and economically, in a manner that is comfortable for people. This type of heating can be used in various residential areas.

What can be the layout of water heating pipes?

There are two options for installing the water circuit:

- single-pipe;

- two-pipe.

Each of these types of pipe systems has its own disadvantages and advantages; they must be taken into account when deciding how to arrange heating pipes in the house.

A single-pipe system involves one pipe leaving the boiler, which sequentially passes through all the heating batteries, and only then returns back to the boiler.

This installation results in significant pipe savings, but there are also disadvantages:

- The batteries that are closer to the boiler are hotter. The latter are almost always cold. The only way out that will work here is to increase the number of radiators in the distant rooms and reduce them in those close to the boiler room.

- If bypasses are not installed during installation, then when replacing radiators you will have to turn off the heating and drain all the coolant.

In a two-pipe distribution, heating devices are connected in parallel to two pipes - one of them goes to the inlet, the other to the outlet of the cooled coolant.

There is only one drawback here - increased pipe consumption. In this case, the heating level of all radiators is the same; you can install temperature regulators on each device.

How to make plastic heating in a house to save on expensive metal pipes? It is necessary to take into account all the requirements for the quality of the pipeline, remembering that plastic has the ability to expand at high temperatures.

The types of two-pipe systems are as follows:

- Dead end - you need a few pipes, but even with a long water circuit, the last radiators will be cold. Therefore, it is advisable to make such a system with a maximum of seven radiators.

- A type of two-pipe system called the Tichelman scheme. You need a lot of pipes, but with a large number of radiators, and especially in two-story private houses, it is very effective. Many people do not like the appearance of such a system, which spoils the design of the rooms. Sometimes you have to bend the pipe around the outline of the door and install an air vent there.

- Beam (collector) type of system. Expensive installation, as you need a lot of pipes and a manifold. Separate lines (supply and return) are connected to the radiators. But the advantage is that you can control the heat transfer in each radiator.

Most water heating systems are based on bottom supply of coolant. In multi-storey private houses, top supply systems are also made, as they are more economical.

The water system requires the installation of an expansion tank, since water has the ability to change its volume depending on the temperature. There are two types of tanks: open (regular containers) and closed (membrane). Therefore, in the first case the system is called open, in the second - closed.

A simple tank is installed in the attic. It's cheap, but you have to constantly add water because it evaporates.

In order not to monitor the coolant level, you can install an automatic float device that will control the amount of coolant in the system. However, only water can act as a coolant here.

Antifreeze does not need to be added to open systems, if only for the reason that the fumes from it are often toxic.

An open type expansion tank is installed in a heating system with natural coolant circulation. The membrane tank works ideally with the forced circulation option.

Gas release

The second part of the start-up is the release of air from the pump, for which the heating regulators are brought to the operating position. The circulation pump turns on, which is accompanied by a faint hum and gurgle of water. To eliminate noise, you need to bleed air from the heating system: the cap in the center of the pump is slightly unscrewed, and when water begins to come out instead of gases, the cap is screwed back.

https://youtube.com/watch?v=taQJKUjiso8

After this, the noise will stop, the electric burner will start working, and the boiler will start working. You should also check the pressure and add more water if necessary. To set up a working system, you need to screw the batteries closest to the boiler, and start the distant ones using control valves, which are located in the water supply section to the radiators.

You also need to take care of the sewage system: during installation, you need to calculate the volume of condensate at the rate of 1 liter per 1 kW of equipment power per day.

Ventilation is located 25 cm from the ceiling with a diameter of 10 cm. Date: September 25, 2021

Advantages of pump heating

Not so long ago, almost all private houses were equipped with steam heating, which was powered by a gas boiler or a conventional wood stove. The coolant in such systems circulated inside the pipes and batteries by gravity. Only centralized heat supply systems were equipped with pumps for pumping water. After the appearance of more compact devices, they also began to be used in private housing construction.

This solution provided a number of advantages:

- The coolant circulation rate has increased. The water heated in the boilers was able to flow much faster into the radiators and heat the rooms.

- The time it takes to heat homes has been significantly reduced.

- An increase in flow rate entailed an increase in the circuit capacity. This means that smaller pipes can be used to deliver the same amount of heat to its destination. On average, the pipelines were reduced by half, which was facilitated by the forced circulation of water from an embedded pump. This made the systems cheaper and more practical.

- In this case, to lay highways, you can use a minimum slope without fear of complex and extended water heating schemes. The main thing is to choose the right pump power so that it can create optimal pressure in the circuit.

- Thanks to household circulation pumps, it has become possible to use heated floors and closed systems of high efficiency, the operation of which requires increased pressure.

- The new approach made it possible to get rid of many pipes and risers, which did not always fit harmoniously into the interior. Forced circulation opens up possibilities for laying circuits inside walls, under floors and above suspended ceiling structures.

A minimum slope of 2-3 mm per 1 m of pipeline is necessary so that in the event of repairs, the network can be drained by gravity. In classic systems with natural circulation, this figure reaches 5 or more mm/m. As for the disadvantages of forced systems, the most significant of them is the dependence on electrical energy. Therefore, in areas with unstable electricity supplies, it is necessary to use uninterruptible power supplies or an electric generator when installing a circulation pump.

You should also be prepared for an increase in bills for consumed energy (with the correct selection of the power of the unit, costs can be minimized). In addition, leading manufacturers of equipment for heating systems have developed modern modifications of circulation pumps that can operate in increased economy mode. For example, the Alpfa2 model from Grundfos automatically adjusts its performance depending on the needs of the heating system. Such equipment is quite expensive.

What it is?

An autonomous heating system involves a complete rejection of central heating.

That is, it will be necessary to dismantle the radiators and pipes related to this system. The basis of individual heating in this case will be gas or electric boilers. And to them, in turn, new pipes and batteries should be attached. The principle of operation of boilers is quite simple - they heat water and send it to circulate through the created system, thereby heating the premises in the required mode.

Features of parallel connection

Let's take a closer look at what a standard parallel connection diagram for gas and electric boilers looks like:

- Each unit has coolant supply circuits. They join the common line.

- It is imperative that there are safety groups and shut-off valves.

- The return lines, also equipped with shut-off valves, are connected to the other line.

- A circulation pump is installed on the return line (or supply), in front of the unit for combining the piping circuits.

- The lines of both heating units are connected to the collectors.

- An expansion tank is installed on one of the distribution manifolds. A make-up circuit is also connected to its pipe, equipped with a check valve and shut-off valves.

- From the distribution manifolds there are main branches to the heated floor, radiators, boiler, each with circulation pumps and valves for draining the coolant from the system.

This is not a schematic diagram, but only its main features. It gives a general idea of how best to connect an additional electric boiler to the main gas boiler. The assembly option can be complicated and improved, for example, with an automation system and a servo drive.

With a parallel connection, you can also install a hydraulic arrow and an automation unit, but before doing this, carefully consider this decision; installing them is not always advisable

Choosing a boiler

Let us repeat: the main component of any heating system, and a closed type in particular, is the boiler. In order for the installation work to be carried out successfully, it must first be selected, and correctly.

To begin with, we note that from the boiler the heated coolant moves through the pipeline to the heating devices, which, in turn, transfer thermal energy to the room.

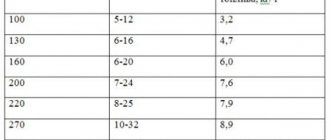

First of all, you should calculate the required power of such a boiler. To do this, it is necessary to take into account the individual characteristics of a particular building. These features include the area of the heated room, the thickness and height of the walls, the material from which they are made, and a number of other parameters.

To at least approximately calculate the required boiler power, you can use the generally accepted approximate thermal power consumption per 10 square meters - it is 1 kilowatt. Let us repeat, this is only an approximate formula, therefore, when calculating, you should use a correction factor relating to the heat loss of all enclosing structures. If the power of the heating boiler is calculated correctly, you will thereby create the most comfortable living conditions in your house/apartment during the cold season. Moreover, it will help you save significantly on electricity and reduce your heating costs.

You can find out how to calculate heating costs in an apartment here

So, let’s draw some conclusions regarding the installation of a closed-type system.

- When designing it, you must calculate the required power of the heating boiler.

- Find out what materials and in what quantities you will need.

- Determine how many radiators are needed. (for more information on calculating the number of heating radiator sections, see here)

- Take into account all the features of building structures.

- Choose the most suitable place to install heating equipment.

Creating an efficient and, most importantly, high-performance heating system requires carefully planned preparatory work.

As a conclusion

As we can see, there are many types of heating systems, and a closed heating system is perhaps the best option. Regardless of what wiring you choose or what material for the pipeline, installation must be taken with great responsibility. If you feel that you cannot cope on your own, then contact a specialist. Yes, it will cost more, but you will be protected from all possible troubles in the future.

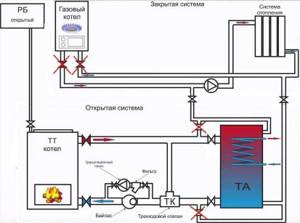

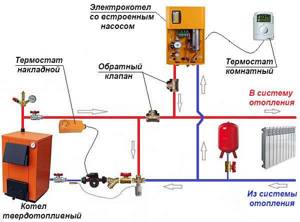

Parallel operation of wood and gas boilers

This option for heating a house from two boilers provides for their separate connection to the circulation system. Each heat source must have its own circulation pump installed at the return line inlet. There is no need to do this for a wall-mounted gas boiler; the pump is already installed by the manufacturer. If solid fuel burns out, the temperature of the coolant will decrease and the gas boiler will automatically turn on.

An important design point is the piping of the solid fuel boiler with metal pipes and the presence of an emergency discharge device with the simultaneous supply of cold water to the return line.

1 scheme (open and closed systems)

This method is convenient because the liquids of the two systems do not mix. This allows the use of different coolants.

Advantages and disadvantages

| pros | Minuses |

| Possibility to use different coolants | A large number of additional equipment |

| Safe operation, the reserve tank will release excess water in case of boiling | Efficiency is lower due to excess water in the system |

| Possibility of use without additional automation |

2 scheme, two closed systems

It uses a closed system, which eliminates the need for a heat accumulator. Control is carried out by thermostats and three-way sensors. Operational safety is ensured by automation.

Here we use the battery for excess heat. Thus, we increase the efficiency of the system and eliminate the need for temperature sensors and automation.

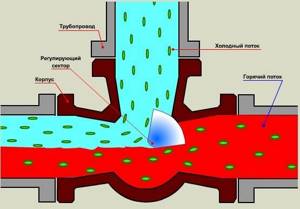

Heat supply via 3-way valve

Each boiler must be equipped with its own circulation pump, and another pump will be required to ensure circulation through the heating system devices. An automatic air vent should be installed at the top point of the hydraulic separator, and a tap for emergency drainage of water at the bottom.

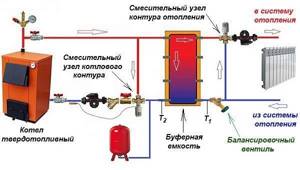

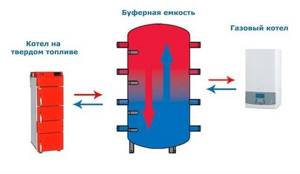

System with a heat accumulator, why is it used?

The heat generated by the wood-burning boiler enters this container. From not, through a coil, heat exchanger or without them, into a gas boiler. The automation of the second understands that the water has the required temperature and turns off the gas. This will continue as long as there is enough temperature in the heat accumulator.

A heat accumulator or a heat-insulated container with a built-in coil, designed to accumulate heated coolant and supply it to the heating system. In this scheme, the gas boiler, heating devices and battery are connected by pipelines into one closed system. The solid fuel boiler is connected to the built-in battery coil and thus heats the coolant in a closed system. The organization of heating operation in this scheme occurs in the following order:

- In a solid fuel boiler, wood burns and the coolant is heated from the coil in the container;

- solid fuel has burned out, the coolant has cooled;

- the gas boiler turns on automatically;

- the firewood is laid again and the solid fuel boiler is ignited;

- The temperature of the water in the battery rises to the same temperature as that set on the gas boiler, which stops automatically.

This scheme requires the greatest costs for the purchase of materials and equipment, but has a number of advantages:

- the solid fuel boiler can operate in an open circuit;

- highest level of security;

- no need to constantly replenish the firebox with wood or coal;

- coolant circulation through a closed system;

- the possibility of simultaneous operation of two boilers simultaneously and each separately.

Additional costs include the purchase of an accumulator tank with a coil, two expansion tanks and an additional circulation pump.

calculate the required volume of container

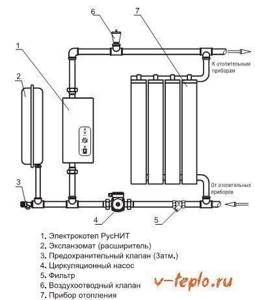

Connection diagram of an electric boiler to the network

Before connecting an electric heating boiler, please note that the electric boiler must be connected to the network using copper wiring. The cross-section of the wire must be no smaller than that specified in the document that came with the device. Electrical connections of the external type device must be made through special cable terminals. These pins should be located in the lower left corner. There should also be a brass grounding terminal with an M6 bolt.

Power cable connection diagram

When inserting an electric boiler into the heating system and installing grounding, you need to ensure that good and reliable contact is ensured between the metal body of the device and the brass bolt. Before connecting the bolt to the frame of the device, you need to thoroughly clean the connection area.

If electric heating is planned to be organized for a building with a large area, then when purchasing equipment you need to choose one that provides the possibility of installing a cascade. In order for the devices to operate normally in a cascade, the terminals of the control device must be connected to the unit that is being controlled. If the system installation is controlled using a room-type regulator, then the control contacts must be connected to the terminals of the control device.

Diagram of the electrical heating system of a two-story house

The device must be inspected visually and make sure that it is in the correct position, the water pressure in the system is normal, and all communications are connected. All this is defined in the unit documentation.

After this, the installation diagram for an electric heating boiler involves the following steps:

- It is necessary to check the serviceability of the pipeline fittings located in front of the unit. To do this, you need to switch it from the “closed” to “open” position, and vice versa.

- All pipeline fittings of the electric heat generator are moved to the “closed” position. It is also necessary to move the pipeline fittings of the water supply and heating systems to this position.

- On those pipelines that supply cold water to the unit, you need to open the shut-off valves. If you use an electric heating system, it is not recommended to use antifreeze liquids for it. This is because they have properties that can affect the operation of equipment in a negative way. Antifreeze fluids have a composition that can cause aging or rapid wear of rubber components.

- It is necessary to install a sump filter or filter before entering the unit on the return pipeline. You can install both of these elements.

- After the heating system is completely filled with water, you need to check how tight it is.

When the installation of an electric boiler with heating radiators is completed, you need to check how efficient the system sensors are. These include sensors such as: temperature controller, water pressure sensor, signal and control components of the unit, emergency temperature sensor.

During repairs to the heating unit or during unfavorable installation conditions, an electric heating unit can be connected using rubber hoses.

For the heating system it is necessary to use water with a minimum hardness level. Then the service life of the heating elements can be significantly extended.

Homemade electrode boiler: manufacturing features

Electric boiler diagram.

Most often, in order to make a homemade electric heating boiler, an electrode boiler circuit is chosen.

The design feature involves the use of a large diameter pipeline; it depends on the size of the heating element you choose. As an option, a scheme with a removable pipe can be used. Although this design is more complex to manufacture, it allows you to make the equipment universal and, if it is necessary to replace or repair the heating element, do it quickly and simply, without dismantling the heating system.

Advantages of an electric boiler:

- the main argument for installing such equipment is that electricity is the most affordable source of energy, which cannot be said about gas or, for example, wood;

- its work is easy to control and automate;

- there is no noise during operation;

- there is no need to install and maintain the chimney;

- simpler registration compared to registration of gas equipment;

- the use of temperature regulators does not allow the boiler to overheat;

- affordable price;

- small overall dimensions;

- high level of reliability and the ability to work around the clock.

Electrode boiler diagram.

Usually they take a heating element whose power does not exceed 5 kW, but here it all depends on what area you plan to heat. The heating element usually operates from a 220 V network, so there are no difficulties with its connection.

When choosing the shape of the housing for the heating element, there are no special requirements; it can be of any shape. Its size should not be very large, otherwise the heat exchange between hot water and air will take place in the boiler itself, and not in the heating radiators.

You need to know that as the heating chamber increases, the efficiency of the equipment will decrease. Depending on the chosen design, the heating element can be installed directly into the pipe; in this case, the boiler is simply absent. Do not forget to provide for the possibility of simple and affordable replacement of the heating element.

In order to set the temperature, the heating system uses a potentiometer, which is installed near the thermostat or in another convenient place in the heating main. In the case when the temperature at the boiler outlet is low, it is necessary to reduce the speed of the circulation pump.

Pipes

What pipes can be used to connect the boiler to the heating system?

Forced circulation

Typical parameters for a circuit with a circulation pump are:

| Parameter | Meaning |

| Pressure | 1-2.5 kgf/cm2 |

| Supply temperature | 70-75С |

| Return temperature | 50-55С |

Autonomous heating operates in a pipe-friendly mode. In the photo, the electric boiler maintains a supply temperature of +65 ºС.

In normal mode, these parameters cannot be exceeded at any point on the circuit. What happens when the pump stops?

- Gas, electric, diesel boilers : the thermostat will turn off the heating and keep the circuit parameters within acceptable and safe limits;

- Solid fuel boiler : the thermostat will close the damper, but the fuel will continue to smolder for some time. The temperature of the water leaving the boiler heat exchanger will increase noticeably.

A solid fuel boiler is a device with high inertia. With the vent closed, it will heat the coolant for another 15-30 minutes.

That's why:

- For boilers of the first three types, you can safely use any plastic and metal-plastic pipes with an operating temperature of 80C and above declared by the manufacturer;

- At least the first 1-2 meters of the pipeline from the nozzles of the solid fuel boiler (or, better yet, all the spills) must be laid with metal pipes - steel, stainless or copper.

The section between the heat exchanger of the solid fuel boiler and the three-way valve is mounted with a steel pipe. The rest of the filling is polypropylene.

Natural circulation

In a gravity system, the coolant moves much more slowly than in a forced circulation circuit. When kindling, the hydraulic resistance of the entire circuit will prevent the start of circulation, and the water temperature at the outlet of the heating boiler can reach 90 degrees or more.

That is why the section of the circuit connecting the boiler and the expansion tank (what it is - I will explain a little later) is laid only with metal pipes. For all types of plastic, temperatures above 90 ºС are abnormal conditions.

The consequences of operating pipes in this mode are predictable:

- Multiple reduction in resource (from 25-50 years to several weeks, or even hours);

- Softening of plastic shells and the appearance of leaks (at temperatures above 130 ºС).

Rupture of a reinforced polypropylene pipe due to overheating.

When installing the circuit yourself, please note that in a gravity system, the internal diameter of the filling should not be less than 32 mm. A large pipe cross-section means minimal hydraulic resistance. Don't forget: gravity heating operates with minimal hydraulic pressure.

Carrying out installation work

Every homeowner wonders how to properly heat the house. Do-it-yourself installation of a heating system in a private house is carried out in several stages:

First, they arrange the room where the boiler will be installed. The interior decoration of this part of the house should be made of fire-resistant materials. You should also ensure good ventilation. When installing the boiler, remember that the equipment should not stand tightly on the floor, press against the wall or reach the ceiling. All measurements must maintain a slight indentation

In addition, it is important to ensure free access to the boiler. After installing the boiler, you can connect a circulation pump to the system or install a collector. The actions depend on the type of heating system selected. Next, the necessary control sensors and metering devices are mounted and secured, as well as elements that allow regulating the operation of the entire system or a specific section of it. At the next stage, installation of main pipelines is carried out

To fix the pipe elements, holes are made in the walls using a hammer drill. During the work, you should adhere to the basic rule for installing a heating system: for each linear meter, make a slope of 5 mm. Neglecting this rule can reduce the efficiency of the entire heating system, so you need to approach this stage responsibly. The completion of installation work can be called the installation of radiators. To fix them on the wall, make marks with a pencil or marker and use a puncher to punch holes into which the brackets are inserted. When making markings, adhere to the following: the distance from the floor to the lower level of the radiator should be 10 cm, from the wall to the rear surface - 2 cm, from the window sill - 10 cm. The inlet and outlet of each radiator is equipped with a valve for easier replacement or repair. After installing all system elements, a check is performed. When installing a gas boiler, the presence of a gas service representative is required.

From all of the above, we can conclude that installing heating systems in a private house is not a complicated process, which allows you to do most of the work yourself. The main condition is compliance with the rules and leisurely installation. However, this is possible if you have a lot of free time. If the time frame for completing installation work is short, then you can entrust some stages to specialists. In some situations, this can save both time and money.

In order for the heating system to function flawlessly for a sufficiently long period of time, it is necessary to purchase only high quality materials. By purchasing high-quality radiators, you can achieve maximum efficiency of the heating system and reduce fuel costs.

How best to connect a gas boiler - choosing a circuit

There are several boiler connection schemes: the connection may also include a DHW circuit for heating hot water. In the simplest version of installing a gas heating boiler, a dead-end circuit is used. This connection diagram for a floor-standing gas boiler is also suitable for wall-mounted models, providing for switching heating devices between spills. The disadvantage of this option is the unevenness of the temperature regime in different parts of the circuit: nearby radiators will always be hotter than distant ones due to the passage of the main volume of coolant through them. The problem can be solved by balancing (throttling) the connections of the batteries closest to the boiler.

In the schematic diagram for connecting a double-circuit gas boiler, domestic hot water is prepared in a separate heat exchanger. In general, DHW is implemented very simply: cold water is supplied inside the heat exchanger.

The diagram on how to properly connect a double-circuit gas boiler is much more interesting:

- Circulation inside the small circuit is ensured by a pump built into the boiler, which closes the heat exchanger and the hydraulic valve.

- Behind the hydraulic valve there is a manifold wiring for 6 autonomous circuits: 2 for standard sectional radiators, and 4 for a heated floor system. Each pair of underfloor heating combs is able to provide 2 circuits.

- It is imperative to synchronize circuits with different temperature conditions. For this purpose, the movement of the coolant through the tubes of the water heated floor is used.

- Connecting a gas heating system is only possible after obtaining the appropriate permit.

To organize DHW in a private home, a separate heater is often used, since connecting a single-circuit gas boiler is much easier. The preparation of hot water here takes place in an indirect heating boiler, with further partial transfer of energy from the coolant to the heat exchanger. To make it possible to organize a heated floor system, a connection diagram for a single-circuit gas boiler with a three-way valve and recirculation is provided here. In summer, water is supplied only through the boiler and boiler.

After the heater stops, water circulation between the heat accumulator and the heating radiators continues. The temperature control of the batteries here is also ensured by a three-way tap and a thermostat. For these purposes, a certain volume of water or antifreeze from the return line is circulated again.

Results

As a conclusion, we can say that the connection diagram for a gas boiler in a private house largely depends on the method of circulation of the coolant inside the heating system. The simplest in terms of organization are single-circuit gravity schemes, where the coolant moves by gravity due to the creation of the necessary slope of the pipes. However, forced systems that include a circulation pump are considered more effective: it ensures more intensive movement of the heated coolant through the pipes. The presence of excess internal pressure in closed circuits requires the mandatory use of additional control devices and safety valves.

DIY installation and connection

Before you begin installing the equipment, you need to familiarize yourself with its design features. As a rule, these are wall-mounted single-circuit models that do not have a separate tank to provide hot water supply. In such cases, a flow-through or capacitive-type water heater is additionally installed.

You should read the documentation supplied with the equipment in detail and take into account a number of general rules:

- The equipment must be located in an accessible area, with space on the sides for maintenance or repairs.

- Before installing attachments, make sure that the wall surface can withstand the load being applied.

- The work must be carried out primarily by a specialist. If this is not possible, he must inspect the assembled system before putting it into operation.

Installation introductory video

Main working steps

Installation of electric boilers is much simpler than those using traditional energy sources. There is no need to store solid or liquid fuel, install a chimney, etc.

The work is divided into the following stages:

- First, the boiler is hung on a wall surface or installed on a designated area (for wall-mounted and floor-mounted equipment, respectively)

- It is necessary to make sure that the installation is located in the desired place without distortion

- Reliable grounding is being considered

- The boiler and heating system are connected

- Commissioning works

The installations offered on the market are not always equipped with a boiler and circulation pump. In this case, they are installed separately at the stage of connecting the heating system.

Commissioning work means the following operations: testing in various modes, removing air trapped in the system, checking tightness, checking grounding, etc.

Other installation features

Despite the simplicity of the work performed, the installation of electric boilers for heating a house has its own characteristics. To ensure that the equipment does not cause trouble, certain rules must be taken into account:

- The installation location must be selected in such a way that access to the equipment is always free

- The surrounding surfaces must be made of non-combustible material and can withstand the applied load.

The only fundamental difference between wall-mounted and floor-mounted equipment is the installation location. Connection and connection to pipelines occurs in exactly the same way.

Main stages of boiler installation

In order to install a heating system based on the use of a solid fuel boiler, you will need the heating unit itself, pipes and heating radiators, an expansion tank, a circulation pump, a heat accumulator, and components of the automatic boiler control system.

The latter include:

- safety valve;

- air valve;

- pressure gauge;

- Temperature regulator.

All manipulations associated with the installation of a solid fuel boiler and the connection of peripheral systems and devices are carried out in accordance with a strict step-by-step algorithm. So, on the eve of installing the boiler, a specialized foundation is erected at the site of its planned location.

In this case, it is imperative to maintain all the required dimensions of the indents and correctly position the body of the heating unit both vertically and horizontally.

Next, electric heating elements are installed if they are included in the boiler package. As a rule, solid fuel boilers are equipped with mounts for mounting heating elements, next to which a temperature regulator is installed.

The next stage involves installation and connection of heating system pipes

It is important to close all connections using intermediate shut-off valves, and seal the butt joints with plumbing tape or material consisting of flax fibers. This will make it easier to access for future repairs.

Installation of thermal communications is done so that during operation of the heating system it is possible to easily carry out maintenance and repair work

In the case when the heating system involves the use of connections to the home’s electrical network, at this stage it is necessary to make all the necessary wire connections, their insulation and grounding.

Next, the security group is installed. Its configuration depends on the model of the solid fuel boiler, but, as a rule, it consists of: a safety valve, an air valve, a temperature regulator, a draft sensor, a pressure gauge and other devices. All these devices are installed before all locking devices.

The next step will be the installation of the chimney pipe. At the junction points of the smoke exhaust system elements, sealing is carried out with a sealing substance that is resistant to high temperatures.

The installation method, the height of the chimney duct, as well as the cross-sectional area are calculated in such a way as to further ensure the process of natural draft at the proper level. And to do this, you must strictly follow all the instructions in the operating instructions for the boiler model being installed.

Next, the thermal circuit of the solid fuel boiler is filled with water. At first, the water pressure level should be slightly higher than the working one. This stage involves testing the system for leaks.

Then you need to check all the internal elements of the solid fuel boiler firebox: plugs for cleaning, ignition valve, fireclay stones, grate bars, etc.

And finally, you should release the pressure in the boiler to operating values, put the dampers in the firebox and in the chimney in the position prescribed in the instructions, and put solid fuel into the boiler.

Having completed all the above manipulations, you can proceed to starting the heating system based on the use of a solid fuel boiler

To start the heating process, simply load fuel into the boiler and set it on fire. Then, after 10-15 minutes, you need to tightly close the kindling damper.

After the temperature is established at 80-85 degrees, you will need to set the temperature controller to the desired heat supply mode. Subsequently, you will simply need to supply the boiler with solid fuel if necessary.

How to connect 2 boilers in the system?

You can’t just randomly connect 2 devices, the system will either not work or will work incorrectly. It is necessary to use carefully designed and competently designed ones from an engineering point of view.

There are two main connection schemes, these are:

- Sequential, when all elements are connected to each other without additional nodes. In this case, one device will heat the coolant, and the second will reheat it;

- Parallel, in which the devices included in the circuit have 2 connection points and the boilers operate independently of each other.

The sequential system is more suitable for low-power boiler installations and is rarely used.

Serial connection is considered impractical, if only because it is impossible to remove one boiler without affecting the second. In fact, the problem is solved by installing bypasses and shut-off valves, but still parallel connection is preferable

Meanwhile, parallel connection in a single system of gas and electric boilers has many advantages. Therefore, it is used most often, despite the fact that this arrangement requires more materials and is considered more expensive.

In such a device, you can turn off one of the devices at any time and even remove it for replacement or repair, while the second one will continue to operate as normal.