Many people still perceive the induction electric heating boiler as an innovative product that should help significantly save your money.

However, by and large, this is an advertising trick by marketers, which the majority believed in and, as a result, did not receive any savings.

In reality, these units have obvious disadvantages even at first glance:

- very high price

- large dimensions

- Difficulty in operation when connecting additional equipment (boiler)

Manufacturers loudly advertise their positive qualities, but if you look at them in more detail, even they seem very dubious.

How do advertisers communicate these benefits? They almost always compare it with a heating element boiler. Since they occupy 90% of the electric boiler market.

At the same time, the disadvantages (real or imaginary) for equipment with heating elements are highlighted, and the advantages are given, which are not even close to this in induction ones. Which means they are better.

Let's go over these disadvantages and advantages in more detail.

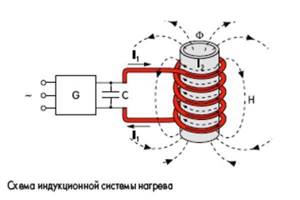

How does an induction heater work?

Very simple.

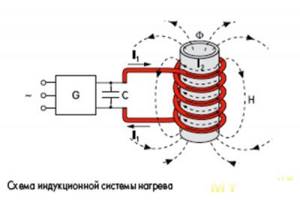

Apply operating voltage to the coil. An electromagnetic field is created in the coil. Then we read carefully - here is the essence of his work: The electromagnetic field induces Foucault currents or eddy currents in the heating pipe and the metal pipe begins to heat up.

If anyone doesn’t know, the transformer’s magnetic circuit is specially assembled from many thin plates of electrical steel, insulated from each other.

This is done precisely to avoid energy losses from heating by eddy currents.

The fact is that the more massive the conductor, the more it will heat up from Foucault currents; in turn, the force of influence of eddy currents can be increased by the rate of change in the magnetic flux.

Did you know that a power transformer with a voltage of 110 kV at idle, even without load, produces a thermal power of about 11 kilowatts?

This is mainly due to the influence of eddy currents, which heat the magnetic circuit on which the primary and secondary windings are mounted.

At the same time, it is magnetically conductive, but if it were solid, then the heat losses would increase many times over!

And the transformer would simply burn out from overheating.

An induction electric boiler works on the same principle and the steel pipe with water running inside the coil gets very hot, BUT! - due to the circulation of water, the heat has time to be removed from the pipe into the heating system and overheating does not occur.

But can it be more economical compared to electric boilers using heating elements? Due to what?

Let's first think about these two types of boilers without analyzing and comparing them:

There is a house

It doesn’t matter which one and it doesn’t matter where. Either underwater or on Everest

This house has a heat loss of 6 kilowatts.

Through walls, through windows, through the ceiling, etc., heat is lost and in order to maintain a constant temperature, it is necessary to compensate for these heat losses and for this, naturally, 6 kilowatts of heat are also needed.

And it doesn’t matter where and how this heat comes from, this thermal energy - 6 kilowatts - even if you burn a fire, even gas, even gasoline, the most important thing is that these necessary kilowatts of heat are released!

Now the most important thing:

To heat such a house you will need either an induction heater or an electric boiler with heating elements - still with a power of at least 6 kW.

In other words, the boiler simply converts electrical energy into thermal energy.

And how he does this is completely unimportant, because for us the most important thing is that the house be warm. Energy is simply converted from one type to another, from electrical to thermal

And if you allocated a 6 kW heat boiler, then you took at least the same amount of electricity from the network, and given that the efficiency of the boilers is not 100%, then even a little more energy is consumed from the network

Energy is simply converted from one type to another, from electrical to thermal. And if you allocated a 6 kW heat boiler, then you took at least the same amount of electricity from the network, and given that the efficiency of the boilers is not 100%, then even a little more energy is consumed from the network.

Then maybe the efficiency of an induction boiler is higher? According to manufacturers, this value reaches 98%.

The same is true for an electric boiler with heating elements. Their efficiency reaches 99%.

Well, think for yourself - where else can the energy in the heating element go except to be released into heat?

All energy consumed from the heating element network is converted into thermal energy. I took 5 kW and released 5 kW of heat.

I took 100 kW and released 100 kW of heat. Well, maybe a little less if you take into account the energy loss in the transition resistance at the heating element’s terminals, but again, this energy loss is released in the form of heat (the clamp gets hot) and in the supply cables.

But both the clamps and the cable cross-section are the same in parameters for both the vortex induction electric boiler and the heating element.

DIY induction heating boiler

A forum for discussing any questions on all boilers except gas, electric and solid fuel.

Answer

Posts: 21 • Page 1 of 3 • 1 , ,

DIY induction heating boiler

Guest » 29 Aug 2012, 15:57

Induction is the conversion of electrical energy into thermal energy through the use of eddy currents or Foucault currents.

Everyone knows this from physics. Tell me, is it possible to build such a heating boiler with your own hands so that it does not need to be descaled and does not touch the electrical part of the heated coolant? Guest

Return to top

DIY induction heating boiler

Sergey N » Aug 29, 2012, 5:16 pm

You can even build a nuclear reactor, the question is whether it will pay for itself. There are already ready-made boilers based on the induction principle, which are not expensive, their power parameters and electricity consumption are already known. I think there is no point in reinventing the wheel when it has already been invented a long time ago. There you need to build complex current/voltage converters and tanks. And you can never tell right away what output parameters it will have.

The most economical gas heaters + reviews - https://www.optcentre.ru/topic/3185-otzy ... #entry4007

Sergey N

Messages: 2684 Registered: March 11, 2012, 23:18 From: Kazan

Return to top

DIY induction heating boiler

Bibikin Ivan » August 31, 2012, 2:22 pm

Don’t worry, if you’re not a specialist, buy a ready-made one. Today there are excellent induction boilers with high-frequency electricity converters. Their cost is adequate, so it’s not a matter of developing it yourself from scratch. Brought it, connected it correctly and enjoy. The truth is, for me, it is much better to use a gas boiler; in the end, it will still be cheaper, a gas boiler is much cheaper than any type of electric boiler in terms of consumption. Attachments

kotel1.jpg (111.46 Kb) kotel2.jpg (98.05 Kb)

We are moving to live on a desert island! With us?! — https://www.neobitaemyi.ru/

Bibikin Ivan

Messages: 1662 Registered: May 16, 2012, 14:10 From: Moscow

Return to top

DIY induction heating boiler

Serg_i_K » 01 Sep 2012, 17:27

In general, for a competent and handy mechanic + electrician it is quite possible to make such a boiler, and there are several quite workable schemes on the network. But it’s worth thinking three times about the feasibility of such an assembly - the cost of materials alone can be from $300, plus the purchase of the necessary tools (which can be even more expensive), plus a significant investment of labor and time. And if a professional assembles such a boiler smoothly, then an inexperienced person will make a bunch of mistakes, the correction of which will cost more than all other factors. Maybe it's worth buying the whole boiler?

Construction materials, tools, full set, equipment, delivery - Luninets, district, tel. Velcom (029) 6484008, MTS (033) 6806008, Personal Message.

Serg_i_K

Messages: 575 Registered: July 29, 2012, 17:48 From: Gomel, Luninets

Return to top

DIY induction heating boiler

switch » November 27, 2012, 02:59

Hello everyone!

If anyone else is interested in the topic, I can tell you how I made my first induction boiler (late 80s). 1. Find (buy, pick up at a landfill, dismantle from decommissioned equipment - underline what is necessary) a three-phase transformer of the required power. Actually, we need transformer hardware with fasteners. 2. Look carefully at what wire the primary is wound with, how many turns and what kind of connection (Y – Δ). Our primary is two identical windings connected in series. The wire is the same as in the original, the number of turns of each winding is half the original one. It is better to order windings from craftsmen (impregnation and drying at home is not a pleasant task). The height of the windings is such that, placing them on the core, the gap between them is about 20-25mm. 3. Select a copper pipe for the secondary winding. We draw on whatman paper the location of the transformer rods in section (3 rectangles). Draw a snake from a copper pipe. The pipe should go around each rod and touch itself. The contact points will then need to be welded using gas welding. We try to ensure that the length of the pipe around each rod is the same. We select the pipe by resistance (knowing the allocated power: transformer power/3, voltage: 220/number of turns of the primary winding, resistivity of copper). 4. After selecting the pipe, we return to our drawing. Draw a life-size pipe. We try not to touch the transformer rods. According to our drawing, we make a stencil for bending a copper pipe (if it’s disposable, then it can be made from plywood with a thickness no less than the outer diameter of the copper pipe). We know how to bend and weld a copper pipe. Weld pipes to the inlet and outlet ends of the pipe. 5. Assembling the induction boiler. We assemble the core. We tighten with fasteners. We disassemble the upper yoke. We lay the lower part of the primary winding, then textolite, thermal insulation, copper pipe, thermal insulation, again textolite and the upper part of the secondary winding. We secure all parts with textolite wedges. Assembling the upper yoke. We fix it. We connect the parts of the primary winding in series. We connect the lower terminals into a star. Upper terminals to the starter. The induction boiler is ready. All that remains is to add overheating protection, automation, check the insulation, turn on the pump and use it. If your hands have grown on the right side and your head is cooking, and you are not ashamed to ask what you don’t know, then you will definitely do it. It will work for a long time and trouble-free. switch Messages: 3 Registered: 27 Nov 2012, 01:28

Return to top

DIY induction heating boiler

Bibikin Ivan » 06 Dec 2012, 14:20

switch wrote: Hello everyone! If anyone else is interested in the topic, I can tell you how I made my first induction boiler (late 80s). 1. Find (buy, pick up at a landfill, dismantle from decommissioned equipment - underline what is necessary) a three-phase transformer of the required power. Actually, we need transformer hardware with fasteners. 2. Look carefully at what wire the primary is wound with, how many turns and what kind of connection (Y – Δ). Our primary is two identical windings connected in series. The wire is the same as in the original, the number of turns of each winding is half the original one. It is better to order windings from craftsmen (impregnation and drying at home is not a pleasant task). The height of the windings is such that, placing them on the core, the gap between them is about 20-25mm. 3. Select a copper pipe for the secondary winding. We draw on whatman paper the location of the transformer rods in section (3 rectangles). Draw a snake from a copper pipe. The pipe should go around each rod and touch itself. The contact points will then need to be welded using gas welding. We try to ensure that the length of the pipe around each rod is the same. We select the pipe by resistance (knowing the allocated power: transformer power/3, voltage: 220/number of turns of the primary winding, resistivity of copper). 4. After selecting the pipe, we return to our drawing. Draw a life-size pipe. We try not to touch the transformer rods. According to our drawing, we make a stencil for bending a copper pipe (if it’s disposable, then it can be made from plywood with a thickness no less than the outer diameter of the copper pipe). We know how to bend and weld a copper pipe. Weld pipes to the inlet and outlet ends of the pipe. 5. Assembling the induction boiler. We assemble the core. We tighten with fasteners. We disassemble the upper yoke. We lay the lower part of the primary winding, then textolite, thermal insulation, copper pipe, thermal insulation, again textolite and the upper part of the secondary winding. We secure all parts with textolite wedges. Assembling the upper yoke. We fix it. We connect the parts of the primary winding in series. We connect the lower terminals into a star. Upper terminals to the starter. The induction boiler is ready. All that remains is to add overheating protection, automation, check the insulation, turn on the pump and use it. If your hands have grown on the right side and your head is cooking, and you are not ashamed to ask what you don’t know, then you will definitely do it. It will work for a long time and trouble-free.

Informative, but now all these devices are already losing their effectiveness IMHO.

Firstly, there is a very large assortment of inexpensive Chinese boilers on the market, and secondly, electricity itself is very expensive compared to gas and firewood. Is it worth designing such devices if they are not effective? Perhaps the only advantages of such boilers are their simplicity and a small number of wearing parts. In fact, an induction boiler can be built. simply winding the winding around the pipe and turning on the current. The iron pipe will heat up well, and the circulating coolant will also heat up from it. We are moving to live on a desert island! With us?! — https://www.neobitaemyi.ru/

Bibikin Ivan

Messages: 1662 Registered: May 16, 2012, 14:10 From: Moscow

Return to top

DIY induction heating boiler

switch » Dec 07, 2012, 00:25

Bibikin Ivan wrote: switch wrote: Hello everyone! Informative, but now all these devices are already losing their effectiveness IMHO. Firstly, there is a very large assortment of inexpensive Chinese boilers on the market, and secondly, electricity itself is very expensive compared to gas and firewood. Is it worth designing such devices if they are not effective? Perhaps the only advantages of such boilers are their simplicity and a small number of wearing parts. In fact, an induction boiler can be built. simply winding the winding around the pipe and turning on the current. The iron pipe will heat up well, and the circulating coolant will also heat up from it.

In 2004, there were 2 manufacturers of induction boilers in Russia. Now there are about 40 pieces. switch Messages: 3 Registered: November 27, 2012, 01:28

Return to top

DIY induction heating boiler

switch » 07 Dec 2012, 01:13

“all these devices are already losing their effectiveness” In my opinion, induction boilers are just gaining momentum.

I am sure that few people stood close to these boilers. If you carefully consider the various designs of industrial boilers, you can understand that boilers of the typical transformer type have the most positive qualities, and they are usually more expensive. Here are some qualities of the “correct” induction boilers: . Water quality doesn't matter. The scale does not settle down AT ALL. Gases dissolved in water are released and exit through the air valves with exceptional speed (1 ton of water - 10-20 minutes). oxygen-free bacteria do not develop. electrical safety at the highest level. service life (continuous operation) more than 50 years, etc. switch Messages: 3 Registered: 27 Nov 2012, 01:28

Return to top

DIY induction heating boiler

Roller » March 25, 2013, 11:42 pm

Breaker, great experience! Not like the others - expensive, impractical: just take it and do it! Well done! Here's another inventor - he made an induction heater with his own hands

Roller Administrator

Messages: 71 Registered: 10 Mar 2012, 16:38

to come back to the beginning

DIY induction heating boiler

Anatoly » May 13, 2013, 01:54

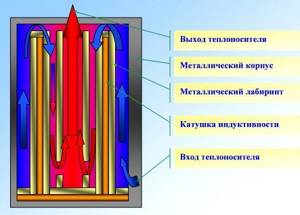

You can make induction boilers yourself... However, such boilers have already been developed and are produced by industry... in the form of induction boilers SAV© PROF series, with a power of 2.5 to 7 kW, and in general, boilers of the SPEC+ series have been developed with power from 100 to 500 kW It turns out that these developed induction boilers can operate on alternating currents at a standard frequency of 50 Hz... The boiler works due to an inductive coil that creates an alternating magnetic field using a current with a frequency of 50 Hz.

The metal system of labyrinths, on the one hand, under the influence of Foucault eddy currents, heats up due to magnetization reversal and transfers the released energy to water as a coolant almost without losses, and on the other hand, it intensifies the heat exchange process itself. The boiler uses an inductive coil, which, in addition to consuming energy, is also a generator, because its conductor is in an alternating magnetic field, which causes the generation of reactive power. During the recuperation process, the active current consumed from the network is very small, and the reactive current closed in the circuit is quite large, which allows SAV boilers to use the additional power generated in the oscillating circuit and reduce electricity consumption by up to 30%. Therefore, it is advisable to do a comparative analysis of a homemade boiler with an industrial one... 50 years of impeccable operation still needs to be checked over time!!! In the meantime, this is a feature and nothing more... Anatoly Messages: 1707 Registered: April 3, 2013, 01:23

Return to top

Answer

Posts: 21 • Page 1 of 3 • 1 , ,

Return to Other types of boilers

Who's at the conference now?

Registered users: no registered users

Switch to mobile style

Vortex Induction Heater

A vortex induction heater (VIN) is a type of induction cooker. It consists of a coil, a magnetic core and a heat exchanger. Alternating current flowing through the coil creates an alternating magnetic field. If a conductive material is placed in this field, it will heat up. The main advantage of VIN is that the inductor temperature does not exceed 140 degrees C. In addition, the alternating magnetic field counteracts the formation of scale. Unlike a vortex heat generator, the operating principle of a VIN fits into the laws of physics. The efficiency of a vortex induction heater is close to 100%, which gives it the right to use in heating systems and other liquid heating systems. However, what do the sellers of vortex induction heaters promise us? And this is where miracles begin. They promise savings of up to 50% compared to conventional heating elements. That is, either the efficiency of the heating element is 50%, or the efficiency of the VIN is 200%. Let's try to figure it out. Your humble servant was not lazy and called several companies selling vortex induction heaters. The most important question that was asked was: what advantage will I get by paying quite a lot of money for this device? Here are the answers I received:

- We have a lot of sales and everyone is happy

Fantastic reliability and durability

Savings up to 50% compared to heating elements

No noise

Well, you can argue with the first and second statements. Regarding noise, heating elements do not make noise either. But, with savings, this is interesting. It turns out (according to sellers), the formation of scale on the heating element reduces its efficiency. Accordingly, the efficiency of VIN is due to its constant efficiency compared to heating elements. But excuse me, how does scale reduce the efficiency of heating elements? Let's remember the law of conservation of energy. Let's say we supplied 1 kW of electrical power to the heating element. Accordingly, we should receive 1 kW of thermal energy. If we receive less heat, then the remaining energy must be released in some other form. I don’t remember that heating elements in water glowed or emitted, say, electromagnetic waves. Undoubtedly, scale reduces the heat transfer of the heating element, but this does not in any way affect its efficiency. With a decrease in heat transfer, the temperature of the heating element itself increases, and, consequently, its electrical resistance increases. As the electrical resistance increases, the power consumed by this heating element decreases. In fact, the change in temperature and power consumption is so small that the average user won't even notice it. Will the kettle boil in a minute or in a minute and 5 seconds - does it matter? At the same time, the amount of electricity required to heat a kettle of water will remain unchanged. However, VIN sellers are trying to turn the situation upside down and talk about a decrease in efficiency.

Thus, VIN can be an alternative to heating elements, but it will not provide any savings. There are no miracles. And as for “fantastic reliability”, for the money that VIN costs, you can buy several electric boilers and arrange a backup. Reliability will be several times higher.

Replacing the heating element

The service life of heating elements depends on the quality of the coolant. As “comparators” assure, this is only 1000 hours of work, if you do not take action and soften hard water. Well, if they softened it, then about 5000.

When using this data, the heating and water supply systems are confused.

In closed heating systems there are not as many impurities as in water supply. In most cases, water softening is simply not required here.

This may only apply to domestic hot water or central heating. There, the boiler room operator is unable to track water leaks.

If we are talking purely about your home, where everything is assembled and connected without leaks or holes, then no constant water preparation is required. Of course, the water will contain some elements, but once they are poured into the heating system, they will react once or more; they will have nowhere to come from.

Induction ones supposedly have low operating costs due to the very rare replacement of components. In fact, this is in high-quality PETN samples; the elements change extremely rarely, as mentioned above.

But if you need to change something in the induction room, you will think twice before doing it. Everything there is sealed in a sealed flask and you can’t get inside without physically cutting it.

Main types of induction boilers

Before buying an induction electric heating boiler for your home, you need to choose which type is most suitable.

There are two varieties on sale - induction boilers SAV and vortex boilers (VIN), which have characteristic differences.

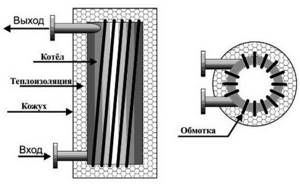

Induction heating boilers SAV

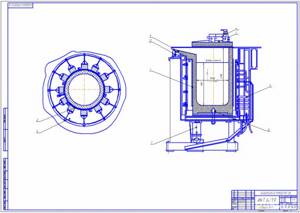

Boilers of this type do not require the use of an inverter. A network voltage of 50 hertz is supplied to the winding (inductor). The secondary winding in the form of a system of metal pipes of the heat exchanger is very quickly heated by Foucault currents. The heated coolant moves in the circuit forcibly using a circulation pump. Boilers are produced for voltages of 220V and 380V. A 2.5 kW boiler heats a room up to 30 m2, and you can buy an induction electric heating boiler complete with a control and automation unit for about 30 thousand rubles.

Induction boilers VIN (vortex)

These are new generation induction boilers; their operation requires an inverter - a frequency converter for the electrical network. This technical solution made it possible to make the device compact and lighter than SAV-type boilers. The heat exchanger is made of ferromagnetic material, and the magnetic core and secondary winding are not only the heat exchanger, but also the boiler body.

A VIN type boiler with a power of 3 kW can provide heat to 40 m2.

The kit includes an automation unit, a pump and a circulation pump, so the highest price for an electric induction heating boiler is about 38 thousand rubles.

Operating principle of an inverter boiler

Traditional electrical equipment operates on the principle of transferring energy directly to the coolant through heating elements. At the same time, if the device is equipped with heating elements, then, therefore, you need to prepare a place for heating water.

Heating elements are also highly susceptible to corrosion, so they must be protected from irreversible processes.

Inverter equipment operates on the basis of electromagnetic induction. The current itself is generated due to an alternating magnetic field. For this purpose, it is necessary to convert direct mains current into alternating current. An inverter, which can operate both from the mains and from batteries, copes with this task perfectly.

There are two types of circuits in an inverter boiler:

- Magnetic, allowing you to generate an alternating magnetic field.

- A heat exchanger that helps heat the coolant.

With appropriate supply of alternating electricity, the coil begins to form a magnetic field. This helps to heat the liquid in the system and further transfer it through the pipes.

Induction heating system diagram

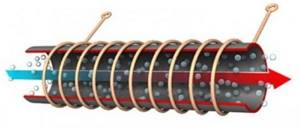

Water heaters type VIN

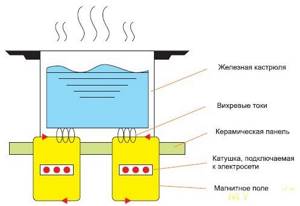

The heart of the unit is a coil consisting of a large number of turns of insulated wire, and placed vertically in a cylindrical housing in the form of a vessel. A metal rod is inserted inside the coil. The housing is hermetically sealed at the top and bottom with welded lids, and the terminals for connection to the electrical network are brought out. Cold coolant enters the vessel through the lower pipe, which fills the entire space inside the body. Water heated to the required temperature goes into the heating system through the upper pipe.

Coolant heating circuit

Due to its design, when connected to the network, the heat generator constantly operates at full power, since it is irrational to supply the heating installation with additional voltage regulation devices. It is much easier to use cyclic heating and use automatic shutdown/on with a water temperature sensor. You just need to set the required temperature on the display of the remote electronic unit and it will heat the coolant to this temperature, turning off the water heating induction element when it is reached. After the time has passed and the water has cooled by a few degrees, the automation will turn on the heating again, this cycle will be repeated constantly.

Since the heat generator winding provides a single-phase connection with a supply voltage of 220 V, induction-type heating units are not produced with high power. The reason is that the current in the circuit is too high (over 50 amperes), it will require laying large cross-section cables, which in itself is very expensive. To increase power, it is enough to put three water heating units in a cascade and use a three-phase connection with a supply voltage of 380 V. Connect a separate phase to each device in the cascade; the photo shows a similar example of the operation of induction heating.

Heating with induction boilers

Design features of heaters of the “Sibtekhnomash” type Using the same effect of electromagnetic induction, another company develops and produces water heating devices of a slightly different design that deserves attention. The fact is that the electric field created by a multi-turn coil has a spatial shape and spreads from it in all directions. If in VIN units the coolant passes inside the coil, then the Sibtekhnomash induction boiler device provides a spiral-shaped heat exchanger located outside the winding, as shown in the figure.

The winding creates an alternating electric field around itself, eddy currents heat the turns of the heat exchanger pipe in which water moves. Coils with coils are assembled in a cascade of 3 pieces and attached to a common frame. Each of them is connected to a separate phase, the supply voltage is 380 V. The Sibtekhnomash design has several advantages:

- induction heaters have a separate, collapsible design;

- in the zone of action of the electric field there is an increased area of the heating surface and a larger amount of water due to the spiral circuit, which increases the heating rate;

- Heat exchanger piping is accessible for cleaning and maintenance.

An example of connecting an induction boiler

Despite the differences in the design of the heat generator, its operating efficiency is 98%, as in heaters of the “VIN” type, this efficiency value is declared by the manufacturer itself. The durability of the units in both cases is determined by the performance of the coils, or more precisely, by the service life of the winding and electrical insulation; manufacturers set this indicator within 30 years.

Pros and cons of an inverter boiler

There are a number of advantages that inverter installations have, including:

- increase in operational parameters as a result of the absence of heating elements;

- slight inertia when heating, thus, if there is a centrifugal pump, the coolant will heat up faster;

- the operation of the system is not affected by the chemical composition of the coolant;

- the ability to install the device anywhere.

Like other heating systems, the inverter boiler has several disadvantages:

- the rather high cost of inverter equipment compared to similar devices operating on heating elements;

- has impressive dimensions and weight, and therefore requires strengthening of the base on which the boiler will be located;

- The device requires an electronic control system for subsequent power adjustment.

Despite minor shortcomings, inverter boilers are still very popular among consumers and the demand for them is constantly increasing.

Inverter equipment design

Long-burning solid fuel boilers

Despite the wide variety of heating systems, solid fuel boilers are still very popular. Today, instead of stoves, into which it is necessary to constantly add firewood, more modern solutions are used - long-burning boilers. They do not require constant monitoring of the combustion mode, air flow adjustment or temperature monitoring. Most modern boilers have an automated system, and the combustion process, depending on the model, can take place continuously from 30 hours to 7 days.

Myths about induction boilers

One of the most popular myths is created by sales representatives selling induction electric boilers. The bottom line is that these boilers are supposedly 20-30% more efficient than other heating electrical installations, especially heating elements. This information is not true, since all heat generators that convert electricity into heat operate with an efficiency of at least 96% in accordance with the physical law of conservation of energy. The only undeniable fact is that heating elements heat up the coolant a little longer due to their multilayer structure. The tungsten spiral first heats the quartz sand, then the tube material, and then the water. In this case, energy is not lost anywhere, and the efficiency of the heating element unit is 98%, the same as the vortex unit.

Example of a heating system

Another myth is that an induction electric boiler requires no maintenance at all, since the alternating magnetic field prevents deposits from settling on the heating elements. This question depends on the quality of the water and scale appears on the coil core in the same way as in heating element heaters if the coolant is not desalted. Therefore, at least once every 2 years, the heat generator itself and the heating system must undergo a flushing procedure.

Contrary to the assurances of the sellers, the water heater cannot be installed in any room. There are two reasons: the danger of electric shock and the presence of an electromagnetic field around the device. It is better to place it in a technical room with limited access (boiler room).

Heating installations that use eddy currents for heating do have many advantages, especially the heating speed, compactness and durability. How much these advantages justify the high cost of the product - each homeowner will have to decide individually.

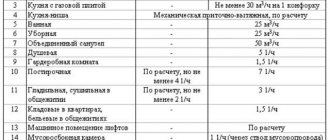

Which induction boiler is better to choose?

Manufacturers offer two types of induction boilers - single-phase and three-phase. Many boiler models are available with control panels. The choice of an induction boiler is made based on a power of 60 watts per 1 sq. m of heated area. If the house is not intended for permanent residence, then the specified power rate can be reduced to 50 watts. With a house area of 120 sq.m. in this case, an induction boiler with a power of 60 kW should be installed.

According to consumer reviews, the main disadvantage of induction boilers is their high price - such boilers are much more expensive than heating elements. But in this case, the high cost of such equipment is justified: induction boilers last longer than heating elements, which form scale and sharply lose heat transfer.

Comparative calculations of the operating efficiency of heating elements and induction boilers indicate that the difference in cost pays off in the first year of operation of the induction boiler. Moreover, the colder the heating season, the faster such a boiler will pay for itself.

The efficiency of an induction boiler and its energy consumption allow it to be considered energy-saving equipment. Along with the advantages of induction boilers, consumers note the need to insulate their homes - only in this case can they count on high efficiency of the equipment.

In the photo, my choice is the EPO Evan 9.45 kW induction boiler

Induction water heater

Induction water heaters have a body and an original electric inductor (transformer) inside it, and its secondary winding is the metal pipe with water itself, in the form of a short-circuited turn.

As a result of the flow of significant electrical currents in it, from the inductively induced electrical voltage in it, this pipe intensively heats up and heats the water in it with its heat.

In a nutshell, how does an induction heater work?

this is a step-down transformer that is installed in a pipe

At first I decided that if the word “induction” is in the name, then heating occurs with high-frequency currents, like in a microwave oven, but it turned out not.

There is no trace of any high frequency, power supply is 220/380 volts, industrial frequency 50 Hertz.

The technology is actually very simple - there is an ordinary coil in a shielded pipe - this is like the primary winding of a transformer, if we draw an analogy with a transformer.

The role of the secondary winding, and at the same time the magnetic circuit, is performed by a metal heating pipe!

Operating principle

First, let's talk about the general operating principle of such heaters. As you know, when a direct current circuit is turned on or off, an electromagnetic field is formed, which, in turn, creates a current in conductors located in a certain way. This action heats up the conductor on which it acts.

This idea was used to create induction heating boilers. Now let's look at how exactly they are arranged.

The entire device is located inside a metal casing.

The heating element is seamless metal pipes that are located inside it. They are located inside a coil, which is placed inside a closed housing. An alternating electric current is passed through it, as a result of which the metal pipes and, accordingly, the liquid that flows through them are heated.

For this purpose, ordinary water or other specialized types of liquids can be used. Typically, in order to circulate the liquid, a pump is used to push water through the pipes.

An important feature of this type of heating is the presence of microvibration, which plays an important role in preventing scale formation in pipes. In addition to water, antifreeze or, for example, machine oil can also be used as a coolant.

Advantages and disadvantages

The real advantages that induction boilers have for heating a home or industrial building are as follows:

- High, as with all water heating installations, operating efficiency is in the range of 97-98%.

- Durability due to the absence of moving parts and simplicity of design.

- Small dimensions allowing heating equipment to be placed in a room of any size.

- High heating rate of the coolant and lack of inertia when it is turned off.

- Comfort during operation, an induction electric boiler does not require constant attention from the owner of the house, and the frequency of its maintenance depends entirely on the quality of the water used in the system.

Vortex heaters are supplied with automatic control kits, which makes it possible to connect heat generators with other climate systems at home.

Sectional view of the heater

This equipment also has disadvantages. The main one is the high cost, especially for heat generators of the Sibtekhnomash type. While using these units for industrial purposes is quite acceptable, induction heating of a private home may turn out to be unreasonably expensive.

The experience of practical use of vortex heaters by homeowners and maintenance personnel of service companies is not yet very extensive, but at the moment there are no significant complaints about the equipment.

Solid fuel boilers for private homes

Heating a house with a solid fuel boiler is carried out in conditions where there is no gas supply, and also where, for one reason or another, it is impossible to install an electric boiler. In addition, firewood or coal is much cheaper than gas, diesel or electricity, so such a boiler is an ideal solution for a country house located far from central communications. Solid fuel boilers can fully replace gas heaters in private homes. Long-burning solid fuel boilers come in several types - with manual or automatic fuel supply, as well as differing in combustion method and type of fuel.

Vortex induction heater VIN Useful DIY

It turns out that this mysterious VIN heater is very simple and can be easily assembled right at home. Let's briefly consider the principle of operation.

The operation of such heaters is based on the heating of conductive materials by Foucault currents, which are induced by a high-frequency magnetic field. The resulting thermal energy is taken by the coolant (water, oil, etc.) and used, for example, to heat a room.

As you can see, nothing complicated. Now let's see how I managed to put all this into practice.

In order not to create unnecessary complications, I decided to use a ready-made high-frequency welding inverter with a welding current of 15A (I had a sample with the ability to continuously adjust the current). You can, of course, take something more powerful. It all depends on the required heater power. Since I was just conducting an experiment, I took the high-frequency inverter that was available.

As a material that will be heated in a high-frequency field, I decided to use pieces of thick steel wire. I was able to get a wire rod with a diameter of 7 mm and bit it into pieces of about 5 cm. If you do everything for centuries and for yourself, then you can get scraps of stainless steel, although if the heating circuit is always full, then this is not necessary. Even ordinary iron will not rust.

As the section of the pipeline where the water will be heated, I decided to use a thick plastic pipe. The internal diameter should be chosen slightly smaller than the length of our wire scraps. We attach an adapter to one side of the pipe to connect it to the rest of the heating system, lay a metal mesh on the bottom (so that the pieces of wire rod do not fall further) and pour our wire inside. Then we close the free end of the pipe with the second adapter in the same way. You need to pour in so many wire scraps so that they occupy all the free space there.

Now let's make the induction coil itself: to do this, we simply wrap the middle of our plastic pipe with scraps of wire rod with copper enameled wire turn to turn (PEV or similar). For my inverter, 80-90 turns of wire with a diameter of 1.5 mm will be enough.

That's basically all. All that remains is to connect our device to a break in the heating circuit, fill the whole thing with water, connect a welding inverter to the winding and turn on the pump (to ensure forced circulation of water in the system). Of course, it is highly not recommended to turn on the inverter without water, since in this case our plastic pipe is guaranteed to melt from the heated pieces of wire inside.

Thus, in a matter of hours, I was able to assemble a working vortex-induction heater from scrap materials. By the way, it is very economical - if you believe what they say, its efficiency reaches as much as 98-99%!

You can not stop there and, in order to further increase efficiency, organize cooling of our inverter with the same coolant from the heating circuit. True, this only makes sense if the inverter circuit itself is located outside the heated room.

You can also organize automatic temperature control. To do this, you just need to get a thermostat and connect it to the inverter power supply line, and place the thermostat sensor in the controlled area.

I did all this a long time ago, but I’m writing about it only now (at the urgent request of one friend), so there will be no photo report. I’ll be honest, I only assembled the heater itself, I didn’t turn it on anywhere, I didn’t try to heat anything with it. Yes, I didn’t even have a pump. I just poured water inside and turned on the device. The water quickly heated up to boiling point. So, as you can see, the described method for making VINs really works and there is nothing complicated about it.

Induction heater. Fire, water, working people, but not fire!

I was looking forward to this toy. I have known about induction heating for a long time, since my student days. Sometimes I saw videos of how workpieces are hardened, carbide plates are soldered onto cutters, and so on. But for me, all this was something from the field of production, dirty, hot and stuffy workshops. Therefore, when I saw this heater in the list of gadgets offered for review, there was no hesitation. I just wanted him!

Freudian slip and paragraph 18

Like probably most readers, I am interested in different things. There is always a temptation and desire to buy something for your hobby, or you just want to play with a gadget you like; as you know, the price of toys only changes with age. Reviews are a combination of business and pleasure. I like to share my experience of interacting with various things, sponsors seem to like how I do it, and it turns out to be a mutually beneficial cooperation. I never review things that I'm not interested in and don't want to spend some time with. As a rule, I take things whose purpose and characteristics I have a good idea of, so I avoid my and yours, my dear readers, disappointment in most cases.

I do reviews objectively, I do not advertise products, and my goal is to give you food for thought and share my experience of using this item. Read, think, write your opinion in the comments - the truth is born in communication and exchange of opinions!

Recently there was a review of this device from the respected dia. In this review, dia even removed some of the parts to better understand the structure of this gadget and drew its electrical circuit. I won’t duplicate his work, you can go to that review and see everything. And don't forget to put a plus sign on dia please.

In my review, I would like to tell you what induction heaters are, why they are needed at all, and why I was so happy and waited for the arrival of this gadget. And the most interesting thing is what I did with it

As usual, let's start with a short excursion into history.

The phenomenon of electromagnetic induction was discovered by Michael Faraday in 1831. Electromagnetic induction is the phenomenon of the occurrence of electric current in a closed circuit when the magnetic flux passing through it changes. Without Faraday's discovery, we would not have had transformers, generators, radios, and the electrical and electronics industry in general.

Induction heating is the heating of materials by electric currents that are induced by an alternating magnetic field. Those. By creating an alternating magnetic field and placing material there, we can heat it. And already in 1900, the Swedish one built and launched the first induction steelmaking furnace!

In order to melt or at least heat the metal, we need to create an oscillatory circuit and place a metal object in the field created by this circuit.

Here is a drawing of an induction steel melting furnace. It shows that the crucible with molten metal is surrounded by coils that induce an alternating magnetic field on it.

And this is the oven in action.

In general, the induction heating circuit looks like this: We have a generator and an oscillating circuit. The oscillation frequency in the circuit depends on the inductance of the coil and the capacitance of the capacitors. Different materials are susceptible to different vibration frequencies. For example, at the frequency of circuit oscillations at which steel melts, for example, non-ferrous metals may not even begin to really heat up. And vice versa.

Where is induction heating used? In fact, in a huge number of places. He is everywhere around us. Induction electric stoves, as the most striking example

Induction instantaneous water heaters

Portable heaters, with their help, for example, you can heat up and unscrew a rusted nut.

And in production, an induction heater is used for surface hardening of products. It is fast, economical and safe, in terms of the absence of fire and flammable materials.

And the most interesting thing for me is probably, because... I am the owner of small home turning and milling machines - soldering carbide plates onto cutter holders.

As I said, for me, induction heating systems have always been either the lot of industry or craftsmen who solder huge monstrous circuits with giant power supplies, for which it’s a stretch to find a place in the home. And what a surprise it was to discover a tiny device from the “plug into the power supply and have fun” class.

Let's move on to the hero of our review. It consists of two parts. A generator built on the basis of a conventional two-transistor multivibrator (for the circuit, you can go to the review of the respected dia), for those who understand electronics, then nothing complicated, but for those for whom these are unfamiliar terms, then in a nutshell - a simple and reliable circuit that works "from the box". An assembly of containers is located on the generator board. The second part is the oscillating circuit coil. Both parts are connected with a screw connector.

The size is miniature 5.5 cm by 4 cm and 2 cm thick. Coil diameter 2.8 cm, length 7.5 cm. Device power supply 5-12V, current up to 5A.

Those. the maximum power consumption can be 12V x 5A = 60W. This is the consumption of not the brightest incandescent light bulb. Is it a lot or a little? Let's estimate on our fingers. The modern steel industry spends on average 650 kWh to melt 1 ton of steel, i.e. 650 Wh per 1 kg or 65 Wh per 100 gram melt. Thus, our little one, with the proper approach and minimizing heat loss into the atmosphere, can melt a little less than 100 grams of steel in an hour. Very, very good. It would seem 60 W of power consumption and 100 grams of molten steel. It is very useful to count everything, because... Some things are not at all obvious to the eye, as was the case for me in this case.

Let's move from words to entertainment.

I had a whole bunch of ideas that I wanted to implement.

I made a detailed video on all the ideas. You can watch it at the end of the review

.

Idea number 1. Hardening screwdriver bits. Often, if you have to tighten a lot of screws with a screwdriver, you will see a picture of the bits licking off the crosspiece.

There is a way to extend the life of bits. Often bits are sold slightly under-hardened. This is apparently done to avoid their splitting during operation. Or for some other unknown reasons. Such bits can be additionally hardened. This is what we will do.

How are metals hardened? There are a huge number of alloys and individual heat treatment modes. I will not dive into these jungles within the framework of this review. If everything is simplified to the extreme, then for hardening products made of unidentified steel in primitive home conditions, you can (with a bunch of conventions, of course) use the following method.

A. Heat until cherry brown (750 degrees Celsius). b. Cooling in water c. Leave in the oven at a temperature of 180-190 degrees Celsius for 1 hour. Vacation is necessary to relieve internal stress so that the product does not burst in our hands during operation

Here is a picture with the colors of the metal and their corresponding temperatures

Accordingly, we warm up the bat

And cool it in water. Then leave in the oven and... voila. We have a stronger bat in our arsenal.

Idea number 2. Make mini wood chisels from the remains of a hacksaw blade. Detailed process in video. I’m only sharing a photo of the final products.

They look unsightly, but they cut wood properly. The test is on video.

Idea number 3. Make a real drill from improvised nails and pieces of iron. And the drill turned out! It has successfully drilled through wood, aluminum... and more. Look at the video))) Everything withstood the sharpening and the hardened tip, except for the body of the drill, which I released, but did not harden again. This is what happened to him after my bullying)))

Idea number 4. Water heater. Test of concept. We put the nail in the tube, the tube in the spiral - the water boils.

You can heat something, for example water in a container. Put a can of milk there, connect a temperature sensor to control the temperature and there will be a yogurt maker))).

Here is a video of my mockery of matter)))

Like a resume. I liked the induction heater. For home use, I personally will definitely find it useful. From time to time I need to harden some small part (a knurling axis for a lathe, for example). And I like this method better than the burner at home. I also got great pleasure from the process of creating qualitatively new things from scraps of saws and unnecessary keys.

Do I want a higher power heater? To the apartment - definitely not. Other modes, different safety precautions. To a separate workshop - definitely yes.

I'm amazed at the speed of progress, to be honest. And technology. A device the size of a matchbox allows you to feel like a blacksmith, a thermostat, and a plumber-heater))

Enjoy life, choose the tools and toys you like, and good luck!

The product was provided for writing a review by the store. The review was published in accordance with clause 18 of the Site Rules.

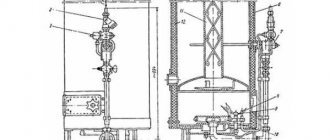

Design and principle of operation of an induction boiler

An induction boiler consists of the main elements:

- Housings;

- Induction coil;

- Core.

The operating principle of induction units is extremely simple: passing through a coil, an electric current generates a strong electromagnetic field. In accordance with the Joule-Lenz law, under the influence of electromagnetic waves, the tubular core intensively heats up, giving off thermal energy to the coolant circulating inside it.

The performance of such systems is evidenced by the fact that, since the 30s of the twentieth century, the principle of electromagnetic heating has been successfully used in metal smelting furnaces.