What is a sewer air valve, how does it work and what is it needed for?

The unpleasant smell of sewerage is not just an irritating factor, it is much more dangerous than is commonly believed.

Sewage gas is harmful to human health, flammable, and in some cases can even explode. The problem is serious, so to solve it, ventilation of the entire drainage system is used. To implement it, various devices are used, but most of them are intended for outdoor installation. The only element that is used indoors is the air valve for the sewer, which should be discussed in more detail.

What is an air valve

A vacuum valve for a sewer is a plumbing device that is installed in an unventilated sewer riser. Externally, the simplest ventilation valve is a compact polypropylene body with protruding elements (there are other, more complex designs in plastic or metal cases).

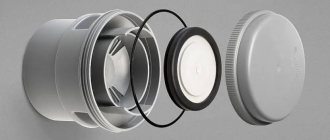

Being similar in nature to a drain pipe, a vacuum valve for sewerage allows you to stabilize the pressure in the pipeline without complex and time-consuming engineering work. It protects the siphon of plumbing fixtures from the breakdown of the hydraulic valve when negative pressure exceeds 5 mmHg. When the pressure rises to a normal or elevated value, the valve cuts off the system from the external atmosphere, acting as a plug and preventing the possibility of biogas leakage.

Air valve

A sewer ventilation valve is a simple and reliable device that does not require specialized maintenance or routine maintenance; as it wears out, it is simply replaced with a new one, since the cost of such devices is low. There are standardized samples that correspond to the nomenclature sizes of sewer pipelines. They are purchased and installed in the appropriate holes as needed.

Features of operation

Rules regarding the selection and installation of air valves in the sewer systems of apartments and private houses were included in SNiP only about 10 years ago. The decision on the mandatory installation of such a device is made by a specialist, however, it is believed that the use of an aerator cannot reduce the efficiency and quality of the system. In general, this statement is true, but it is important to monitor the condition of the equipment and its serviceability.

Disturbances may include sticking of the membrane or rod in a certain position.

- If the stop occurs in the “open” position, there is a risk of unpleasant odors from the sewer entering the room.

- If the valve gets stuck in the closed position, the water seals may rupture.

At the same time, the simplicity of the design and the associated high reliability and durability of the equipment, combined with timely inspections of the valves, will make it possible to avoid emergency situations.

Sewage air valve 110 mm installed on riser

Installing aerators together with traditional ventilation outlets or vent devices virtually eliminates the possibility of a critical change in pressure in the system and failure of water seals.

Sometimes a situation arises when an air valve that has worked effectively for several years ceases to “cope with its responsibilities,” although there are no breakdowns or malfunctions. Most often this is due to changes in the operation of the sewer system itself, for example, with the installation of a washing machine that discharges water under pressure. At high flow rates, the pressure in the pipeline changes more sharply, so it is better to install an additional individual valve on the new unit.

Purpose of the device

When draining water, a negative pressure is formed in the pipes - vacuum . It is capable of tearing off the water seals of toilets, bathtubs or sinks, connecting the internal volume of the system with the atmosphere of living quarters. After removing the water plug in the siphon device of plumbing fixtures in residential premises, a foul odor appears, indicating the penetration of biogas.

The only possible solution to the problem is to supply air to the system. The owner of a private house has the opportunity to make a vent pipe leading to the roof.

In a private house or apartment

Installing a vent pipe is a simple and affordable way to eliminate odor, but it also has disadvantages. An aerator installed on the roof not only supplies air into the system, but also allows gases to escape from it, so placing such systems inside residential premises is impossible.

For people living in an apartment in a multi-storey building, the only way to solve the problem is to install an air valve on the sewer. This procedure is not very difficult, but it is better to perform it during the initial construction work. Inserting such devices into a common operating pipeline is a labor-intensive undertaking that causes inconvenience to all residents whose apartments are located on this riser.

Example of air valve installation

You may also like - Sewerage in a private house - do-it-yourself step-by-step installation

Benefits of installing an air vent valve

An unventilated sewer riser is a clear violation of the rules of operation and installation of the system. This connection scheme is allowed only with a simple drain system, when no more than 2-3 plumbing fixtures are connected to the central riser. With complex wiring diagrams, the presence of ventilation is mandatory, since the sewage system will not be able to work effectively without it.

There are several ways to ensure air flow: by installing a vent pipe or a ventilation valve. The latter solution has several advantages:

- According to SNiP, when constructing a sewer main, it will be necessary to install a return pipeline to ensure the necessary air flow. The installed ventilation valve allows you to avoid installing additional ventilation pipes and reduce costs.

- The ventilation valve is superior in efficiency to the vent pipe. When more than 5 plumbing units are connected at the same time, even when installing a ventilation pipeline, malfunctions in the operation of the system are observed. The ventilation valve completely and effectively solves the issue of ventilation.

- The ventilation valve can be installed at any time during the operation of the sewer system, and the drain pipe is installed at the very beginning of construction.

The ventilation valve is a simple and effective device necessary for every sewerage system.

Species and types

The valve for the sewer riser can have different types of designs. They differ in certain characteristics. There are samples intended for installation:

- on a vertical riser;

- directly to the drain of a certain appliance - toilet, bathtub, etc.

Based on their operating principle, they are divided into:

- automatic air sewer valve. It has a relatively low throughput, therefore it is used mainly in private systems;

- anti- vacuum Capable of both supplying air flow inside the system and releasing excess pressure from it (if necessary). Can work with several pipes simultaneously;

- combined view. The operation of such devices demonstrates the capabilities of both types.

By type of construction:

- membrane (or lifting). The working body is a flexible membrane installed in a PVC housing. When the pressure changes, the membrane bends, allowing air to flow upward;

- cylindrical _ These are reliable metal structures, the body is made in the shape of a cylinder with a thread for the lid. The device works like a classic check valve and is considered one of the best solutions for the sewer system of a private home;

- lever _ They also have a metal body. It works on the principle of a gravity valve, where under the influence of passing masses the lid opens and then closes under the influence of gravity. In practice, a manually adjusted spring is usually used instead of natural weight.

According to the connection method, there are valves:

- threaded;

- flanged;

- coupling.

The choice of the optimal option depends on the type of system, installation location and other factors. The most popular are devices that can work simultaneously with several pipelines.

There are home craftsmen who make similar devices for fan pipes. Homemade valves in normal condition cover the outlet, and when the pressure changes, they open, admitting or releasing air flow. Typically, such structures have to be installed on pipelines in large private houses with an extensive sewage system and their own septic tank. They produce a large amount of gas, which creates a high load on the system and requires correction using mechanical devices. In addition, such devices help protect the system from the penetration of insects, rodents, debris and dust.

Advantages and disadvantages of the device

The main advantages of using a vacuum valve include:

- prevention of emergency situations and isolation of premises from the penetration of sewer gases and water;

- Using the valve allows you to avoid installing a drain (ventilation) pipe. The vent pipe is led to the roof, which means there is no need to make an extra hole in the roof and perform rather complicated work.

Helpful information! It is allowed to install the aerator on an already ventilated system. The use of such a device is considered an additional precaution.

The main disadvantage of such a device is jamming. Over time, the functional parts of the valve become old, worn out, or become clogged. Clogging of the valve occurs quite rarely, since it is almost impossible for debris to enter the structure without compromising its integrity. But wear of the structural elements of the device is inevitable over time, which can lead to deterioration in the mobility of the valve membrane.

Operating principle

Let's look at the operating principle of the most common design. An example would be a 110 mm vacuum sewer valve, one of the most popular models. Such devices are installed on sewer pipelines with a diameter of 110 mm. There are other sizes, for example, for a 160 mm pipe, or a device for horizontal lines with a diameter of 50 mm. All products of the same model range operate according to the same scheme, so there is no fundamental difference in their design.

The operation of the device is based on the principle of operation of a reverse-action vacuum valve. When negative pressure occurs, the lid is forced to open and let in outside air. The peculiarity is the direction of influence - the tube has a chamber of a specific shape that communicates with the internal cavity of the sewer pipes. An area of reduced pressure interacts with the top of the lid, lifting it and letting outside air in. When the pressure normalizes, the lid is lowered under its own weight and placed in its original place. The operation speed of the mechanism is high, so it is impossible for gases from the sewer to enter the apartment or house.

Application

An air valve for sewage 110 mm (or another size) is used in the following cases:

- when there is no drain pipe in the sewerage system and the system is not ventilated;

- if it is not possible to bring the vent pipe to the outside of the roof;

- in apartments of multi-storey buildings, where pressure drops often occur when large quantities of water pass through a long vertical pipeline.

There are other valve designs, but they are typically used in large industrial or public service applications.

Design and principle of operation of the air valve

Main technical characteristics of aerators

Masters identify 2 main technical characteristics of air valves:

- diameter;

- throughput.

Diameter indicators can be: 50, 75 and 110 mm. Fifty-millimeter parts are ideal for installation on individual plumbing fixtures, as are valves with a cross-section of 75 mm. But products with a diameter of 110 mm are needed for installation on a sewer riser, as they can withstand greater pressure.

Important! For installation on pipes that have a different diameter, there are special adapters. In addition, some modern models are equipped with multi-stage pipes. Thanks to such connections, vacuum sewer valves can be connected to pipes with different diameters (for example, 32 mm).

The throughput of these devices can range from 7 to 47 l/s, depending on the model. But as a rule, most devices pass from 32 to 47 l/s.

Installation

The installation method depends on the design and type of valve. There are two common options:

- installation of a vertical (common) riser into the gap.

- separate installation for each device - sink, bathtub, toilet, etc.

In the first case, a 110 mm sewer valve is usually used, corresponding to the standard size of a plastic riser. It is inserted into the riser assembly in the same way as any elbow or tee.

The second option requires installing an outlet with an inlet pipe where the device is connected.

There are some general rules that must be followed during installation work:

- the installation point of the device must be in a heated room;

- it is necessary to organize access to the device for inspection, replacement or repair;

- the height of the valve should not exceed the highest drain point;

- installation into the socket must be carried out only with an o-ring.

Knowing these little tricks, you can do the installation work yourself.

Overview of the air valve - how it works and what it is needed for

How to choose the right valve?

When choosing an air valve for sewerage, they are guided by the location of the pipe (vertical or horizontal) in the place where it is planned to be installed. The device must correspond to the nominal pressure in the network and have appropriate installation dimensions.

You also need to consider:

- how the aerator will be attached;

- strength of the material, its anti-corrosion properties;

- possibility of manual adjustment in case of mechanism failure;

- availability of protection for rodents.

Where and how to install the valve correctly?

When installing the valve, it is necessary to follow a number of rules that will allow it to fulfill its purpose as efficiently as possible, namely:

- Aerators may only be installed in rooms with constant heating.

- The device should be placed in a place where there is easy access to avoid problems with future maintenance.

- If there is a grate in the floor of the room, then the distance from the floor level to the device must be at least 35 cm.

- Installation of the automatic valve should be carried out at a point in the system that is 10 cm above the maximum level of flow into the main riser, in order to prevent clogging of the aerator with waste and feces passing through the system.

- The device must be mounted in a vertical position directly in the socket of a straight line of a sewerage pipeline at a distance of at least 0.2 m to the nearest siphon.

Possible locations for installing the device

Aerators of modern design can be installed:

- into a vertical riser with an exit through the roof;

- cylindrical aerator models with a lid are placed on a drain pipe; simple valves are suitable for individual plumbing fixtures: toilet, sink, bathtub or washbasin;

- devices with a diameter of 50 mm are mounted on long horizontal pipes or on lines with a transition of sections of one diameter to another. Maintaining a slope when installing pipelines will promote the natural flow of wastewater and prevent the occurrence of stagnation and foul odor;

- devices with a diameter of 110 mm are mainly installed on a drain pipe; installation on an auxiliary riser is possible.

Video

An excellent video that clearly shows both the principle of operation of such a valve and the need for its use. Be sure to check it out, it's worth it.

However, all sources agree that proper installation of the ventilation valve guarantees reliable operation of the sewer system and prevents the entry of fumes from the drainage system. According to the majority, it is the ventilation valve that can best solve the issue of reliable sewerage operation in houses up to three floors. Even in multi-entrance buildings of this number, you can combine 3-4 risers with a common ventilation outlet and install a valve on it instead of a plug.

The importance of sewer ventilation

The exhaust part of the riser is important for air exchange in the system, stable operation of siphons of sanitary devices, which contain water, which acts as a hydraulic seal. The need for reliable ventilation of the sewer riser is clear from the physics of the process:

When the toilet is flushed, water flows into the riser. This water draws in air, creating a vacuum or negative pressure difference. It is important that the drainage of a huge amount of water and the lack of supply of external air to smooth out the pressure in both branches of the water seal lead to the appearance of a critical vacuum in the pipe. If there is no ventilation, when the toilet is flushed, air is drawn in, creating negative pressure. Thanks to this negative pressure, water from the elbow of the weakest water seal is sucked into the gravity pipe. The phenomenon is called “hydraulic seal failure”: in order for the pressure inside the pipe to equal atmospheric pressure, air must come from somewhere. The path of less resistance is the siphon (hydraulic seal) of the sink, which has a lower water seal height. The air is drawn through the siphon, and water is immediately drawn out from there and the water seal is destroyed. When the siphon loses water from the elbow, sewer odors open their way into the room. After this, sewer fumes freely enter the premises, and a corresponding sewer smell appears in the apartment. Sewer odors can be harmful, toxic and even explosive. They usually contain methane, but can also contain viruses, bacteria, pathogenic fungi and other organisms.