Sewer ventilation device

Unpleasant “odors” from the sewer system are blocked by vacuum valves in plumbing siphons. But, if the drain was too sudden and the amount of liquid was large, then the internal pressure may decrease and water will begin to be sucked out of the siphon. At such a moment, unpleasant odors can enter the building, bypassing the barrier. The stench may appear due to the plumbing being idle for a long time; the water from the blocking device simply evaporates. Also, the reason is often the small size of the siphon.

The best solution would be to install an air valve for the sewer or a drain pipe. The air passing through them regulates the pressure inside the sewer with atmospheric pressure. In this case, all unpleasant odors are carried through the pipes into the collector system, and are not removed by a siphon.

Other types of vacuum shut-off valves

Vacuum valves are used not only in sewer systems; for example, a bellows electromagnetic (electrovacuum) valve provides the release or supply of air in various equipment.

The throttle valve (electric) provides vacuum support in general systems.

In addition, vacuum valves have found wide application in the automotive industry (car brake booster, fuel pump, automatic transmission, in the hydraulic steering system of the front axle, for exhaust gas recirculation (thermal vacuum valve), turbine vacuum modulator, etc.).

The engine of a modern car cannot function without this equipment. Of course, such devices are much more complex than vacuum valves for sewer systems; accordingly, the price for the equipment package is much higher.

Need for a valve

An air aerator in the piping system reduces the risk of reverse water breakthrough and also:

- blocks water when there is a threat of flooding due to breakthroughs;

- reduces sewer noise;

- prevents rodents from entering the house through sewer pipes;

- protects the house from odors from pipes in case of long periods of inactivity.

Aerator disassembled Source www.egoing.ru

Features of valve operation

The fan valve kit includes:

- plastic housing with a removable lid for cleaning;

- rubber membrane;

- sealing gasket for additional sealing.

If the pressure inside the riser coincides with atmospheric pressure or is higher than it, the aerator remains closed and blocks sewer “odors.” When the water is washed away, the pressure inside the pipes decreases, causing the rubber membrane to shift and the valve to open slightly. Afterwards, air flows through it, the pressure is equalized, and the membrane closes it in the opposite direction.

Air aerators, depending on the method of operation, are divided into several types:

- Kinetic . Used to control air flow in low pressure systems.

- Automatic . They only discharge the accumulated air in the riser, are not used for powerful water pressures and are installed, as a rule, in private houses.

Automatic air aerator Source boiler.com.ru

- Combined . The most progressive models absorb the best qualities of the previous ones.

Depending on the structure of the sewer pipes, which may have many multidirectional sections, the design of the internal mechanism may vary.

For horizontally installed small diameter pipes, a ball valve is used. The bolt part is placed in the form of a ball, pressed against the trigger using a spring.

A wafer valve is ideal for both directions of sewer pipes. It is quite compact, and its design allows the liquid to be passed both directly and through the corners of the pipes. Placed in vertical and horizontal position of the riser. The locking device is plate-shaped and has a diameter from 3 to 75 cm.

The main task of the intake valve is to slow down the movement of solids from the sewer and block their movement further through the pipes. The device is available with a built-in filter and a diameter of 25 cm. It is usually used before installing the pump in horizontally directed pipes.

Reception aerators Source prom.st

See also: Catalog of companies that specialize in utilities and septic tanks.

It is recommended to install a damper on a return aerator with a petal or rotary device. It reduces the likelihood of failure due to the spool (locking mechanism) hitting the surface of the seat. Basically, valves with a wide diameter break. Using a broken appliance causes sewer failures and filter malfunction, which causes hydraulic shocks and stops blocking the stench.

Vacuum valves differ in the method of mounting into pipes. The following methods are distinguished:

- welding , used in sewerage of industrial organizations;

- coupling , in which fastening is performed using threads;

- flanged , at the end of which there are clamping flanges that secure the aerator to the pipe.

A separate flange valve is distinguished, which additionally uses sealed gaskets that additionally block gases and odors from the pipeline. Specifications depend on the required model. The diameter of home aerators varies from 50 to 110 mm. The most popular model of a sewer valve is 110 mm, which has a capacity of 5 to 40 l/s, calculating 27 l/s per liter.

Flange valve Source climatik.su

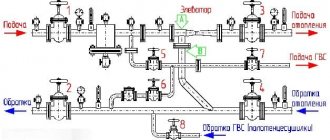

Briefly about the operation of the sewer system

Before considering the design of the valve itself, it is necessary to understand how the sewer system itself works.

In all of them, wastewater pipes (from the sink, bathtub, shower, toilet, washing machine and dishwasher) are led to a sewer riser (the liquid enters by gravity). This is a vertically located pipe that runs through the entire house. At the bottom, the riser enters the central sewer, through which wastewater flows into a treatment plant or cesspool.

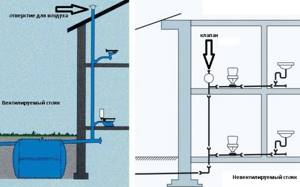

In the upper part of the pipe - it exits through the roof, ending above the roof level (or exits into the attic). It is not closed with plugs on top, but remains open. The purpose of this hole is to equalize the atmospheric pressure with the pressure inside the pipe. This design is called a fan pipe. It is relevant for any buildings with a height of 2 floors or more.

In some cases, the location of the ventilation pipe opening on the roof is not suitable. If there are windows or balconies close to the outlet (at a distance of less than 4 meters), the smell of sewage will be heard in these rooms.

Malfunction and purpose of the valve

For a number of reasons, the operation of the system described above may be disrupted:

if an error was made during calculations or installation (rules and standards are standardized in accordance with SP 30.13330.2012, “Internal pipeline and sewerage”);

if the riser itself is damaged;

if the pipe at the top is clogged with foreign objects (leaves, construction debris, insects or even birds can get there);

if the pipe on top is frozen.

Ventilated and non-ventilated (with valve) riser

When water is drained, a vacuum is created inside the sewer: the liquid sucks in air. Moreover, its quantity can be quite large: for example, water from a washing machine (entered under pump pressure) requires 25 l/s of air per 1 l/s of liquid.

If this amount of air is not enough (this is exactly what the hole in the riser at the top is for), the flow going through the pipe sucks water from the “weakest” water seal (almost always this is the sink).

As a result, noise is heard in the room, and in addition, the smell easily penetrates inside (since the water from the water seal has gone into the pipe). This is not only unpleasant, but also harmful: sewer gas is toxic, and in high concentrations it is explosive (due to the methane it contains). Of course, an explosion due to an odor entering the room is unlikely - too much gas must be present in the air.

If you ignore the unpleasant odor for a long time, in addition to the health hazard (possibly due to the presence of hydrogen sulfide in the gas), the room itself may suffer. The fumes also contain bacteria that contribute to the formation of mold. If there is also high humidity in the bathroom, this will very quickly lead to its development.

The solution to the problems described above is to install an air valve on the sewer pipe. This solution was invented in the Scandinavian countries: due to snowfalls and cold weather, the sewer risers leading to the roof froze.

The air valve itself allows fresh air to enter the pipeline, quickly normalizing the pressure (equalizing internal and atmospheric pressure). It can be used instead of a pipe going out onto the roof (that is, onto an unventilated riser). and together with it, in addition.

Pros and cons of the device

The installed vacuum valve blocks foul gases and odors. The main thing is that during installation there is a non-ventilated riser. Its analogue can be a vent pipe laid through the roof, however, this method will take more time and money.

The disadvantages are directly related to its structure and design. Due to downtime of the sewer system, the water seal can dry out, as a result of which it ceases to block foul odors from the pipes. Over time, rubber membranes lose density and become less airtight, the operation of the mechanism is disrupted and its efficiency decreases. To prevent breakdowns, it must be regularly maintained and worn parts, be it a gasket or a membrane, must be replaced.

Advantages and disadvantages

The vacuum valve has a number of advantages, the first of which is the preservation of the integrity of the roofing material, since its installation does not require making a hole in the roof. Another advantage is that a system equipped with this type of air valve does not spoil the appearance of the building, since the riser does not extend beyond the building. Moreover, due to the fact that there is no need to take the system outside the home, you can significantly save on the purchase of materials.

Forget about the smell from the sewer

Another advantage of such a device is its ease of installation and maintenance. This is a fairly significant advantage; moreover, such a device does not require periodic maintenance or frequent repairs. But the vacuum valve has several disadvantages, but in principle they cannot be called significant. The first drawback is, of course, that one device can only serve one toilet at a time. The second disadvantage is the high cost of the device, but if you take into account the savings on materials and the simplification of installation, then in the end the installation of such a device turns out to be profitable.

Valve installation recommendations

When installing, it is important to follow the rules that will help maximize the efficiency of the sewer valve:

- Installation is only permissible in a heated room. This will help avoid valve failure due to low temperatures.

Installed device under the bathroom Source homemasters.ru

Installation instructions

Almost all vacuum aerators are manufactured for the common pipe connection DN110 with a diameter of 110 mm. If the diameter does not fit the connection, a profile adapter is used. There are also pipes DN50 and DN75, with a diameter corresponding to the digital designation, for which valves with an outlet of 50 and 75 mm are used.

It is important to understand that a 110 mm sewer air valve used for pipes with a diameter smaller than this size is installed at a maximum of two points in the main line. To install the valve in a metal pipe, special adapters are also used, which guarantee a tight joint between the plastic and the metal.

Before installing a vacuum aerator, it is necessary to decide on the installation location, taking into account the location rules and accessibility for future maintenance. After this, turn off the water in the room by closing the taps on the pipes. If installation is required in an already completed pipeline, the valve is inserted and the appropriate adapter is installed.

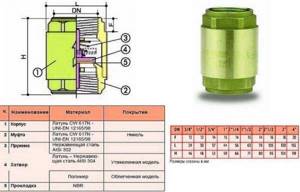

Materials, markings, sizes

The check valve for water is made of stainless steel, brass, larger sizes are made of cast iron. For household networks, brass is usually used - it is not too expensive and durable. Stainless steel is, of course, better, but it is usually not the body that fails, but the locking element. This is where you should approach your choice carefully.

For plastic plumbing systems, check valves are made from the same material. They come in polypropylene and plastic (for HDPE and LDPE). The latter can be welded/glued or threaded. You can, of course, solder adapters to brass, install a brass valve, then again an adapter from brass to PPR or plastic. But such a unit is more expensive. And the more connection points, the lower the reliability of the system.

For plastic and polypropylene systems there are check valves made of the same material

The material of the locking element is brass, stainless steel or plastic. Here, by the way, it’s hard to say which is better. Steel and brass are more durable, but if a grain of sand gets between the edge of the disk and the body, the valve jams and it is not always possible to return it to functionality. Plastic wears out faster, but it doesn’t jam. In this regard, it is more reliable. It’s not for nothing that some manufacturers of pumping stations install check valves with plastic discs. And as a rule, everything works for 5-8 years without failures. Then the check valve begins to “poison” and is replaced.

What is indicated in the labeling

A few words about the marking of the check valve. It states:

- Type

- Conditional pass

- Conditional pressure

- GOST according to which it is manufactured. For Russia, this is GOST 27477-87, but there are not only domestic products on the market.

The conditional diameter is designated as DU or DN. When choosing this parameter, you need to focus on other fittings or pipeline diameter. They must match. For example, you will install a check water valve after a submersible pump, and a filter next to it. All three components must have the same nominal diameter. For example, all should have DN 32 or DN 32 written on them.

A few words about conditional pressure. This is the pressure in the system at which the shut-off valves remain operational. You should definitely take it no less than your working pressure. In the case of apartments - no less testing. According to the standard, it exceeds the working one by 50%, and in real conditions it can be much higher. You can find out the pressure for your home from the management company or plumbers.

What else to pay attention to

Each product must come with a passport or description. It indicates the temperature of the working environment. Not all valves can work with hot water or in a heating system. In addition, it is indicated in what position they can work. Some should only stand horizontally, others only vertically. There are also universal ones, for example, disk ones. That's why they are popular.

Opening pressure characterizes the “sensitivity” of the valve. For private networks it rarely matters. Only on supply lines close to the critical length.

Also pay attention to the connecting thread - it can be internal or external. Choose based on ease of installation

Don't forget about the arrow that indicates the direction of water movement.

Dimensions of check valves for water

The size of a check valve for water is calculated according to the nominal diameter and they are produced for all - even the smallest or largest pipeline diameters. The smallest is DN 10 (10 mm nominal bore), the largest is DN 400. They are the same sizes as all other shut-off valves: taps, valves, drains, etc. Conditional pressure can also be referred to as “dimensions”. The lowest is 0.25 MPa, the highest is 250 MPa.

Each company produces check valves for water in several sizes.

This does not mean that any of the valves will be in any variant. The most popular sizes are up to DN 40. Next come the main ones, and they are usually purchased by enterprises. You won't find them in retail stores.

And also, please note that for different companies, with the same nominal diameter, the external dimensions of the device may differ. The length is clear

Here the chamber in which the locking plate is located may be larger or smaller. The diameters of the chambers also differ. But the difference in the area of the connecting thread can only be due to the thickness of the walls. For private houses this is not so scary. Here the maximum working pressure is 4-6 Atm. But for high-rise buildings it can be critical.

How to check

The easiest way to test a check valve is to blow into it in the direction that is blocking it. No air should pass through. At all. No way. Also try pressing on the plate. The rod should move smoothly. No clicks, friction, distortions.

How to test a check valve: blow into it and check for smoothness

Video description

The following video describes the features of installing a valve for a washing machine:

If the riser is installed in a closed box and is difficult to access, air access must be ensured. To do this, perform a small ventilation, depending on the size of the mesh. The housing is securely mounted into the wall, the fasteners are leveled so that its outer side is flush with the wall. The decorative grille, if present, is the only visible structural element; it is secured with bolts or self-tapping screws. The grille is produced for aesthetic reasons in different color options.

Briefly about the main thing

Installing a vacuum valve greatly improves the operation of the sewer network and protects the room from foul odors. But it will not protect against all problems associated with interruptions in the drainage system. It is important to take into account the purpose of the aerator, its main advantages, and use it only for its intended purpose. It is worth choosing a valve based on the characteristics of the pipeline in the room. Installing a protective mechanism, with the proper skills and knowledge, will not take much time and effort.

Ratings 0