A newly purchased gas boiler heats the room as silently as an electric kettle .

However, after some time (depending on how you install and configure the boiler), it may knock quietly or, conversely, hum like a car.

Causes of noise

There are actually not so many reasons for knocking in heating pipes when heating. Some noise can be ignored - it does not harm the system or heating devices. But noises such as buzzing, crackling, knocking, gurgling, and howling should give reason to think and take urgent action.

Common reasons:

- air pockets in the system;

- clogging or overgrowing of pipes due to poor-quality coolant;

- leaks in the pipeline;

- violation of installation work when installing taps, valves and laying pipes;

- failure or wear of working equipment;

- cavitation, an increase in pressure in places where the diameter of pipes increases (decreases);

- incorrect calculation or non-compliance with design recommendations when installing the heating system.

These circumstances arise in private closed-loop systems and make us think about their urgent elimination.

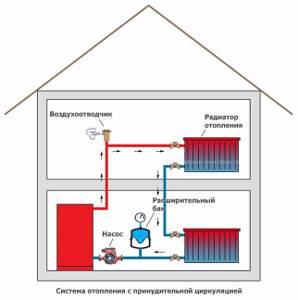

The circulation pump in the heating circuit system promotes forced movement of water, which leads to uniform heating and displacement of accumulated air from the system.

If the heating in a house or apartment is connected to a central pipeline, then startup, accompanied by similar sounds, is normal. Water, filling the general system, pushes out air, and, flowing along the contour, is accompanied by gurgling, knocking and crackling sounds.

As soon as the equipment enters operating mode, the general adjustment of the system will end - the temperature of the batteries will increase, and everything will stop. This is clearly visible in the diagram of heat supply to consumers from the central boiler house.

This is interesting: 6 disadvantages of plastic heating pipes that everyone should know about

Types of noise and its diagnosis

If water makes noise in the heating pipes during heat supply operation, then there are certain reasons for this effect.

First you need to identify them, and then begin to reduce the noise or eliminate it completely. Why is the water noisy in heating pipes and how to correct this problem? Let's look at the main types of extraneous sounds. They point to the objective factors in the occurrence of an undesirable effect:

- Crackling in pipes. Occurs when the heating system is turned on;

- Clicking sounds that appear at regular intervals;

- Constant hum in transport highways;

- A barely audible knock.

All these extraneous effects - noise in the heating radiator or radiators - significantly reduce the comfort of living in the house. In addition, they may indicate improper operation of the heating supply. If action is not taken to correct the situation in time, some heating element may fail.

If the heating pump or other system component is noisy, you should first try to localize the cause of the extraneous sounds. To do this, it is recommended to use the following method:

- Monitor the frequency of occurrence of the effect.

- Try to identify the relationship - temperature increases in pipes, pressure surges, etc.

- Make sure that the noise in the heating boiler comes from it, and not from other objects located in the boiler room.

If it has been determined that the source is a component of the heating system, certain actions should be taken to eliminate this phenomenon.

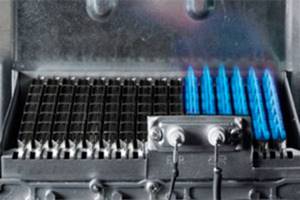

Incorrect burner installation

Quite often, a noise resembling tapping or whistling can be caused by the fact that the gas burner in the boiler was initially incorrectly configured and installed. To check, you will need to compare the level of gas pressure leaving the burner and the recommended indicators in the technical data sheet of the equipment. Entrust this task to the specialist who installed the gas boiler.

What causes noise in the boiler?

Extraneous noise in a boiler is most often not as dangerous as it might seem to the average person. The only threat is the appearance of malfunctions when the boiler requires major repairs or replacement. Do not put off checking the heating system for a long time if extraneous sounds appear in the gas burner. You should immediately contact a specialist who can determine the cause of the noise and eliminate it. It is not recommended to disassemble the boiler yourself if you are not sure of how it functions and what parts it consists of.

Most often, the causes of humming, tapping, hissing and other noise accompanying the operation of a gas boiler are:

- operation of non-freezing media

- reduction in gas pressure

- scale on boiler parts

- malfunction of circulation pumps

- incorrect burner installation

- fan malfunction

When the boiler is turned on, a popping sound is heard

If, when you turn on the gas boiler, you hear extraneous noises: pops, clicks, knocks, you should immediately start looking for the problem.

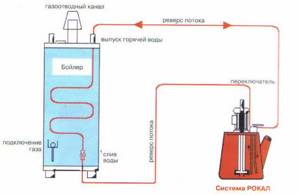

The three-way valve is the main component of a double-circuit gas boiler. Its task is to regulate the redistribution of flows when the hot water supply is turned on. If the cause of extraneous noise lies in the valve, it is faulty and the part needs to be replaced

What to do if the gas boiler slams sharply when turned on:

- Three-way valve malfunction. This device sends water in a small circle when drawing sanitary water from taps. If it clicks, it needs to be replaced.

- Prolonged spark ignition. When ignited, the resulting excess gas flares up and a characteristic pop is heard. In this case, it is recommended to check the igniter, burner, electrode, and all contacts.

- The chimney or filter is clogged. In this case, they need to be cleaned. The chimney is checked with a lit match. If the flame deviates, everything is fine; if there is no draft, cleaning is required.

- Installation error. If the equipment is installed incorrectly, but when heated, the metal is deformed and popping sounds are heard. The same sound occurs when it cools as the metal returns to its original position. When switching to hot water supply, the boiler hums. The problem is solved by reinstalling the gas boiler.

- The injectors are clogged. A thin wire is used to clean them. You must first turn off the gas.

If the boiler vibrates during operation, it is recommended to place a gasket under the body.

Conclusions and useful video on the topic

The reason for the noise during operation of the gas boiler:

Whatever gas boiler is installed in your home, first of all you should make sure that it is installed correctly. Equipment requires regular preventive inspection. This will allow problems to be identified and corrected in a timely manner.

It is recommended to periodically clean the coolant from dirt and scale. These simple manipulations will allow the device to work as long as possible, efficiently and without extraneous noise.

Have you ever encountered a gas boiler that slams, clicks, whistles or makes noise? How did you resolve this problem, or what services did you contact? Share your experience with readers in the comments and ask our experts any questions you have.

Sounds from heating devices

If you hear a howl in the middle of the night, then most likely the system has leaked. A cloud of steam and a characteristic whistle will immediately indicate a gust or a failed valve. In some cases, it is enough to close the tap to bring the heating system into working condition.

If no obvious causes are found, and the howling is accompanied by a crackling sound, it is necessary to check the pressure. Perhaps the flying scale blocked the free flow of the coolant, which caused increased pressure - it is urgent to stop the boiler, drain the water and look for the problem.

It happens that the batteries start to “shoot” - this is another reason to be wary. Such noise is typical for bimetallic batteries when the pressure in the system does not coincide with the calculated one.

When purchasing heating appliances, you need to take into account the operating parameters of the boiler and select the appropriate radiators. Otherwise, the problem may result in a rupture of the heating device due to water hammer, which is completely inappropriate in the winter cold.

Heated water is not able to compress; it needs to move freely along the contour. Banal deposits in pipes can provoke an increase in pressure and rupture of pipes due to water hammer.

Another reason is an air lock, which can be eliminated through the Mayevsky drain valves located at the ends of the batteries. The procedure is simple, and anyone can handle it.

Malfunctions of the Navien gas boiler

In order for you to be able to repair Navien gas boilers yourself, we have compiled this guide. It will provide invaluable assistance in eliminating breakdowns and failures. Let's see what self-diagnosis systems can tell us - let's present the error codes of the Navien boiler in the form of a list:

Despite the huge number of possible breakdowns, most of them do not pose a serious problem and can be solved quite quickly and with little cost.

- 01E – overheating occurred in the equipment, as evidenced by the temperature sensor;

- 02E – in Navien boilers, error 02 indicates a break in the flow sensor circuit and a decrease in the coolant level in the circuit;

- Error 03 in Navien boilers indicates the absence of a signal about the occurrence of a flame. Moreover, the flame can burn;

- 04E - this code is the opposite of the previous one, as it indicates the presence of a flame in its absence, as well as a short circuit in the flame sensor circuit;

- 05E - an error occurs when there is a malfunction in the circuit for measuring the temperature of the coolant in the heating circuit;

- 06E – another temperature sensor failure code, indicating a short circuit in its circuit;

- 07E - this error occurs when there is a malfunction in the temperature sensor circuit in the DHW circuit;

- 08E – error of the same sensor, but diagnosing a short circuit in its circuit;

- 09E - error 09 in Navien boilers indicates improper functioning of the fan;

- 10E – error 10 indicates problems with smoke removal;

- 12E – the flame in the burner went out;

- 13E – error 13 indicates a short circuit in the heating circuit flow sensor;

- 14E – code for lack of gas supply from the main;

- 15E is a rather ambiguous error, indicating problems with the control board, but without a specific indication of the faulty node;

- 16E - error 16 in Navien boilers occurs when the equipment overheats;

- 18E – problems with the smoke exhaust system sensor (sensor overheating);

- 27E – the electronics have detected errors in the air pressure sensor (APS).

There are no repair instructions included with the boilers, since repair work must be carried out by a service company. But nothing prevents us from repairing a faulty unit ourselves, without resorting to the help of specialists.

Let's see how Navien boilers are repaired at home.

The Navien boiler does not reach the set temperature

In order to prevent the appearance of scale, install a system for purifying and softening tap water - the costs will not be the greatest, but you will extend the life of your boiler.

First you need to clean the heat exchanger of the Navien gas boiler. At home, this is done with citric acid, toilet bowl cleaners, or special products (if available). We remove the heat exchanger, fill it with the selected composition, and then rinse it under high pressure of water.

In a similar way, you should clean the heat exchanger of the DHW circuit if the Navien boiler does not heat hot water. In the most advanced cases, the exchanger must be completely replaced.

The Navien boiler quickly gains temperature and cools down quickly

A very complex error indicating some kind of malfunction or defect in the heating system. Try to correct the situation by adjusting the speed of the circulation pump, make sure there is no air in the system. It is also necessary to check the filter and heat exchanger clearance. In some cases, it may be necessary to replace the coolant.

How to eliminate error 03 in Navien boilers

For some reason, the electronics do not receive a signal about the presence of a flame. This may be due to a lack of gas supply or a malfunction of the flame sensor and its circuit. Sometimes the error appears after some work has been carried out on the gas main. Another possible reason is that the ignition does not work. Eliminating the error:

- We check the presence of gas supply;

- We check the functionality of the ignition;

- We check the ionization sensor (it could be dirty).

If there is no malfunction in the Navien gas boiler, error 03 may occur due to some problems with grounding (if any).

How to eliminate the buzzing of the boiler when turning on bitter water

If noise occurs from the boiler, you can resort to the following measures:

- call a technician specializing in the repair and maintenance of gas boilers;

- Try to find the cause of the problem yourself. To do this, you should diagnose all components of the system - from the gas pipe to radiators and hot water taps;

- Clean the system using suitable products. You can use special factory chemicals or folk remedies such as vinegar and citric acid;

- check the pressure in the system and, if possible, adjust it to the optimal level.

You should not interfere with the operation of the equipment without professional knowledge. This poses a serious danger to others. Work with gas equipment should only be trusted to specialized professionals. It is best to contact a service center recommended by the boiler manufacturer.

Climate control boiler

This is interesting: How to connect a heated floor without grounding

Causes of extraneous noise in various models

Why does the Navien gas boiler click regularly? There are two possible reasons: scale formation and problems with the coolant.

How to fix the problem yourself:

- disassemble the device;

- clean or replace the heat exchanger;

- check the taps;

- reduce the water temperature.

Extraneous noise is also observed during operation of Beretta brand gas boilers.

Typical reasons:

- poor heat transfer in the heat exchanger, scale formation;

- Wrong pipes are connected.

Why does the Concord gas boiler whistle? The most common reason is increased load in cold weather. The boiler power declared by the manufacturer does not correspond to reality and in practice the figures are lower.

For example, if the documentation indicates 13 mbar, then in reality it is 10 mbar. The device should not be set to maximum.

It is recommended to clean your gas boiler at least once a year. For this purpose, you can contact a service center or carry out the procedure yourself.

In a Baxi gas boiler, noise occurs most often when the heating function is turned on. To identify the cause, the bypass should be checked, and the valve should be cleaned and adjusted. Users of AOGV devices often complain about whistling. The cause is scale and a clogged filter.

Vailant boilers hum after turning on the heating function and turning off the fire. The first reason is that the heating circuit strainer is clogged; cleaning it will correct the situation. The second reason is a malfunction of the valve on the bypass line. Adjusting the valve will help solve the problem.

The cause of noise in Ariston boilers is poor coolant circulation. The problem will be solved by blowing the heat exchanger with a compressor. If the Ardelia gas boiler is humming, you should check that the pump settings are correct. If the situation cannot be corrected in this way, then it is recommended to replace it with a new circulation device.

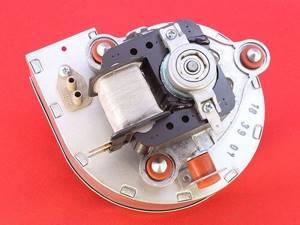

Pump noise

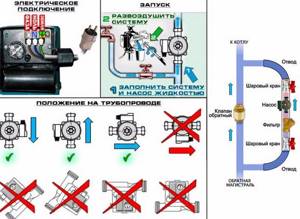

A common cause of problems is pump operation. Typically, it has three positions to raise the water column to a certain height, which depends on the power of the device. The uniform movement of the coolant along the thermal circuit is not accompanied by noise effects.

If you hear strange sounds that sound more like mechanical sounds, you should check the operation of the pump.

In case of failure:

- water gurgles in the heating pipes of a private house;

- a hum appears;

- cracking is possible;

- The boiler begins to make noise and knock.

In this case, you need to turn off the pump, and if the sounds stop, then the reason has been found. Cracking and noise are mechanical damage: this means that the graphite sliding bearings have worn out or dirt has gotten into the housing.

Scale settles on the inner walls of the pump due to poor-quality coolant and has a destructive effect on its components.

Checking is simple:

- it is enough to remove the pump;

- lower its working part into a container of water;

- when turned on, it must pump water; if this does not happen, it must be repaired.

Important! The pump cannot be turned on without water.

When noises occur

The new boiler operates almost silently, no louder than a household kettle. But sometimes, over time, if the components are incorrectly installed, configured or worn out, the device beeps quietly or even makes noise like an airplane.

Loud noises in the heating boiler disturb users; the reasons may be the following:

- The water in the system is highly oxygenated. When heated, air bubbles are released which produce noise. This happens most often in open heating systems. At the same time, not only the device itself vibrates, but also the wall radiators.

- The boiler puffs if a lot of air has accumulated in the coolant system.

- Scale in the heat exchanger. If the water is hard, over time lime will build up on the walls of the radiator pipes.

This also reduces equipment durability and efficiency. A sign of scale accumulation is that the device hisses like a kettle when it warms up.

- Strong noise can be produced by an incorrectly operating fan designed to remove combustion products. This can be caused by drying out of the lubricant inside its bearings, imbalance, or accumulation of dust and dirt on and around the blades.

- Perhaps it is not configured correctly, and that is why the gas valve or bypass is howling.

Bypass installation example - When operating at high power, a faulty gas meter rattles.

- If the equipment power exceeds the required, vibration occurs from excess pressure created by the pump. The device also cracks if there is too little coolant in the system.

- Often a loose valve or a valve inside it rattles.

Extraneous sounds in the heating boiler

Sometimes the heating of the boiler is also accompanied by some sounds. When cold equipment heats up and begins to crack, the characteristic clicks should not cause panic - metal makes such sounds when it warms up.

Gurgling and gurgling are also possible - this is also a normal phenomenon: the coolant began to heat up and set the system in motion. However, the same sounds can occur if there is insufficient coolant in the pipes. In this situation, it is enough to add water to ensure uniform heating.

Cotton

You can hear such sounds if the gas outlet pipes are clogged. This happens when the boiler is ignited: the accumulated gas, without having time to escape, creates a bang. This is dangerous, as a sudden burst of flame can cause burns or fire.

If the boiler is gas, then the reasons for such noise are clogged nozzles or a malfunction of the three-way valve. In this situation, it is necessary to clean the equipment from soot.

Knock

The occurrence of a knocking sound in the boiler indicates its incorrect installation or unregulated operation of the pumping equipment. If the pump operates unevenly, moving the coolant in jerks, resonance occurs between the boiler and the pump, accompanied by a characteristic knocking sound. In this case, it is necessary to regulate the operation of the pump.

Sounds in different boiler models

Noise can occur for a trivial reason, which lies in the boiler model itself. This is typical for gas boilers equipped with ventilation burners. To avoid such trouble, you need to choose boilers with atmospheric burners and an electronic control system.

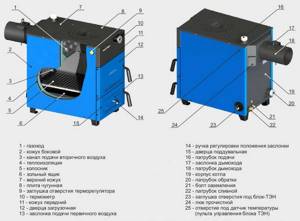

When choosing a solid fuel or electric boiler model for heating your home, you should always familiarize yourself with the technical characteristics of the equipment. Often the cause of noise can be incorrectly selected equipment, as well as the presence of a fan in the boiler.

Double-circuit boilers also suffer from noisy operation: although not obvious, water overflows and filling of the system are always accompanied by sounds.

ZOTA boilers are very sensitive to the quality of the coolant, so unpleasant effects can be caused by:

- clogged mud trap;

- oxygenated water;

- scale on working elements;

- Broken bearings on the fan.

Therefore, it is worth choosing single-circuit models and purchasing a boiler to heat hot water.

Prices for ZOTA boilers

boilers ZOTA

Prevention

Timely prevention of all components of boiler equipment can minimize the likelihood of noise.

Thus, flushing the system once a year is a prerequisite for trouble-free operation. Moreover, this is becoming a mandatory requirement of many resource supply organizations in preparation for the heating season.

You can flush the system yourself or use the services of specialists.

Depending on the coolant, the type of cleaning is selected:

- Washing with water under pressure generated by the compressor. Sometimes this is enough.

- For iron oxide deposits on pipes, appropriate chemicals are used. They eliminate the problem and additionally create a protective barrier from further exposure to an aggressive environment.

- You can use the services of a specialized organization that has the equipment and tools to perform the work.

Each operating manual for heating equipment provides a recommendation for preventive inspection and cleaning of the working parts of the boiler from corrosion and all kinds of contaminants with partial disassembly - at least once a year. If maintenance is not carried out, the manufacturer withdraws its warranty obligations.

Reasons for whistling in a gas boiler by model

Different boiler models are subject to specific breakdowns. Let's look at some of the models and the common faults that occur in them.

- NAVIEN. A common problem with these models is a weak pump. It can be solved by purchasing and installing a special stabilizer. Another cause of noise is clogged parts. Requires cleaning.

- Mimax. There may not be enough water pumped by the pump. Or lack of indoor air. In the latter case, it is enough to open the window while the boiler is operating and the problem will go away.

- Baxi. There may be three reasons: the gas valve is incorrectly adjusted, incorrect gas pressure (the norm is 13 mbar), or blockages in the gas reducer/burner.

- AOGV. Resonances may occur in the burner or the fan may not work properly. Sometimes the problem is solved by cleaning the solenoid valve and lubricating the part.

How to remove an air lock with your own hands

Air in the system after a long stop is common. This problem arises not only in the private sector, but also in apartment buildings. It's quite easy to solve.

Heating radiators are equipped with Mayevsky taps located at the ends of the radiators. This could be a valve or a fitting with a notch for a screwdriver.

How to fix:

- armed with a small container (for draining water), you need to unscrew the tap and let out the air;

- Actions should be performed carefully so as not to get burned by the escaping steam;

- when water comes out of the hole, close the valve;

- Such manipulations are carried out on each battery.

This eliminates noise and allows the coolant to move freely through the system, evenly releasing heat.

Methods for cleaning radiators from dirt

During operation of the heating system, dirt accumulates in it: iron oxides, dissolved salts and possible mechanical impurities. But if water moves through the pipes at high speed, then in the radiators the process slows down and the sedimentation of suspended matter increases. Therefore, cleaning radiators is a must.

There are two methods: flushing the entire system together and disconnecting the batteries and cleaning using a compressor unit. Favorable conditions are created in the batteries for the accumulation of dirt, since the coolant slows down the movement in them. To flush, the radiator is connected to the compressor, and dirt is cleaned from it with water pressure.

If you carry out annual preventive maintenance of the entire system, then drastic measures will not be required. It is quite possible to limit yourself to a general flushing of the entire heating circuit with ordinary water. Chemical reagents are used in cases where the coolant does not meet the established parameters and significant deposits of salts and scale appear on the working elements.

After using chemicals, leaks may form in radiators and cracks may appear that were successfully covered with dirt.

To avoid an emergency, all equipment must be checked for functionality before starting the system.

Timely preventive maintenance of all components of the heating system will protect it from complex accidents and save the budget. Find out how to insulate the foundation base from the outside with penoplex at the link.

Video

By watching the video, you can find out why the circulation pump is noisy and what needs to be done.

Evgeniy Afanasyev chief editor

Author of publication 08.11.2018

Did you like the article? Save so you don't lose!

Knocking in the heating pipes of a private home is a common occurrence for owners with individual heating. Why the noise occurs and what influences it is necessary to understand.

The main indicator of trouble is poor-quality coolant containing dissolved salts and mechanical impurities.

Why does a gas boiler click and why are these noises dangerous?

Knocking, clicking, vibration or sometimes even an “explosion” in gas boilers most often occurs due to the build-up of dirt and fossils in the hot water heat exchangers or in the main heat exchange center of the heating system.

The clicks or hums themselves do not pose a danger to the residents of the house. No defects or problems will appear due to them.

The most they will bring is discomfort.

Reference! However, clicks (and other noises) usually become an indicator of malfunctions in the gas boiler. This could be either a serious breakdown of the part or a build-up of dirt.

The gas boiler clicks during heating, switching on and/or switching off.

During power on

In case of malfunction of the three-code valve.

- If you hear a loud bang or knock, the ignition system is most likely faulty. This happens when the spark ignites much later than it should.

In this case, a large amount of gas accumulates. When a spark appears, the gas ignites and a bang is heard.

- Such noise is caused by a clogged wick (if the gas boiler is semi-automatic) or a defect in the chimney. At the same time, the electrodes (in boilers with automatic ignition) also become clogged, which short-circuit and click. When heated, they deviate more.

- Clogged nozzles in the burner lead to a poor-quality mixture of natural (or liquefied) gas and air. This is evidenced by the noise when lighting a fire.

During heating

- The gas boiler makes noise if the radiator mounting brackets are installed incorrectly. Then during heating (sometimes during cooling) the thermal expansion in the heating system will not be balanced.

- A clogged mesh in the housing also leads to clicking sounds. At the same time, the draft decreases when heated.

- Sometimes resonance occurs in the system due to improper operation of the pump.

- The evaporation of a large amount of water is also accompanied by various sounds.

When cooling

A lot of free space is needed for heat to spread, and if the pipes were installed without taking this into account, then most likely the boiler will click or crack.

This phenomenon is most noticeable when cooling the heating device , when the temperature changes downward.

Why is a gas boiler humming - reasons and solutions

Users, as a rule, prefer silent gas boilers. If the unit is in good working order, it should not produce too loud noises. But it happens that the boiler makes an uncharacteristic hum. Then the question arises, why is the gas boiler humming? If it is new, then in most cases there are no problems here, just some new elements expand and contract under the influence of temperature changes. It takes time for them to get into working shape and fall into place.

The most common reasons why a gas boiler hums loudly are:

- fan malfunction;

- a large amount of oxygen in the coolant;

- sediment on parts;

- reduction in gas pressure.

Sometimes the reason why a double-circuit gas boiler hums is a malfunction of the fan. This is caused by a lack of lubrication and contamination of the blades. In this case, it is necessary to clean the fan and lubricate the bearing with oil. If necessary, the broken part is replaced with a new one.

The hum of a gas boiler can be monotonous or periodic with crackling. Smooth noise occurs even with new units. In this case, boilers in which the coolant circulates naturally are usually noisy. The cause is an excessive amount of air in the coolant. The fact is that when heated, many air bubbles form in the water, which produce noise. This is the answer to a common question from consumers, why a gas boiler hums when heating. Such noise does not mean there is a problem with the gas unit, but it does cause some discomfort.

The problem can be solved by converting the system to a closed one. You can change the type of system by installing valves and replacing the expansion tank with a membrane one. It will also be useful to connect weather-sensitive automation. Such measures will help extend the life of the unit.

Another common reason why a gas boiler hums loudly is the accumulation of limescale deposits. When the coolant is heated to more than 60ºC, scale begins to actively develop, which over time clogs the heat exchanger pipes. In this case, the heat exchange between the circuit and the coolant deteriorates, and the efficiency of the unit is significantly reduced. Under the influence of circulating water, pieces of scale break off and move, while they hit the metal walls of the heat exchanger and create a knocking noise.

The problem is solved by cleaning the heat exchanger. However, flushing can only be done on regular circuits. If the bithermal heat exchanger becomes clogged, all you have to do is throw it away and buy a new one. In addition, such circuits become clogged faster than their classic separate counterparts.

After installing a cleaned heat exchanger in a gas boiler, it will stop making noise.

In some cases, noise in a gas boiler causes a decrease in gas pressure. Because of this, water circulation in the system decreases and air pockets appear. As a result, the unit overheats, trying to reach the required temperature, and begins to hum.

You can eliminate noise by solving the problem of low gas pressure. The reason for the decrease may be:

- low pressure in the line;

- gas pipeline contamination;

- presence of a leak (accompanied by a characteristic smell of gas);

- gas meter malfunction.

If the “root of the problem” is a leak or low pressure in the centralized main, then only representatives of the gas service can help.

If a gas pipeline is clogged, it needs to be cleaned. If a breakdown occurs in the gas meter, fuel will pass through it with difficulty. A symptom of a problem with the meter is noise and crackling noise coming from it. After replacing the measuring device with a new one, the pressure will return to normal and the noise will stop.

Note! It is necessary to know the optimal gas pressure readings and measure it periodically. The value should be within 1.5-2 atmospheres.

There are other reasons why a gas boiler hums or makes noise:

- The bypass or gas valve is not set correctly, resulting in a howling sound.

- If the power of a gas appliance exceeds what is required, this often results in vibration and rattling sounds.

- If there is a lack of coolant in the system, the gas boiler will also make vibration noise.

- If sounds of rattling metal appear, this may be due to installation errors of the unit.

How to get rid of unpleasant sounds?

A good way is to convert an open water supply system to a closed one. Then the water will boil a little less, and there will also be less sounds. This procedure will also additionally protect metal parts from lime or corrosion.

Attention! Changing the type of system does not affect its functioning without a pump. Changing the system means installing air vents and replacing the expansion tank with a membrane one.

When dirt accumulates, the situation is somewhat different. When lime forms on the walls of a gas boiler, the temperature inside these walls gradually increases. This, in turn, will lead to a decrease in the life of the heat exchanger and to the appearance of clicks and knocks.

Important! Not only clicks and tapping are a sign of deposits in the boiler, but also such characteristic sounds as vibration, crackling and “explosions” (in advanced cases).

Only cleaning the gas boiler from lime will help here. This can be done either independently (don’t forget to turn off the heat exchanger) or with the help of a wizard.

To avoid dirt deposits, it is recommended to regularly wash the components in a 4% vinegar solution . This procedure must be carried out after removing the heat exchanger. The parts must then be washed in clean water.

Photo 1. Disassembling a gas heating boiler and checking components for the presence of lime and mud deposits.

If an important part is seriously damaged, then the best option is to call a specialist, because replacing it yourself can damage the boiler even more. Do not forget that a gas boiler can be life-threatening if used incorrectly.

How to solve a problem

The fix will depend on the original cause, therefore:

- If there is an excess of oxygen in the water, it is necessary to re-equip the entire system. That is, you will have to install air vents and replace them with a membrane expansion tank.

- If the whistle comes from the valve, then it is advisable to check the settings. This can be done using the recommendations in the instructions.

- When the pump power exceeds the needs of the structure, the speed of the work process should be reduced.

- It is also worth replacing valves with ball valves. But you can also install an auxiliary rubber gasket.

- To prevent knocking when the temperature in the radiator changes, you need to change the location of the wall mounts.

- And to prevent pipes intended for heating from ringing, you should lay a special material - Merelon - around them. This will promote isolation.

- To eliminate sounds from the heat exchanger, you need to clean the inside of the scale.

Subscribe to our Social networks

The appliance is noisy when heating water

Modern boilers operate quietly, so vibration, noise, and extraneous sounds should alert you. What could be an indirect reason:

- Incorrect installation, connection.

- Incorrect setting.

- Wear of components.

There are also very specific reasons why the boiler is humming.

High oxygen content

The water in the pipes is oversaturated with oxygen, which causes bubbles to form when heated. This effect leads to increased noise and vibration not only of the device, but also of the batteries.

Air accumulation in the system

If the boiler knocks and puffs, it is necessary to bleed the air in the pipes. Modern radiators have taps installed. By unscrewing them, you can remove the accumulated air.

Scale formation

A high content of salts in water leads to their deposition on the walls of the heat exchanger. Therefore, when heated, the unit will hiss. In addition, the heating rate and heat transfer are reduced. It is recommended to clean the radiator once a year. To do this, a pump with a reagent is prepared, and the cleaning liquid is pumped through the hoses.

Fan problems

The fan operates in models with a closed chamber and forced removal of combustion products. Why does it make strange sounds when rotating, whistling:

- The grease in the bearings has dried out due to placement above the burner. When exposed to high temperatures, the lubricant dries quickly, which leads to bearing wear. The part is disassembled and lubricated.

- Unbalanced blades, accumulation of dirt and dust. The blades are cleaned and rotated.

Excessive pressure in the heating pump

The pump produces high pressure; its settings need to be adjusted. Too high pressure in the system can lead to an emergency. The values can be adjusted by switching the white lever on the terminal box.

A lack of water in the system leads to serious overheating. First of all, check the thermostat settings, set them to lower values. Measure the pressure and add coolant if necessary.

And:

- If the boiler howls, it is due to an incorrect setting of the gas valve or bypass (jumper pipe).

- When operating at high power, the gas meter may rattle.

- A worn valve makes rattling sounds.

Causes of noise in heating equipment

The new gas boiler operates virtually silently. However, over time, the unit begins to make noise.

This is a sign of hardware failure:

- scale formation;

- the fan has failed;

- wear of device components;

- manufacturing defects;

- incorrect settings or installation of the boiler.

To understand why a gas boiler makes loud noise, you need to listen to the noise the equipment makes.

If the hum is heard directly from the boiler, then you should check the water level and add it if necessary. If noise is heard from radiators or piping, then air has entered the system and must be removed. Extraneous noise in the pump itself indicates a manufacturing defect.

Clicking sounds that occur at short intervals indicate problems with the fan. If the boiler hisses or whistles, it means that a lot of scale has accumulated in the device

If the circulation pump breaks down, this element often needs to be replaced. The gas supply to the system must be adjusted from time to time. High pressure is undesirable.

Problems with the exhaust fan

If extraneous noise occurs at intervals, you should check the fan. Its task is to systematize the operation of the smoke removal system, due to which combustion products are removed from the boiler with the intensity necessary to ensure the complete safety of others.

The fan blows through the system, clearing it of combustion residues, and also serves to remove smoke. The longer the boiler operates, the greater the fan wear

The main reason is age. Most likely, you just need to replace the fan with a new one. The second reason that leads to rapid wear of the cooler is its location above the burner at the top of the device.

Under constant exposure to high temperatures, the bearing lubricant quickly dries out, causing it to wear out. To fix the problem, you also need to replace the fan.

Another reason for the appearance of extraneous noise effects is that the part may be clogged with dust, to remove which you need to do the following:

- Inspect the fan. If necessary, it should be cleaned. The main blades are located inside the housing. You need to remove dirt and dust from them, and then lubricate the bearings.

- If the problem cannot be solved, replace the outdated valves with new ball valves.

- If the previous two steps did not bring results, reinstall the cooler.

It is better to entrust the replacement of parts to a gas boiler repairman from a service with which an agreement has been concluded for the maintenance of devices and the supply of blue fuel. Timely and competent replacement of worn parts will eliminate the need to buy a new unit.

Scale deposits on the walls of the heat exchanger

Thanks to the heat exchanger, heat is redirected from gas to water. If the water is hard, then scale may form in the heating system as it heats up. To remove mineral deposits deposited on the walls, it is recommended to regularly chemically flush the heating system and clean the heat exchanger.

A household chemical for cleaning the heat exchanger can be purchased at the store. Craftsmen often use 4% vinegar for these purposes. After cleaning, parts should be rinsed with water.

This problem is noticeable after 15-20 minutes from the moment the gas boiler is started. The reason for the sound is the narrowing of the passage for water. As a result, steam and small bubbles are formed. Scale reduces the efficiency of equipment, as well as its heat transfer and wear resistance.

You can descale the unit using chemicals containing soda and similar substances. You can do this yourself. To do this, remove the heat exchanger, remove the casing and unfasten all connected pipes. A special chemical solution must be poured into the device for 2-5 hours.

Lack of water in the heating system

If there is not enough water flowing through the heating system, the boiler begins to make noise due to overheating. This is because air pockets form inside, interfering with the normal circulation of fluid in the system.

Airing the system leads to incorrect operation of the boiler. If there is not enough water in the pipe section, an air lock will form. At the same time, the heating device partially cools down, and water cannot circulate normally in the system, so it overheats by the burner. At the same time, a dull whistle or howl is heard

Airing leads to the following problems:

- the circulation of water in the coolant decreases or stops;

- The boiler automatically turns off due to overheating of the coolant.

Reasons why air ends up in the heating system:

- violation of sealing during repair work;

- violation of the integrity of the system;

- drainage of water from the DHW circuit.

To make the device work, you need to adjust the thermostat. You also need to make sure that the thermostat is installed correctly, add water, and adjust its supply and circulation.

The Mayevsky valve, which is mounted at the end of the radiator, will help get rid of air in the system. It has a fitting that, when opened, allows access to the inside of the battery. The faucet is most often installed at the top of the device, where warm air accumulates.

You can also use an air separator. The device collects air that collects into bubbles as water flows along the circuit. When excess air has been completely removed from the pipes, replenish the coolant through the make-up tap and make sure that the boiler operates without any extraneous sounds.

Arranging a perfectly sealed heating system will prevent the accumulation of air in the coolant. This is troublesome and expensive, but it will eliminate the occurrence of extraneous noise in the gas boiler.

Consequences of low pressure

Reasons why pressure in the system may decrease:

- water leak;

- breakdown of the boiler expansion tank;

- long interruption in electricity supply;

- Incorrect setting of the gas boiler.

If the pressure in the system drops, the boiler begins to make loud noises. Your task is to first check if there is a leak in the heating circuit. A simple napkin will help you with this; use it to wipe all joints and joints. Once the source of the leak is discovered, it must be eliminated.

If the pressure in the system drops, the boiler stops working because it is blocked automatically. Lack of water in the heating circuit leads to overheating, it is detected by sensors, after which the boiler turns off automatically

The cause of pressure changes may be cracks in the expansion tank or heat exchanger. To identify their location, all water should be removed from the system, and then air should be pumped into it using a compressor. In places where microcracks form, air will leak out with a characteristic whistle. The appearance of microcracks indicates wear and the need for complete replacement.

This occurs as a result of frequent flushing of the system with chemical reagents, due to poor quality metal, a sharp increase in pressure in the line, and water hammer. If you can remove and repair the heat exchanger yourself, then you can try soldering the resulting microcracks.

To prevent such problems, it is recommended to regularly inspect the boiler, as well as install auxiliary equipment that will allow you to control the pressure by displaying the value on the screen. Standard pressure indicators are 1.5-2 atmospheres.

Incorrect unit setting

Incorrect adjustment or installation of equipment can also cause a valve or bypass to whine. Extraneous noise may occur as a result of improper load redistribution.

If the operating power of the unit exceeds the permissible values, vibration occurs as a result of excess pressure and the pump begins to rattle

If the sound of metal hitting metal occurs during heating or cooling, uncompensated heat expansion occurs in the device. The reason lies in incorrectly installed radiator mounting brackets.

If you don’t know why your gas boiler is constantly whistling, you should first check the settings. The rules and sequence of actions when setting up a gas boiler can be found in the technical documentation for the unit; operating parameters can be found on the nameplate attached to the equipment body.

Types of noise in pipes

The noises that accompany the general heating start-up differ from emergency ones - they are intermittent and are accompanied by gurgling or gurgling. In bimetallic or aluminum batteries, a crackling or buzzing noise may be heard - this is also normal.

It is clear that prolonged noise is unpleasant, so it is necessary to prevent the situation in a timely manner.

The knocking and hum that occurs in the room with increasing force give reason to be wary and take drastic measures:

- Check heating devices and temperature conditions in the circuit. If a pump is installed, then its operation.

- Pay attention to the valves - if they break, a characteristic whistle appears. Sometimes a small adjustment is all it takes to get the equipment working.

- Having discovered visible problems, you need to stop the coolant and turn off the heating devices. Having assessed the breakdown, proceed to eliminate the accident yourself or invite a specialist.

These are primary measures that can prevent the development of major destruction.

Why does the speaker crack and click?

Clicking and crackling noises are another common malfunction of gas instantaneous water heating equipment. Failure occurs in both automatic and semi-automatic boilers. Below is the nature of the sounds and what exactly can cause them:

- The gas heater clicks, but does not ignite - the contacts on the ignition unit have oxidized. The module cannot be disassembled and requires replacement. The catalyst for the geyser crackling but not igniting can be dead batteries.

- The gas water heater clicks after turning off the water - the “frog” water regulator has failed. Inside the block there is a rod with legs connected to the ignition block. After turning off the water, the metal rod should be returned to its original position by a spring. If the rod is rusty, it may jam. The ignition unit remains switched on and continues to produce a spark. For this reason, the speaker crackles after switching on. The malfunction can be caused by a coarsened frog membrane - it needs to be replaced.

- The piezoelectric element is constantly cracking - the contacts have oxidized, which leads to jamming and stable operation.

Noise in the column is caused by insufficient draft (the flame burns with a hum, changes color, soot is present), poor air circulation (observed after installing metal-plastic windows in the kitchen), clogging of the burner ignition wick or scale build-up on the heat exchanger. The malfunction is found by elimination during the next maintenance of the column.

Why does the gas boiler hum and/or whistle?

There are times when the boiler interferes with the noise it makes. When the burner operates, it makes a noise similar to that of a jet plane. The gas boiler is noisy and can be heard throughout the house. It naturally interferes with sleep, especially when it turns on after a pause. How to reduce the noise made by a gas boiler?

Usually, it is not the boiler or the fan installed in it that makes noise, but not the correct installation of the chimney. To make the boiler start to make a noisy sound, you just need to narrow the chimney a little, and you will get a sound like at the airport. The solution is to change or expand the chimney.

There are very frequent cases when gas equipment with pressurized burners begins to hum. The fact is that fan units are equipped with a stabilization system aimed at regulating the gas pressure supplied to the combustion chamber. When operating, such a boiler hums like a vacuum cleaner. To reduce unpleasant humming to a minimum, it is better to build the boiler room building away from a residential building and provide good sound insulation for it.

The boiler may begin to hum due to a thick layer of deposits on the inside of the heat exchanger tube. The boiler begins to boil - it makes a sound like the sound of water in a boiling kettle. The primary heat exchanger is clogged. You can check this in the following way: set the boiler to the maximum temperature and close the return or supply valve so that there is minimal water flow. When the temperature reaches about 80 degrees, the hum increases. The only way to solve the problem is to clean the heat exchanger.

Shock-absorbing lining - what is it?

The shock-absorbing lining is a rubber sheet 10-12 mm thick or rubber washers of the same thickness. To reduce noise, all connections must be sealed and rigid, the chimney must be additionally insulated with thermal insulation (basalt mineral wool, etc.)

It happens that when you press the ignition button, a whistle is heard from the pilot burner nozzle. If air appears in the gas pipeline or gas fittings, it is necessary to unscrew the nut at the junction of the gas tube to the gas fittings, press the ignition button, having first loosened the pipe, bleed out the air until the smell of gas appears. Tighten the nut.

If there is a flame separation, the pilot burner gas pressure should be adjusted using the adjusting screw. There are times when the wrong nozzle is installed, then it just needs to be replaced. This situation occurs in domestic units. The injector may also have a manufacturing defect, expressed in the absence of a chamfer along the edges of the holes. When switching to high intensity mode, the gas flow escapes and the boiler begins to whistle. The only solution in this case is to replace the nozzle.

We should not forget that gas boilers are explosive, so to fix problems it is better to contact specialists by phone.

Main causes of clicking

In fact, there are not so many reasons for clicking in the boiler. Here are the main ones:

- component failure;

- appearance of lime;

- violation of the thermal balance in the boiler.

The rest are variations of these reasons. If you cannot independently determine the cause, then it is better to ask for help from specialists. The technician will tell you why the gas boiler is cracking and eliminate unnecessary sounds. It may be more expensive, but it’s still better than risking yourself or the boiler and fixing the problem yourself.

Navien Ice boiler malfunctions

Let's look at the characteristic malfunctions of this series, especially since there are not so many of them. For example, in the Navien Ace 24 K model, error 10 often occurs. This gas wall-mounted double-circuit boiler is built according to a closed combustion chamber, so problems with smoke removal often arise. Most often, the cause of the malfunction is a broken fan; it will need to be replaced.

Error 02 occurs no less often. This is what can appear when the Navien boiler quickly gains temperature and quickly cools down. The reason lies in airing of the circuit or a malfunction of the flow sensor. The heating system must be freed from air - for example, by connecting it to a water supply and driving the coolant under pressure. In our reviews, we have already written about how heating lines become de-aerated.

Control board malfunctions

The most unpleasant mistake, since it is difficult to understand something here. It is designated by code 15E. It is almost impossible to understand the board structure on your own without a specialized education. Therefore, we recommend calling a specialist. He will test the electronic board for faults, localize the breakdown and fix it. How testing and repair will be carried out, at home or in a service center, will be determined by a specialist.

Popping and clicking noises when igniting

When starting an Ariston or another brand of boiler, do you hear knocking and popping noises? The problem requires an immediate solution.

Three-way valve

The part is used to switch the operation of the unit from heating hot water supply (DHW) to heating, and vice versa. A faulty valve will click every time it is ignited. In this case, it needs replacement.

Ignition block

A loud bang occurs when the spark ignites for a long time. Then a lot of gas accumulates, which flares up when ignited. It is necessary to carry out diagnostics of the unit: burner, igniter, electrode, contacts and connections.

Wick clogged

When ignited, the product bangs, which indicates a clogged wick or chimney. The problem is typical for semi-automatic models. Inspect the wick: if clogged, clean it.

To make sure that the chimney shaft is clogged, check for draft:

- Place a lit match near an inspection window or vent.

- If the flame deviates to the side, the draft is normal; if it burns evenly, it needs cleaning.

For your part, you can clean out the mine. But to completely remove contaminants, it is better to contact utility services.

In models with automatic ignition, the electrode may become clogged. Clean the part and install it 3-4 mm from the burner.

The injectors are clogged

When heating, a noise is heard, ignition does not occur, or the flame bursts out in jerks. Turn off the gas supply and clean the holes with a thin wire.

Incorrect installation

If the calculation and mounting of the device body is incorrect, the sounds of metal impacts appear. When the cladding heats up, the metal expands, and when it cools, it returns to its previous position, which leads to extraneous sounds.

The same thing happens with pipes that are walled into walls. When you turn on the heating and start hot water, the pipes expand slightly, which leads to knocking. When installing pipes into walls, it is necessary to leave a gap for thermal expansion.

Heat exchanger plates clogged

Then the boiler explodes when heated. And the plates can become clogged with dust, soot and soot. Remove the housing and clean the parts with a wire brush or a special vacuum cleaner.

The mesh located at the bottom of the case could become clogged with dust. In technology with an open combustion chamber, this leads to a decrease in thrust. Don't forget to clean.

Incorrect operation of the circulation pump

As a result of uneven operation, resonance occurs in the system, which leads to extraneous noise. Adjust pump settings.

Before starting any work, close the gas valve.

Important! If you smell gas, turn off the tap and call the gas service.

To reduce vibration, place a gasket under the housing. Regularly maintain the unit and clean parts from scale and dirt. This will allow you to operate the boiler safely and for a long time.