Heating and water supply networks of industrial and civil buildings today are unthinkable without such a simple and reliable shut-off valve, such as a ball valve. His invention, without any exaggeration, can be considered one of the most important engineering achievements of the 20th century. Today on sale you can find products from numerous manufacturers, made of different materials, familiar shapes and stylish designs, simple and with unexpected functionality. Making the right choice can be difficult. The editors of the Yanashla website offer a review of “The best manufacturers of ball valves for water supply for 2021,” compiled according to customer opinions and expert assessments.

A little history

They were familiar with centralized water supply in ancient Egypt, Hellas, and the Roman Empire. Roman aqueducts still exist in Italy, Spain and Germany.

Interesting! An aqueduct is the name given to the oldest colossal stone structure for supplying water to major European cities, built during the Roman Empire.

Some of them are still used today for their intended purpose. Such a mass of water flowing into ancient cities had to be managed. This is how the first samples of shut-off and water fittings appeared. On the island of Capri, archaeologists discovered ancient brass and bronze cork valves. These are the world's very first models of shut-off valves, predecessors of valves, ball and water taps.

The next impetus for the rapid development of gates and valves was the invention of the steam engine. The need to control water supply and control steam has led to the development of reliable gate valves and adjustable spring-loaded safety valves.

Some technical solutions have not lost their relevance in our time. In the twentieth century, utility networks began to be equipped with butterfly valves, diaphragm valves and ball valves. Today, the development of shut-off valves is moving in several main directions:

- durability;

- reliability;

- manufacturability;

- cost reduction.

Installation and connection of a valve for a radiator for heating

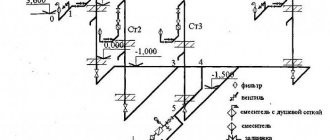

Depending on the layout of the heating system, hot water supply pipes to the radiator are supplied in different ways, and, accordingly, plugs and control valves are installed in different places. Before installation, it is necessary to shut off the coolant supply to the heating battery and drain the water.

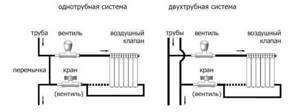

If a single pipe system is used. where hot water flows through one pipe and heating devices are connected in series, a pipe enters the upper part of the battery and supplies coolant. It passes through the installation, exits from below on the same side and goes into the main line. In this case, the thermostat is installed on the bypass - pipe jumper. This jumper connects the forward and return pipes of the heating device and allows hot water to move after the pressure is blocked by the valve.

You can make a jumper with your own hands by welding a small diameter pipe (up to 8 cm) to steel pipes, having previously prepared the holes in the right places.

On a two-pipe system. where there is one pipe for the influx of coolant, and another for the outlet, there is no need to install a jumper; the thermostat is mounted on the water supply pipe.

Installing a radiator control valve is especially effective in an individual heating system, but in a centralized heating system it also gives a significant saving effect, provided that there is a hot water meter.

Ball valve prototypes

The plug tap was known to the ancient Egyptians. Simple and reliable, these devices are still used today. Let us recall the most famous options for their use:

- Samovar. The same one with which tea was always poured from samovars, both the most ancient and modern electric ones.

- Bath. KrB is still used in the washing departments of public baths, for which it received its official name.

- Gas. Familiar to everyone who uses a gas stove, water heater or heating boiler that runs on natural gas.

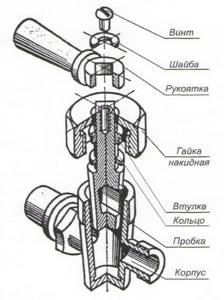

How does a plug valve work?

The simplest device is the samovar version. There are two components: a body and a cone - a plug with a rectangular cutout and a non-removable handle. The body follows the shape of the cork and has the same internal dimensions. By turning the plug 90 degrees, the slot of the plug is installed along the axis of the product, opening the passage for water. The flow is blocked by turning the plug 90 degrees in the opposite direction. The position of the permanent handle indicates the position “Open” if it is parallel to the axis of the “spout”, and “closed” if the handle becomes perpendicular to the axis of the shut-off valve. In this part, cork and ball devices are very similar. The difference is in the locking organ: a cone in a cork device, and a sphere in a ball device. The difference is visible when it comes to the seal between the locking device and the body of the product.

To prevent leaks, plugs made of soft brass or copper were ground to the housings until the gap was completely eliminated, by repeatedly turning them into place. Gas and bath models are more complex because they operate under pressure, and in the case of the gas version, the slightest leak of the working medium will cause an explosion and fire. These models have a closed bottom, an oil seal with a threaded lid. With ball locking devices, rubbing will not help. Spherical polymer seals are used here.

What are radiator taps needed for?

For a general understanding, let’s clarify the terminology a little. In common parlance, faucets are any plumbing device that has a handle for manually controlling the flow of water. In fact, it is technically correct to call a faucet a shut-off valve, but not a control valve. That is, it is intended only to block the flow of liquid, and to regulate its quantity there are other devices - gates and valves. Moreover, all these products are used for batteries.

Shut-off and control valves are placed on the supply pipelines to heating devices for the purpose of:

- turning off the battery during periods of the year when it is not too cold outside or for other reasons;

- shutting off the water for inspection and washing of the device without emptying the entire pipeline network;

- manual or automatic control of coolant flow, adjusting its quantity depending on the room temperature.

Item one of the list illustrates well how installing taps on batteries is associated with energy saving. The situation when the central heating system is turned on during the warm period is not uncommon. It’s still quite warm outside, but the radiators are already glowing with heat, and the house is stuffy. If there is a tap, the problem is solved with one turn of the handle. And when a heat energy meter is installed on the entrance or the entire house, then with the same movement you block the flow of funds from the family budget to the account of the heat supply organization.

The same thing happens in a private house equipped with an individual heat source. Taps allow you to turn off part of the radiators in living rooms or temporarily used technical rooms, for example, in a garage

Equally important for saving money is periodic flushing of heating appliances. After all, what happens: a battery contaminated from the inside gives off less heat to the room, which means coolant with a higher temperature goes into the return pipeline

This coolant will heat your neighbors’ homes, but your apartment will feel a lack of heat. When it comes to a private house, the water returns back to the boiler and there are no losses. But the rooms become cooler and to obtain the required amount of heat you will have to raise the temperature of the heating system, increasing the fuel consumption of the heat generator. The pollution process is insidious because it takes some time and becomes noticeable only when the cost of heating the building increases.

The use of manual control valves or automatic valves with thermal heads makes it possible to save energy during the heating season by maintaining the required indoor air temperature. Manual valves for radiators allow you to adjust the coolant flow when setting up the system so that it does not go beyond the calculated limits. Valves with thermal heads control the flow of liquid automatically, reducing or increasing the flow area depending on the air temperature in the room.

Who invented the ball valve

Complicated story. There is evidence that the first such device was first used in the fuel lines of airliners somewhere in the middle of the last century.

On a note! According to some sources, a patent for it was issued in 1954 to the American inventor Howard Freeman.

The product did not provide complete tightness and was not widely used in those days. A qualitative leap occurred later, with the invention of polymer materials.

The problem was that, unlike cork, the locking organ of the new device was a steel ball with a hole in the center. It was difficult to ensure a reliable seal between it and the walls of the structure without an elastic and at the same time abrasion-resistant material. The problem was brilliantly solved with the advent of Teflon, and later fluoroplastic. From that moment on, the ball valve quickly conquered the world market for shut-off valves. Today, dozens of inventors hold patents for various types of such devices.

Methods for adjusting the heating system

The first is to change the coolant supply parameters directly on the boiler. Most modern boiler equipment allows you to perform this setting manually or automatically.

To implement the second method, it is necessary to use a control ball valve, installing it directly in front of the heating device. After all, heating taps can be used not only to shut off the movement of the coolant, but also to regulate it. In addition, if a leak occurs in the battery, it is enough to shut off the flow and you can repair or replace the damaged device.

Installing ball valves provides many benefits to the homeowner. In particular, this is the ability to adjust the coolant flow at any time of the heating season. In addition, as already mentioned, it is possible to disconnect the heating device from the network for its repair or restoration.

To allow the coolant to drain into the system, a ball valve for heating is installed. From it you can lead a pipe to drain the coolant into the sewer. Thus, taps for the heating system allow repairs to be made on devices and other fittings involved in the work.

Often homeowners have serious concerns that the heating ball valve may leak or, worse, break. But if you choose the right equipment and follow the installation technology, this will not happen.

The simplicity of the ball valve design ensures its reliability in use and a fairly low price in comparison with other shut-off devices. These heating taps are made from high quality brass. For the seat in which the ball valve is located, fluoroplastic or their analogues are used. Another undoubted advantage of valves of this type is their small size, which allows them to be installed almost anywhere in the heating system.

What types of ball valves are there?

Differences in case material

The operating mode and technical characteristics of the working and environmental conditions depend on it.

Brass products

A universal, environmentally friendly and durable material, equally suitable for connecting to steel, polypropylene or copper pipes. Not subject to corrosion. Works great in hot water supply, heating, drinking water systems, gas and pneumatic pipelines. Disadvantages include high cost and the impossibility of joining or repairing by welding.

Stainless steel

They are cheaper than brass. They are more convenient when repairing pipelines, since they can be welded to the pipeline or welded fistulas and cracks. Heavy. In terms of the number of models, they are significantly inferior to brass ones, and the cost is slightly less.

Polypropylene

They are distinguished by their low weight and affordable price. The disadvantage is that it can only be used with polypropylene pipes. All of the listed materials are used for the manufacture of both industrial and household models.

Bandwidth

Important characteristic. There are full bore and part bore models. The first are so called because the diameter of the ball hole coincides with the diameter of the pipeline, and their throughput is 100%. This also includes gates with a throughput characteristic ranging from 90 to 99%.

Incomplete bores are called:

- semi-bore, the diameter of the hole is one size smaller than the diameter of the pipe, and the throughput varies from 70 to 90%;

- partial flow - used to reduce water consumption, since they pass from 40 to 70% of the full flow.

By connection method

This parameter distinguishes between:

- Welded models. They are connected to pipelines by electric welding. It is reliable and airtight. It's really difficult to remove for replacement. You'll have to cut the pipe. This method is used in the construction of industrial facilities where all other methods are unprofitable or impossible for safety reasons.

- Flanged. They are produced with flanges at the inlet and outlet and are connected to mating flanges on the pipeline. Typically used when laying pipelines with a diameter of two inches or more. The connection is simple and quite tight. If necessary, it can be quickly disassembled and assembled.

- Wafer. Like the previous version, it is mounted to counter flanges. The difference is that the product itself does not have flanges, but is simply installed between the pipeline flanges and tightened with bolts or studs. There is a so-called hairpin models. They are fastened with bolts that are inserted into the holes of the pipeline flanges and screwed into holes with internal threads in the body of the structure.

- Couplings. Attached by thread. The advantages include ease of installation and dismantling. Suitable for use on pipelines with a diameter of two inches or less. Often used in household utility networks. There is only one drawback: insufficient professionalism of the installer when sealing the connection will certainly lead to the formation of a leak.

- Combined option. Combinations of the above options: flange at the inlet and thread at the outlet, or thread on one side and a welded end on the other.

The method of connecting the reinforcement is determined at the project development stage. In this case, the decision on one or another method of installing shut-off valves is made taking into account the diameter and material of the pipeline.

Tips for choosing

Since there are a lot of Chinese products in stores, both high-quality and outright fakes, you should approach the choice of shut-off valves responsibly.

Before purchasing, you should determine the diameter of the pipe on which the device will be installed and the type of threaded connection (internal or external).

High-quality devices are supplied complete with a passport, which indicates: warranty period, product number, material and installation instructions. Saving on shut-off valves can lead to significantly higher repair costs, for example, in the event of a ball valve failure.

The ball valve should rotate fairly freely. If it takes significant effort to turn it, it is better to refuse the purchase.

Also, do not buy products with a handle made of plastic. With frequent use, over time the handle will begin to rotate.

Another important point is the indicators of conditional and working pressure. The first one should be higher. If the technical specifications indicate equal values, serious damage may occur during operation in the event of a sudden surge in pressure in the water supply system.

It is also worth paying attention to:

Appearance

The metal should have a uniform shine, without drips or sagging. All parts are symmetrical, the coating is without cracks or chips, and the thickness of the case walls is the same. The markings are clear, with easily distinguishable and readable letters. A sign of a fake is a matte or cloudy outer coating.

Type of metal

Brass is the most common and affordable. Ideally the brass marking is CW617N. Such products are heavy in weight, the threaded walls are thicker. It is also worth noting that faucets made of silumin, an alloy of aluminum and silicon, are much cheaper than their brass counterparts. But at the same time they are characterized by increased fragility. They are quickly destroyed by exposure to hot water. They are used as shut-off valves for systems that do not require high pressure and only for cold water. You can identify a silumin device by its appearance - poor coating, uneven seams. Silumin products are also distinguished by their characteristic silver color.

Many people recommend this method of checking ball valves: remove the top nickel layer with any sharp object. The problem is that this can only be done after the purchase. After all, it’s unlikely that anyone in a store will allow you to scratch and damage goods. Therefore, you need to purchase shut-off valves from trusted sellers or directly from official representatives of the manufacturer.

Steel - made of carbon steel, they are distinguished by high performance characteristics and resistance to mechanical stress. The price is more expensive than brass ones.

Specifications

Depending on the purpose for which the crane is purchased, pay attention to the manufacturer’s recommendations:

- if the water temperature does not exceed 150 degrees and the pressure is 40 bar, brass devices are suitable;

- at temperatures up to 200 °C, pressures up to 160 bar - steel;

- for installation of heating and cold water supply systems - cast iron.

Although recently experts have recommended replacing cast iron fittings with steel ones. Because at a higher cost, cast iron products are no different in technical characteristics from their steel counterparts.

Ball valve

Must be perfectly smooth, without scratches or damage. High-quality valves are made from brass followed by chrome plating.

A fake can be easily recognized by the characteristic matte color of the coating. You can also check the metal with a magnet. If it attracts, it means that the manufacturer saved money and used electrical steel, which is susceptible to corrosion. As a result of constant contact with water, the valve will quickly become rusty and fail.

The best manufacturers

If you buy good quality items, then you should choose the best manufacturers who value the company’s reputation and the trust of the buyer. Branded models are expensive, but who said that cheap means the best! We present several companies whose models are popular due to decades of producing high-quality products with excellent consumer characteristics.

Bison

Well-known domestic manufacturer. The main activity is shut-off and control valves for industrial pipelines. It produces affordable models with various types of connections to networks, using corrosion-resistant materials: brass and stainless steel.

Gekon

Russian trademark. Production facilities with the most modern equipment are located in Russia and Italy. The quality of the product is confirmed by domestic and European certificates. Popular models of the brand are in constant demand among specialists. Prices are affordable.

Valtec

Russian-Italian company, founded in 2002. One of the most common brands sold on the domestic market of shut-off valves. The products are high-quality and relatively inexpensive, satisfying all the features of domestic engineering networks. The model range is quite wide.

Honeywell

American manufacturer of high-quality shut-off and control valves. The company's production facilities are located in the United States and are fully automated. The brand's products are full bore, made of hardened brass, and can withstand pressure up to 16 bar. Devices from Honeywell are equipped with a wide and comfortable handle that does not cause discomfort to the user, which compares favorably with products from other companies. Devices with compact electric drives are in high demand. Such models are widely used in industrial circuits with automatic control of temperature and pressure of the working environment, for protection against water leaks in Smart Home systems, etc.

Bugatti

Another Italian brand with a model line of more than a hundred high-quality products with various functionality. Particularly popular are two- and three-way devices used to work with instrumentation that shows pressure and temperature in several circuits simultaneously, or hot water supply systems with automatic mixing of cold water. To increase the working life, the surface of the shut-off element (steel ball) is thoroughly polished using diamond paste. This treatment protects Teflon seals from destruction. Bugatti products are distinguished by their stylish design.

Oventrop

One of the oldest companies in Europe. Founded in Germany in the middle of the 19th century. The main direction of its activity was initially the production of furniture fittings. A hundred years later, the company began producing components for fuel systems. The company mastered the production of sanitary fittings in the 80s of the last century. The Oventrop product range includes more than 400 units and this is not the limit. The fittings of the German manufacturer are distinguished by their reliability, increased service life, stylish design and reasonable prices.

Stout

The brand and capital are Russian, production in Italy from Italian and European components. The final product is adapted to the operating conditions of Russian utility networks. The quality complies with domestic GOST and is confirmed by European certificates. The products can be used at ambient temperatures ranging from -50°C to +150°C. The bodies are made of high-quality brass, the stuffing box seals are made of fluorine rubber.

Interesting! Fluorine rubber is a polymer belonging to the group of elastomers. It has unique physical properties: high strength, elasticity and temperature resistance. Resistant to aggressive environments.

Particularly popular are corner models, often used to connect washing machines and dishwashers to water. Among the new products, patented models with a built-in filter are interesting.

FIV

And again a manufacturer from Italy. On the market since 1984. The main activity is the production of shut-off and control valves, heated floors. High-quality German brass made in Germany was selected as the raw material for production. The company's products cannot be confused with other brands. All of them have a branded engraving on the surface. The production process is automated. To facilitate installation, the products are sold complete with American connecting elements. The handles are made of aluminum alloy to reduce overall weight and resist rust.

ITAP

One of the leading Italian companies producing shut-off valves. On the market for over 50 years. He has a lot of patents for his innovative models. Consumers include more than 100 countries. Coupling models are available with external and internal threads. High-quality brass cases are plated with nickel. All products, regardless of where they are manufactured, are subject to pre-sale testing. According to customers, products bearing the ITAP brand are among the most reliable in the world.

FAR

Italian brand. Founded in 1974. Manufactures components of engineering networks: gearboxes, measuring instruments, filters, thermostats and fittings. For automated industrial engineering networks and household energy-saving systems such as “Smart Home”, the company has mastered the production of ball valves with electric drive. Products are produced only on the territory of the Italian Republic from components produced in EU countries. The high quality of the company's products is confirmed by ISI, ENI, UNI certificates. In addition to basic fittings, the company produces De Luxe quality products.

Danfoss

International manufacturer of household and industrial equipment for heating, refrigeration, ventilation automated systems, with head office in Norborg, Denmark. More than a third of the components for such systems sold on the domestic market are branded by this company. It has been on the market for more than 70 years and has representative offices in more than 100 countries. Owns a large number of assembly shops, with strict quality control at the output. Ball valves, manual and electric, from Danfoss are a guarantee of long-term trouble-free operation of engineering systems.

Royal Thermo

Russian manufacturer, best-selling in the former USSR. Specializes in the production of components for water supply and heating systems: boilers, radiators, fittings and shut-off and control valves. Production facilities are equipped with equipment from leading European brands: ABB, Marconi. A distinctive feature of the Royal Thermo shut-off valves is the size of the faces of the inlet and outlet internal threads, allowing them to be grasped with an open-end wrench.

This is not a complete list of brands whose products can be purchased “with your eyes closed.” It’s up to you to decide which company’s product is best to buy. In any case, you should listen to the advice of equipment installation specialists, get recommendations from consultants in a specialized store, study the product description, its characteristics, find out how much the selected model costs and make the right choice.

How to install correctly

They install a thermostat for a heating radiator at the inlet or outlet of the heating device - there is no difference, they work with equal success in both positions. How to choose a place to install?

According to the recommended installation height. There is such a clause in the technical specifications. Each device is configured at the factory - they are calibrated to control the temperature at a certain height and usually this is the upper radiator manifold. In this case, the heat regulator is installed at a height of 60-80 cm; it is convenient to adjust it manually if necessary.

Installation diagrams for heat regulators for radiators

If you have a bottom saddle connection (pipes fit only from the bottom), there are three options - look for a device that can be installed at the bottom, install a model with a remote sensor, or reconfigure the thermal head. The procedure is simple; the description must be in the passport. All you need is to have a thermometer and at certain moments turn the head in one direction, then in the other direction.

Installation is standard - on fum tape or linen winding with packaging paste

The installation process itself is standard. The valve has a thread. The appropriate fittings are selected for it or a matching thread is cut on the metal pipe.

One important point that those who want to install a thermostat for a heating radiator in apartment buildings should remember. If you have a single-pipe installation, they can only be installed if there is a bypass - a section of pipe that stands in front of the battery and connects the two pipes to each other.

If you have a similar wiring (there may not be a pipe on the right), a bypass is required. The thermostat should be installed immediately behind the radiator

Otherwise, you will regulate the entire riser, which your neighbors will definitely not like. For such a violation, a very substantial fine can be issued. Therefore, it is better to install a bypass (if not).

How to choose a ball valve

To purchase a suitable model, you should understand some criteria for choosing shut-off valves:

- The diameter of the control elements of the utility networks must correspond to the diameter of the pipeline. The parameter in inches, for example, Dn1”, or millimeters (25 mm) must be indicated on the side surface.

- When choosing shut-off valves, check the pressure of the working medium in the pipeline and select a valve with a “reserve” of pressure. The parameter value in bars is applied to the surface of the product after the designation, for example, Pn 16 bar.

- Brass products have the greatest working life. Stainless steel samples will cost less, but have more mass.

- For underground or underwater communications, it is better to choose welded models.

- When installing drinking water supply from polypropylene pipes, only plastic taps are used.

- Heating pipelines with high steam or water pressure and a diameter of 50 mm or more are best equipped with flanged fittings.

Natural and forced coolant circulation

It is worth noting that the method of connecting pipes to radiators will also depend on how the coolant circulates inside the heating circuit. There are two types of circulation - natural and forced.

Natural circulation of liquid inside the heating circuit is achieved through the application of physical laws, and no additional equipment needs to be installed. This is only possible when using water as a coolant. If any antifreeze is used, it will not be able to circulate freely through the pipes.

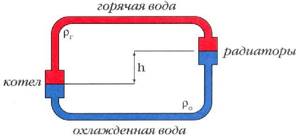

Heating with natural circulation includes a boiler for heating water, an expansion tank, 2 pipelines for supply and return, as well as radiators. In this case, a working boiler gradually heats the water, which expands and moves along the riser, passing through all the radiators in the system. Then the cooled water flows by gravity back into the boiler.

To ensure free movement of water, horizontal pipes are installed with a slight slope towards the direction of movement of the coolant. A natural circulation heating system is self-regulating because the amount of water changes depending on its temperature. When water is heated, the circulation pressure increases, which ensures uniform heating of the room.

In systems with natural circulation of liquid, it is possible to install a radiator with a bottom connection, provided there is a two-pipe connection, and also use a scheme with a top connection in a one- and two-pipe circuit. As a rule, this type of circulation is carried out only in small houses.

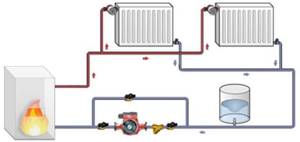

If the area of the house exceeds 100 m2, then the method of circulation of the coolant must be forced. In this case, you will need to install a special circulation pump, which will ensure the movement of antifreeze or water along the circuit. The power of the pump depends on the size of the house.

The circulation pump can be mounted on both the supply and return pipes

It is very important to install automatic bleeders at the top point of the pipeline or provide Mayevsky taps on each radiator to remove air pockets manually. The use of a circulation pump is justified in both one- and two-pipe systems with vertical and horizontal types of radiator connections.

The use of a circulation pump is justified in both one- and two-pipe systems with vertical and horizontal radiator connections.

What else to pay attention to

- Shut-off valves made of silumin are distinguished by their modest price and increased fragility. Buying a silumin faucet means throwing money away.

- When installing the pipeline close to the wall, you should select shut-off valves with a butterfly handle. Unlike a long lever, it will not rest against the wall and will not interfere with the control of the device.

- If it is necessary to control the pipeline pressure using an indicating pressure gauge, two- or three-way ball valves are used, which make it possible to increase the service life of the pressure gauge, since the medium pressure is supplied to the device only when it is necessary to make the next observation.

- Before paying for your purchase, open and close the shutter several times and check how easily the apple moves. The tight movement of the locking element makes normal operation of the device difficult.

- It's better to choose an option. Having an expanded set of functions: a built-in filter, a pile with a built-in thermometer, or a drainage pipe for draining water in winter (if it is a watering tap).

- For watering the garden, it is better to choose an angle tap for a hose. A special nozzle - a brush - allows you to easily attach a rubber-fabric or plastic sleeve to the nozzle and securely fix it with a clamp. This same option will be ideal when tying up a washing machine.

Self-installation

How to install the faucet and what scheme to choose depends on the type of shut-off and control valve model.

In most cases, taps are installed as follows:

- With centralized single-pipe heating, two ball valves are installed: one on the inlet line, the second on the outlet line. This design makes it possible to leave the coolant in a separate battery when draining water from the system or when dismantling the radiator for cleaning and periodic maintenance.

- In a nuclear two-pipe system, a thermostat is placed on the input line, and a valve with balancing capability is installed on the output line. It will maintain normal pressure in the system.

- When using a nuclear one-pipe system, a thermostatic valve is placed on the inlet pipe, and a ball valve is placed on the outlet pipe.

Rating of quality ball valves from the best manufacturers

Bugatti New Jersey 915

The review opens with the New Jersey 915 model from the Italian company Bugatti. The photo shows a sample with a diameter of 1/2 “, full bore, coupling. The products are made of CW 617 N brass, produced in Europe. Control is carried out by a lever handle, which can be replaced with a butterfly handle if necessary. The operating pressure should not exceed 50 bar. Connecting thread BP/HP (internal on one side and external on the other). The average cost is 300 rubles.

Bugatti New Jersey 915

Advantages:

- material – high-quality brass;

- high design pressure;

- threaded connection BP/MS.

Flaws:

- handle - lever is produced only in black, which is not very convenient when installing on pipelines with hot and cold water.

FIV 1/2 “gas

The sample from the Italian brand FIV is full-bore, half-inch, intended for use on gas pipelines, as evidenced by the yellow color of the lever handle. Coupled, with BP/BP thread. Material – brass, with a chrome finish. Designed to operate at a pressure of 40 bar. Average cost: 389 rubles.

FIV 1/2 “gas

Advantages:

- brass body;

- handle - the lever turns the apple;

- protective covering.

Flaws:

- the design pressure is too high for use on a natural gas pipeline and increases the price of the product.

8.Bison 51216-3/4-3/4 for hose

A Russian-made sample in a brass case, 20mm or 3/4 inch in diameter. Designed for watering. Equipped with a removable nozzle - a brush for connecting a watering hose. Control is carried out with a convenient lever handle. The device is designed for operation with a working pressure of no more than 25 bar. Average cost: 426 rubles.

Bison 51216-3/4-3/4 for hose

Advantages:

- stylish design;

- the apple turns without much effort;

- removable brush attachment for connecting a hose.

Flaws:

- not identified.

7.Gekon 551 1 coupling

Water valve from a Russian brand, made in Italy. Full bore brass valve with half-inch connecting thread. Control is performed using a butterfly handle. Average price: 584 rubles.

Gekon 551 1 coupling

Advantages:

- brass body;

- protective covering;

- Teflon seals.

Flaws:

- Operating the butterfly handle requires considerable effort.

6.Royal Thermo Optimal 1 1/4 “

Product from a domestic manufacturer. Full bore version with connection diameter 1 ¼ inches or 32 mm, internal threads. The body is brass with a protective coating (nickel plated). The design pressure does not exceed 40 bar. The convenient butterfly handle allows you to open and close the shutter effortlessly. Average price: 731 rubles.

Royal Thermo Optimal 1 1/4 “

Advantages:

- protective covering;

- comfortable handle;

- the edges of the input and output threads are “sharpened” for open-end wrenches;

- high working pressure.

Flaws:

- not identified.

5.Oventrop Optiflox KFE, DN-15, 1.2H

Product from the oldest German manufacturer. Made in a brass body with BP/HP threads with a diameter of half an inch. Controlled by a flag handle. The set includes a removable nozzle - a brush made of durable plastic for connecting a watering hose and a brass plug. The device is universal because it can be installed in a pipeline or used as a watering tap. Average cost: 867 rubles.

Oventrop Optiflox KFE, DN-15, 1.2H

Advantages:

- high quality materials;

- combination of internal and external threads;

- versatility.

Flaws:

- Using the flag pen requires effort.

4.Valtec 1” with American

Water seal from the famous Italian manufacturer. Made in a brass body with a protective coating (nickel-plated), full bore with inch H/N threads. Design pressure 40 bar. Equipped with American. Average cost: 1074 rubles.

On a note! American is a quick-release connection consisting of two threaded bushings and a union nut, which allows you to install shut-off and control valves into the pipeline without welding.

Valtec 1” with American

Advantages:

- durable material;

- combination of male/female threads at the inlet and outlet;

- American included.

Flaws:

- uncomfortable butterfly handle.

Stout SVB – 0001 – 000050

Russian-Italian locking device for heating and plumbing systems. The photo shows a two-inch sample with a brass body and a stainless steel apple, designed to operate at a pressure of no more than 32 bar. A convenient lever handle is provided for control, allowing you to perform manipulations without much effort. The inlet and outlet threads are internal. Average cost: 1918 rubles.

Stout SVB – 0001 – 000050

Advantages:

- European quality materials;

- reliable assembly;

- 10 year warranty.

Flaws:

- Quite a high price for a standard shutter.

2.ITAP 138 1” built-in

This Italian device for controlling water pressure in water supply and heating systems receives the best reviews. Designed for hidden installation with the handle exposed on a surface lined with decorative material: ceramic tiles, MDF or plastic panels, etc. The body is brass with half-inch internal threads, designed for a maximum pressure of 25 bar. It differs from the standard options in the elongated stem and the presence of a decorative stainless steel cover. Handle - brass flag, chrome plated. Average cost: 3658 rubles.

ITAP 138 1” built-in

Advantages:

- quality material;

- decorative cover;

- reliable assembly;

- the apple turns effortlessly;

- brass chrome handle.

Flaws:

- high price.

What taps should be installed on radiators and will they be needed?

You can’t understand: which taps for heating radiators are better than other options? Then you have come to the “right address”! Here and at the present moment we will try to understand the “practical problems” of shut-off and control valves for heating systems, at the same time drawing up advice on equipping standard heating device piping with taps.

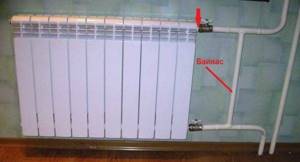

An example of installed shut-off and control valves for heating systems

Will taps be needed on the heat supply radiator?

Of course yes! Since with the help of shut-off and control valves we solve several problems simultaneously:

- First of all, we block the flow of the coolant, giving the technician the opportunity to dismantle the damaged section without draining the coolant from the heating system. To put it simply: without shut-off valves, you simply cannot physically “repair” a heating radiator without “freezing” the entire house.

- Second, we remove the air collected in the heating devices, restoring the circulation of the coolant in normal volumes. In other words, without a return valve that allows the medium to pass exclusively outside (beyond the wiring), not a single heating device will want to work, since when the system is filled with water, an “air pocket” will first appear in such a battery, blocking the circulation of the coolant.

- Third, we dose the flow of coolant. By installing an adjustment valve on the heating radiator, we gain the opportunity to control the temperature regime in each specific room, using not a window and energy-ineffective ventilation, but a more technologically advanced and justified from the point of view of fuel economy procedure for dosing the heat flow.

To put it simply: without taps, you plan to live poorly, but not for long.

What taps should be installed on radiators?

In order to solve the problems described above, we will need the following types of fittings:

Shut-off unit - using its help, you can close the flow of the coolant. And taps with a round hole are considered an excellent option for shut-off valves for a heating system. After all, the shut-off element in such fittings closes the flow almost quickly, literally with one turn of the handle. And if boiling water “spouts” from the battery, then you definitely won’t have time to screw in the valve that pushes the axle box. Also, the ball insert will live in the system much longer than the axle box.

Bottom connection shut-off unit

Calibration unit - using its help, you can dose the heat flowing to the heat exchanger by closing or expanding the channel in the body of the shut-off and control valve. In other words, in this case we will make a valve with a shut-off piston, the stroke of which is changed by the number of turns of the valve handle.

Alignment unit with thermostatic valve

However, in addition to the handle, the stroke of the piston can be controlled by a thermostatic component, which becomes wider or narrower under the influence of external temperature, pushing the locking piston either down or up. In the end, temperature regulation occurs as if by itself. Due to this, an automatic thermostat must be used as a unit that dispenses the coolant.

Non-return valve - using it you can “bleed” air from the battery. By pressing on the outer valve stem, or turning the locking unit around its axis, you open a hole to “bleed” air from the heating device. By removing the pressure or turning the lock back, you seal the system as the piston and rod or cone valve slides back into place, closing the air bleed hole. Actually, according to this scheme, a typical Mayevsky faucet does not stop working.

Spring check valve

What does a standard heating radiator piping look like?

After fixing the battery to the supporting surface, the following types of fittings are screwed into its pipe sections:

- Straight or angle ball valves, which are installed in the return (lower) section of the pipe.

- Straight or angular thermostat valves of an automated type, which are installed in the pressure (upper) section of the pipe. Moreover, here the thermostatic valves for heating radiators also work as shut-off valves. Thanks to this, a separate valve to shut off the flow into the pressure section of the pipe is not installed - its functions are performed by a thermostat.

- Mayevsky faucet, which is installed in the free upper section of the pipe.

- A plug is screwed into the remaining free section of the pipe.

A similar piping scheme is used in single-pipe wiring with circular pumps, and in two-pipe or radial wiring.

How much does it cost to wire heating batteries?

The most inexpensive part of the piping is the Mayevsky valve. The price of a faucet for a heating device with pipes for? inches – 0.5-1.0 US dollar. The cost of an air vent for a heating device with pipes for? inches - $1.5-2.0.

A locking unit with a ball valve will be a little more expensive.

For example, the Chinese crane of the trading company Gross Optimal at ? inches costs about 3.0-3.5 $. A slightly larger tap on the ? inches from the same manufacturer costs 4-4.5 $.

Italian taps with a round hole are a little more expensive. For example, fittings from IVR at ? inches costs 5.0-5.5 $. And for the tap? inches you will need to pay $7.0-8.0.

The thermostatic valve is considered the most expensive element of the battery piping. After all, such fittings are designed more extreme than the usual valve. Moreover, in addition to expensive mechanical components, the design of such faucet regulators also uses very expensive electronic parts - touch monitors, processors, and more.

In the end, the cost of a thermostat depends on the degree of automation and design of the controls for such fittings.

Mechanical thermostat from HERZ, mounted on batteries with fittings or pipes with a diameter of ? inches, costs from 14.5-15 US dollars.

Thermostat HERZ CALIS-TS-RD 1 1/4

Automated thermostat - RAS-C Danffoss - with a thermostatic element, mounted on heating devices with a piece of pipe or a connecting element with a thread on ? inches, costs 27-30 US dollars.

Set of radiator thermostats Danfoss RA-FN

A programmable nozzle for a thermostat with a thermostat - ROSSWEINER PH60 - with a mounting thread M30x1.5, an LCD display, six preset operating modes and a control accuracy of ±0.5 °C costs at least 45-50 US dollars.

Electronic thermal head Rossweiner PH 60

At the same time, such a nozzle also requires a mechanical thermostat costing from $25.

In the end, wiring one battery in a budget style will cost the homeowner 18-20 US dollars. Well, if you choose premium fittings of the electromechanical type, then you will need to pay at least $80-85 for the wiring of the heating device.