Why tow (plumbing flax) is better than fum tape

To seal the threads, you can use fum tape, plumbing flax (tow) and anaerobic sealants.

The last option is not used so often because it has specific application features. As for sanitary flax and fum tape, these two sealing materials are most widely used today. At the same time, sealing threads with tow and fum tape also has its own characteristics.

And if you don’t know what to give preference to - fum tape or sanitary flax, then this article from the construction magazine samastroyka.ru is just for you.

Plumbing flax: application, advantages and disadvantages

Flax fibers have been used as a sealing material for over 50 years. It replaced hemp tow, the main disadvantage of which was the non-uniform structure of the thread, which significantly complicated the work. The requirements for sanitary flax are clearly stated in GOST 10330-76.

The flexibility and strength of linen threads ensures high-quality winding and contributes to the formation of a uniform seal that does not lose its functionality even at high (up to 1600C) temperatures. When heated, the material does not release toxins or other harmful substances.

The most significant advantages of flax include:

- Hygroscopicity

. In a humid environment, the material significantly increases in volume, which prevents even the slightest leakage due to the dense filling of the grooves of the threaded connection; - Versatility

. Experience in using flax fibers as a seal shows that, provided they are installed correctly, the material is suitable for working with any media, and the quality of sealing is practically independent of the diameter of the pipeline and the design features of the thread; - Manufacturability

. Winding can be done on an unprepared thread surface. No preliminary cleaning of dirt and corrosion is required, which greatly simplifies the work. In addition, natural fibers can provide high-quality sealing even to damaged threads; - Availability

. The cost of the material is low, and you can buy sanitary flax at any hardware store.

Thanks to the above properties, natural sealants based on flax fibers are widely used, however, some disadvantages of the material should be taken into account:

- The organic structure of flax intensively decomposes at high humidity, and a significant increase in temperature leads to drying out and loss of elasticity of the seal. The use of various impregnations, mastics and oil paints helps to avoid premature destruction, but at the same time the complexity of dismantling increases significantly.

- When winding, it is necessary to accurately determine the thickness of the seal, taking into account possible swelling. An excess can lead to internal stresses in the connection and a significant increase in the tightening torque, and an insufficient number of turns will not ensure tightness.

Currently, despite the presence of a large number of synthetic substitutes, plumbing flax is actively used for compaction:

- Connections with a thread diameter of more than 1 inch, as well as in the presence of erosion and mechanical damage on its surface;

- When installing permanent connections that require special reliability.

What is the best way to seal plumbing threads: thread, anaerobic sealant, flax or fum tape video

Based on the above, we can conclude that the use of natural flax fibers is not only economically profitable, but also provides a reliable and tight connection.

What is sanitary flax (tow)

Plumbing flax, or as it is often called “tow,” is a product of processing flax and hemp. This material is widely used in a number of plumbing, plumbing, and works related to the installation of heating systems. Here flax is used to seal threaded connections made of both ferrous and non-ferrous metal.

The technology for winding sanitary flax (tow) on a thread is as follows:

After sealing the thread, a special product (paste), such as Unipak, is applied on top of the plumbing flax.

This product is intended to prevent plumbing flax from “aging”, in simple words, so that it does not rot or deteriorate when exposed to moisture.

What is fum tape

Fum tape is a more modern material for sealing threads. The basis for its production is a fluoroplastic PTFE film, which is resistant to chemical influences. This material is not afraid of the influence of fungus and microorganisms.

As a result, when winding fum tape there is no need to use any additional means of protection, as required by sanitary linen. As for the advantages and disadvantages, they will be discussed below.

What sealants does the building materials market offer?

There are several types of sealing materials that differ in cost, ease of use and reliability of use:

- FUM tape (fluoroplastic sealing material)

- Sealing thread

- Linen thread

Among all the FUM proposals, tape is quite difficult to use, sealing thread has good qualities, but is too expensive, and only flax is an impeccable product that has proven itself over many decades.

How to properly wind flax on a thread?

To ensure a strong and tight connection, the threaded areas must be cleaned of rust using fine-grained sandpaper

At this stage it is important not to damage the threads. Then you should check whether there are notches on the thread - with them, the laid flax threads are fixed and do not move when connecting the parts

If there are no notches, they can be applied with a file or a plumbing wrench.

Proper winding of flax consists of several steps:

Check the tightness of the connection with a clean, flax-free thread to understand how thick the winding should be. Take a bunch of flax and separate a strand of sufficient thickness from it to obtain a tight connection. The flax hairs should be the same length, without lumps, straw or debris. Twist the strand into a loose rope of such thickness that it can fill one thread groove. Holding the end of the flax rope at the edge of the thread, wind it in the direction opposite to how the nut is tightened. Each subsequent turn should fit tightly to the previous one

Here it is important not to overdo it with the number of layers, there should be no more than two, otherwise the connection may burst when tightened or from hot water during operation. If the bundle turns out to be short, winding should be continued with the next bundle. Inspect the reverse side of the winding and make sure there are no bald spots. Apply a layer of special paste or silicone on top of the flax and tighten the connection until the paste hardens

The use of a sealing composition contributes to the durability of the connection, prevents rotting of the flax, and makes it easy to disassemble the structure in the future. Sealant should not be used as a sealant; such a connection is difficult to disassemble.

Using a sealant when threading pipe systems is easy. This approach does not require the use of expensive equipment, and can be easily performed by both a professional and a home plumber.

1. Purpose of tow and how it works.2. Types of sealing materials.3. Method of sealing pipe threads with tow.

In plumbing work, tow is used to seal pipes and transitions connected by threads. It is made mainly from flax waste and is a coarse fiber of small size. If you wind the tow correctly, protection against leaks will be provided throughout the life of the pipeline. Answering the question of how to wind tow on a thread, it should be said that the quality of workmanship prevents the risk of a leak in the plumbing system. There is a gap between the threaded connections through which water freely flows out of the pipeline. If it contains properly laid plumbing tow, then the gap becomes smaller, and as water penetrates into such a connection, the flax swells and the leakage stops.

Why tow (plumbing flax) is better than fum tape

Tow for sealing threads is a material from the last century that is successfully used today. Why does this happen, and why do modern materials, such as fum tape, lose to sanitary flax?

In fact, everything is very simple. Plumbing flax is a natural product with excellent sealing properties.

But even if we put aside this whole race for environmentally friendly materials, then it will be enough to say this:

As for the disadvantages of sanitary flax, the main one is its susceptibility to rotting. However, if special protective agents are used, tow can provide a reliable connection for many decades.

Fum tape also has its advantages. For example, she is not afraid of aggressive environments; after working with her, your hands always remain clean. However, tow came to us from the last century, and threads collected using it still serve today.

Well, since fum tape is a relatively new material for packaging, in 20 years we will see how good it really is at work. This is why plumbing flax is better than fum tape, and many professionals use it in their work.

Fum tape - advantages and disadvantages of the modern analogue

Fum tape or fluoroplastic sealant is a thin material of white or transparent color with the addition of fluorine, designed for sealing threaded connections. After purchase, the tape is completely ready for use; there is no need to purchase additional sealing cream or paste, as is the case with flax.

Fum tape is sold completely ready for use.

Fum tape is suitable for connections of cold and hot water, engineering systems operating under a pressure of no more than 9.8 MPa. Externally, the seal looks like a thin elastic patch wound on a reel. Depending on the diameter of the thread, you can purchase tape from 1 to 10 cm. There are also thinner options that resemble a sealing thread in appearance.

The material also differs in its lubricant content:

- Fum tape M1. Used for systems working with aggressive chemical compounds. The tape is impregnated with a lubricant containing up to 20% petroleum jelly.

- Fum tape M2. Not impregnated with lubricant, suitable for engineering systems working with oxidizing agents.

- Fum tape M3. Suitable for drinking water lines and other highly pure media.

The service life of the finished connection will depend on two main components - the quality of the fluoroplastic seal and the correct winding technique. The price does not reflect the characteristics of the tape. To check it, just pull the winding and check for strength. If the seal immediately breaks into fibers, you have a low-quality material that will become rough and unusable in a couple of months. The tape should stretch smoothly and withstand the applied tensile forces. The seal must be wound tightly, deepening it well between the turns. After sealing, the threads should be completely covered.

Fum tape has the following advantages:

- Suitable for thin wall fittings, dirty, wet, small and plastic connections.

- Does not stain your hands and leaves no marks.

- Resistant to chemical and aggressive environments.

However, this is where the advantages of a modern seal end. Despite its widespread use, many have a negative attitude towards it. Perhaps everything will fall into place when you learn about the disadvantages of the tape:

- After tightening, it will not be possible to adjust (adjust) the connection without losing the tightness. If such a need arises, you will have to unwind the connection and rewind the tape.

- At the stated temperature of 250°C, the seal can easily withstand 120°C heating. At higher rates, the structure and properties of the material are lost. Therefore, it is not advisable to use fum tape in a heating system.

- The seal does not withstand vibration loads.

- It is preferable to use fum tape for threaded connections with a diameter of up to 1 inch, otherwise it is worth taking more budget-friendly analogues.

Fum tape

I'll start with fum tape, this is probably the most common sealing material! I usually use it for sealing threaded connections of small diameters 3/4, 1/2 and smaller, and almost always for plastic threads. The tape comes in different thicknesses, from 0.075 to 0.2 mm and more, the width is also different. For work, I use a thick tape, make 3-4 turns per thread, the diameter of which is indicated above.

It is the most difficult thing for an inexperienced craftsman to work with tape, and no one will tell you exactly how much you need to wind, since you need to write a whole article for this! That is why I try to work with it less, since connections sealed with tape most often leak, it’s enough not to rewind or rewind a little and that’s it, problems cannot be avoided. I use one type of tape, I know exactly how much to wind and leaks occur very rarely, I usually buy tape without a casing, you can see which one in the photo below. If you have little experience, I advise you to practice before using!

Some tips for working with tape:

A huge disadvantage of fum tape is that the threaded connections sealed with it cannot be adjusted, which means that if you need, for example, to unscrew the tap a little to align it, the connection will definitely leak!

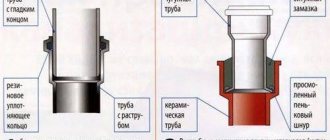

How does compaction occur?

Inch threads have a conical shape and all compaction occurs on the last two threads. They are not completely cut and are smaller than the other turns; they are sealed by wedging the sealing material between the parts. There should still be some paste applied here.

As for the thread, it must be applied to the thread with notches. If the thread is smooth, a special key is used for the notches. The thread is wound starting from the third turn. It is necessary to wind carefully, filling the threads so that there are no empty spaces. The first two turns remain free, just like with flax, and just like with flax, the compaction on the last ones.

Fumlenta on metal thread

The glue is applied to the thread immediately before joining and then spread well with your finger over the entire thread. This is necessary so that empty spaces do not appear through which water can then seep through. There are some minor problems with the glue - you should always check how well it adheres. We must check the thread after connecting. Therefore, glue is used quite rarely and in the most necessary cases. For example, when you need to connect a plastic part to a metal one, you can’t think of anything better than glue. It is also better to use glue when there is a possibility that the connection may leak and access to it is limited.

Sealing thread

If my memory serves me correctly, it appeared on the shelves in a plumbing store (at least in our village) 7-8 years ago, correct me in the comments if I’m wrong. It was Tangit Uni-Lock from Henkel. Everyone began to actively buy it, there was such a laudatory advertisement, everyone really liked it, but after a while people began to make repairs, change the plumbing, heating and other appliances.

We were faced with a very unpleasant problem, especially on large thread diameters; the connections were either very difficult to unscrew or simply impossible, we had to burn the thread with an acetylene torch! And all because the thread was almost not lubricated with anything, that is, the metal began to rust, since it absorbed moisture and, it seems to me, let oxygen through, because I can’t find any other explanation. The threads were just in terrible condition, I don't use it anymore. I agree that it is very convenient to pack and the connections are reliable and do not leak, although you also need to practice! I can recommend additionally lubricating it with sealant or plumbing paste.

How to reel

everything is very simple. The main thing is not to be afraid and not to overdo it. The bottom line is this: If you wind too much, the connection may burst; if you wind too little, it may leak. How to use Unipack? The manufacturer recommends spreading the paste onto the cleaned threads, then wrapping flax and adding another layer of uniatka on top. We smear only on top, and sometimes I just smear the entire strand with unipak and then wrap it around the thread.

The most important thing is that you need to wind the flax so that when twisting it does not unwind. On a regular thread, wind it clockwise

When twisting the product, the linen will not unravel

And so, here we go:

When twisting the product, the linen will not unravel. And so, here we go:

Did you reel it in and apply a unipak? Now let's twist it.

The most important thing is not to wrap too much so that the fitting does not crack. This connection must be carefully tightened with two keys. And we can end here. Let's move on to the next connection.

To seal connections you need to use your choice:

1. Linen + sanitary paste.

Linen is not suitable for temperatures above 90 degrees; over time, it boils, burns, and loses its properties.

2. TANGIT Uni-Lock or equivalent.

Tangit Uniloka is more expensive than its analogues, 20 meters of Tangit Uniloka (packaging on a blister on which it is written that it is enough for 50 connections for a 1/2-inch thread) costs 130 rubles, and the analogue - “Plumbing” 50 meters costs the same 130 rubles ( in Leroy-Merlin, St. Petersburg).

3. Polyamide thread + silicone lubricant.

On the packaging of Tangit Unilock and its analogues the composition is written: polyamide thread + silicone. If we want to save money, we conclude: you can buy regular thick polyamide thread at a hardware store or a sewing store and buy thick or liquid silicone grease from auto parts or the same plumbing paste.

4. Linen rope + plumbing paste.

Construction and hardware stores sell household linen, jute and similar ropes made from plant materials. They cost about 50 rubles. for 50 meters.

Silicone sealant is not suitable because it polymerizes/hardens and if you need to position the connection, say, after a few hours, it will be torn inside the thread. Therefore, it is necessary to use a non-hardening and non-washable sealing filler. Additionally, vinegar-based silicone sealants can be corrosive to metals.

In general, in order to understand what is better, you just need to experiment.

How to wind? Crosswise, as indicated in the instructions for Tangit unilok, either with or against the thread - it’s all a matter of habit. The main thing is to wind it tightly so that the thread is covered with the material used. I can wind it this way and that way, and nothing will come out of the thread or leak. But still, thread or flax wound against the thread will be cut faster when tightening the nut, this is obvious.

Winding different materials for 1/2" thread:

1.

We take flax, smooth it, cut off a strand one, or maximum two, matches thick. We smooth the separated strand again, holding it between our fingers, and throw away the small fibers. If desired, you can twist the strand into a lace. We wind it very tightly along the thread, starting from the edge so that the thread groove is completely closed. Then we take the plumbing paste and spread a small amount with rotational movements onto the wound flax. If your hands grow from the right place, then everything should work out very neatly. Then we tighten the connection, twisting should occur with a certain force, but not with all the dope! If the nut tightens easily, it means there is not enough flax, or there is too much gap between the internal and external threads. You need to unwind the flax and wind more new one. If everything is done correctly, then the linen should not come out from under the thread and it will be dry :)

2.

We wind the Tangit unilock thread along the thread or crosswise 6-8 turns and connect it. And that's it.

3.

Homemade option. We also wind the polyamide thread and coat it with plumbing paste or thick silicone grease. Or first soak the entire skein of thread with liquid silicone lubricant. We wind on the connection. Let's connect. That's all. If you soak or soak a skein of thread in liquid lubricant, then you need to put it in some small plastic box or bottle so that dirt does not stick to the thread and it does not stain anything.

4.

We separate the linen rope into two laces from which it is twisted. We cut off 40-50 cm. We wind it onto the thread. Lubricate with plumbing paste and tighten the connection.

Synthetic thread - Tangit Unilock or an analogue - is the most versatile!

True knowledge will come only with experience!

List of sources

- chudovanna.ru

- secretmastera.ru

- mr-build.ru

- shtyknozh.ru

- kbumb.ru

- funer.ru

Plumbing flax

This is my favorite sealing material, which I use all the time, and if everything is done correctly, the connections are reliable and very rarely leak! Some wind flax without using lubricants or sealant; this is a huge mistake, since this material absorbs moisture very well and allows oxygen to pass through, as a result of which it begins to rot and rot. This leads to leaks and corrosion of the metal; connections sealed in this way quickly become unusable, and just as in the example with the thread, difficulties arise when unpacking!

Therefore, always use flax using special lubricants or silicone sealant! Many people smear flax with paint the old-fashioned way, and when I come across such connections, I grab my head, because without an acetylene torch, it’s simply impossible to unpack them!

The most important advantage of this material is that connections sealed with flax are very easy to adjust, for example, you packed a faucet and it became uneven, you can always unscrew it half a turn and the connection will not leak! In my opinion, this is the best sealing material that I use most often and in 99% of cases there are no problems! Regarding compaction with flax, I will write an article and tell you everything in detail, since this is a separate topic for discussion! That's all, write comments, I hope the article was useful to you! Please like and subscribe to my channel!

Source

Review of sanitary flax

Linen is a popular material for winding. The outdated name is tow. Linen is an environmentally friendly material that does not pose any harm to human health. The product does not require certification, therefore, it is possible to seal drinking water pipes.

The additional material that is also needed for impregnating sanitary tow is environmentally friendly. Thanks to impregnation, this material will last for a fairly long period of time. Linen is a publicly available product. The product is sold in absolutely any plumbing store, so finding it will not be difficult.

Let's consider the advantages and disadvantages of this material in detail.

Benefits of flax

Pros of this product:

- Low cost. Tow has the smallest price tag in comparison with other windings. Therefore, when purchasing, it is better to pay attention to the quality of sanitary tow. If flax is sold in the form of a braid, then it is a quality material. If it is in the form of a tight coil, then this indicates low quality.

- Versatility in use. Can be used for any type of connection if winding is carried out correctly.

- During swelling, the volume of the winding becomes larger. This means that if the connection starts to leak, the material will immediately close everything. Small leaks will be closed.

- Resistance to mechanical stress. Only flax allows you to orient plumbing fixtures more accurately. You can make one revolution back without losing the tightness.

Disadvantages of flax

There are also disadvantages:

- In addition to tow, it is necessary to use other means, for example, grease, sealing paste, silicone and other products. If flax is an organic material, then it can rot due to the influence of water and air. Air gets in during repairs or maintenance, which must be carried out every year. And the listed products can interfere with this process.

- It is necessary to carry out preliminary preparation of the thread. Most manufacturers who produce fittings make already prepared threads for plumbing tow. It has notches. If they are missing, then they must be created. This can be done using pliers, a file or a hacksaw. They are necessary so that the plumbing material cannot slide along the coils.

- If the connections are made of brass or bronze, then during winding it is necessary to carry out the work carefully and carefully. If you apply a thick layer of winding to such connections, defects will appear on the threads. It may even happen that the thread breaks.

- Strict rules must be followed when winding this organic material. In addition to the thread, you need to first prepare the plumbing material itself. It is necessary to impregnate it with some substance to prevent future rotting. Winding must be carried out observing the direction. Winds against twisting. The ends of the flax must be brought beyond the boundaries of the thread, then they should be tightened. Hold with your finger and twist.

- It is also worth noting that the additional materials indicated above do not prevent the destruction of the connection. If you use silicone to glue different connection elements, then it will be extremely difficult and even impossible to separate them later. If flax is used without the use of additional materials, then rust appears on the winding, which will transfer to the steel.

Comparison with FUM tape

Sealing involves sealing the water pipe. If it is necessary to seal cold water pipes, then in this case flax and tape are equally suitable. You just need to wind it correctly. But if it is necessary to seal pipes made of plastic or metal-plastic, then it is better to choose FUM tape.

The main advantage is that using tape the work will go much faster, since installation is quite easy. Also, the threads of the fittings are smooth, so the use of plumbing tape will be much more effective.

Might be interesting

Waterproofing

Foundation waterproofing: optimal choice of technology

Waterproofing

Clean water is the key to health, waterproofing concrete…

Waterproofing

Instructions for waterproofing a swimming pool

Waterproofing

Selection of materials, methods of waterproofing work...

However, fum tape loses its effectiveness if it is necessary to seal a pipe whose diameter is more than 20 millimeters. For pipes with this diameter, flax should be used.

The hot water pipeline sets its own conditions. The product must not only seal perfectly, but also have good resistance to high temperatures. PTFE sealing material (fum tape) in this situation is not the best option.

During winding, the FUM tape splits into fibers, which fill all the voids, thereby preventing the penetration of water. High water temperatures can affect the fibers so that they begin to shrink, eventually leading to leaks. Tow has a high level of resistance to hot water.

Also, do not forget about the low price of tow even with the use of additional materials. Plumbing tape is an expensive rewind. If you need to carry out large volumes of work, then you will feel a significant difference in cost. But installation is much easier and faster using fum tape.

It may be that you need to combine two plumbing materials. The turns of the FUM tape can be laid using tow fibers. Or in a completely different way, that is, two turns of plumbing tape can be wound from the top of the tow. This procedure is practiced quite rarely due to the distinctive installation features.

Mounting a linen product requires certain skills from a person. Even a beginner can install fluoroplastic sealing material.

What is tow made of?

Plumbing flax is a sealing material to which we have devoted more than one article and video review. You already know about the properties of flax, its advantages and disadvantages, you know how to wind threads and seal a variety of joints. Now let's figure out what tow is made of, how linen ribbon is obtained and where production is concentrated.

HOW DO YOU MAKE FLEN-TOWL?

Tow is a tangled, coarse fiber and is essentially a waste product from the processing of bast crops. These include hemp, jute, kenaf and, of course, flax. Fibers, intended mainly for the textile industry, are obtained from plant stems. To do this, the plucked flax is soaked for a long time so that the fiber is separated from the stem. After this, it is dried, cleaned, crumpled, ruffled and combed out. Today, all flax processing operations are mechanized.

How to wind flax on a thread

Before you start winding, check the threads - if they are completely new, then you should prepare the turns. Most manufacturers currently produce fittings that already have threads, but with notches for winding flax. The fact is that the material begins to jump off the smooth thread and bunches up into a single bunch, and this can lead to a violation of the tightness. So that the fibers can catch well, notches should be made on the turns. If necessary, you can always apply them with a needle file, file or hacksaw. Some of the craftsmen may use a plumber's wrench or even pliers - the thread should be grasped, and then apply the notches with a slight movement of the hand.

The main thing is that roughness appears on the turns. Before you start winding flax onto the thread, you should separate a small strand from the whole braid. You should capture enough fibers so that the winding is not too thin, but not too thick. Professionals advise using a thickness of material that is the same as 1 or 2 matches in girth. If there are lumps in the strands, remove them and small lint.

Work methodology

You can apply tow using your own technology, which you like more than others. Some specialists twist flax into flagella, while others braid it into a weak braid, while others simply lay it in the form of loose threads. The order in which materials such as pastes are applied also varies. Sometimes you can first lubricate the thread, wrap it with fibers, and then apply a second layer, and someone saturates the fibers in advance, and then everything is prepared. Both options are correct, and if you think about how to wind flax onto a thread - counterclockwise or clockwise, then you should listen to the advice of craftsmen who wind pipes with flax both clockwise and counterclockwise at the same time.

In addition, the strands must be pinched with your fingers outside the turns, and the first turn should form a cross, which will allow the material to be fixed. Do not leave any gaps, lay all the turns one to one. If you are making a connection, a lot of the material used may be squeezed out of the fitting, this happens when working with a steel coupling and an iron pipe. Brass connections can burst under strong pressure; this is true for elements manufactured using modern technologies.

Recommendations from professionals

Plumbing pastes or other sealing type materials should be applied around the flax, and the movements should be rotational. The work must be done extremely carefully. Glue the other end closer to the edge of the thread, and before directly tightening, check whether the pipe hole is filled with sealant. Now you know how to wind flax on a thread, and a photo of the process can be found in the article.

But from them you will not understand that twisting the elements should be done with force, but moderate. If the nut moves easily, then little flax was used. Winding will be considered correct if the material does not come out and the surface around the joint remains clean. For connections on gas pipes, it is better not to use organic tow, since under the influence of gas the winding and silicone, which will be used as an additional material, will be destroyed. Here it would be most appropriate to use FUM tape.

Winding flax on eco-plastic products

If you have ever thought about how to wind tape around a pipe thread, you can use the technology that is used when working on ecoplastic products. This material, like brass, can also burst. The main thing when twisting is not to overdo it.

Before starting work, connect both fittings and count the number of revolutions. Wind the flax evenly, coat its surface with additional compound, and only then can you connect the fittings. If at idle you counted, for example, 6 turns, then after winding the tape it is better to make 5.5 turns, but do not pull the fitting all the way. In this case, it would be more appropriate to use packaging paste instead of sealant.