Plastic pipelines differ favorably from metal ones in that during their installation, the connection of PVC pipes can be carried out manually, without the involvement of qualified specialists and the use of complex equipment. Of course, if you want to save yourself the hassle, leave the laying of communications to professionals, but believe me, you can easily handle some of the installation of PVC pipes yourself.

There are several types of connections for polyvinyl chloride pipes:

- bell-shaped;

- flanged;

- adhesive connection (using the “cold welding” method).

Let's take a closer look at each of them.

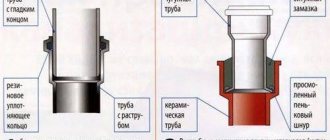

Examples of PVC pipe connections: socket (left) and flange (right)

How to connect plastic pipes

There are several ways to install polymer pipes, each of which has its own characteristics. Experts recommend choosing how to connect plastic pipes depending on several conditions:

- purpose of the pipeline - water supply is often welded, sewerage is joined with sockets, heating is assembled with couplings of different types

- material of the products used - most polyvinyl chloride pipes are equipped with sockets; the industry produces compression couplings for assembling polyethylene lines; polypropylene pipes are soldered with manual or mechanical soldering irons

- scope of work - for heating pipes, installation of water supply, it is easier to buy a manual soldering iron, do the work yourself, connecting the external pipeline with sockets, for welding large diameters the services of specialized teams will be required

For polymer products, threaded connections are not used, since they cannot ensure sufficient tightness of the pipeline.

All other technologies remain available, with welding, sockets, and couplings being the most effective.

Connecting polymer pipes with couplings

HDPE compression couplings solve the question: “How to connect plastic pipes?” in drainage and water supply systems. They are used for standard sizes 50 – 16 mm, provide the necessary tightness and do not cause blockages.

The ends of the pipes are clamped with nuts, cone-shaped sealing rings that withstand the pressure of pressure water pipes, sewage drains, and heating circuits. There are compression couplings that are rigidly attached to the pipe body of a one-piece type.

In addition, threaded connections are used with flaring of the ends of the products after putting nuts on them. Each method is used depending on local conditions; the decision on how to connect plastic pipes is made depending on the material of the parts being joined.

In addition to compression couplings, there are similar fittings: tees, bends, plugs, flanges, saddles, taps.

Connecting polymer pipes by welding

Polymer welding is present in 50% of household communication systems; the joints have improved characteristics, since the process occurs at the molecular level.

The user manuals included in each set of welding equipment describe in detail the technology of how to connect plastic pipes and select the heating time depending on the wall thickness.

Hand soldering irons are used for products 50 – 16 mm; large diameters are soldered with mechanical welding machines. Removable sleeves heat the ends of the pipes, after which it remains to press them with slight force for a few seconds.

Welding with electric couplings is an improved version of the previous method, since the heating and joining process is controlled by a program. The quality of the joint increases, there is no need for fixation. Devices with electrodes are used to supply voltage to the heating elements inside the coupling.

Special connection methods

Push fittings, press fittings, flanges are special compounds of polymer materials.

They also solve the problem of how to connect plastic pipes in difficult cases: a joint with a metal main, a connection of different diameters. Push fitting allows you to use a minimum of tools (calibrator, knife). The fastening element consists of polyvinyl soufflon, brass, suitable for heating and water supply circuits.

The connection is considered permanent, the tightness is ensured by rubber rings. The pipe is inserted all the way into the fitting body, after which it is impossible to remove it back. Press fittings are crimped onto the body of the pipe with a hand wrench; they are also non-removable and are suitable for heating and water supply.

Source: aquagroup.ru

Techniques for connecting plastic pipes with pipes made of other materials

When replacing outdated plumbing and heating systems, service companies are increasingly choosing plastic that is easier to install. Entire multi-storey entrances are equipped with polymer pipes.

This lightweight material, which is easy to cut, can give the impression that assembling a connection to a battery or bathtub will not pose any difficulties even for an inexperienced craftsman.

How to build a polymer riser for hot water or how to connect a plastic pipe to a metal one in a bathroom is a job the master must know thoroughly.

Socket connection

There is another option for connecting PVC pipes for water supply - socket:

- First of all, the surface of the edge of the pipe product to be joined is cleaned of dirt.

- Remove even the slightest dirt from the inner surface of the bell.

- The connection is sealed using a rubber ring, which is inserted into the groove of the socket.

- The end of the pipe with a chamfer is treated with glycerin.

- The pipe is placed in the socket.

- Finally, the quality of the connection is checked. The fact that the rubber ring is located in the right place is evidenced by unhindered rotation relative to the longitudinal axis.

Characteristics of polymer pipes

Plastic pipes are a good alternative to outdated metal water pipes. Even a master inexperienced in technical aspects can easily name their advantages:

- reduced noise level from fluid movement compared to a metal counterpart;

- hermetic connection by monolithic soldering of homogeneous materials;

- resistance to environmental influences, and specifically to rust;

- smoothness of the inner surface, which does not allow sediment to accumulate.

Plastic pipes, which do not appear durable, are in fact only susceptible to strong impacts and sudden compression. Even an increase in internal pressure is less dangerous for them than for pipes made of metal or metal-plastic.

When transporting hot water, the pipe can expand, thereby reducing the risk of rupture. There are no difficulties in deciding how to connect plastic pipes to each other so that water hammer does not lead to an accident: a high-quality seam makes the joint no less durable than the walls of the pipe elbow itself.

The disadvantages of plastic communications are not so obvious, but we should not forget about them. First of all, these are the properties of expansion when heated up to a certain point, which is an advantage.

With significant heating of the environment, pipes can not only expand, but also elongate, which leads to loosening of threaded assemblies and non-monolithic connections. The critical temperature for polypropylene is considered to be +140°C, and this level is quite achievable in the event of a failure in the heating system.

The consequences of such an incident do not seem critical: the risk that the pipe will burst is practically eliminated. But the pipe can bend significantly and even destroy the masonry if placed in a hidden manner.

However, the advantages of plastic pipes are difficult to overestimate. This is the optimal material for cold water supply: by specifying how to connect the tap to a plastic pipe, you can set up a summer shower in a country house in a matter of hours, without using any specific equipment.

In addition, manufacturers of reinforced plastic pipes cope well with the problem of resistance to heat. A layer of plastic or fiberglass forms a kind of skeleton inside the pipe, preventing it from deforming under the influence of heat and pressure. You just have to take into account that when installing communications, pipes made of monolithic plastic and reinforced ones are considered different materials.

When deciding how to connect plastic pipes and plastic pipes with reinforcement, it is impossible to do without additional fittings, such as plastic fittings.

Installation of a pipeline made of plastic pipes

There is no question of how plastic pipes are connected to each other if they are the only material of the entire system. The plastic is mounted by soldering or connecting and/or distribution fittings made of the same material.

The use of metal components is not recommended: the difference in thermal conductivity will affect the quality of the connection. Methods for connecting plastic to other components depend on the material and type of reinforcement.

Building up

It is not difficult to understand how to connect plastic pipes for sewerage or water supply to extend them. The fitting for this type of material is a piece of a similar tube with a slightly larger diameter.

This capsule is placed over the cleaned and degreased edges and compressed with a special soldering iron set to medium temperature.

It’s not difficult to understand the working technique: soldering irons are designed for a certain standard diameter, so you don’t have to control the level of pressure and temperature. The connection turns out to be non-separable and even unnoticeable.

Connection with metal pipe

Connecting dissimilar pipes is more problematic. When figuring out how to connect a cast-iron sewer pipe with a plastic one or an outdated metal heating system with a modern one made of reinforced plastic, it is worth focusing on several important aspects:

- before choosing fittings, you must carefully measure the diameter of the metal elbow;

- to cut and strip a metal pipe you will need a grinder; The adapter between metal and polymer will be a plastic socket.

Having decided where and how to connect the plastic pipe to the cast iron one, you can begin installation. The operating procedure is as follows. The metal piece is cleaned and degreased. The seal is placed in the grooves of the socket and pressed tightly against the inner walls. After placing the pipes, the system is intercepted with clamps.

This technique is often used when installing a toilet. A successful alternative to such a system is a drain with a corrugated drain: since it is much easier to connect the corrugation with a plastic pipe.

Instead of fastening clamps, glue or sealant is used. Connection with a metal-plastic pipe To connect a plastic pipe with a metal-plastic pipe, collet fittings are used. Their basis is a thread applied to the outer part of the capsule. A pipe of the appropriate diameter is screwed onto it.

Collet fittings are commercially produced only for communications with a combination of materials, but also units designed for joining pipes of different diameters to each other. The use of press fittings with plastic materials is irrelevant.

You can install water supply and heating systems yourself, saving on calling a specialist. This can only be done if you are fully confident that your skills are sufficient to carry out such work.

Otherwise, the savings may be tripled to eliminate the consequences of the breakthrough.

Source: trubsovet.ru

Types of docking

A popular method of producing modern tubular products is the use of styrene. The materials make it possible to produce durable pipelines that are resistant to aggressive environments.

Plastic water pipe

They are used when installing plumbing with hot and cold water. At the same time, there are several methods for joining plastic pipes.

PP pipelines

Pipeline polypropylene parts are connected to each other using soldering. In this case, the joined elements of the system are heated using special welding equipment. It is usually called soldering iron or iron.

Connection with other types of pipe products is carried out using special combined couplings. They are PP products, on one side of which a metal sleeve with external or internal thread is pressed.

The other end of the fitting looks like a polypropylene pipe. It is this part that is soldered to the PP pipe. The other side of the coupling allows you to make a threaded connection with a pipeline made of a different material or with plumbing fittings.

Fittings set

Manufacturers produce PP combined couplings with turnkey edges. Such fittings are first screwed or twisted into a pipeline made of another material, and then welded with a special soldering iron with a PP pipe.

American pipes are also used for joining dissimilar pipes. These are dismountable connecting elements with a union nut and sealing materials.

They are made only of metal with threads on both ends or have a polypropylene pipe on one side. American women take a drag with minimal effort.

HDPE pipelines

Pipe sections made of low-density polyethylene are connected by creating a weld or fittings. In the second case, the tightness of the joint depends on the quality of the connecting elements and compliance with the installation technology.

Installation of water supply

The weld is created using special equipment. Installation is carried out using an electric coupling or the “butt-to-butt” method. The use of welding implies the creation of a permanent connection.

To ensure that the joint can be disassembled if necessary, special sealed parts are used. These are inexpensive, reusable HDPE fittings. Their design contains a clamping nut, the degree of tightening of which determines the tightness of the connection.

Special fittings are also produced for connecting pipelines made of dissimilar materials. Such elements have a thread at one end, and the other side is a smooth HDPE pipe with a clamping nut.

There are other options for joining pipelines made of different materials. They will be described below.

Features of solderless connections

Connecting plastic pipes without soldering will not require large financial expenses. And you won’t have to get expensive soldering equipment from somewhere (obviously, not everyone has it) either.

It is worth admitting that the soldering process itself seems very complicated to some. A person must be able to properly handle a soldering machine, set the required pressure and temperature, and select solder. In general, in order to solder pipes efficiently, you really need to know a lot of nuances.

There is also an option such as soldering polypropylene pipes without a soldering iron. To do this, you simply take solder paste (this is a mixture of flux, solder powder and lubricant sold ready-made), apply it to the joint and heat it up.

Moreover, instead of a soldering iron, it is proposed to use a gas burner or lighter. But this method may also cause rejection for some, since here you have to deal with open fire.

Let's imagine a force majeure situation: there was a break in a plastic water pipe. It can take a long time to restore its seal by soldering. And restoring the tightness of pipes connected without soldering can be carried out much faster - this is a really important advantage.

Connecting HDPE to polypropylene pipe

Most often, such situations occur during the installation of irrigation systems. Let's consider the situation using the example of joining a polypropylene (cut) pipe with a HDPE pipe. To connect polypropylene pipes with other types of pipes, specialized fittings have been created with one-sided threads. The part of such a fitting that is without thread is welded to a PP pipe, and the opposite side (where the thread is) is connected to a pipe of the same diameter (made of HDPE).

The thread of the fitting system for joining different types of pipes can be found both externally and internally. It is also possible to install 2 types of these pipes using a part such as a combined coupling. In this situation, a collet connection with thread is attached to the HDPE pipe, and a combined coupling is installed on the propylene pipe. For better sealing, fum tape or a similar sealant is screwed onto the thread before tightening. Next, the structure is screwed in with force.

The simplest way is to connect two types of different pipes (HDPE and polypropylene) using a flange. To improve the sealing properties, a rubber gasket is inserted between the flanges. The structure is tightened with bolts. When preparing pipes from different materials for installation, their dimensional parameters and technological properties should be taken into account; the surfaces to be connected must be cleaned and prepared.

Connection with fittings

To connect plastic pipes without soldering, press fittings (also known as compression fittings) or new Belgian push fittings, which are actually fixed by themselves, are very often used.

Standard press fittings are usually made from steel alloy or cast iron. And they are best used for polypropylene or other plastic pipes of small diameter.

The advantage of these plumbing products is that they can be used to build transitions between pipeline elements and connect them at different angles.

Most often, fittings are installed on bends and branches of a plastic pipeline. An ordinary press fitting consists of a main body, a cover, a sleeve and two rings: a clamping ring (it is located in a special socket) and a seam ring (it is used to fix the plastic pipe).

If we are talking about fittings with a diameter of less than fifty millimeters, then they can be installed manually, without additional devices and equipment.

And one more important rule. The plastic pipe must first be prepared before installing the fitting - cut, remove burrs, clean from dust and degrease. Such preparation must be carried out in any case, regardless of the chosen connection method.

After the plastic product is brought into an acceptable condition, you need to install a nut on it, previously removed from the fitting. Next, a clamping ring is put on this nut. Now you can insert the pipe into the fitting as far as it will go and secure it. The same actions must be done with the second pipe being connected.

Connection of cross-linked polyethylene pipes

Products made of cross-linked polyethylene are connected with fittings:

- compression;

- fittings;

- electric welded.

The connection is carried out in the presence of an equal coupling, two mounting sleeves and a flaring tool. The sequence is:

- A section of about five centimeters in length is cut off from the working pipe strictly perpendicularly, and the chamfer is trimmed.

- The coupling is put on the product in the direction of the coupling to be connected, using the internal fixing groove.

- The pipe is flared. Use hand or hydraulic tools. Its expansion nozzle is rotated relative to the workpiece. After the first flaring, another turn is made, approximately 30º.

- The coupling is inserted and held for some time (with a diameter of 11 cm - about three to four minutes). This time is enough for the product to tightly press the fitting.

- The sleeve is pushed onto the coupling until it stops.

Pipes made of cross-linked polyethylene can be connected using couplings that are fixed with special pliers

The same operations are carried out for the other end of the pipe, completing a tight and reliable joint.

Using flanges

You can connect plastic pipes with flanges without soldering. This joint is considered very reliable - metal flanges can withstand enormous positive temperatures and high pressure.

Today, even large-diameter pipelines are equipped with flanges. They provide a really strong connection.

Flanges for assembling household plastic pipelines are always threaded on one side only. As a rule, they are designed for a pressure of 1.6 MPa. At the same time, in stores you can find flange options with different sections - from 20 to 1200 mm.

The connection algorithm using flanges is quite simple. First of all, you need to carefully pull the flange onto the pipe and put on the rubber sealing gasket. The gasket should extend beyond the edge of the plastic pipe no more than one centimeter. Then the flange is carefully pushed onto this gasket.

At the next stage, joining with exactly the same flange of another plastic pipe is carried out. And the bolts here should be tightened very carefully. If you apply too much force, the plastic surface may crack.

Options for joining metal and polypropylene

There are two technologies that allow joining steel and polymer:

- Threaded connections are used for pipes under pressure and with a diameter of no more than 40 mm.

- The flange connection is made without threads and is suitable for pipelines with a diameter of 40 mm or more.

Each method has a number of features and involves the use of special devices.

Threaded connection: step-by-step instructions

To join metal and polymer, you will need a special adapter - a fitting. On one side it is a coupling with a smooth surface, on the other there is a thread. Plastic is soldered onto the coupling, the other edge is screwed to the iron terminal of the route.

Step-by-step instruction:

- The riser is cut, or if there is a coupling, it is unscrewed. If we are talking about a cut, then use a tool to cut a new thread.

- FUM tape or linen sealant will help prevent water leakage. It is wound in 1-2 turns in turns (clockwise).

- The O-ring is installed.

- The “American” fitting is screwed on very gently, as it is made of a fragile alloy.

The coupling is welded to the polypropylene pipe using a soldering iron. After this, water can be supplied.

Flange connection step by step

A flange is a connecting device without threads that allows the transition from iron to plastic pipes. It is a bushing that is installed in a steel or cast iron outlet of the route. The flange is attached to polypropylene using a bolted connection, which eliminates axial displacement and depressurization.

The installation procedure is as follows:

The metal is cut off, the burrs are removed with a grinder

It is important that the cut is perpendicular to the axis of the pipeline. The flange is adjusted with a file if there are interfering protrusions on its surfaces

Sagging on the edges is removed, because they can damage polypropylene. The flange with the adapter is pressed using connecting bolts. There is no need to tighten it right away. You can tighten it up after the system is turned on. This is in case a leak is detected.

Using couplings

An ordinary coupling for plastic pipelines is a fairly simple part in its design. It consists of:

- cast iron body;

- two nuts;

- rubber gaskets;

- four metal washers.

The coupling can be found at the nearest plumbing store, or, if you have certain skills and knowledge, you can make it yourself. In this case, the characteristics of the coupling must strictly correspond to the dimensions of the products being connected.

Ordinary couplings are suitable for both pressure plastic pipelines and pipelines without pressure. With their help, they provide a reliable connection of polypropylene without the use of a soldering iron.

To form a connection, the ends of the pipes must be inserted into the coupling so that they touch in the middle. The ends must pass through washers, gaskets and nuts. Then you need to tighten the nuts tightly so that the pressure on the gaskets is strong enough.

Joining plastic pipes with a coupling provides a 100% sealed seam, even without the use of soldering. But in certain cases, for example, if the pipe is short or adjacent directly to the floor (or other horizontal surface), it is not possible to install an ordinary coupling.

For such difficult cases, a clamping coupling was invented. How to use it? First you need to clean the edge of the plastic pipe. Then you need to unscrew the coupling and put all the fastening parts on the plastic product in the correct sequence. Moreover, the sealing ring should ultimately be located at a distance of at least one centimeter from the edge of the product.

Then you need to insert the body of the clamping coupling into the end of the plastic pipe. And then you need to move all the existing rings to this body and tighten the bolt. And to the thread located on the other side of the coupling, it will be necessary to attach an “American” fitting with a plastic pipe connected to it.

To control the strength of the connection, you must carefully pull the coupling towards you, holding the pipe to which it is attached with your free hand. The coupling must remain stationary.

If it moves, it means that the wrong size part was selected. That is why it adheres so poorly to the pipeline. However, this is easy to fix - you just need to tighten the threads.

Features of the method

Welding is carried out in a certain sequence:

- The attachments are attached to the welding equipment with screws. Set the temperature to 250-270° and connect the device to the network.

- Take measurements and cut the pipe into sections.

- The edges are cleared of burrs using a sharp knife. If the product has an aluminum layer, then first remove the middle and top layers to the length of entry into the coupling. After this, the same manipulations are performed as with a solid plastic pipe.

- Use a knife to remove the chamfer and bevel the outer edge of the product at an angle of 30-45° from the side intended for heating.

- When welding products with a diameter of more than 40 millimeters, it is necessary to control its oval shape. The joint is cleaned of the oxidized layer to a thickness of 0.1 millimeters.

- The distance of connection with the fitting is marked on the pipe, taking into account the depth of its coupling, and the end of the piece of product does not need to be inserted all the way - a small gap of about 1 millimeter is left.

- The length of the connection section is indicated on the fitting and pipe.

- Prepare the surface intended for welding by cleaning and disinfecting.

- The fitting is put on the already prepared nozzle and the uniformity of its fit is checked.

- Also, a pipe is placed on the hot nozzle of the device and the contact density is monitored.

- Then the heating procedure follows and welding of PVC pipes begins.

- Then they remove both the pipe and the fitting from the nozzle and fix them, placing the product on the connecting element, focusing on the depth of the markings.

- It takes 20-30 seconds to join the seam.