Tank cap problem

As you know, when the engine warms up, the coolant also heats up - it expands. Accordingly, this creates increased pressure, which is greater than atmospheric pressure, this is natural. It should be noted that slightly increased pressure in the CO is neither bad nor good; by and large, the engine doesn’t care! The main thing is that it is enough for the system to function. It must also be airtight.

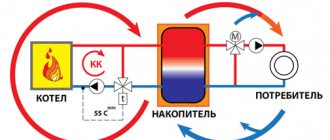

If you want, this can be compared to a home heating boiler. The boiler is an engine, the pipes are pipes, there is an expansion tank in both places.

The more the antifreeze or antifreeze heats up, the more pressure arises in the system. It should be noted that many old units operate at temperatures of 90 - 95 degrees. But modern engines have great performance, so it is not uncommon to work at 100 - 110 degrees Celsius, for example, my AVEO is a high-temperature motor, its normal performance is about 115 degrees. As you understand, these are average values, but at peaks they can reach even higher values of 120 - 125. Coolant at such temperatures can increase by 20, sometimes even by 25% - that’s excess pressure.

In order to prevent pipes, radiators, pipes and the expansion tank itself from bursting, a special valve was invented, which is located in the lid.

Normal pressure in various systems on warm engines should be in the range from 1.1 to 1.5 (bar) atmospheres. It's already dangerous.

Just if the pressure rises much higher, the cooling system can be damaged, in simple terms, it will simply rupture all your hoses or, even worse, the radiators.

This is where the expansion tank cap comes into play; it “bleeds off” excess pressure, bringing it to a normal level of, say, 1.1 atmospheres. This way, all your pipes and hoses remain undamaged.

Low blood pressure is also dangerous!

Just imagine - you drove on business in the winter, and then you parked the car (parked overnight), the antifreeze will begin to cool and decrease in size, that is, “sink down.” And the pressure will also begin to drop (after all, the excess pressure was released by the valve and closed), thus, the decrease in pressure will begin to create a slight vacuum. Hoses and pipes will shrink inward - which is also not good.

Again, the expansion tank cap starts to work, it also has a low pressure valve, that is, if a vacuum begins to create, then the system opens and replenishes with air. The hoses expand to normal levels.

Thus, the expansion tank cap works both in one direction (high pressure) and in the other (low pressure). This is a very smart and very necessary element of the system, despite its simplicity.

Very often it primarily protects radiators from damage (after all, they are expensive on foreign cars).

Verification Instructions

Trying to create pressure with your mouth in order to check the functionality of a potentially failed valve cover from the expansion tank is usually in vain. It is better to abandon such an idea. Otherwise, there is a risk of drinking antifreeze. And if he is also hot, then a visit to the hospital cannot be avoided.

The easiest way to check it is at a car service center. There are special pumps to create pressure. They pump the required number of atmospheres, which makes it clear whether the valve operates or not.

But many are interested in self-checking. It is also possible.

Here you need to act according to a certain algorithm.

- First, turn off the engine, let it cool for a while, then carefully unscrew the cap from the tank. Examine its condition visually. Any breaks in the seal, chips or cracks indicate the need for replacement;

- In the absence of mechanical damage, there is still no guarantee that the element is in working order. Screw the plug into place, turn on the engine at idle speed;

- Wait until the engine temperature reaches operating parameters;

- Listen carefully, standing near the tank, to see if there is any hissing in the area of the lid. The sound is reminiscent of opening a can of soda;

- If there is a hissing sound, this directly indicates that the valve is holding excess pressure inside and not releasing it;

- If there is no hissing, check the operation for pressure build-up. To do this, feel the pipes that are accessible without difficult dismantling;

- If they are pressed in and compressed from the inside, then the discharge valve does not work.

Device, principle of operation of the tank lid

As I already indicated above, the task of the lid is to maintain pressure to a certain limit. It becomes clear that it should tightly adhere to the tank and not allow the pressure to bleed, up to a certain limit - 1.1 - 1.5 atmospheres.

The cap itself holds practically nothing; it is only needed to press the high-low pressure valve, which plunges into the neck of the expansion tank.

As a rule, there are one or two sealing gaskets on the valve body, which act as a kind of seals. In many foreign cars there is only one valve, it is also inlet and outlet, that is, it can bleed and build up pressure.

It is worth noting that on many domestic VAZs, the lid is designed differently, there are physically two valves, one, as you guessed, only works to relieve pressure, the other to pump it up (normalize) to normal.

These valves are named:

- Protective – against high rates

- Vacuum – from low values

But as long as the pressure in the system is normal and both are closed, they do not work, this is the norm! However, the cover often breaks, which is difficult for a simple motorist to determine (and it is very difficult for a beginner), although this entails quite expensive breakdowns. Now a few words about the signs of such malfunction.

Bought a new cover and it doesn't work?

If checking the new expansion tank cap shows that one or both valves are faulty, you can try to modify the part. Owners of VAZ 2110 and 2114 cars often encounter this problem. Usually the valves do not work correctly due to the manufacturer using too stiff springs.

First you need to disassemble the cover using a flathead screwdriver and pliers. During disassembly, remember exactly how all the components were installed, since the springs may fly apart in different directions. After disassembly, it is necessary to reduce the length of the springs. The large spring for the pressure relief valve is shortened by one turn, and the smaller one by two.

The safety valve spring (large) must be shortened taking into account exactly when the valve was triggered during the check of the cover. The main thing in this matter is not to overdo it. But with the second spring everything is much simpler - it should create at least minimal pressure on the intake valve at the moment of its closing. After finishing the cover, all components must be assembled in reverse order. The plug check must be repeated to ensure that the valves operate in a timely manner.

How well do vehicle owners know their vehicle? After all, he is also susceptible to various diseases that need to be eliminated in a timely manner. The cooling system of any car (domestic or foreign production) deserves attention. It includes a special container, which is simply impossible to do without, since it plays the main role. However, any element of the system performs its task, and without them, effective engine cooling is impossible. And while experienced drivers know how to check the expansion tank cap, beginners may experience difficulties.

The design of the container is simple, but this does not negate its importance. Many car enthusiasts consider the pump and radiator to be the most important components of the cooling system. Are they right? And what secrets can be hidden around such an inconspicuous and small detail as the expansion tank cap?

Signs of a faulty expansion tank cap

Often the high pressure valve fails; it simply begins to release antifreeze at normal levels, or does not release it at all.

- When the normal pressure is released (with a warm engine), antifreeze or antifreeze splashes out and, accordingly, it decreases. Steam can often come out from under the hood because the liquid gets onto the hot exhaust manifold. Moreover, the engine temperature is not in the red zone, that is, it is working - which means 90% of the lid.

- If the vacuum valve fails, completely different symptoms will appear. This is how air pockets often arise in the system - this leads to the following: the engine overheats, and cold air comes out of the stove.

To be honest, there can be a lot of reasons, for example, another sign is when pipes burst or clamps break. YES, the tank itself can burst - this means that the high pressure valve does not release the “excess” and it begins to exceed 1.5 atmospheres, which, by the way, can damage the radiators themselves, let me remind you of their two main ones and the stoves (in the cabin).

So if your connecting clamps or other connections start to “snot”, and hoses often get knocked out, change the cover.

How can I check the work myself?

To be honest, this is a little problematic; the valve-lid needs to create either increased or decreased pressure.

However, first you need to inspect it visually; if you notice cracks, abrasions, rupture of sealing gaskets, or other mechanical damage, then this is most likely the cover. Also, the internal elements of the valve can become unusable over time; some manufacturers recommend changing these plugs every two to three years, then there will be no problems.

Now a few simple ways to determine the malfunction:

- Start the engine, warm it up, then carefully begin to unscrew the cap; if a “bang” occurs, it means it is holding its “atmospheres”, most likely working.

- We look at the thick hoses; if they are severely deformed, as if squeezed, then the vacuum valve does not work - the cover needs to be replaced.

- There is another way, but it is not always possible to use it. We unscrew the cap from the tank, strongly squeeze one of the thick hoses, then, without releasing the hose, screw the cap on - if they return to their original shape, then our plug is working. If not, change it. The only downside is that this is quite difficult to do on many modern foreign cars.

Of course, at many stations there are special pressure pumps, to which the caps from the tank are screwed and pumped - 1.5 atmospheres, after this critical indicator is crossed, the valve should open, if this does not happen, it means it is faulty.

In conclusion, I would like to say that on many foreign cars the cap breaks when unscrewed, the valve itself remains inside the tank and does not come out. This suggests that the vacuum that has been created inside does not allow it to come out! A replacement is needed, not because it is broken, but because the valve is “dead.”

This is how the article turned out, for those who are lazy, watch the video version.

I’ll end here, I think it was interesting, read our AUTOBLOG.

Similar news

- Engine cooling system pressure. A few words about radiators...

- The antifreeze (TOSOL) has darkened and turned brown. Why? Let's sort out the...

- Can antifreeze evaporate: on its own from the expansion tank...

Add a comment Cancel reply

What's the result?

As you can see, in the design of a modern car, increased demands are placed on the engine cooling system and its correct operation. For this reason, for efficient operation, a special tank is additionally used in the design.

Malfunction of the valves in the cover often leads to damaged pipes, the thermostat fails faster, the cooling system pump (pump) suffers, the engine may overheat, etc.

Checking the car cooling system pump. Main symptoms of malfunctions. Diagnostics of the water pump without removal, troubleshooting with removal from the engine.