One of the most important stages in the construction of a bathhouse is the installation of a chimney. And its insulation is a mandatory process during construction, which has two goals: fire safety and corrosion protection.

If you do not make thermal insulation, then under the influence of temperature changes condensation will form, gradually flowing inside and contributing to the destruction of the structure itself.

Insulated smoke exhaust channels warm up faster, making the stove in the sauna work much more efficiently.

Depending on what the sauna chimney is made of, various materials are used for its thermal insulation.

There are several types of already insulated chimneys for sauna stoves, the most common of which are sandwich pipes made of stainless metal. A good option is ceramic sections, which are already installed in expanded clay concrete modules.

What factors influence the condition of the smoke exhaust system?

Factors influencing the safety of the smoke system:

- Condensation accumulation. Humidity and high pressure remain inside the chimney. A sharp temperature difference from the outside and inside leads to the formation of harmful condensation. The condition of the metal deteriorates due to the constant presence of moisture.

- Settlement of harmful substances. The aggressive substances formed after fuel combustion pose a great danger to human health. Under the influence of traction, they come out. If the chimney is faulty, all substances settle on the walls, which has a destructive effect on the condition of the material.

Advantages of insulation

Condensation practically does not occur when selecting high-quality insulation materials. There is no accumulation of harmful acids or moisture. Advantages:

- Fewer harmful substances settle on the walls of the smoke exhaust channel, since the thermal insulation layer reduces the temperature difference between unburned hot particles and the pipe.

- An insulated system requires lower energy costs. Fuel consumption is reduced. Less energy is required to maintain a constant temperature.

- The thermal insulation layer, in addition to its main function, serves as a protective frame. The strength and stability of the chimney increases. This advantage is especially noticeable when installing pipes with thin walls.

- The frost resistance of the system increases.

- The impact of high temperatures where the pipe exits through the roof is reduced.

- Foreign elements of the bath structure are not heated by the pipe, which prevents fire inside the room.

Sealing with mortar

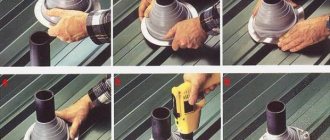

To seal the gap between the chimney pipe and the slate or tile roof, use moisture-resistant cement mortar and a decorative collar. This is the most affordable way to insulate the attic and rafters from moisture with your own hands. This requires dry mortar, water, a mixing container, steel corners and a collar. Installation work is carried out in the following order:

- The gap between the roof and the outer wall of the pipe is lined with stainless steel corners. If the chimney is oval or round in shape, you can use a rubber seal with an adhesive backing.

- A decorative collar made of galvanized steel is put over the chimney head and secured with self-tapping screws.

- A pre-mixed viscous solution is poured into the gap between the collar and the pipe and allowed to harden for 1 day.

- After a day, check the quality of the filling and the degree of hardening of the solution. A surface for liquid drainage is made from a sheet of sheet steel. To do this, a hole is cut out in it, the diameter of which corresponds to the size of the collar, put on the head and fixed with self-tapping screws.

Important! To ensure that the structure is reliable and does not collapse during the first serious downpour, high-quality waterproof cement is used. Otherwise, cracks will appear on it, through which water will leak into the rafter frame.

Work rules

For insulation you can use:

- Mineral wool based insulation. The material is susceptible to moisture, so when using it you need to install waterproofing.

- Glass wool. Its properties are similar to its mineral predecessor.

- Brick. Both whole materials and their fragments serve as insulation.

- Slag based solution.

When choosing insulation, you need to take into account the material from which the chimney system is made:

- Made from asbestos cement. The internal surface of the chimney is cleaned of accumulated dirt and layers of dust. Mineral wool is placed in a steel casing, then it is put on the pipe. This part is made of galvanized iron. Its diameter should be 12 cm greater than the size of the chimney. When putting on the casing, you need to evenly distribute the insulation with which you need to wrap the structure starting from the ceiling.

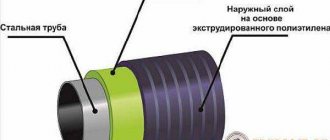

- Of steel. The design is complex, consisting of two pipes of different diameters. A casing is placed on the smaller part, providing protection from external factors. A thermal insulation layer is laid between the pipe elements.

- Made of brick. For thermal insulation, plastering is carried out. The solution is placed in 3-4 layers on top of the reinforced mesh. The top surface of the chimney must be whitened.

Seal gaps between chimney and slate roof

Sometimes the question arises of how to seal the gap between the pipe and the slate.

The technology provides the following sequence:

- First, a round hole is cut in the steel sheet that will be needed to finish the ridge.

- Next, a ring of sheet asbestos cement is placed on the pipe.

- For absolute sealing, so that in the future there will be no problems with the leaking pipe on the roof, the joint between the pipe and the roof is sealed with an asbestos cement solution (proportion 1:2).

- In addition, the same solution is used to fill the gap between the chimney pipe and the slate sheet. To do this, you can temporarily make a limiter out of cardboard.

Choice of insulation

The materials used to insulate the chimney system must provide insulation against the ingress of foreign substances and moisture from rain, retain the heat accumulated inside the bathhouse, and be non-flammable.

A well-insulated chimney will be protected from icing. Condensation will not accumulate inside the channel.

For insulation you can use:

- Hydro- and heat-insulating plaster. Suitable for chimney systems made of brick and stone. Disadvantage: installation of an additional reinforced structure is required to apply the solution.

- Brick. Used as a heat insulator for brick and steel chimneys. Broken material is used. A protective casing is attached around the pipe, under which brick fragments are poured. The distance between the outer and inner parts of the structure is 60 mm. Sometimes brick is replaced with slag. This way ensures a high degree of thermal insulation of the chimney system.

- Cotton wool based on basalt. An insulating material that is produced in mats, cylinders, differing in cross-section. Cotton wool is wrapped around the diameter of the pipe. Steel crimp clamps are used for fixation.

Basalt wool

To save money, the outer casing made of steel can be replaced with slabs of wood or slag concrete. In this case, a rectangular frame is made around the pipe, and thermal insulation material is poured into the free space.

When choosing insulation, you need to pay attention to its properties. It must be made from components that are not subject to combustion, since the insulation during the operation of the stove heats up to 100–150 degrees.

Pipe insulation in a traditional Russian bathhouse

At elevated temperatures, fire-resistant red brick retains its performance properties, therefore it is in demand when constructing a chimney in a bathhouse with a stone stove. In this case, you are guaranteed protection of the pipe from fire and long-term heat retention.

The service life of the structure depends on how well the brick pipe is constructed. Do not skimp on materials during the construction of the chimney, because... Then the repair will cost you much more.

Let's take a closer look at how to insulate a pipe in a bathhouse from the ceiling:

- Use asbestos to cover the pipe outlet on the ceiling and through the roof.

- Using galvanized material, insulate the walls on the inside of the pipe. Standard iron sheets are completely unsuitable for this purpose due to their tendency to corrosion.

- Make a box around the pipe where it passes through the ceiling.

- Pour expanded clay inside the box to retain heat and protect the wooden floors from fire.

You have professionally wrapped the pipe, but this is not the end of the chimney installation work. The next step is measures to insulate the stove, ceiling and walls of the bathhouse.

Installation features

When operating the heating unit, the temperature inside the smoke exhaust channel reaches 200–300 degrees. The material chosen for the cladding must have high heat resistance to prevent fire. For insulation you can use glass and mineral wool, basalt.

There are ready-made cylinders on sale that have a special foil screen. They are used to design the flue and adjacent roof segments. Installing shielded protection prevents fire and the entry of cold air masses.

Before starting insulation work, you need to study the regulatory requirements:

- The height of the pipe for the exit of combustion products is at least 5 m. This ensures maximum draft.

- The distance between the roofing and the external element of the steam room must be at least 250 mm.

- If the roof is sheathed with slate, roofing felt, ondulin, or soft tiles, which are not fire-resistant materials, a spark arrester must be installed on the chimney.

After making sure that all requirements are met, you can begin wrapping the chimney with a heat-insulating layer.

Insulation methods

The method of insulating a metal chimney depends on the type of chimney:

- Steel products. Sheathing involves the use of a solution based on a dry mixture and water. The surface of the structure is treated with the resulting composition. A reinforcing structure made of fire-resistant fiberglass is placed on top. Then a layer of plaster is applied.

- Sandwich-type structures. The chimney consists of a layer of mineral wool and 2 metal pipes. The main sleeve is the upper one and has a larger diameter. The smoke exhaust channel is an element with smaller dimensions. To insulate the roof and ceiling, you need to make a hole that will exceed the dimensions of the chimney by 250 mm. Cover the pipe with a winding made of fireproof basalt wool. Steel wire is used to attach the insulation. The last step is installing the casing.

In bathhouses, the chimney can be wrapped to prevent ignition:

- Thermal insulation. This is foamed polyethylene covered with sheets of foil. With it, the stove smoke does not heat the chimney much. The chimney is wrapped with insulation on all sides. For fixation, use wire or metallized tape.

- Folgoizol. It is a fiberglass layer covered with bitumen and aluminum foil on top. Suitable for outdoor use. It should not be confused with foil-isolon, which is made of polyethylene and has a reflective foil ball on top. This material is used for interior decoration. The main advantage of both materials is the thermos effect. Retain more than 90% heat.

Why insulate a chimney?

During operation of a sauna stove, its chimney becomes hot, and the inevitable proximity to flammable materials can lead to a fire.

If the chimney pipe is made of brick, it heats up less, and if the chimney is made of metal, then much more.

Metal pipes heat up over 600 C°, and their proximity to the wooden lining of the steam room is very dangerous, especially if the bathhouse is close to residential buildings.

The second, no less important problem is the appearance of condensation in the chimney. Condensation is the main enemy of all smoke removal systems.

This is not just moisture that forms on the walls of the chimney, but an aqueous solution of sulfuric acid, which can destroy almost any material. It appears as a result of the passage of heated air through a still cold chimney.

As a result of the impact of condensation on an uninsulated brick chimney, the masonry is destroyed, since it has the ability to penetrate microcracks in the brick, and when freezing, it expands. Metal chimneys also suffer greatly from condensation.

Metal of ordinary brands is not resistant to acids, so it quickly becomes unusable when exposed to condensation.

The only way to combat the appearance of condensation is to insulate the smoke exhaust ducts, in which the pipe will cool less and the sauna stove will return to operating combustion mode faster.

Examination

To check how well the thermal insulation layer is laid, you need to light the stove. For diagnostics it is better to use a thermal imager. The optical-electronic system will help determine the quality of sealing of the outer casing. With proper installation of the wall of the chimney structure, the seams at the joints do not allow heat to pass through. The places where the heat flow leaks will be indicated by the device screen. Incomplete sealing leads to overheating of the insulating material. If a problem is detected, the outer casing is dismantled and re-insulated.

If, after insulating the chimney structure, condensation continues to form on the walls, the heat insulator is selected incorrectly, and the thickness does not meet the established standards. The minimum size is 4 cm. For steel and asbestos pipes with a height of 6 m or more, insulation with a thickness of 10 cm is selected. In brick chimneys, slabs with a thickness of 8 cm are used.

Insulation work should be carried out after the installation of the chimney system and ventilation elements is completed. When installing chimneys, it is necessary to use modern types of insulating materials. It is better to use finished products with thermal insulation.