Features of the technology

Termal heating radiators are made of corrosion-resistant aluminum alloy AD 31. Production technology is extrusion. Vertical columns and horizontal collectors are molded separately. In the columns, latches are extruded using the stamping method, which engage with the corresponding grooves in the collectors. This lock ensures high strength of the product.

This is what it looks like in the interior

Tightness is ensured by double rubber sealing rings. Around each vertical channel in the horizontal manifold, two grooves are machined into which sealing rings made of heat-resistant rubber are placed.

The tightness of the connection between vertical and horizontal collectors is ensured by two rubber rings

After assembly, the assembled radiators are molded under pressure into a single unit. Therefore, Thermal aluminum radiators are non-separable and cannot be repackaged. They are delivered from the factory fully finished. For installation, all that remains is to hang the battery on hooks or brackets (you can also order it from the factory), install adapters, shut-off valves, an air vent and a plug.

The assembled products are painted using the powder spraying method in an electrostatic field. This technology makes it possible to achieve high paint resistance to mechanical damage. A special pigment is added to the base paint, which prevents the paint from turning red over time or under the influence of ultraviolet radiation.

Aluminum radiator Thermal 500 (7 sections)

General information and advantages of aluminum radiators "Thermal"

- Thermal radiators are made by pressing from extruded aluminum alloy, which has high strength, corrosion resistance and a “mirror” surface finish.

- Production is organized at a high technical level and certified according to the international quality system ISO 9001–96.

- Each radiator, without exception, undergoes acceptance tests, has an individual number, a technical passport with an QC mark and a 5-year warranty.

- The devices have a particularly durable glossy coating based on powder painting in an electrostatic field.

- The Thermal radiator is a flat device (60 mm thick) with a modern design. Its compactness is especially important when placed on an open wall or under narrow window sills. The radiator is lightweight and “installation” symmetrical, has a unified thread of G3/4 pipe connections with an inlet chamfer for a standard O-ring of fittings, which greatly simplifies design and installation work. It also has a nomenclature step that is convenient for selection when designing heating systems.

- The Thermal radiator has a wide range of standard sizes with optimal thermal density for modern buildings. It is safe from injury and is supplied in full construction readiness. The device fully meets modern professional requirements for heating devices in terms of such important qualities as safety margin, stability of parameters, product range, and documentary support. See ABOK Standard 2005 "Heating devices."

- The hydraulic characteristics of the Thermal radiator allow it to be used without restrictions, both in pump heating systems of high-rise buildings and in gravity systems of individual houses. The device is compatible with pipes made of plastic, steel and combined materials.

Strength

The Thermal radiator can withstand excess coolant pressure of 12 MPa without destruction. Thus, it is completely superior to steel panel and cast aluminum radiators, and is slightly inferior to bimetallic radiators and convectors.

Chemical resistance

The Thermal radiator easily meets the RD34 standards. According to this indicator, it is at the level of bimetallic and panel radiators and is significantly superior to cast aluminum ones.

Reliability

Thermal radiators are equipped with a two-level blocking of leaks. Sealing of connections is carried out by pressing in the fittings of the sections and a block of rubber rings. This pressing works even after the frozen section has been heated, and the ring block “triggers” when the joints are loosened during installation.

The unpretentious operation of Thermal radiators is created thanks to aluminum fins that protect important parts in the event of accidental impacts, and high structural rigidity.

The products have been tested for long-term performance by equivalent resource-climate tests, which confirmed the possibility of operating radiators for up to 20 years.

Operational stability

The flow parts of Thermal radiators have a constant cross-section and “mirror” walls, which gives high durability against sludge deposits, which greatly impair hydraulic and thermal power.

Radiators made from extruded aluminum profiles have an excellent flow pattern and are well protected from potential gas damage.

Characteristics and scope

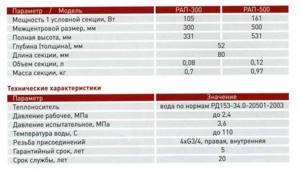

Batteries are available in two sizes - with an interaxial distance of 300 mm and 500 mm. The total height is 331 and 531 mm, respectively. The center distance is shown in the title. They are called RAP 500 and RAP 300.

They are distinguished by a very small depth of 52 mm and low water capacity. In one conditional section (conditional because it is not dismountable) there is 0.12 l for Thermal 500 and 0.08 l for the smaller size.

The thermal power of one section is 161 W for the higher model and 105 W for the lower one. The operating temperature of the coolant is +100oC, with a short-term increase to +130 oC (no more than an hour per heating season). The sections are equipped with one-piece heating batteries. Minimum quantity - 3 pcs., maximum 16 pcs. A fairly small step allows you to select the thermal power with fairly high accuracy.

The pressure is very high: working pressure up to 24 Bar, test pressure up to 36 Bar, burst pressure 120 Bar. The hydrogen activity of the coolant Ph is not higher than 9.

All these characteristics allow the use of Thermal aluminum radiators for installation in apartments of multi-storey buildings. They can be installed both in houses with vertical and horizontal wiring; the type of system is one-pipe or two-pipe. To avoid making a mistake in your choice, you must first make sure that the network parameters meet the specified standards. Go to DEZ, DEU, etc. and find out Ph, operating and test pressure and coolant temperature for your home. Compare the obtained data with the technical characteristics from the table. If you are satisfied with all of them, you can buy.

In individual heating there can be no pressure restrictions: in such systems it rarely exceeds 2-3 Bar. They are compatible with any boilers, only when working with solid fuel units you need to monitor the temperature of the coolant: it should not rise above +100oC. It is not recommended to install them in a network with a copper heat exchanger; the use of copper pipes is prohibited.

Technical characteristics of aluminum radiators "Thermal"

Aluminum heating radiator THERMAL RAP 300.

Center distance - 300 mm. Depth - 52 mm.

| Model | Center distance, mm | Overall dimensions, mm | Nominal heat flux, (W) | Coolant volume, l | Weight, kg | PRICE | ||

| height | depth | width | ||||||

| Thermal RAP 300/4 | 300 | 331 | 52 | 320 | 436 | 0,32 | 3,28 | 1480 rub. |

| Thermal RAP 300/ 5 | 400 | 545 | 0,4 | 4,1 | 1850 rub. | |||

| Thermal RAP 300/ 6 | 480 | 654 | 0,48 | 4,92 | 2200 rub. | |||

| Thermal RAP 300/ 7 | 560 | 763 | 0,56 | 5,74 | 2590 rub. | |||

| Thermal RAP 300/ 8 | 640 | 872 | 0,64 | 6,56 | 2960 rub. | |||

| Thermal RAP 300/ 9 | 720 | 981 | 0,72 | 7,38 | 3330 rub. | |||

| Thermal RAP 300/ 10 | 800 | 1090 | 0,8 | 8,2 | 3700 rub. | |||

| Thermal RAP 300/ 11 | 880 | 1199 | 0,88 | 9,02 | 4070 rub. | |||

| Thermal RAP 300/ 12 | 960 | 1308 | 0,96 | 9,84 | 4440 rub. | |||

| Thermal RAP 300/ 13 | 1040 | 1417 | 1,04 | 10,66 | 4810 rub. | |||

| Thermal RAP 300/ 14 | 1120 | 1526 | 1,12 | 11,48 | 5180 rub. | |||

| Thermal RAP 300/ 15 | 1200 | 1635 | 1,2 | 12,3 | 5550 rub. | |||

| Thermal RAP 300/ 16 | 1280 | 1744 | 1,28 | 13,12 | 5920 rub. | |||

How to install

Aluminum Thermal radiators can be connected with the following types of pipes:

- steel;

- polymer (polypropylene or cross-linked polyethylene);

- metal-plastic.

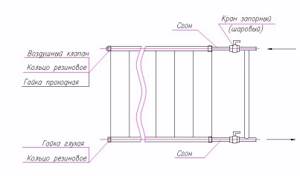

For ease of operation, it is desirable to use shut-off valves; to regulate heat transfer, it is possible to use manual or automatic thermostats or control valves (read what to use to adjust the radiator here). It is mandatory to install an air vent valve on each battery (manual valve "Mayevsky" or automatic type).

When choosing control and shut-off valves, you need to look only for chrome-plated or galvanized models. Uncoated brass and bronze are incompatible with aluminum, as they contain a high percentage of copper. And copper and aluminum form a galvanic couple, the process of electrochemical corrosion begins, which is also stimulated by the presence of a coolant. All this leads to rapid destruction of the heating system elements.

For sealing, acidic silicone sealants cannot be used, only neutral ones. It is recommended to use linen tow and FUM tape as winding. Since aluminum is a soft metal, excessive force must not be applied during installation: the torque is no more than 1.2 kg/m.

Installation option with ball valves: supply from above, return from below, single-pipe connection with bypass

When installing, it is not advisable to remove the protective film in which the radiator is supplied from the factory. During hanging, it is cut only in those places where necessary (in the places of connection and installation of brackets). It can be removed only after finishing work is completed.

Installation is allowed only on pre-leveled and plastered walls, the upper edge being strictly horizontal. A slight deviation from the horizontal is possible only for better air removal: the edge where the air vent is installed is raised slightly.

When installing, the following distances must be observed:

- From the floor to the radiator - no less than 8-10 cm and no more than 15 cm. If you put it lower, it will be difficult to clean under it, if higher, cold air will accumulate below.

- There is a gap of at least 10 cm from the window sill to the top of the radiator. A smaller distance will interfere with air circulation.

- The distance from the wall to the rear panel of the radiator is at least 25-35 mm. A smaller gap will result in dust accumulating on the wall behind the heater.

A unique sealing system is used in production

Aluminum heating radiators Termal have a slightly different mounting system: they are not hung by the manifold, like sectional ones. They have special holes on the back panel for brackets: two on top, two on bottom. This must be taken into account and the installation locations of fasteners on the wall must be marked with high accuracy, not forgetting about the horizontal installation.

The installation procedure is as follows:

- The mounting locations for the brackets are marked on the wall. Holes are drilled in the marking areas and wooden plugs or dowels are inserted into them.

- The brackets are secured with screws with a length of at least 35 mm and a diameter of 6 mm.

- Make holes in the plastic film protecting the radiator opposite the mounting points.

- Hang the battery on the brackets. Check that the installation is horizontal.

- Install shut-off and control valves, air vents, plugs, and adapters. When installing them, you need to use non-acid sealant or PMS200 paste.

The most common option for connecting radiators with vertical wiring (feed from above) is shown in the figure.

To maintain the warranty (5 years), installation must be carried out by specialists licensed to work in high-pressure systems.

Operating rules

Let us remind you once again: Thermal radiators are a non-separable design, it is impossible to sort them out: the seal will be broken. It is prohibited to completely shut off the supply pipeline when the drain valve on the air vent is closed. You cannot leave the radiator unfilled with coolant for a long time: active corrosion begins.

It is necessary to bleed the air two or three times a season. If an automatic air vent is installed, you do not need to do anything, if it is a manual one (Maevsky valve), you need to manually open the valve. To do this, insert a key or screwdriver into the corresponding groove and turn it counterclockwise one turn (no longer necessary; with high pressure, returning the unscrewed lock cylinder to its place will be problematic). If there is air in the battery, it begins to come out (hissing is heard), then the coolant gradually begins to come out (prepare a jar and/or rag). When the stream of coolant becomes continuous, all the gas has escaped. Tighten the tap by turning the key (screwdriver) in the opposite direction. You don’t have to tighten it too much - gas will gradually escape through the micro-hole, and you will have to vent it less often.

In general, this procedure is repeated after starting the system several times with each radiator. Then periodic checks will be needed (every couple of months). If gas formation is active, this means that the system is not working correctly and requires consultation with a specialist.

To prevent damage to the radiator during pressure testing of multi-storey building systems, a short-term shutdown is possible during testing. Just before closing the ball valves, you need to unscrew the air vent valve.

External surfaces should be cleaned 2-3 times a season. Use only soft materials without abrasive components.