Autonomous heating systems for private houses or other premises are usually built on the basis of gas boilers.

This is the most economical and effective heating method, which does not take extra time and effort from the owner and does not require him to constantly monitor the operation of the system.

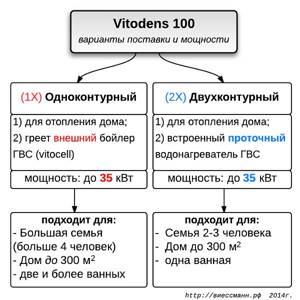

There are two main design options for such boilers, the difference between which lies in functionality.

Some work only to heat the house, others are capable of supplying hot water in parallel with heating.

These two groups are represented by single- and double-circuit units, respectively, which need to be considered in more detail.

What is the difference between double-circuit and single-circuit boilers

The fundamental difference between single- and double-circuit boilers is the functionality of the units.

If the first group of equipment is intended only for supplying coolant to the heating circuit, then the second, in addition to heating the house, performs an additional task - preparing hot water for domestic needs.

As the name suggests, dual-circuit models have an additional circuit designed to heat water. At the same time, the main (basic) function for both groups of boilers is heating the coolant for the heating system.

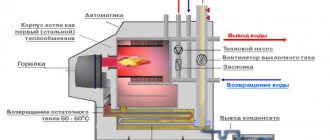

It is provided by the main structural components - a gas burner and a primary heat exchanger, which is built into the heating circuit together with a circulation pump.

IMPORTANT!

Non-volatile boilers do not have a circulation pump and are designed for operation in systems with natural circulation.

The hot water heating function is additional - it is provided due to the partial transfer of thermal energy from the hot coolant, which, at the outlet of the main heat exchanger, enters the secondary, plate type.

It heats water in flow-through mode, which creates some restrictions on consumption - the more water is drawn, the less time the water flow has to heat up.

Some models can be configured to prioritize one or another circuit, when, with active consumption of hot water, the temperature in the heating system decreases or, conversely, the DHW temperature drops.

To solve the problem of efficient distribution of thermal energy between two circuits, a combined, or bithermic, heat exchanger was created. It is a coil coiled from a coaxial pipe.

The outer volume is occupied by coolant, and the inner volume is occupied by hot water. Heating occurs simultaneously, and there are no heat transfer losses. the efficiency of such a device is much higher.

However, experts speak with reserve about bithermal heat exchangers, since they quickly fill up from the inside with lime deposits, which are extremely difficult to remove.

Flushing such a heat exchanger is a labor-intensive and ineffective procedure, and replacement costs too much money.

This significantly limits the demand for models with a combined heat exchanger, although no one denies the increased efficiency of these units.

To more clearly display the difference between the design of single- and double-circuit boilers, let’s create a table:

| Features and Features | Single-circuit | Dual-circuit |

| Coolant heating | + | + |

| Preparing DHW | — | + |

| Number of heat exchangers | 1 | 2 or 1* |

| Possibility of cascade connection | + | — |

| Unit power limitations | — | + |

| Thermal energy losses | Minor | Average |

*for double-circuit boilers with bithermic heat exchanger

Principle of operation

A 2-circuit boiler operates in 2 modes: heating and water heating. However, the device cannot perform these functions simultaneously. The first switching on of the burner in heating mode is characterized by a long operating time, since the temperature of the coolant in the circuit must rise to the set values. As soon as the liquid is hot, the fuel supply stops. If there is a temperature sensor in the room, the burner turns on and off automatically.

The movement of the coolant is ensured naturally (due to pressure differences) or by a circulation pump. Combustion products are removed through a chimney or using a fan. To turn on the water heating, you need to turn the water tap valve. The liquid heats up in 5 seconds. In this case, the heating circuit does not work.

In this case, the system is adjusted by a three-way valve. This device redirects a certain volume of heated water inside the secondary heat exchanger. It raises the temperature of the rest of the liquid.

Characteristics

2-circuit gas boilers have the following characteristics:

- power: from 10 to 280 kW;

- heating area: from 100 sq.m.;

- Efficiency: from 90%;

- type of heat exchanger: aluminum, copper, stainless steel;

- chimney type: natural, coaxial.

Most models of such boilers require connection to the electrical network.

Single-circuit boilers

A single-circuit boiler is an installation that provides heating and preparation of the heating circuit coolant in accordance with the specified operating mode of the system.

The design includes:

- Gas burner combined with a heat exchanger.

- Circulation pump.

- Turbofan.

- Gas equipment.

- Three way valve.

- Electronic control board equipped with a self-diagnosis sensor system.

- Housing, control panel.

- Chimney.

There are non-volatile models that do not have devices powered from the mains.

They have a simplified design, but are able to provide heating for the house in the absence of power supply.

Types of single-circuit boilers

There are single-circuit boilers:

- Floor-standing . Installed directly on the floor (or on a stand). They can have a lot of weight and, accordingly, high power. Many floor-standing boilers are equipped with a cast iron heat exchanger of increased efficiency and heavy weight. Some models are connected in a cascade, forming powerful connections for heating buildings or structures of large area and volume.

- Wall mounted . Compact gas boilers that are mounted on solid (preferably load-bearing) walls. The specifics of the installation require a weight limit, which automatically affects the power of the boilers.

In addition, single-circuit boilers can have different combustion chamber options:

- Atmospheric (open) . The air comes directly from the room, and the smoke is removed naturally under the influence of stove-type draft.

- Turbocharged (closed) . Air is taken in from the outside using a turbofan. It also creates pressure that displaces smoke and other gases formed during fuel combustion.

All single-circuit boilers can have additional functions - remote control, programming of operating modes, etc.

Principle of operation

The operation of a single-circuit boiler is aimed at solving a single task - heating the coolant for the heating circuit.

The unit is connected to a gap in the system, one pipe is connected to the direct line, the second to the return line. The liquid flow continuously moves through a heat exchanger, which is located in the heating zone of the gas burner flame.

At the outlet of the heat exchanger, the flow enters a three-way valve, where it is mixed in a given proportion with the colder flow from the return. Having received the required temperature, the coolant is again discharged into the heating circuit.

The temperature is adjusted by adjusting the operation of the three-way valve.

NOTE!

Non-volatile models work on the same principle, only flow circulation occurs naturally.

Advantages and disadvantages

The advantages of single-circuit boilers include:

- Simplicity and reliability of design.

- No power loss during heat transfer.

- Ability to develop greater power.

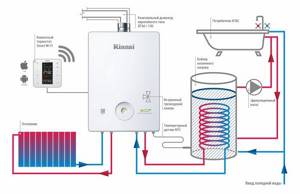

- Possibility of connecting an external indirect heating boiler to produce hot water.

- The cost of single-circuit boilers is lower than that of more functional models.

The disadvantages of single-circuit boilers should be considered:

- Lack of water heating function.

- Limited capabilities compared to dual-circuit models.

IMPORTANT!

Some users claim that single-circuit boilers in conjunction with an external storage tank are much more convenient and efficient than double-circuit designs.

Advantages and disadvantages of equipment

Both types of gas boilers are easy to operate, efficient and durable. They also have an attractive appearance. The design of each type of gas boiler is designed to meet the needs of different categories of users, which clearly demonstrates their advantages and disadvantages. They also provide an opportunity to understand the differences between a single-circuit gas boiler and its double-circuit counterpart, helping the potential buyer make the right choice.

Pros and cons of single-circuit units

Such products are capable of providing stable heating of premises of any size, number of floors, or distance from the heat exchanger. And, in addition, single-circuit boilers:

- more reliable than their double-circuit counterparts, the design of which is more complex, which leads to a slightly larger number of breakdowns;

- easier to maintain , which is also caused by design features;

- cheaper.

An important advantage is that single-circuit units can become a base for connecting other equipment . This will expand their functionality and increase the comfort of living. You should always remember that if you need to provide hot water supply in the premises, you will have to buy a storage boiler along with a single-circuit boiler. And this will lead to considerable additional costs. And a set of the listed equipment will take up a lot of space, which can be critical for small apartments

This type of equipment, in the absence of the need for hot water supply, has no pronounced shortcomings. But otherwise, the lack of universality immediately affects. Which leads to the need to purchase an additional electric heating device. As a result, its joint operation with a single-circuit boiler leads to:

- high costs for purchase, installation, maintenance;

- limited volume of water for domestic needs - boilers are most often purchased for joint use with single-circuit units, so the question may arise about the rational consumption of water, the volume of which depends on the capacity of the storage tank;

- greater load on the wiring.

The last drawback is relevant in cases where the house or apartment has old wiring or powerful electrical equipment is used in parallel. Thus, it may be necessary to modernize the electrical wiring and select a cable with a larger cross-section. You should also be aware that a set of a single-circuit boiler and boiler takes up significantly more space than one double-circuit boiler. And with limited space this can be a significant disadvantage.

Advantages and disadvantages of double-circuit boilers

Units that belong to the specified type have some restrictions, but are still capable of providing hot water to two systems at once (heating, hot water supply). They also take up less space than their boiler counterparts. As a result, double-circuit boilers are more convenient to use.

In addition, the competitive struggle of manufacturers has led to the fact that the difference in the cost of both types of units is gradually leveled out. Therefore, today you can find a double-circuit boiler whose price is slightly higher than that of a single-circuit product. Which in some cases can also be considered an advantage. If we talk about the disadvantages of double-circuit boilers, the most important is the inability to instantly provide hot water at the same temperature to all water consumption points in a house or apartment. Thus, their heat exchangers heat up the amount of water that is needed right now. That is, no stock is created. As a result, the water temperature may differ from what you expect or may change as you use it. This happens when the pressure or pressure changes, for example, after opening/closing the second tap.

As for installation, installation of double-circuit boilers is a more complex procedure, especially at the design stage. Since you will have to follow numerous manufacturer’s recommendations

It would seem that double-circuit boilers are definitely better, because they are more practical and functional, but in practice everything is not so simple and before choosing, we recommend that you carefully weigh all the operating features, the pros and cons of each equipment, which we will describe in this article.

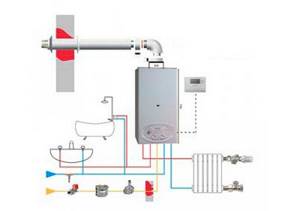

The concepts single-circuit or double-circuit mean that the heating boiler has either one main (primary) water circuit intended exclusively for heating, or is equipped with an additional (secondary) circuit intended for hot water supply - DHW. Accordingly, single-circuit boilers are capable of providing only heating for the house, while double-circuit boilers, having the same dimensions, provide both heating and heating of sanitary water for the bathroom and kitchen. It would seem that double-circuit boilers are definitely better, because they are more practical and functional, but in practice, everything is not so simple and before choosing, we recommend carefully weighing all the operating features, pros and cons of each equipment, which we will describe in this article. Read in the article

Double-circuit boilers

Double-circuit boilers have an additional option - DHW preparation.

At the same time, the basic function (heating of the coolant) is the main one; the operating settings set the priority of heating over DHW.

Kinds

According to the installation method, double-circuit boilers can be::

- Floor-standing . Installed directly on the floor.

- Wall mounted . Hanged on a load-bearing wall.

By heat transfer method:

- Convection . The usual method of heating is in a burner flame.

- Condensation . Two-stage heating - first preheating from thermal energy obtained by condensing moisture from flue gases. Then normal heating is carried out using a gas burner. Since the coolant has already been prepared, it is possible to reduce gas consumption and the overall heating mode without reducing the final result.

By heat exchanger type:

- Separate . Two heat exchangers operate - primary (heating the coolant) and secondary (heating the hot water from the hot coolant).

- Combined (bithermic) . A coaxial type of heat exchanger is used, in which both the coolant and hot water are simultaneously prepared.

By type of combustion chamber:

- Atmospheric.

- Turbocharged.

The designs of single- and double-circuit boilers have no fundamental differences, but are intended to operate under different conditions.

Principle of operation

The operation of a double-circuit boiler differs from single-circuit designs only in the presence of an additional heat exchanger.

At the exit from the primary, the coolant enters the secondary heat exchanger, where it heats water for hot water supply . The rest of the work is no different and follows the standard pattern.

Advantages and disadvantages

The advantages of double-circuit boilers include:

- The ability to receive both heat and hot water from one device.

- Efficient, economical and compact.

- Wide range of functions and capabilities.

- You can turn off DHW heating if not in use.

Disadvantages can be considered:

- Limited amount of hot water.

- Dependence of temperature in the heating circuit on the intensity of hot water collection.

Double-circuit boilers are considered more attractive, capable of solving all issues.

Advantages of gas boilers with two circuits

- The device is cheaper than a single-circuit boiler with a boiler.

- Compactness . It is small in size and therefore can be installed in the kitchen without hassle.

- Availability of all necessary additional equipment.

- Ease of installation . Almost all models are wall-mounted. To connect, you need to connect the pipes of the heating system of the house and the hot water supply. It is also necessary to connect the gas pipe, but this must be done by specialists from the gas supply company.

- Heats the amount of water that is needed. Thanks to this, it is more economical .

Which boiler should you choose?

The choice of one type of gas boiler or another is determined by working conditions and people’s needs.

When deciding which boiler is more suitable in a given situation, it is recommended to consider all the criteria:

Dimensions

The size of a gas boiler is not determined by its functionality. Most often, in one model line, all units are produced in the same standard housing size .

Wall-mounted boilers are more compact, but the main factors influencing the size are the power and performance of the units.

Life time

The duration of operation of gas boilers is determined by operating conditions, loads and power levels.

In addition, an important indicator is the quality of water - the appearance of scale quickly damages the heat exchanger . This applies equally to single- and double-circuit boilers.

Saving

Users note some advantages of single-circuit boilers in terms of gas consumption. This affects fuel payments . At the same time, if an external boiler is connected, gas consumption increases.

Convenience

In terms of ease of use, double-circuit boilers definitely win. They do not require the installation of additional water heaters, which greatly simplifies the creation of communications .

Single-circuit models are convenient only where you only need to heat the room, but such situations are rare.

Price

The cost of both boilers mainly depends on the power and other parameters of the boiler.

However, if we compare a single- and double-circuit model with the same characteristics, then a single-circuit boiler will be cheaper.

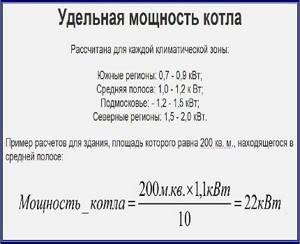

Heating area

The heating area of the boiler depends on its power. It is taken into account at the rate of 1 kW of power = 10 m2 .

In this case there is no dependence on the set of functions; the ratio is equally valid for both types of units.

Additional functions

Dual-circuit models are usually equipped with additional functions. There is remote control, programming, and the ability to connect a room thermostat.

Single-circuit boilers are simpler and less equipped with additional devices due to lack of demand.

Conclusion - which boiler is better?

It is impossible to say unequivocally which boiler is better. We must be guided by the needs and objectives of the premises, consider the number of people, lifestyle and other factors.

Both types of boilers may or may not be necessary in different situations..

In order to name a suitable option, you need to consider all the influencing factors, and only then make a decision.

User manual

Gas boilers are used for heating and hot water supply of apartments, private residential and country houses, and public buildings. In this case, it does not matter at all whether the system is connected to the main gas pipeline, since the units can operate on liquefied fuel, which is supplied in cylinders.

The manual for the use of gas equipment is a set of requirements and rules, compliance with which makes the operation of the device safe and efficient. Initially, the device is connected to the gas main, as well as to the water supply pipes, heating system, and electrical network. The device is connected to the main line only by qualified specialists authorized to perform such work.

If there is a need to replace parts of the device, only original spare parts are selected. If a malfunction occurs, the unit is immediately disconnected from the gas supply. It is prohibited to carry out any service work to eliminate breakdowns yourself. Before the start of the heating season, the condition of chimneys and air ducts is checked. When the equipment is turned off for a long time, the gas valve is closed.

Do not use aggressive chemicals to clean the unit. Before turning on the boiler, you need to make sure that there is coolant in the heating system, that the burner, safety valve and automation are working properly. During operation of the unit, you need to ensure that there is no smell of gas in the room. The burner is periodically cleaned of dirt.

Popular manufacturers

When choosing heating equipment, not only its characteristics are taken into account, but also the manufacturer. It is better to choose equipment from companies that have good reviews and an impeccable reputation.

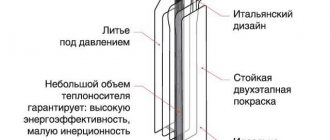

Ariston

Ariston double-circuit gas boilers are produced in Italy. The company offers a wide range of equipment characterized by modern automation and functionality. This technique has the following advantages:

- low power consumption;

- environmental cleanliness, safety;

- the main heat exchanger is made of copper;

- compactness;

- possibility of adjusting the flame strength;

- automatic ignition;

- multi-level protection system.

Among the disadvantages is the need for periodic manual adjustment of the boiler. In addition, it makes noise when operating.

Buderus

The manufacturer offers wall-mounted models of double-circuit boilers that are adapted to domestic operating conditions: pressure drops. The equipment runs on natural and liquefied gas. The heating system is quickly adjusted to optimal functioning, the boiler has thermal and sound insulation, and reliable automation. The devices are distinguished by their modern design and reasonable cost. However, the units do not have protection against voltage surges.

Hephaestus and others

Domestic manufacturer, highly reliable. The automation on the units is Italian and functions without failures. The devices are simple in design, so control is intuitive. The risk of breakdowns is reduced to zero, since the device has a minimum of auxiliary components. Hephaestus boilers are easy to maintain. Users can choose from floor-mounted or wall-mounted options.

Popular among other manufacturers are:

- Vaillant. A German company offering wall-mounted and floor-mounted models, turbocharged and naturally aspirated. The power of the devices ranges from 4-280 kW. The equipment is high-tech. The advantage of the unit is self-diagnosis. Efficiency – from 92%. The boilers have an ergonomic design. Servicing of these devices is expensive.

- Baxi. The Italian company offers devices protected from pressure drops, coolant freezing, and 3-way valve failure. The equipment is adjusted in manual and automatic modes. Operation and installation are simple, automation responds to weather changes.

Gas double-circuit boilers are the best devices for heating houses or apartments of any size, with an additional function of heating water. Proper installation and compliance with operating rules will increase their service life.

Conclusion

Those who value convenience and efficiency should pay attention to dual-circuit models. But if the priority is the reliability of the equipment, ease of maintenance/repair and operation, the best solution for a private building is a combination of a boiler with one circuit and an “indirect” boiler.

In any case, it is advisable to consult a professional regarding the choice of equipment. This ensures that the money is spent wisely.

The online store alfatep.ru offers heating boilers of all types from well-known manufacturers. The company’s specialists will help you decide which model – single- or double-circuit – is better suited for a particular building, taking into account its specifics and operating conditions of the equipment. By calling the hotline 8 (495) 109-00-95 or through the “Feedback” option on the website, the buyer will receive comprehensive answers to questions that interest him. We offer residents of the Moscow region services for the design and installation of heating systems according to any scheme; turnkey delivery with guarantee and further technical support of products.

Design features, fundamental differences

A single-circuit boiler is used for heating premises by heating the coolant using 1 heat exchanger built into the boiler. Gas boilers, the design of which involves two heat exchangers, i.e. separately heating the coolant water for heating and hot water supply - called double-circuit.

Photo from ktl.by

Devices are classified:

- by location - floor and wall;

- in terms of energy efficiency: conventional, using a low calorific value and condensing, designed to consume a higher calorific value of fuel with the additional use of thermal energy released with condensate from water evaporation;

- according to the design of the gas burner - with an open and closed combustion chamber.

We also recommend reading: floor-standing or wall-mounted gas boiler, which is better and Top 10 best floor-standing gas boilers

When operating a gas boiler room, it is necessary to remember that gas is not only a benefit, but also a source of increased danger. Therefore, independent installation of equipment can lead to gas leaks and irreparable consequences.

To put it into operation, you must obtain a package of permits and consult with a specialist. It’s even better to entrust heating installation to professionals. You should not save on the health of your loved ones.