Localizing the problem of boiler malfunction

With the development of modern low-rise construction and gas networks, the boiler has become a common household appliance in every house or apartment. Basically, after installation, the boiler does not cause users any trouble. Modern boilers operate completely autonomously and require only regular maintenance or inspection. In our opinion, the average operating time of units before the first breakdown is from 4 to 6 years. Some users encounter problems even after 9 years, and some, on the contrary, earlier. In this material I will tell you what can be done if the boiler simply does not turn on, and I will also consider the most common malfunctions of gas boilers. The concept of “does not turn on” can mean completely different problems:

- There is no indication (the display is not lit)

- The boiler does not light up

- The boiler does not operate in any particular mode

Therefore, these different situations should be considered separately in detail. Please note that to eliminate some malfunctions, user intervention is sufficient, but in some cases it is necessary to call a qualified specialist.

This is important to remember

Gas devices are classified as high-risk equipment. Therefore, the main thing to do in case of a problem is:

- turn off the boiler;

- check if there is gas contamination in the room;

- ventilate the room.

Only after this can you figure out what to do if the gas boiler does not light.

After this, the main thing is to check the traction, and then study the error code on the display. This will help you understand whether you are able to fix the problem yourself or whether you will have to call a technician.

So, if the boiler does not ignite or if its flame is very weak and goes out after a while, then this may mainly be due to mechanical reasons (clogging). And such malfunctions can be eliminated yourself.

If the reason is different (or it cannot be determined reliably), it is preferable to contact a gas equipment servicing company to call a technician.

Over the years of uninterrupted operation of gas heating equipment, you have probably become accustomed to warmth and comfort. But suddenly the boiler stopped turning on, the burner did not light, and meanwhile the room quickly cooled down. We have to look for the reasons for the failure in order to restore the operation of the equipment. Our recommendations will help you find the problem and fix it on your own.

Why doesn't the boiler start?

Often problems are shown as an error code on the display. All modern models Vaillant (“Valiant”), Baxi (“Baxi”), Ferroli (“Ferroli”) are equipped with a self-diagnosis system. Each brand has its own codes and their meanings. If the display does not show symbols, then you need to look for the cause of the problem yourself.

Problems with wall and floor units can be caused by external and internal factors.

External ones include:

- Insufficient gas pressure in the main;

- Chimney problems;

- Power surges in the network;

- Draft, low temperature in the room/boiler room.

Internal factors include breakdowns of electronics - sensors, wiring, as well as individual components - pump, heat exchanger.

How to fix the ignition yourself

Self-repair of household appliances or their components is a rather risky undertaking, since the likelihood of aggravating the problem is quite high. It is very difficult to repair the electric ignition of a gas boiler without special knowledge and skills. The device may fail due to contact with water or grease, power surges, or neglect. The main sign of a device malfunction is the absence of a spark. If there is a spark, but the flame cannot be ignited, it is necessary to clean the contact areas of the burner and candle. If the electric ignition unit is broken, you should check the current-carrying paths and winding resistance. When repairing the ignition, new components may be needed.

How to deal with problems

If the boiler goes out and does not light up again, check the quality of ventilation in the room. This is a common cause of problems for atmospheric models “Proterm”, “Navien”, “Ariston”, “Bosch” with an open combustion chamber, because they take combustion air from the room.

- Organize high-quality ventilation in the room;

- Install ventilation valves on sealed window packages;

- Open the window in the boiler room for air flow.

Check the presence of draft in the boiler chamber. To do this, light a match and bring it to the control window or chimney outlet. If there is draft, the flame will deviate to the side. If not present, it will burn evenly. In the latter case, a chimney inspection is required.

This is excess, deficiency or backdraft. All this leads to the fading of the wick and automatic shutdown of the equipment.

Backdraft or blowing out occurs due to weather conditions: strong winds, pressure changes lead to the burner extinguishing. During installation, take into account the requirements for the height of the chimney:

- The height of the pipe on a flat roof is at least 50 cm;

- With a distance from the roof ridge of 1.5 meters - from 50 cm above the ridge;

- At a distance of 1.5–3 meters - level with the ridge.

Compliance with these parameters will help to avoid blowing and backdraft.

Excess air flow occurs with a powerful kitchen hood or ventilation. The solution is to turn off the hood while the boiler is operating.

Lack or absence of traction provokes:

- Blockages. Occurs in stationary chimneys. Clear the mine of leaves, debris, and construction debris. Fixed and coaxial pipes can become covered with ice in winter. Along with combustion products, hot steam escapes into the street, condensation forms, which freezes on surfaces. Insulate the chimney.

- Damage, burnout of the pipe. Only replacing the chimney will help.

Does the dual-circuit device “AOGV”, “Beretta” or “Vailant” turn off and not turn on? This is possible when the fuel supply is unstable. For the same reason, the burner does not light the first time. First of all, check:

- Pipes and joints for gas leaks. To do this, lubricate them with soap foam. If bubbles appear, there is a leak. Then turn off the valves, open the window and call the gas workers.

- Counter. If there is a breakdown, the meter readings do not change; noise and crackling are heard. You can’t fix the problem yourself—you need a specialist.

If everything is fine, wait until the gas supply is restored.

Does your equipment not start after a long shutdown? It may be worth using antifreeze as a coolant. It does not freeze when the temperature drops and allows you to safely start the system after a long period of inactivity.

All boilers with a closed combustion chamber - such as Buderus, Wolf, Danko, Lemax - are equipped with fans. They forcibly discharge combustion products into the street. If you hear strong noises when the blades rotate or do not hear operating sounds at all, carry out diagnostics and replace the element if it breaks.

To find other problems, it will be useful to know the structure of the boiler you are going to repair. “Aton”, “Siberia”, “Buderus”, “Ferolli” or another brand may have their own characteristics. But the following sensors and components often break down:

- Circulation pump. If it fails, the boiler may make noise and the flame in the burner goes out. In such cases, the equipment will not work for heating and hot water supply. The only solution is to replace the pump.

- Igniter. Incorrect pressure adjustment results in flame failure. The protection is triggered and the operation stops. Set the correct fuel supply.

- Burner. The appliance has switched off and will not re-ignite. Check the burner nozzles for blockages. Clean them from soot and dust. Also clean the sensor photocell and try ignition again.

Diagnostics and replacement are also carried out in case of breakdown of the thermocouple, pressure and draft sensors.

Does the device not start after turning off? Check the remote control, replace the batteries. Examine the display. If it does not work, diagnose the controller.

Heating equipment that is additionally connected to the network suffers from power surges. If the values are lower or higher than the nominal value, the unit will not work. It is recommended to connect a voltage stabilizer.

It is important to understand that a boiler emergency stop can happen for a variety of reasons. It's good if a code appears on the display. For example, the display of the Proterm model may display error A6. This means that the temperature in the room has dropped and you need to connect an additional heater. So, thanks to symbolic codes, it is easier for the user to detect the problem. In other cases, you will have to check all boiler systems.

It is always easier to prevent a breakdown than to repair it. Therefore, monitor the operation of the boiler and carry out maintenance once a year.

To understand the reasons why a gas boiler does not light up or goes out, it is important to understand the principle of operation of the system. An analysis of the most common practical situations - why the boiler does not turn on or light up, and recommendations for repairs - is presented in the material.

Methods for troubleshooting geysers

Geyser "Vector" is one of the most popular in Russia. This is evidenced by sales statistics.

When the piezoelectric element does not work in the Vector gas water heater, a spark does not appear and the burner does not ignite. The reasons for the problems are:

- Lack of draft in the chimney. It could simply be clogged and need to be cleaned. There is a special sensor in the column that monitors the presence of traction. If it is not there, it will not start working. If you cannot do this yourself, it is better to call a special service.

- No water pressure. If the water pressure is very good, then it affects the membrane, which presses on the valve. Very low pressure may indicate problems with the membrane or that the filter is clogged.

Solution: You need to disassemble the filter and wash it under water, and it is best to replace the membrane as it becomes damaged over time. You can do this yourself.

- The nutrient element is not working. Ignition is done using batteries, without which there will be no current to create a spark. You need to remove the panel, then take out the battery pack, pull them out and insert new ones.

How to light a flame on a gas boiler

When you purchase and install gas equipment, the first question that arises is how to light a gas boiler. The first start-up of a gas boiler is carried out by a specialist, from whom you can get recommendations on the use of the equipment. During subsequent starts, you can also set the required temperature using the coolant heating level control knob.

Read more about the procedure for starting gas equipment in the material: Starting gas into a private house. Primary requirements

At the same time, the circulation pump is connected. Excessive noise indicates stagnant air in the pump. To release it, you need to remove the boiler cover, then unscrew the pump cover. When water appears from under the lid, screw it back on. As soon as the pump starts, automatic ignition occurs and the boiler operates normally.

The feed tap is of great importance for the operation of double-circuit boilers. Due to it, pressure is maintained so that the equipment operates without interruption.

The principle of operation of a gas burner

It consists of the following: air and fuel are mixed, and the combustion products must go through the entire combustion process.

We can conditionally distinguish three tasks in the operation of this element of the system:

- preparing air and fuel for combustion by determining temperature, speed and direction;

- mixing these elements;

- combustion, that is, oxidation of combustible elements with the help of oxygen, combustion due to the nozzle at the end point of the tube.

The reasons that the burner does not light up must be sought in the principle of its operation.

The burner itself is essentially a metal tube that is hollow inside and has several holes called nozzles. The gas burns in it, heading towards the combustion chamber. The mixture of combustion products is discharged outside. And if the air is collected by natural injection, then the gas is distributed and directed inside thanks to the system of indicated holes.

If the gas boiler does not ignite, it means that the combustion conditions are not met: there is no gas, no air is supplied, and combustion products do not come out. Understanding the cause of problems allows you to eliminate them in a timely manner and restore system operation. When lighting a gas boiler, be careful. This equipment requires special care.

Fan faults

Boilers that have a closed chamber are equipped with a fan. It is needed so that combustion products do not return back, but go outside into the street. If the fan is too noisy or, conversely, it is silent, check and change the fan if necessary. A fan failure can also result in the gas boiler not heating hot water.

How to start a gas boiler: step-by-step instructions

If the heating system has been idle for a long time, before performing any actions, check its integrity, all threaded connections, taps and valves, and the expansion tank.

If water is used as a coolant, the heating system must be filled at above-zero temperatures to avoid traffic jams. It is also worth remembering that it is not recommended to drain it more often than once a year; untreated and hard water forms scale and settles inside the system, narrowing the cross-section of the circuit. It is better to use boiled or purified and softened water, or buy distillate.

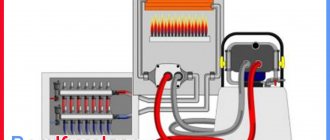

In an open heating system, it is enough to fill the coolant through the expansion tank until it is filled to the proper level. In a closed heating system with a floor-standing boiler, the coolant is poured through a specially designated drain and fill valve. In modern wall-mounted boilers, the fill and make-up tap, as a rule, is already installed from the factory and is located below, between the supply and return (most often it is blue). The exact location is always indicated on the diagrams in the model passport.

Location of the feed tap in wall-mounted gas boilers.

When filling from the water supply, keep in mind that the pressure there is high, from 3-4 bar, so the make-up tap must be opened gradually and not completely. You need to stop filling the water when the pressure on the pressure gauge reaches the operating range, higher to the upper limit. Typically the operating range is 1.3-2 bar, it differs depending on the model, so the exact values are always indicated in the operating instructions.

Air locks lead to uneven heating of radiators; they can form in both new and old heating systems. Modern wall-mounted models are already equipped with an automatic air vent, which is located inside: in the upper part above the heat exchanger or at the circulation pump. For floor-standing models, the air vent is installed as part of the safety group.

In any of the cases, everything happens automatically; the end of air bleeding is indicated by a decrease in pressure in the system (if it drops below the operating level, add coolant).

If automatic air vents are not provided either in the boiler configuration or in the piping, the air is bleed from the radiators using the Mayevsky valve. To do this, you need to prepare a small container, since a small amount of coolant will escape with the air.

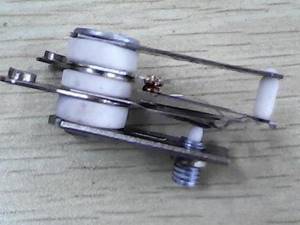

This is what Mayevsky's crane looks like.

- Place a container under the radiator, use the special wrench from the installation kit (or any other suitable tool) to slightly unscrew the tap until air begins to come out with a characteristic hiss.

- Next, the air will begin to escape with the “spitting” of the coolant.

- We wait until only a trickle of coolant flows, without air impurities, and close the tap tightly. Depending on the presence of air in the system, the process takes 2-5 minutes. It is recommended to repeat with each radiator.

In properly designed heating systems with natural ventilation, air is released under the influence of the laws of physics: it itself exits through an open expansion tank.

Pressure testing is an optional step, which, first of all, must be carried out for safety reasons: if depressurization of the heating system occurs during the heating season, there will be much more hassle and discomfort. It is carried out using a pressure test pump, the pressure is set to x1.25 of the working pressure, the duration is 8-10 minutes. If a decrease in pressure is noticed during the run, there is a leak.

Flushing is carried out every 4-7 years to remove deposits on the walls of the pipeline, radiators and heat exchanger.

To clean the entire system, hydrodynamic flushing is used at once - running a chemical composition with abrasive particles under high pressure, carried out using a booster. The run pressure should be as high as possible, but not exceed the permissible limit of the most vulnerable element (usually a steel heat exchanger with a limit of 1.5-2 bar). The cost of the equipment is about 35-45 thousand rubles, so everyone usually calls a team of specialists every 5 years.

Piezo ignition works on the principle of ignition by a spark (as in lighters); it is used not only on old-style non-volatile models, but also on modern boiler units. Before starting, make sure the gas valve is open. To start a gas boiler:

Designation of boiler control elements using the example of common Danko models. The controls for non-volatile models from other manufacturers are practically the same.

- Turn the mechanical thermostat counterclockwise until it stops.

- Press and hold the start button (usually inside the thermostat), then press and release the piezo ignition button to light the igniter (wick) of the gas boiler. It may take several presses of the piezo ignition button to ignite the wick. We hold the start button all this time and then for 30 seconds, until the burner goes out when it is released.

- Turn the mechanical thermostat to the desired temperature. If the gas boiler is started in a cold private house in high frosts, the temperature must be increased gradually, over 5-10 minutes, to warm up the chimney and prevent backdraft. When igniting after a short break or in warm weather, this is not necessary; you can immediately set a comfortable temperature level.

The location of elements and time intervals and the process itself may vary slightly depending on the model, configuration and version of the automation. The exact algorithm is always indicated in the operating instructions. If it is lost, try to find an electronic version; today there are electronic copies even for quite old models.

Volatile boilers require connection to the electrical network, are equipped with auto-ignition and multifunctional automation, so starting them is much simpler and comes down to pressing a couple of buttons. Accordingly, their location and order may differ slightly. Let us explain using the example of the most common wall-mounted double-circuit BAXI Eco Four 24f. To turn on the gas boiler:

- Connect the boiler to the mains and make sure the gas valve is open.

- Press the Start/Stop button ( ) to turn on the boiler and select one of the modes, they are in the sequence Summer>Winter>Heating Only>Off. Accordingly, to work only on heating, you need to press the button 3 times. Summer mode means working only to heat hot water.

- Use the “+” and “-” buttons to set the desired heating and hot water temperature values. All the rest of the work is done by automation and auto-ignition.

Once again we would like to remind you that the described instructions are intended for the next start before the heating season or after a short-term shutdown/fading. The first start-up of a new gas boiler must be carried out by a certified specialist who will put the appropriate stamp in the model passport. Without a stamp, the warranty on the boiler will not apply.

Possible startup problems

The gas boiler slams when the main burner starts

The most common problem, the cause of which is most often clogging of the igniter (dust, combustion products, etc.). It is recommended to call a specialist to clean it.

The reason may also be that the pilot flame is too low: below the main burner. When using electrode ignition, the electrode may be clogged or faulty. In rare cases, the cause may be excess gas pressure in the line. It is important to understand that slight, barely audible pops are characteristic of most models of gas boilers that do not have a sound insulation layer.

Only the wick burns and cannot light the main burner.

The reason may be the same clogging of the igniter or its incorrect installation, when the flame simply does not reach the main burner. Clean the pilot nozzle (it is advisable to entrust this to a specialist) and check the operation: its flame should reach the main burner and simultaneously “wash” the thermocouple. Sometimes the reason lies in a malfunction of the thermocouple, which does not open the gas supply.

What devices use bimetal?

The scope of application of the bimetallic strip is extremely wide. Almost all devices where temperature control is necessary are equipped with bimetal-based thermostats. This is explained by the design simplicity and reliability of such relay systems. In our usual technology, thermostats are:

- In household heating appliances: stoves, ironing systems, boilers, electric kettles, etc.

- Heating systems: electric convectors, gas and solid fuel boilers with electronics.

- In electric packages there is automatic shutdown.

- In electronics in measuring instruments, as well as in pulse generators and time relays.

- In thermal engines.

In industrial technology, bimetallic plates are installed in thermal relays designed to protect powerful electrical devices from temperature overloads: transformers, electric motors, pumps, etc.

Why the gas boiler does not turn on, what to do

Over the years of uninterrupted operation of gas heating equipment, you have probably become accustomed to warmth and comfort. But suddenly the boiler stopped turning on, the burner did not light, and meanwhile the room quickly cooled down. We have to look for the reasons for the failure in order to restore the operation of the equipment. Our recommendations will help you find the problem and fix it on your own.

Often problems are shown as an error code on the display. All modern models Vaillant (“Valiant”), Baxi (“Baxi”), Ferroli (“Ferroli”) are equipped with a self-diagnosis system. Each brand has its own codes and their meanings. If the display does not show symbols, then you need to look for the cause of the problem yourself.

Problems with wall and floor units can be caused by external and internal factors.

External ones include:

- Insufficient gas pressure in the main;

- Chimney problems;

- Power surges in the network;

- Draft, low temperature in the room/boiler room.

Internal factors include breakdowns of electronics - sensors, wiring, as well as individual components - pump, heat exchanger

If the boiler goes out and does not light up again, check the quality of ventilation in the room. This is a common cause of problems for atmospheric models “Proterm”, “Navien”, “Ariston”, “Bosch” with an open combustion chamber, because they take combustion air from the room.

What to do:

- Organize high-quality ventilation in the room;

- Install ventilation valves on sealed window packages;

- Open the window in the boiler room for air flow.

Check the presence of draft in the boiler chamber. To do this, light a match and bring it to the control window or chimney outlet. If there is draft, the flame will deviate to the side. If not present, it will burn evenly. In the latter case, a chimney inspection is required.

This is excess, deficiency or backdraft. All this leads to the fading of the wick and automatic shutdown of the equipment.

Backdraft or blowing out occurs due to weather conditions: strong winds, pressure changes lead to the burner extinguishing. During installation, take into account the requirements for the height of the chimney:

- The height of the pipe on a flat roof is at least 50 cm;

- With a distance from the roof ridge of 1.5 meters - from 50 cm above the ridge;

- At a distance of 1.5–3 meters - level with the skate. Compliance with these parameters will help to avoid blowing and backdraft.

Excess air flow occurs with a powerful kitchen hood or ventilation. The solution is to turn off the hood while the boiler is operating.

Lack or absence of traction provokes:

- Blockages. Occurs in stationary chimneys. Clear the mine of leaves, debris, and construction debris. Fixed and coaxial pipes can become covered with ice in winter. Along with combustion products, hot steam escapes into the street, condensation forms, which freezes on surfaces. Insulate the chimney.

- Damage, burnout of the pipe. Only replacing the chimney will help.

Does the dual-circuit device “AOGV”, “Beretta” or “Vailant” turn off and not turn on? This is possible when the fuel supply is unstable. For the same reason, the burner does not light the first time. First of all, check:

- Pipes and joints for gas leaks. To do this, lubricate them with soap foam. If bubbles appear, there is a leak. Then turn off the valves, open the window and call the gas workers.

- Counter. If there is a breakdown, the meter readings do not change; noise and crackling are heard. You can’t fix the problem yourself—you need a specialist.

If everything is fine, wait until the gas supply is restored.

Does your equipment not start after a long shutdown? It may be worth using antifreeze as a coolant. It does not freeze when the temperature drops and allows you to safely start the system after a long period of inactivity.

All boilers with a closed combustion chamber - such as Buderus, Wolf, Danko, Lemax - are equipped with fans. They forcibly discharge combustion products into the street. If you hear strong noises when the blades rotate or do not hear operating sounds at all, carry out diagnostics and replace the element if it breaks.

To find other problems, it will be useful to know the structure of the boiler you are going to repair. Aton, Siberia, Buderus, Ferolli or another brand may have their own characteristics. But the following sensors and components often break down:

- Circulation pump. If it fails, the boiler may make noise and the flame in the burner goes out. In such cases, the equipment will not work for heating and hot water supply. The only solution is to replace the pump.

- Igniter. Incorrect pressure adjustment results in flame failure. The protection is triggered and the operation stops. Set the correct fuel supply.

- Burner. The appliance has switched off and will not re-ignite. Check the burner nozzles for blockages. Clean them from soot and dust. Also clean the sensor photocell and try ignition again.

Diagnostics and replacement are also carried out in case of breakdown of the thermocouple, pressure and draft sensors.

Does the device not start after turning off? Check the remote control, replace the batteries. Examine the display. If it does not work, diagnose the controller.

Heating equipment that is additionally connected to the network suffers from power surges. If the values are lower or higher than the nominal value, the unit will not work. It is recommended to connect a voltage stabilizer.

It is important to understand that a boiler emergency stop can happen for a variety of reasons. It's good if a code appears on the display. For example, the display of the Proterm model may display error A6. This means that the temperature in the room has dropped and you need to connect an additional heater. So, thanks to symbolic codes, it is easier for the user to detect the problem. In other cases, you will have to check all boiler systems.

The boiler blows out in a strong wind, what to do in this case

Mechanical heating boilers can go out due to being blown by strong winds. Any atmospheric phenomena - rain, high humidity, low atmospheric pressure, wind can affect draft, causing its excess or deficiency, and also cause reverse draft. Result: the boiler went out. What to do in this case?

The solution to the problem is as follows:

- You can install a special mushroom-umbrella on the edge of the pipe, which will protect the chimney from unwanted influences;

- Or you can increase the pipe itself if its length is not enough.

By the way, this is not the only problem that can arise with the chimney. In addition to blowing smoke, ice may form on the pipe. The reason for this phenomenon is condensation.

The fact is that moisture tends to accumulate and freeze over time, and then become so thick that it simply blocks the access to oxygen and the flame goes out and the boiler turns off.

However, it happens that it is very difficult to knock off ice build-ups and then you have to defrost them. You can purchase a disposable burner with a small can. To melt the ice, you need to light the burner and insert it into the cleaning hatch. When the pipe warms up, the boiler can be put into operation.

Typical causes of heating boiler breakdowns

The main reason is the destruction of electro-automatic devices, including the “safety unit” and the control unit. Flame, draft and temperature are controlled by bimetallic sensors. If the integrity of the protective fuses or the rules of use are violated, the servomotor will block gas access to the boiler and an error will appear on the information panel. To resume operation, use a multimeter to detect a break in the circuit or a burnt-out temperature sensor.

Low pressure in the expansion tank is the second reason. For correct operation, a pressure of 0.8-1 bar is required. At 0.7 bar the condensing boiler will not turn on. To increase it, remove the water from the boiler and pump up the air with a bicycle pump. The flexible hose connects to a built-in nipple, the pressure is controlled by a mechanical pressure gauge.

The electronic board of the boiler is faulty. An incorrectly selected voltage stabilizer, lack of grounding in the socket and lack of power supply protection unit increase the risk of board burnout. It is impossible to repair the electronics yourself; dismantling and diagnostics by a master electronics engineer will be required. A burnt-out circuit is difficult to restore after moisture has entered; you should order and install a new circuit board according to the model of the electric boiler.

The spark clicks and the burner does not start - the ignition electrode or the boiler ionization sensor is faulty. If the electro-automatic ignition constantly clicks, and upon completion of the start-up the red LED flashes (go into emergency mode), you should inspect the spark plug and high-voltage wires for cracks. If the insulation is broken and the spark strikes away from the main burner, the ceramic spark plug must be replaced.

Insufficient water pressure is reason number five. If the pressure in the heating system drops below 0.5 bar, the boiler will turn off. To resume operation, the system must be recharged with water. Open the feed tap until the pressure stabilizes. For control, a pressure gauge is installed on the front panel. If the fall continues, invite our technician to your home to check the tightness of the pipe welds and threaded connections of the batteries.

DHW or hot water supply does not turn on - the three-way valve of the boiler is faulty. The electric valve is dismantled, disassembled and washed from rust. Then they check the power button, visually it sticks in one position. After assembly, apply voltage to the motor to check the rod. If after repair the boiler does not start, the 3-way valve must be replaced.

Lack of annual preventive surveillance is the seventh reason. We offer qualified cleaning assistance from experienced craftsmen. Write in the chat window or submit a request by phone. An engineer will remotely diagnose a defective device and advise the owner on the cost of services. We will draw up a defective work report and provide a guarantee for equipment repairs for up to 1 year.

Why does a gas boiler go out? Causes and solutions

Today, gas boilers are used everywhere, especially in winter. They act as the main part of an autonomous heating system. It happens that the boiler refuses to work correctly, for example, the flame may go out. When a consumer has a question about why a gas boiler goes out, it is necessary to analyze whether the device is working differently. Therefore, wind noise may be heard. It is important to pay attention to the display, which may show an emergency sign. In this situation, diagnostics should be performed to identify the causes that led to the problem. Otherwise, the temperature in the home may drop significantly, as a result, the system will defrost, which will then become unusable.