With the onset of cold weather, most motorists face the same problem. A car that has been standing all night in the cold either starts in the morning with great difficulty or does not even show “signs of life” at all. The problem is that at low temperatures the mechanisms begin to work with great difficulty (the lubricant has not yet warmed up, so it is thick), and the charge of the main power source drops significantly.

Let's look at how to save battery energy so that it lasts the next morning, and you don't have to remove the battery often to recharge. We will also discuss several options for insulating batteries.

Why do you need battery insulation?

Before considering common ways to protect a battery from hypothermia, let’s pay a little attention to the question of why this element may need insulation. A little theory.

Everyone knows that a battery produces energy through chemical processes occurring in it. The optimal temperature for this is between 10 and 25 degrees Celsius (above zero). The error may be about 15 degrees. Within these limits, the power supply copes well with loads from consumers, restores charge faster, and also requires less time to recharge.

The chemical process slows down as soon as the thermometer drops below zero. At this moment, with each degree the battery capacity decreases by one percent. Naturally, charge/discharge cycles change their time intervals. In cold weather, the battery discharges faster, but it takes longer to gain capacity. In this case, the generator will work longer in intensive mode.

In addition, in winter, a cold engine requires more energy to start. The oil in it becomes viscous, which makes it difficult to turn the crankshaft. When the car starts, the engine compartment gradually begins to heat up. In order for the temperature of the electrolyte in the banks to increase, a long trip is needed. However, even if the car has warmed up well, due to the accelerated heat exchange of metal parts, the engine compartment begins to quickly cool down as soon as the car stops and the engine is turned off.

We will also briefly touch on exceeding the maximum temperature limit. These conditions also negatively affect the generation of electricity, or more precisely, the condition of each lead plate. As for the serviced modifications (more information about the types of batteries is described here ), water evaporates more intensively from the electrolyte. When the lead material is above the acidic level, the sulfation process is activated. The plates are destroyed, which not only affects the capacity of the device, but also its working life.

Let's return to winter operation of batteries. To prevent the old battery from overcooling, some motorists remove it and bring it into the house for overnight storage. This way they ensure a consistently positive temperature of the electrolyte. However, this method has several disadvantages:

- If a car is parked in an unguarded parking lot, then without a power source there is a high probability that the vehicle will be stolen. Alarms, immobilizers and other anti-theft electrical systems most often run on battery power. If there is no battery, then the vehicle becomes more accessible to the thief.

- This method can be used on older cars. Modern models are equipped with on-board systems that require constant electricity to save settings.

- Not every vehicle has a battery that can be easily removed. How to do this correctly is described in a separate review .

So, winter requires more attention to the condition of the battery. To preserve heat, and with it the properties of the power source, many motorists use insulation of either the entire engine compartment or the battery separately. Let's consider several options for how to insulate the battery so that it continues to produce high-quality electricity even in cold weather when the car is parked.

DIY car heater for 12 volts in the car interior

Anyone who has driven a budget car knows how long it takes to wait for heat from the engine when it warms up in winter, especially if you live in the northern part of the country. Attempts to warm up in a car in a minute last for half an hour, and this happens every morning. It is useless to try to warm up a cold steering wheel and a frozen seat with your body heat.

In extreme conditions, ideas for a quick solution to the problem come to mind. The best idea was this: heat the car interior with a quickly assembled fan heater. An old toaster and a broken computer power supply helped us practically realize our plans. Although you can also take the necessary parts from a broken hair dryer. But you definitely need an iron box with a fan.

From this point on, many of the readers will ask themselves: “Why do I need to assemble a heater in my car if I can just buy it at a car dealership?” Also, regarding a homemade heating device, you can say: “This thing is a fire hazard, especially in a car.” If the mentioned comments are serious reasons for you, then you may not read any further.

Store-bought car heaters, which can be bought at car dealerships, are only suitable for blowing off fogged windows. A homemade heater can be assembled with as many watts as your car battery can handle.

Now that all the cowards are gone, we can start putting together our homemade product. But first, let's put on the table all the things and materials that we need.

- Suitable heating elements from a toaster or hair dryer.

- A metal box with a fan and a built-in switch from the computer power supply.

- Two radiators with splayed heat sinks, from the computer power supply.

- Electromechanical relay 12 V, 30 A.

- 30 Amp fuse in housing.

- Steel springs.

- Wires with a cross section of 1.5 mm2.

- Two plastic bushings.

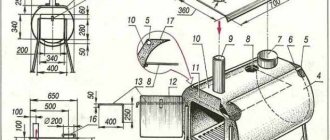

We will start with assembling the heating element, since this is the most important and powerful part of our homemade product.

To begin, you need to screw one radiator directly to the cover of the computer's power supply, closer to the place where the fan is located. Fix the second heat exchanger on the opposite side of the cover, but make sure that it is insulated from the metal, so fix it on insulating plastic bushings.

To finally assemble the heating element, all that remains is to do the following:

- wrap one end of the straightened nichrome wire around the protruding pins of the radiator, which is electrically connected to the cover of the computer power supply;

- screw the other ends of the nichrome wire onto the spring rings, and the opposite rings of these springs must be hooked onto the pins of the insulated radiator.

After reviewing the attached diagram, you will most likely have questions.

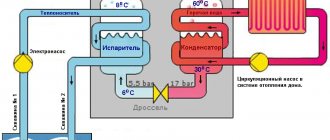

The first of them will be: “Is it necessary to install an electromechanical relay?” Of course not necessary! But then you need to find not even a switch, but a real 30 A switch. But for most modern people, it is still more convenient to turn on any electrical appliances with a small switch. For this we use a small standard keyboard player installed in the computer power supply.

A few words about connecting the fan. It was noticed that when the cooler in the computer power supply runs on 12 V, its speed is not enough to fully circulate air through the homemade heater. And as a result, the insides of the heater overheat. Although, of course, many additional holes were made in the opposite wall of the power supply housing.

Connected to a 24 V voltage, the fan in the computer power supply does not burn out at all, but simply rotates much faster. Therefore, it is advisable to power the fan of a homemade car heater from a voltage twice as high as 12 V.

Where can I get 24 V voltage in a car? And this is not a problem if you are a real craftsman and can solder and also read electrical circuits. A reliable source of overvoltage will be a DC-DC converter from 12 V to 24 V.

How can you insulate a battery?

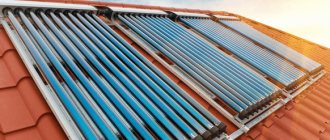

One option is to use ready-made insulation. The car accessories market offers many different products: thermal cases and car blankets of various sizes and modifications.

The second solution is to make an analogue yourself. In this case, you need to select the appropriate fabric so that it does not deteriorate due to accidental contact with technical fluids (not every motor is perfectly clean).

Let's first consider the features of the finished product.

Thermal cases

A battery thermal case is a battery case made of a material that prevents the device from quickly cooling. The product has a rectangular shape (its size is slightly larger than the dimensions of the battery itself). There is a lid on top.

To make these covers, thermal insulating material is used, which is covered with a special fabric. The thermal layer can be made of any insulation (for example, polyethylene with foil as a thermal shield). The casing material is resistant to aggressive acid and oily liquids, so it does not collapse when water evaporates from the electrolyte or when antifreeze accidentally gets on the surface.

To prevent wet weather from affecting the operation of the battery, the fabric has moisture-proof properties. This protects against the accelerated formation of oxidation at the terminals of the device. The cost of such cases will depend on the dimensions of the battery, as well as on what insulation and upholstery material the manufacturer uses. A high-quality insulation case can be purchased for approximately 900 rubles.

Heated thermal cases

A more expensive option is a thermal case in which a heating element is installed. It is made in the form of a plate located around the perimeter, as well as in the lower part of the case. In this form, heating of a larger area of the body is ensured compared to heating elements. Also, the heating element heats up only one part of the contact area more strongly, which increases the likelihood of a fire.

Most of these heaters have controllers that record the battery charge level, as well as its heating. The cost of such devices will start from 2 thousand rubles. It is worth considering that most heating elements will only work when the motor is on. Otherwise, when the car is parked for a long time, the heaters can discharge the battery.

Using a car blanket

Another opportunity to insulate the battery is to purchase or make your own car blanket. This is thermal insulation of the entire engine compartment. It is simply placed on top of the engine before leaving the car overnight.

Of course, in this case, cooling will occur faster compared to the methods mentioned above, because only the upper part of the space is covered, and the surrounding air is cooled by ventilation from under the machine.

True, this method has several advantages:

- The liquid in the cooling system retains its heat, which, with a slight minus in the ambient air, will speed up the engine warming up the next morning;

- When the engine is covered along with the power source, the heat from the unit is retained under the hood, due to which the battery heats up and begins to work like in the summer;

- Of course, the cooling rate of the engine compartment depends on the temperature range at night.

Using a thermal blanket in a car is significantly inferior to thermal cases (especially heated versions). In addition, during daytime use this additional element will constantly interfere. You can’t put it in the interior, because it may have stains of oil, antifreeze and other technical fluids for cars. If cargo is transported in a passenger car, then an oversized blanket in the trunk will also take up a lot of space.

Making a thermal case

The most budget-friendly option for preserving heat for a battery is to make a thermal case with your own hands. Absolutely any heat insulator (foamed polyethylene) will be useful for this. The ideal option for such a product would be one with foil. It may have a different name depending on the manufacturer.

There is nothing complicated in the procedure for making a cover. The main thing is that each wall of the battery is covered with material. It should be taken into account that foil is capable of reflecting a certain amount of heat, but the material must be placed inside as a screen, and not as a heat-insulating material.

Another factor that will affect heat retention is the thickness of the cover. The larger it is, the less losses there will be during battery storage. Although a wall thickness of one centimeter is enough to prevent the battery temperature from falling below -15°C for about 12 hours, provided the ambient temperature is 40 degrees.

Since foamed polyethylene and foil can deteriorate when in contact with technical liquids, the material can be sheathed with a special fabric. A cheaper option is to wrap the inside and outside of the insulation with tape.

It is best if a homemade thermal case completely covers the battery. This minimizes heat loss while the car is parked.

Why do we need thermal cases for batteries?

If the winter frosts are severe and the car is left in the cold for more than 8 hours, this can greatly reduce the battery capacity. To protect and insulate it, special devices are used - thermal bags and covers. They are inexpensive - you can find them from 500 rubles.

They protect against the negative effects of low temperatures and do not allow the battery to quickly discharge. As a result, it remains operational. Even after a very frosty night, the car owner starts the engine without any hassle.

By avoiding frequent discharge of the battery, this extends its service life. Battery heaters can simplify the winter operation of a car in harsh winters. Their use in mild climates is not necessary.

Does it always make sense to insulate a battery in winter?

Insulating the battery makes sense if the car is used in regions with cold winters. If the car is driven every day in an area with a temperate climate, and the air temperature does not drop below -15 ° C, then only protection against the entry of cold air through the radiator grille may be sufficient.

If a car sits in the cold for a long time in winter, then no matter how insulated the power source is, it will still cool down. The only way for the electrolyte to heat up is from an external source (motor or heating elements of the thermal cover). When the vehicle is idle, these heat sources do not provide heating to the battery walls.

In winter, it is better to use a fully charged power source. In this case, even if it loses half its capacity, starting the motor is much easier than with a discharged analogue. When the car is driven, the alternator will be able to recharge the battery for the next start.

Some motorists purchase a battery with an increased capacity for the winter to make it easier to start the internal combustion engine. For the summer they change the power source to a standard one.

If you are planning a long trip during a cold period, then it is better to take care of insulating the battery, because cold air flows cool it during movement. When storing in a garage or being able to bring the battery into the house, this need disappears, since the device will function normally at room temperature.