0

3272

02.11.2015

Today everyone knows that hydrocarbon reserves on Earth have their limits. Every year it becomes more and more difficult to extract oil and gas from the subsoil. In addition, their burning causes irreparable damage to the ecology of our planet. Despite the fact that renewable energy production technologies are very effective today, states are in no hurry to abandon fuel combustion. At the same time, energy prices are rising every year, forcing ordinary citizens to shell out more and more.

In this regard, the production of alternative energy today is becoming not just an eccentricity of individual amateurs, but a completely utilitarian activity and even necessary in some cases. Hundreds of thousands of owners of country houses, not only in the world, but in our country, today are happy to use “green” technologies for generating electricity. How to produce alternative energy with your own hands: an overview of the best renewable sources of electricity can be seen below.

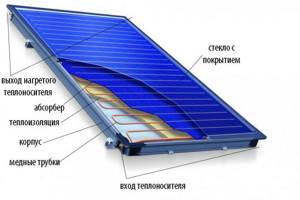

Solar collectors: subtleties of application

To understand the principle of operation of solar collectors, remember an outdoor shower - install a metal tank of water above the shower stall and position it in such a way that it is exposed to direct sunlight for the maximum amount of time. Use heated water for bathing.

Solar collectors are a modern variation of a summer shower. The devices are a system of pipes through which water circulates. To better heat the liquid, the pipes are painted black, because it attracts the sun's rays.

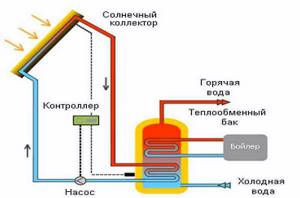

The operation of the system is based on the ability of water to circulate when heated. To do this, the heat exchanger tank must be installed above the collector pipes. When heated, the water rises to the top of the heat exchanger. The cold liquid sinks to the lower part, where it is heated by the sun's rays.

This principle of operation allows you to do without additional equipment, making the operation of the system more economical without loss of performance. And let us immediately note that you can design it yourself. But it is better to give preference to industrial equipment, which will work better, providing the house with hot water all year round. The price of the issue in this situation is higher, but it fully pays off during the operation of the system.

In practice, solar collectors are often used by sanatoriums, hotels, and recreation centers, which have an influx of visitors during the warm season. They are also found in private households, where the owners use a different method of heating and water heating in winter.

Solar power plant

Installation of solar panels will require:

- Storage devices, which are photocells.

- Battery – for accumulating charge.

- A controller that will allow you to monitor the battery.

- Device for converting 12 or 24 V current into 200 V.

- Structural and fixing elements.

Features of installation at home

Please note that the angle of inclination must change. In winter, the alternative solar storage device should be moved to a position with a large angle to the horizon. This is done to prevent snow from accumulating on the solar collector. Otherwise, this will lead to a sharp decrease in efficiency.

You should choose a section of the roof of the house that faces the south, east or southeast sides of the world.

Solar collectors for water heating

To obtain hot water and heating in a private house, an alternative collector powered by solar heat is used. Operating principle and design:

- Box Metal will last longer. Made from OSB, fiberboard, chipboard boards - a cheaper option, but its operation will be shorter. To increase the service life, the slab is impregnated with special septic tanks and varnishes.

- Mineral wool or polystyrene foam is placed at the bottom of the box - they serve as heat insulators and prevent heat loss.

- Pipes are laid in dense rows on the slab. The best material is copper - it has high thermal conductivity. Metal-plastic options are allowed, but their energy efficiency will be 20% less than copper ones.

- The inlet and outlet parts are equipped with fittings. They provide connection to the water supply communications of the house.

- The top of the box is covered with glass. You can also use acrylic material or monolithic polycarbonate. An important point is that the surface should not be smooth, but corrugated, for a better heating process. Solar glass has the ability to eliminate heat loss. It provides less energy loss.

Next, the entire alternative structure is connected to a water source that will circulate indoors.

Types of alternative electricity

The consumer is always faced with a choice based on the question, which is better? And in this regard, it is implied, firstly, the costs of purchasing a new type of source of electricity, and secondly, how long this device will work. That is, will it be profitable, will the whole undertaking pay off, and if it does, then after what period of time? Let's just say that no one has yet canceled saving money.

As you can see, there are plenty of questions and problems here too, because doing electricity yourself is not only a serious matter, but also quite expensive.

Electric generator

Let's start with this installation, as the simplest one. Its simplicity lies in the fact that you need to purchase an electric generator and install it in a secure, enclosed room that will comply with fire safety rules. Next, connect the electrical network of a private house to it, fill in liquid fuel (gasoline or diesel fuel) and turn it on. After which electricity appears in your home, which depends only on the availability of fuel in the generator tank. If you think through an automatic fuel supply system, then you get a small thermal power plant that will require minimal presence from you.

In addition, electric generators are reliable and convenient installations that work almost forever if used correctly. But there is one point. There are currently two types of generators on the market:

Which is better? Let's just say that if you need an alternative source of energy that will be used constantly, then choose diesel. If for temporary use, then gasoline. And that is not all. A diesel electric generator has large overall dimensions, compared to a gasoline one, it makes a lot of noise during operation and emits a huge amount of smoke and exhaust gases. Plus, it's more expensive.

Gas generators have recently appeared on the market that can run on both natural gas and liquefied gas. A good option, environmentally friendly, and does not require a special room for installation. You can connect, for example, several gas cylinders to one generator at once, which will be automatically connected to the installation.

Alternative to hydrocarbon fuels

Among the three types of electric generators, gas is the best and most efficient. But the cost of fuel (liquid or gaseous) is not cheap, so it’s worth thinking about producing your own fuel, investing a minimum of money in it. For example, biogas, which can be obtained from biomass.

By the way, alternative types of energy, which today are called biological, can replace almost all alternative sources of electricity. Eg:

- Biogas is produced by fermenting manure, bird droppings, agricultural waste, and so on. The main thing is to install equipment that is used to capture methane.

- From garbage, for example, in landfills, the so-called cellulose standard is extracted. Or, as experts call it, landfill gas.

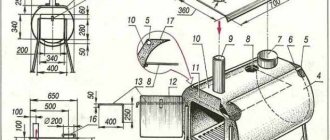

Attention! Scientists have already calculated that if you recycle all the world's landfills, you can get up to 84 billion liters of landfill fuel, which can be used to generate electricity. IBGU-1 - installation for biogas production

IBGU-1 - installation for biogas production

- Soybean and rapeseed, or more precisely, their seeds, produce fats from which biodiesel can be obtained.

- A biostandard (biogasoline) can be produced from beets, sugar cane, and corn.

- Scientists have proven that using ordinary algae you can accumulate solar energy.

That is, there is a large number of scientific developments that produce alternative types of energy. And many of them have already received practical application. For example, the IBGU-1 installation, with the help of which up to twelve cubic meters of biogas can be obtained from manure per day. Domestic farmers appreciated the work of scientists, so this equipment is sold out quickly.

Design and use of wind generators

Wind energy was used by our ancestors. Since those distant times, in principle, nothing has changed.

The only difference is that the millstones of the mill are replaced by a generator and a drive, which converts the mechanical energy of the blades into electrical energy.

Image gallery

Photo from

Step 1: Selection of parts for the manufacture of a wind generator

Step 2: Removing the motor and chuck from the unwanted drill

Step 3: Parts for the wind generator mounting assembly

Step 4: Install the assembled mounting unit

Step 5: Install the Bearing from the Inside of the Plate

Step 6: Assembling the wind generator and installing it on the siteAssembling the wind generator and installing it on the site

Step 7: Attaching the Wind Turbine Blades to the Plate

Step 8: Small homemade wind generatorSmall homemade wind generator

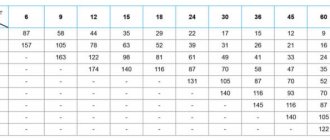

Installing a wind generator is considered economically profitable if the average annual wind speed exceeds 6 m/s.

Installation is best done on hills and plains; ideal places are considered to be the coasts of rivers and large bodies of water, away from various utilities.

Wind generators are used to convert the energy of air masses into electricity; they are most productive in coastal regions

Classification of wind generators

The classification of wind generators depends on the following basic parameters:

- Depending on the placement of the axis, there can be vertical and horizontal ones . The horizontal design provides the ability to auto-rotate the main part to search for wind. The main equipment of a vertical wind generator is located on the ground, so it is easier to maintain, while the efficiency of vertical blades is lower.

- Depending on the number of blades, one-, two-, three- and multi-bladed wind generators . Multi-bladed wind generators are used at low air flow speeds and are rarely used due to the need to install a gearbox.

- Depending on the material used to make the blades, the blades can be either sailed or rigid . Sail-type blades are easy to manufacture and install, but require frequent replacement, as they quickly fail under the influence of sharp gusts of wind.

- Depending on the pitch of the screw, a distinction is made between variable and fixed pitches . When using a variable pitch, it is possible to achieve a significant increase in the range of operating speeds of the wind generator, but this will lead to an inevitable complication of the design and an increase in its weight.

The power of all types of devices that convert wind energy into an electrical analogue depends on the area of the blades.

Wind generators practically do not require classical energy sources to operate. Using an installation with a capacity of about 1 MW will save 92,000 barrels of oil or 29,000 tons of coal over 20 years

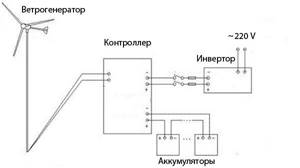

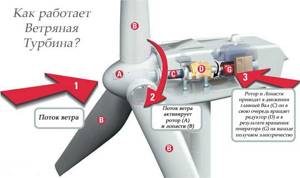

Wind generator device

Any wind turbine contains the following basic elements:

- Bladesrotating under the influence of wind and providing movement of the rotor;

- Generator , which produces alternating current;

- Blade control controller , responsible for the formation of alternating current into direct current, which is required to charge the batteries;

- Rechargeable batteries are needed to accumulate and equalize electrical energy;

- Inverter performs the reverse conversion of direct current into alternating current, from which all household appliances operate;

- A mast is necessary to lift the blades above the ground until the height of movement of air masses is reached.

In this case, the generator, blades that provide rotation and the mast are considered the main parts of the wind generator, and everything else is additional components that ensure reliable and autonomous operation of the system as a whole.

The circuit of any even the simplest wind generator must include an inverter, a charge controller and batteries

Low-speed wind generator from a self-generator

It is believed that this design is the simplest and most accessible for self-production. It can become either an independent source of energy or take over part of the power of the existing power supply system.

If you have a car generator and battery, all other parts can be made from scrap materials.

Step #1 - making a wind wheel

The blades are considered one of the most important parts of a wind generator, since their design determines the operation of the remaining components. A variety of materials can be used to make blades - fabric, plastic, metal and even wood.

We will make blades from sewer plastic pipes. The main advantages of this material are low cost, high moisture resistance, and ease of processing.

The work is performed in the following order:

- The length of the blade is calculated, and the diameter of the plastic pipe should be 1/5 of the required footage;

- Using a jigsaw, the pipe should be cut lengthwise into 4 parts;

- One part will become a template for the manufacture of all subsequent blades;

- After cutting the pipe, burrs on the edges must be treated with sandpaper;

- The cut blades must be fixed on a pre-prepared aluminum disk with the provided fastening;

- Also, after the modification, you need to attach a generator to this disk.

Please note that PVC pipe is not strong enough and will not be able to withstand strong gusts of wind. For the manufacture of blades, it is best to use a PVC pipe with a thickness of at least 4 cm.

The size of the blade plays an important role in the magnitude of the load. Therefore, it would not be amiss to consider the option of reducing the size of the blades by increasing their number.

The blades of the wind generator are made according to a template from ¼ PVC sewer pipe with a diameter of 200 mm, cut along the axis into 4 parts

After assembly, the wind wheel should be balanced. To do this, you need to mount it horizontally on a tripod indoors. The result of correct assembly will be the immobility of the wheel.

If rotation of the blades occurs, it is necessary to sharpen them with abrasive before balancing the structure.

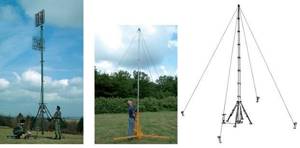

Step #2 - making a wind generator mast

To make a mast, you can use a steel pipe with a diameter of 150-200 mm. The minimum length of the mast should be 7 m. If there are obstacles to the movement of air masses on the site, then the wind generator wheel must be raised to a height exceeding the obstacle by at least 1 m.

The pegs for securing the guy wires and the mast itself must be concreted. As guy wires, you can use steel or galvanized cable 6-8 mm thick.

Mast braces will give the wind generator additional stability and reduce the costs associated with constructing a massive foundation; their cost is much lower than other types of masts, but additional space is required for bracing

Step #3 – re-equipment of the car generator

The modification consists only of rewinding the stator wire, as well as manufacturing a rotor with neodymium magnets. First you need to drill the holes necessary to fix the magnets in the rotor poles.

The installation of magnets is carried out with alternating poles. Upon completion of the work, the intermagnetic voids must be filled with epoxy resin, and the rotor itself must be wrapped in paper.

When rewinding the coil, you need to take into account that the efficiency of the generator will depend on the number of turns. The coil must be wound in a three-phase circuit in one direction.

The finished generator needs to be tested; the result of correctly performed work will be a reading of 30 V at 300 rpm of the generator.

The converted generator is ready for rated voltage testing before the final installation of the entire low-speed wind turbine system

Step #4 - completing the assembly of the low-speed wind generator

The rotating axis of the generator is made of a pipe with two bearings mounted, and the tail part is cut out of galvanized iron 1.2 mm thick.

Before attaching the generator to the mast, it is necessary to make a frame; a profile pipe is best suited for this. When performing fastening, it is necessary to take into account that the minimum distance from the mast to the blade must be more than 0.25 m.

Under the influence of the wind flow, the blades and rotor move, resulting in rotation of the gearbox and generating electrical energy

To operate the system, you need to install a charge controller, batteries, and an inverter after the wind generator.

The battery capacity is determined by the power of the wind generator. This indicator depends on the size of the wind wheel, the number of blades and wind speed.

Types of alternative heating sources

In order to equip alternative heating for a private home with your own hands, there are several options that will help you save a considerable amount of money while consuming absolutely renewable energy.

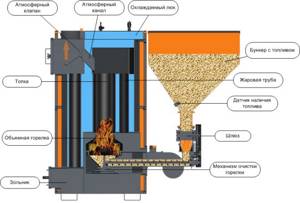

1. Biofuel. This option is completely environmentally friendly due to the use of special briquettes and pellets, which include manure, plants, wastewater and other natural waste. By the way, such fertilizer can be obtained at home.

A boiler is used as a converting device; fuel is supplied automatically. To switch from gas heating to biofuel heating, there is no point in changing the entire heating system: just replace the boiler and connect it to the system.

To independently organize an effective biofuel heating system, you can also build a fireplace, which, if all installation rules are followed, is quite capable of efficiently warming up a small private house.

2. Solar energy. Converting solar energy into thermal energy is a modern and fairly economical way to heat a room. This type of heating is practically free: all you need to do is buy a solar collector or assemble it yourself from components that can easily be found in specialized stores. Installing the collector is quite simple, so you can do it yourself. The collector is installed on the roof, where the device will collect solar energy and transfer it to a mini-boiler room located inside the house. Modern solar collectors are effective even in cloudy weather.

This heating option for a private home will allow you to heat your home for free even in severe frosts. Moreover, if you installed the collector correctly and connected it to internal communications, you can use solar energy to heat water for domestic needs.

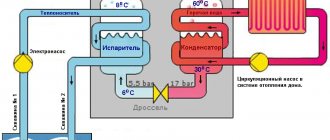

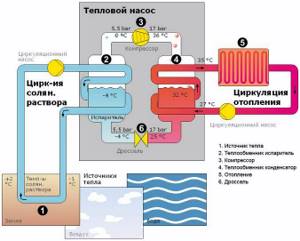

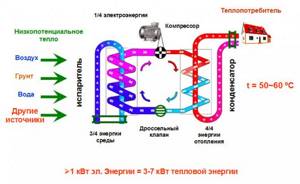

3. Energy of earth and water. To set up such a heating system, you will need to install a heat pump, which requires electricity to operate. In this case, you can save 10-20% of cash costs compared to gas heating. You can also install a heat pump yourself, especially since compared to gas equipment, it is absolutely safe.

Heat pumps can operate in 2 types: - water-water; - brine-water.

For the first type, it will be necessary to drill 2 wells for lifting and 2 for draining water, about 50 m deep. All this work can be carried out on your own, but with the permission of government agencies.

For the second type, you will need a well with a depth of at least 200 m. Pipes with a solution must be laid in the well. To reduce the difference in output heat at different times of the year, you can install a heat exchanger.

Despite the relative complexity of installation, such a heating system will allow you to receive almost free heat, the main thing is to make the correct calculations and take into account all the nuances.

4. Infrared heating and “warm floor” system. Heating using infrared heat sources can be easily arranged independently. To do this, you just need to buy infrared heaters and place them in the house. Their cost is relatively inexpensive, and such devices can become an effective element of home decor.

A heated floor system can also be installed on your own in just a couple of days. To do this, you will need infrared film, which must be laid immediately under the top layer of the floor covering. This process does not require any special skills; you just need to remove the existing coating, lay down a film and put on a new coating.

This alternative heating for a private home is quite simple to install and allows you to effectively heat the room.

Popular sources of renewable energy

Since ancient times, people have used mechanisms and devices in everyday life, the action of which was aimed at converting the forces of nature into mechanical energy. A striking example of this are water mills and windmills. With the advent of electricity, the presence of a generator made it possible to convert mechanical energy into electrical energy.

The water mill is the predecessor of the automatic pump, which does not require the presence of a person to perform the work. The wheel rotates spontaneously under the pressure of water and independently draws water

Today, a significant amount of energy is generated precisely by wind complexes and hydroelectric power plants. In addition to wind and water, people have access to such sources as biofuels, the energy of the earth's interior, sunlight, the energy of geysers and volcanoes, and the power of tides.

The following devices are widely used in everyday life to generate renewable energy:

- Solar panels.

- Heat pumps.

- Wind generators.

The high cost of both the devices themselves and installation work stops many people from receiving seemingly free energy. Payback can reach 15-20 years, but this is not a reason to deprive yourself of economic prospects. All these devices can be made and installed independently.

When choosing a source of alternative energy, you need to focus on its availability, then maximum power will be achieved with a minimum of investments

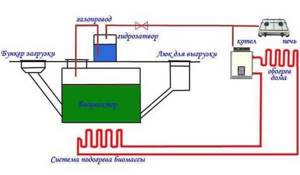

Option 4 installation for biogas production

During anaerobic processing of organic waste, so-called biogas is released. The result is a mixture of gases consisting of methane, carbon dioxide and hydrogen sulfide. The generator for producing biogas consists of:

- sealed tank;

- auger for mixing organic waste;

- pipe for unloading the waste mass;

- necks for filling waste and water;

- pipe through which the resulting gas flows.

Often, a container for waste recycling is installed not on the surface, but in the thickness of the soil. To prevent leakage of the resulting gas, it is made completely sealed. It should be remembered that during the process of biogas release, the pressure in the tank constantly increases, so the gas must be taken out of the tank regularly. In addition to biogas, the processing results in an excellent organic fertilizer useful for growing plants.

The design and operating rules of such a gas generator are subject to increased safety requirements, since biogas is dangerous to inhale and can explode. However, in a number of countries around the world, for example, in China, this method of generating energy is quite widespread.

The design of the generator for producing biogas is very simple, but some caution should be exercised when operating it, since biogas is a flammable substance hazardous to health

The composition and amount of biogas obtained from waste depends on the substrate. The most gas is obtained by using fat, grain, technical glycerin, fresh grass, silage, etc. Typically, a mixture of animal and vegetable waste is loaded into the tank, to which a certain amount of water is added. In summer, it is recommended to increase the humidity of the mass to 94-96%, and in winter, 88-90% moisture is sufficient. The water supplied to the waste tank should be heated to 35-40 degrees, otherwise the decomposition processes will be slowed down. To retain heat, a layer of thermal insulation material is mounted on the outside of the tank.

It always seemed to me that alternative energy was too expensive in terms of investment, but you were able to convince me. On the one hand, it is difficult to assemble the necessary devices manually (I haven’t tried it personally, so I can’t judge). On the other hand, if everything can be done correctly, the alternative energy source will pay for itself in any case. Nowadays electricity costs a lot of money. But I think that alternative energy can only be installed in a private house, because... In the city, the supervisory services (I don’t remember the name) will not look at this very approvingly - perhaps they will even fine you. I live in the city and there is no opportunity to try such things.

If you combine all types of alternative energy production, then perhaps this will significantly reduce energy costs and even pay for your construction someday. Judging by the article, assembling an alternative energy source is not that difficult, but it still requires some skills. If you consider installing solar panels on the roof, and in addition to them a wind installation, you can get an almost universal source of energy in any weather. And if you add biogas, then it will be absolutely beautiful. However, all these methods are good only for the warm season (well, or autumn, when there is a strong wind), but in winter the sun is not often, and neither is the wind. How to be in this case?

Heat pumps for heating

Heat pumps are one of the most advanced technological solutions in obtaining alternative energy for your home. They are not only the most convenient, but also environmentally friendly. Their operation will significantly reduce the costs associated with paying for cooling and heating the premises.

Classification of heat pumps

I classify heat pumps by the number of circuits, the source of energy and the method of obtaining it. Depending on the final needs, heat pumps can be:

- One-, two- or three-circuit;

- One- or two-capacitor;

- With the possibility of heating or with the possibility of heating and cooling.

Based on the type of energy source and method of obtaining it, the following heat pumps are distinguished:

- Soil - water. They are used in temperate climate zones with uniform heating of the earth, regardless of the time of year. For installation, a collector or probe is used, depending on the type of soil. Drilling shallow wells does not require obtaining permits.

- Air is water. Heat is accumulated from the air and directed to heat water. The installation will be appropriate in climate zones with winter temperatures not lower than -15 degrees.

- Water is water. Installation is determined by the presence of bodies of water (lakes, rivers, groundwater, wells, settling tanks). The efficiency of such a heat pump is very impressive, which is due to the high temperature of the source during the cold season.

- Water is air. In this combination, the same reservoirs act as a heat source, but the heat is transferred directly to the air used to heat the premises through a compressor. In this case, water does not act as a coolant.

- Soil is air. In this system, the heat conductor is the soil. Heat from the ground is transferred to the air through the compressor. Non-freezing liquids are used as energy carriers. This system is considered the most universal.

- Air is air. The operation of this system is similar to the operation of an air conditioner, capable of heating and cooling a room. This system is the cheapest, as it does not require excavation work or laying pipelines.

When choosing the type of heat source, you need to focus on the geology of the site and the possibility of unhindered excavation work, as well as the availability of free space. If there is a shortage of free space, you will have to abandon heat sources such as earth and water and take heat from the air.

The efficiency of the system and the costs of its installation largely depend on the correct choice of the type of heat pump.

Working principle of a heat pump

The operating principle of heat pumps is based on the use of the Carnot cycle, which, as a result of sharp compression of the coolant, provides an increase in temperature. Most climate control devices with compressor units (refrigerator, freezer, air conditioner) operate on the same principle, but with the opposite effect.

The main operating cycle, which is implemented in the chambers of these units, has the opposite effect - as a result of a sharp expansion, a narrowing of the refrigerant occurs. That is why one of the most accessible methods for manufacturing a heat pump is based on the use of individual functional units used in climate control equipment.

So, a household refrigerator can be used to make a heat pump. Its evaporator and condenser will play the role of heat exchangers, removing thermal energy from the environment and directing it directly to heating the coolant that circulates in the heating system.

Low-grade heat from soil, air or water, together with the coolant, enters the evaporator, where it turns into gas, and is then further compressed by the compressor, as a result of which the temperature becomes even higher (+)

Heat pump with components from household appliances

Work begins with the preparation of the compressor part of the pump, the functions of which will be assigned to the corresponding unit of the air conditioner or refrigerator. This unit must be secured with a soft suspension on one of the walls of the workroom where it will be convenient.

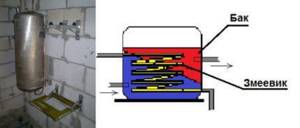

After this, you need to make a capacitor. A 100 liter stainless steel tank is ideal for this. It is necessary to install a coil into it (you can take a ready-made copper tube from an old air conditioner or refrigerator. The prepared tank must be cut lengthwise into two equal parts using a grinder - this is necessary for installing and securing the coil in the body of the future condenser.

After installing the coil in one of the halves, both parts of the tank must be connected and welded together so as to form a closed tank. Please note that when welding you need to use special electrodes, and even better, use argon welding, only it can ensure maximum quality of the seam.

To make the condenser, a 100-liter stainless steel tank was used; using a grinder, it was cut in half, a coil was installed, and reverse welding was performed.

To make an evaporator, you will need a sealed plastic tank with a volume of 75-80 liters, into which you will need to place a coil made of pipe with a diameter of ¾ inches.

To make a coil, it is enough to wrap a copper tube around a steel pipe with a diameter of 300-400 mm, followed by fixing the turns with a perforated angle

Threads must be cut at the ends of the tube to subsequently ensure connection with the pipeline. Once assembly is complete and the seal has been checked, the evaporator should be secured to the wall of the workroom using brackets of the appropriate size.

It is better to entrust the completion of assembly to a specialist. While some of the assembly can be done yourself, soldering the copper pipes and pumping in the refrigerant should be done by a professional. Assembly of the main part of the pump ends with the connection of heating batteries and a heat exchanger. It should be noted that this system is low-power. Therefore, it will be better if the heat pump becomes an additional part of the existing heating system.

Arrangement and connection of an external device

The best source of heat is water from a well or borehole. It never freezes and even in winter its temperature rarely drops below +12 degrees. It will be necessary to install two such wells. Water will be drawn from one well and subsequently supplied to the evaporator. Next, the waste water will be discharged into the second well. All that remains is to connect it all to the inlet of the evaporator, to the outlet and seal it.

In principle, the system is ready for operation, but for its complete autonomy it will require an automation system that controls the temperature of the moving coolant in the heating circuits and freon pressure. At first, you can get by with an ordinary starter, but it should be noted that starting the system after turning off the compressor can be done in 8-10 minutes - this time is necessary to equalize the freon pressure in the system.

Heating a house with solar heat storage collectors

Alternative heating using solar heat storage panels will directly depend on the intensity of the sun's rays, which varies at different times of the year. At night and in cloudy weather, there is not enough solar radiation to operate the collectors.

What is it used for?

Solar panels are often used to heat water or for domestic and household needs. Hot water takes part in heat exchange in monovalent storage tanks. Solar panels can act as an additional source of thermal energy generation for water heating and heating systems in biovalent storage tanks.

Types of solar collectors

Solar collectors are divided into two types:

If the equipment is used in the summer, the performance coefficient of both types will be the same. For winter it is recommended to use vacuum manifolds. They can operate at temperatures down to -35 degrees.

Flat-plate collectors are capable of heating air up to +60 degrees. Vacuum collectors are designed for heating up to +90. In other parameters the devices are similar.

Collectors with vacuum pipes are excellently used as alternative heating for a country house. At the same time, the devices can heat water.

https://youtube.com/watch?v=-oExo23Bhf4

A hydrodynamic water heating system is another good alternative to gas heating. It is not yet very famous, but its simplicity and advantageous use for heating a home makes it noticeable. In addition to water, the installations allow heating oil, salty and dirty water.

Use of solar energy

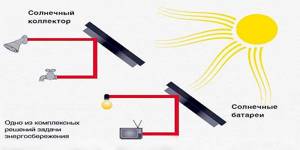

One of the most powerful alternative energy sources for the home is solar radiation. There are two types of installations for converting solar energy:

- solar panels produce electric current;

- solar collectors heat the water.

Solar energy can be used to heat water or generate electricity

You should not think that the installations only work in the south and only in the summer. They work well in winter too. In clear weather with snow falling, energy production is only slightly lower than in summer. If your region has a large number of clear days, you can use such technology.

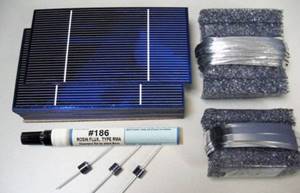

Solar panels

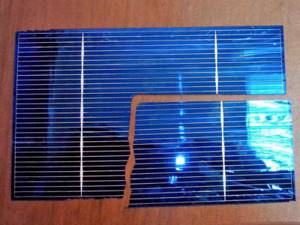

Solar batteries are assembled from photovoltaic converters, which are made from minerals that, when exposed to sunlight, emit electrons - generating electric current. For private applications, silicon photoconverters are used. In their structure, they are monocrystalline (made from one crystal) and polycrystalline (many crystals). Monocrystalline ones have a higher efficiency (13-25% depending on quality) and a longer service life, but are more expensive. Polycrystalline ones generate less electricity (9-15%) and fail faster, but have a lower price.

This is a polycrystalline photoconverter. You need to handle them carefully - they are very fragile (monocrystalline ones too, but not to the same extent)

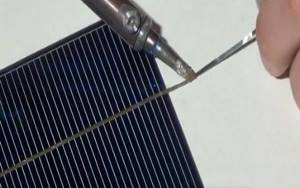

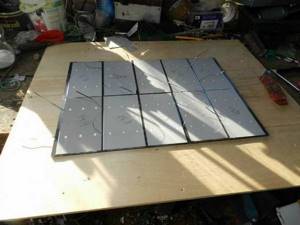

Assembling a solar battery with your own hands is not difficult. First you need to purchase a certain number of silicon photocells (the quantity depends on the required power). Most often they are bought on Chinese trading platforms such as AliExpress. Then the procedure is simple:

- Make a frame (from wooden planks or metal corners). Place a backing on it. Transparent - glass, plexiglass (monolithic polycarbonate) - if the solar battery will hang on the window, and opaque (plywood painted white) if you will install the battery on the roof.

- Using aluminum conductors, connect the elements into one battery (in parallel). The conductors can be soldered directly to the plates (they cost a little more) or you will have to buy them separately and then solder them yourself.

- The finished battery must be sealed. Fill it with epoxy resin or glue it with a special EVA film. When sealing, it is necessary to ensure that there are no voids - air bubbles. They greatly reduce battery performance, so we remove them carefully.

This is a ready-made solar battery

A few words about why the substrate for a solar panel (battery) should be painted white. The operating temperature range of silicon wafers is from -40°C to +50°C. Operating at higher or lower temperatures leads to rapid failure of elements. On the roof, in summer, in a closed space, the temperature can be much higher than +50°C. That’s why white color is needed - so as not to overheat the silicon.

Solar collectors

Using solar collectors you can heat water or air. Where to direct the water heated by the sun - into hot water taps or into the heating system - is up to you. Only the heating will be low temperature - for a warm floor, that’s what is required. But in order for the temperature in the house not to depend on the weather, the system needs to be made redundant so that, if necessary, another heat source is connected or the boiler switches to another energy source.

The most common tubular solar collectors

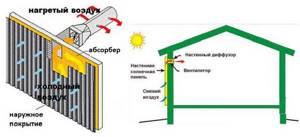

There are three types of solar collectors: flat, tubular and air. The most common are tubular, but others also have a right to exist.

Flat plastic

Two panels - black and transparent - are connected into one body. Between them there is a copper pipeline in the form of a snake. The lower dark panel heats up from the sun. it heats the copper, and it warms the water passing through the labyrinth. This method of using alternative energy sources is not the most effective, but it is attractive because it is very simple to implement. This way you can heat the water in the pool. You just need to cycle its supply (using a circulation pump). In the same way, you can heat water in a container for a summer shower or use it for domestic needs. The disadvantage of such installations is low efficiency and productivity. To heat a large volume of water, you need either a lot of time or a large number of flat-plate collectors.

Flat solar collector

Tubular manifolds

These are glass tubes - vacuum or coaxial - through which water flows. A special system allows maximum concentration of heat in the tubes, which is transferred to the water flowing through them.

Tubular collectors can be vacuum or feather

The system must have a storage tank in which the water is heated. Water circulation in the system is ensured by a pump. You can’t make such systems yourself - making glass tubes with your own hands is problematic and this is the main drawback. This, coupled with its high price, is holding back widespread adoption of this home energy source. And the system itself is very efficient, copes with heating water for hot water supply with a bang and makes a decent contribution to heating.

Scheme for organizing heating and hot water supply using alternative energy sources - using solar collectors

Air manifolds

In our country they are very rare and in vain. They are simple and can be easily made with your own hands. The only negative is that a large area is required: they can occupy the entire southern (eastern, southeastern) wall. The system is very similar to flat-plate collectors - black bottom panel, transparent top, but they directly heat the air, which is forced (by a fan) or naturally directed into the room. Despite the apparent frivolity, in this way you can heat small rooms during daylight hours, including technical or utility rooms: garages, summer houses, sheds for livestock.

Air collector device

An alternative energy source like the sun gives us its heat, but most of it goes “to nowhere.” Catching a small share of it and using it for personal needs is the task that all these devices solve.

Self-production of solar panels

Solar installations are an alternative to traditional electricity, which in finished form is expensive. If you assemble it yourself, you can reduce the cost of the structure by 3-4 times. Before you start creating a solar panel, you need to understand the principle of its functionality.

How does a solar power system work?

To imagine the principle of operation, it is worth starting with the design. The design of solar energy sources includes:

- solar panel - a complex of units for converting sunlight into an electron flow;

- Batteries – there are several of them in the system, the number depends on the power of the consumers;

- charge controller – ensures normal charging of the battery without overcharging;

- inverter - transforms low voltage current from batteries into high voltage current (3-5 kW is enough for a home).

The solar panels individually produce low voltage currents (about 18-21 V), which is enough to charge a 12 volt battery.

Creation of a solar battery

The battery is assembled from modular photocells. One household module contains 30, 36 and 72 elements. They are connected in series to a power source whose maximum voltage is 50 V.

For the body part you will need wooden beams, fiberboard, plexiglass and plywood. The bottom of the box is cut out of plywood and inserted into a frame made of 25 mm thick bars. Holes are made around the perimeter of the frame. To prevent overheating of the elements, the drilling step should be 15-20 cm.

Solar panel assembly

A fiberboard backing with ventilation holes is cut out of the fiberboard using a utility knife. They are made according to a square-nested pattern with an indentation of 5 cm. Then:

- The elements are laid with their upper part on the substrate and soldered.

- Connections are made sequentially, in order.

- The finished rows are connected to busbars that conduct current.

- The elements are turned over and secured in place with silicone.

- Check the output voltage parameters. Its range is from 18 to 20 V.

- The battery is run in for 2-3 days to test the charging ability.

- At the end of the inspection, the joints are sealed.

Preparing the panel for installation

Paint and dry the substrate 2 times.

After checking the functionality, the solar panel is assembled:

- The input and output contacts are brought out.

- Cut out the plexiglass cover and fix it with self-tapping screws to the pre-drilled holes.

- When using a diode circuit of 36 diodes with a voltage of 12 V, remove the paint from the part with acetone.

- Holes are made in the plastic panel, diodes are inserted and soldered.

The final step is installation and orientation of the solar panel to facilitate maintenance access and energy efficiency.

Rules for installing a solar panel

Solar battery connection

Industrial modifications can rotate independently. Household devices must be set according to several parameters:

- Moving away from shaded areas - a tree or a tall building nearby will make the device ineffective.

- Orientation to the sunny side. Residents of the northern hemisphere orient the structure to the south, while residents of the southern hemisphere orient it to the north.

- The angle of inclination is tied to the geographical latitude of the site. In summer, it is better to tilt the solar panel 30 degrees to the horizon, in winter – 70 degrees.

- Availability of access for maintenance - removal of dust, dirt, and accumulated snow.

Solar energy turns into electricity

Solar panels were first made for spacecraft. The device is based on the ability of photons to create an electric current. There are a great many variations in the design of solar panels and they are improved every year. There are two ways to make your own solar battery:

Method number 1. Buy ready-made photocells, assemble a circuit from them and cover the structure with transparent material. You need to work with extreme caution, all elements are very fragile. Each photocell is marked in volt-amperes. Calculating the required number of elements to assemble a battery of the required power will not be very difficult. The sequence of work is as follows:

- To make the body you will need a sheet of plywood. Wooden slats are nailed along the perimeter;

- holes are drilled in the plywood sheet for ventilation;

- A sheet of fiberboard with a soldered chain of photocells is placed inside;

- performance is checked;

- Plexiglas is screwed onto the slats.

Method No. 2 requires knowledge of electrical engineering. The electrical circuit is assembled from D223B diodes. They are soldered in rows sequentially. Place in a housing covered with transparent material.

Photocells come in two types:

- Monocrystalline plates have an efficiency of 13% and will last a quarter of a century. They work flawlessly only in sunny weather.

- Polycrystalline ones have lower efficiency, their service life is only 10 years, but the power does not decrease when it is cloudy. Panel area 10 sq. m. is capable of producing 1 kW of energy. When placing on the roof, it is worth considering the total weight of the structure.

The finished batteries are placed on the sunny side. The panel must be equipped with the ability to adjust the angle in relation to the Sun. The vertical position is installed during snowfalls so that the battery does not fail.

The solar panel can be used with or without a battery. Consume solar energy during the day and battery energy at night. Or use solar energy during the day, and from the central power supply network at night.

Waste into income: biogas plants

All alternative energy sources are of natural origin, but double benefits can only be obtained from biogas plants. They process waste from domestic animals and poultry. The result is a certain volume of gas, which, after purification and drying, can be used for its intended purpose. The remaining processed waste can be sold or used on fields to increase yields - a very effective and safe fertilizer is obtained.

Energy can also be obtained from manure, but not in pure form, but in the form of gas

Briefly about technology

Gas formation occurs during fermentation, and bacteria living in manure are involved in this. The waste of any livestock and poultry is suitable for producing biogas, but cattle manure is optimal. It is even added to the rest of the waste for “ferment” - it contains exactly the bacteria needed for processing.

To create optimal conditions, an anaerobic environment is necessary - fermentation must take place without oxygen. Therefore, effective bioreactors are closed containers. To make the process more active, regular mixing of the mass is necessary. In industrial installations, mixers with electric drives are installed for this purpose; in home-made biogas plants, these are usually mechanical devices - from the simplest stick to mechanical mixers that “work” by hand force.

Schematic diagram of biogas plants

Two types of bacteria are involved in the formation of gas from manure: mesophilic and thermophilic. Mesophilic are active at temperatures from +30°C to +40°C, thermophilic - at +42°C to +53°C. Thermophilic bacteria work more efficiently. Under ideal conditions, gas production from 1 liter of usable area can reach 4-4.5 liters of gas. But maintaining a temperature of 50°C in the installation is very difficult and expensive, although the costs are justified.

A little about designs

The simplest biogas plant is a barrel with a lid and a stirrer. The lid has a terminal for connecting a hose through which gas enters the tank. You won’t get a lot of gas from such a volume, but it’s enough for one or two gas burners.

More serious volumes can be obtained from an underground or above-ground bunker. If we are talking about an underground bunker, then it is made of reinforced concrete. The walls are separated from the ground by a layer of thermal insulation; the container itself can be divided into several compartments in which processing will take place with a time shift. Since mesophilic cultures usually work under such conditions, the entire process takes from 12 to 30 days (thermophilic cultures are processed in 3 days), therefore a time shift is desirable.

Scheme of a bunker biogas plant

Manure enters through the loading hopper; an unloading hatch is made on the opposite side, from where processed raw materials are taken. The bunker is not completely filled with the bio-mixture - about 15-20% of the space remains free - gas accumulates here. To drain it, a tube is built into the lid, the second end of which is lowered into a water seal - a container partially filled with water. In this way, the gas is dried - already purified gas is collected in the upper part, it is removed using another tube and can already be choked to the consumer.

Everyone can use alternative energy sources. It is more difficult for apartment owners to implement this, but in a private house they can at least implement all the ideas. There are even real examples of this. People fully provide for their own needs and for their large households.

WIND GENERATOR IN A PRIVATE HOUSE

The cost of a wind turbine with a capacity of 1 kW/h is at least $600. To install an alternative power supply unit, first of all, you will need to wisely select the free space for the generator mast. There must be a free space of at least 20 m2 around the tower.

You can assemble a homemade design of a backup energy source from the following parts:

- Car generator;

- 2.5m propeller made of plywood and plastic;

- Two-inch steel pipe;

- Cable braces.

The price of a set of parts barely exceeds $150, so the cost of a kilowatt of energy produced by an alternative power system will be less than 3.5 rubles. The backup energy source will pay for itself in three months.

What is an alternative heat source

Since traditionally the house is heated with a gas boiler, by alternative home heating we mean any heating device that does not run on gas.

When is it relevant?

- You are unable to connect to the gas network or it is too expensive;

- You want to reduce your dependence on gas and have insurance in case of severe frosts or interruptions in its supply;

- To save on heating costs. Combining and properly managing heat sources will reduce your heating costs.

Types of Alternative Energy Sources

Conventionally, alternative heat sources are divided into two types:

- Which work in addition to the boiler. For various reasons, they are not able to fully provide the building with heat. The main heating power is provided by the gas boiler, and other sources support its operation during peak loads or off-season.

- Which replace a gas boiler. These are the heat sources that are capable of producing sufficient heating power to warm the building.

Let's consider what devices can be used in each case.

BIOFUEL

Most alternative energy sources have the same drawback - it is almost impossible to store heat or electricity, except for ultra-large thermal accumulators and low-power lithium batteries for solar panels.

Most private home owners would prefer to use an alternative option that is safe and easy to use biofuel, which could be stored for the entire heating season.

Today, two alternative fuel options are used:

- Biogas produced directly on the territory of the estate or household;

- Pellets, granulated products of processing coal, peat, wood, sawmill waste.

The source of raw materials for the production of pellets can be any wood waste. A small rotary press, which can be easily installed at home, turns a bag of crushed wood chips into several kilograms of pellets. As a result, the owner receives a source of alternative inexpensive fuel, which can be stored and burned in special boilers with automatic supply of pellet mass.

Biogas is a product of the processing of organic waste mixed with cow and pig manure by certain bacterial cultures. The raw materials are loaded into a metal container with a free-floating roof and rubbed with powder containing bacteria.

On the second or third day, biogas begins to flow from the tank, which can be used as an alternative gas fuel instead of methane. It is enough just to adjust the operation of the automation to gas with a lower calorie content.

A convenient, but not the safest source of alternative energy, since biogas is odorless and, in case of leakage, can easily lead to a fire.

Descendants of windmills producing kilowatts

There is nothing complicated about the design of wind turbines. It’s not for nothing that our ancestors used wind energy so routinely. Fundamentally nothing has changed. Simply, instead of the millstones of the mill, a drive was installed on a generator, which converts the rotational energy of the blades into electricity.

This is what most modern wind generators look like.

To make a wind generator you will need: a high tower, blades, a generator and a storage battery. We also need to come up with a simple system for controlling and distributing electricity. Let's consider one of the ways to build a windmill yourself

Let's not focus on the design of the tower and blades; there is nothing complicated here for someone who knows at least something about mechanics. Let's focus on the generator

You can, of course, purchase a ready-made generator with the necessary parameters, but our task is to create a windmill ourselves. If you have a motor from an old washing machine and it works, then the matter is solved. We will need to convert it into a generator. To do this, we will purchase neodymium magnets.

We bore the generator rotor on a lathe, making recesses for the magnets. We glue magnets into them with superglue. We wrap the rotor in paper and fill the space between the magnets with epoxy resin. When it dries, remove the paper and sand the rotor with sandpaper.

Attention! To prevent the magnets from sticking, they need to be installed at a slight angle. Now, when the rotor rotates, the magnets will form a potential difference, which is removed using the terminals

This is how magnets are glued to the rotor of a washing machine motor.

Solar power plant

Installation of solar panels will require:

- Storage devices, which are photocells.

- Battery – for accumulating charge.

- A controller that will allow you to monitor the battery.

- Device for converting 12 or 24 V current into 200 V.

- Structural and fixing elements.

Features of installation at home

Please note that the angle of inclination must change. In winter, the alternative solar storage device should be moved to a position with a large angle to the horizon. This is done to prevent snow from accumulating on the solar collector. Otherwise, this will lead to a sharp decrease in efficiency.

You should choose a section of the roof of the house that faces the south, east or southeast sides of the world.

Solar collectors for water heating

To obtain hot water and heating in a private house, an alternative collector powered by solar heat is used. Operating principle and design:

- Box Metal will last longer. Made from OSB, fiberboard, chipboard boards - a cheaper option, but its operation will be shorter. To increase the service life, the slab is impregnated with special septic tanks and varnishes.

- Mineral wool or polystyrene foam is placed at the bottom of the box - they serve as heat insulators and prevent heat loss.

- Pipes are laid in dense rows on the slab. The best material is copper - it has high thermal conductivity. Metal-plastic options are allowed, but their energy efficiency will be 20% less than copper ones.

- The inlet and outlet parts are equipped with fittings. They provide connection to the water supply communications of the house.

- The top of the box is covered with glass. You can also use acrylic material or monolithic polycarbonate. An important point is that the surface should not be smooth, but corrugated, for a better heating process. Solar glass has the ability to eliminate heat loss. It provides less energy loss.

We recommend reading: Recycling waste: what can be recycled?

Next, the entire alternative structure is connected to a water source that will circulate indoors.

Stephen Mark Generator

Using this device, you can accumulate a certain electrical potential to service household appliances without using additional recharge. The technology was patented, resulting in hundreds of enthusiasts trying to replicate the experience at home. However, due to its specific features, it was not possible to release it to the masses.

The operation of the Steven Mark generator is carried out according to a simple principle: in the ring of the device, a resonance of currents and magnetic vortices are formed, which cause the appearance of current shocks. To create a toroidal generator you need to follow the following instructions:

- First of all, you should prepare the base of the device. You can use a ring-shaped piece of plywood, a piece of rubber or polyurethane. You also need to find two collector coils and control coils. Depending on the drawing, the dimensions of the structure may differ, but the optimal option is the following indicators: the outer diameter of the ring is 230 mm, the inner diameter is 180 mm. The width is 25 mm, the thickness is 5 mm.

- It is necessary to wind the internal collector coil using stranded copper wire. For better interaction, a three-turn winding is used, although experts are confident that one turn can power a light bulb.

- You should also prepare 4 control coils. When placing these elements, you must maintain a right angle, otherwise interference with the magnetic field may occur. The winding of these coils is flat, and the gap between the turns is no more than 15 mm.

- When winding control coils, it is customary to use single-core wires.

- To install the last coil, you should use insulated copper wire, which is wound over the entire base area of the structure.

https://youtube.com/watch?v=hIfQjh6DlAI

conclusions

Heating without gas is possible. Some heat sources serve as a complete replacement for a gas boiler, while others can only be used as a supplement. For convenience, let's combine everything into a table:

| Alternative to gas | Addition |

| Ground source heat pump Solid fuel boiler Pellet boiler | Fireplace with water circuit Air fireplace Pellet fireplace Solar collectors Inverter air conditioners Air source heat pump Electric boilers |

There are other alternative ways to heat a building that are not included in the list: stoves, boilers, electric boilers and other heating devices.

And, of course, it is important to remember that installing other heat sources is not the only way to save gas and reduce dependence on it. It is necessary to work to improve the overall energy efficiency of the building: identify and eliminate all heat leaks, use heat more efficiently and minimize heat loss in the building

Homemade hydroelectric power station

If there is a stream or reservoir with a dam on the site, a homemade hydroelectric power station will become an additional source of alternative electricity. The device is based on a water wheel, and the power will depend on the speed of the water flow. The materials for making a generator and wheels can be taken from a car, and scraps of corner and metal can be found in any household. In addition, you will need a piece of copper wire, plywood, polystyrene resin and neodymium magnets.

Homemade hydroelectric power station

Sequence of work:

- The wheel is made from 11 inch rims. The blades are made from a steel pipe (we cut the pipe lengthwise into 4 parts). 16 blades will be required. The discs are bolted together, the gap between them is 10 inches. The blades are welded.

- The nozzle is made according to the width of the wheel. It is made from scrap metal, bent to size and joined by welding. The nozzle is adjusted in height. This will allow you to adjust the water flow.

- The axle is welded.

- The wheel is installed on the axle.

- The winding is made, the coils are filled with resin - the stator is ready. We assemble the generator. A template is made from plywood. Install magnets.

- The generator is protected by a metal wing from water splashes.

- The wheel, axle and fasteners with nozzle are coated with paint to protect the metal from corrosion and for aesthetic pleasure.

- By adjusting the nozzle, maximum power is achieved.

Homemade devices do not require large capital investments and produce energy for free. If you combine several types of alternative sources, then such a step will significantly reduce energy costs. To assemble the unit you will only need skillful hands and a clear head.