What to do if the boiler shows F?

This section lists all possible fault codes along with the corresponding corrective actions that the USER CAN perform to restore the equipment to operation (Corrective Action: ...). Other faults MUST only be repaired by a qualified technician.

Error messages are shown on the display in the place where the pressure value in the heating system is normally displayed. Along with the fault code, the telephone icon and the letter F with the corresponding error code flash on the display.

Under normal operating conditions, the 10 most recent error messages can be displayed on the display by pressing both buttons for setting the heating temperature at the same time for approximately 7 seconds.

| Code | Description |

| F0 | NTC flow temperature sensor circuit open |

| F1 | Return Temperature NTC Sensor Circuit Open |

| F2 | DHW temperature sensor NTC circuit is open |

| F3 | DHW tank sensor NTC circuit is open |

| F4 | Manifold Sensor NTC Circuit Open |

| F5 | Exhaust gas sensor circuit is open |

| F6 | Traction sensor circuit is open |

| F7 | Faulty connection of the NTC temperature sensor in the return line coming from the solar collector |

| F8 | The NTC circuit of the DHW boiler ground sensor is open |

| F9 | Hood Sensor NTC Circuit Open |

| F10 | Short circuit NTC flow temperature sensor |

| F11 | Short circuit NTC return temperature sensor |

| F12 | Short circuit of NTC DHW boiler sensor Short circuit of NTC DHW temperature sensor |

| F13 | Short circuit of NTC DHW boiler sensor |

| F14 | Collector NTC sensor short circuit |

| F15 | Exhaust gas sensor short circuit |

| F16 | Draft sensor short circuit |

| F17 | Short circuit NTC return temperature sensor from solar collector |

| F18 | Short circuit NTC DHW boiler ground sensor |

| F19 | Short circuit of NTC hood sensor |

| F20 | The safety temperature limiter has tripped |

| F21 | The boiler is blocked due to exceeding the threshold value |

| F22 | The water level in the boiler is insufficient, the pump is blocked or faulty |

| F23 | Low water level: large temperature difference between NTC sensors on flow and return lines |

| F24 | Low water level: rapid rise in temperature |

| F25 | Protection against leakage of combustion products into the room has activated |

| F26 | Incorrect current value of the gas valve stepper motor windings |

| F27 | The ionization device signals the presence of a flame, although the gas valve is closed |

| F28 | Unsuccessful first attempt at ignition |

| F29 | Loss of flame during burner operation |

| F30 | Interlock sensor circuit open |

| F31 | Blocking sensor short circuit |

| F32 | Fan anti-freeze protection activated: fan speed is outside the permissible limits |

| F33 | Fan anti-freeze protection activated: pressure sensor open Pressure sensor not open (when fan is not running) |

| F35 | Error in the smoke removal system |

| F36 | Draft diagnostics (only for models with exhaust of combustion products into the chimney) |

| F37 | The fan speed during operation is outside the permissible limits |

| F38 | The measured frequency exceeds the permissible limits |

| F39 | Error in boiler autodiagnostics |

| F41 | Incorrect gas regulation |

| F42 | Coding resistor problem |

| F43 | Incorrect boiler model identification |

| F49 | eBus voltage low |

| F55 | CO sensor error |

| F58 | No feedback regarding preheat |

| F60 | Error in gas valve control + |

| F61 | Error in gas valve control - |

| F62 | Gas valve disabled error |

| F63 | EEPROM error |

| F64 | AOC error |

| F65 | Electronics overheating |

| F66 | IIC data bus error |

| F67 | Flame signal from ASIC is not reliable Diagnosed flame signal input is out of range (O or 5V) |

| F70 | Incorrect OSN |

| F71 | Hot water flow sensor is constantly open |

| F72 | Constant difference in readings of the flow sensor and NTC return temperature sensor |

| F73 | The pressure sensor is not connected or there is a short circuit in it |

| F74 | Malfunction in the electrical part of the pressure sensor (or damaged wire) |

| F75 | Repeated pressure sensor error. After starting the pump, no pressure surge was detected. |

| F76 | Malfunction of the thermal fuse on the primary heat exchanger |

| F80 | Input sensor SHE error |

| F81 | Circulation pump error |

| F82 | Faulty anode tester |

| F90 | Not connected to APC module |

| F91 | Sensor failure in APC module |

How to eliminate the error code F28 on the Proterm boiler?

___________________________________________________________________________

The Proterm Panther boiler turned off spontaneously, the screen displays an error code F28. I cleaned the burner and rebooted the unit, but the result was zero. The boiler starts after zeroing, the burner starts working and goes out. Then the ignition cycle is performed again and an error appears. What's wrong? Gas valve is broken. If damage is detected, replace the gas valve. The ignition electrode is unstable or faulty. Diagnose it for the presence of carbon deposits. Adjust the distance between the gas burner and the flame control electrode if necessary. Inoperability of the gas device. Inspect the coils in the gas valve to determine a possible open or short circuit. If these problems occur, replace the gas valve.

The gas valve becomes stuck. Attach a silicone hose to the fitting located on the front of the valve and apply increased pressure. There is not enough power to ignite. Adjust the ignition power when using the service menu. Malfunction or defect of the control board. The ignition transformer stopped working. Reboot the device. If the error occurs again, the electronic board must be replaced.

Grounding should be checked. The sheathing should not have tension. Excessive moisture can cause the device to block. It is necessary to clean the furnace, ionization electrode and gas burner unit from condensation. Failure of the flame control electrode functions. The control board has detected a flame, although no combustion occurs. Inspect the electrical wiring of the flame control electrode. Poor contacts and breaks are likely. The electrical circuit from the ionization electrode to the control board is inspected for the possibility of a short circuit. The ionization electrode may touch the burner assembly. Damage to the electronics board. It needs to be changed.

___________________________________________________________________________

Similar questions

- How to reset error code A5 on a gas boiler Arderia

- How to eliminate error code 108 for an Ariston gas boiler

- How can you reset the E10 error code on a Baxi boiler?

- Why can a Beretta gas boiler heat up and make a loud noise?

- Why does a Bosch gas boiler reduce pressure?

- For what reason does the Buderus boiler not operate in hot water supply mode?

- Why does the pressure drop in the Celtic gas boiler?

- Why did the Daewoo double-circuit boiler begin to hum and heat up?

- How to eliminate error E4 on an Electrolux boiler

- Why does a Ferroli gas boiler not work on hot water supply?

- Why does the Immergas boiler constantly turn on and off when heating

- Why did the Junkers wall-mounted gas boiler start to hum and get warm?

- Why does the Navien boiler give error 10, how to fix it

- Why does the Neva Lux gas boiler display error 03, how to fix it

- How to eliminate error F22 on a Proterm gas boiler

- Why does the Rinnai boiler not function on hot water supply?

- Why does the Vailant gas boiler show error F36, how to fix it

- For what reasons does the Visman gas boiler show error code F4?

- The pressure of the Electrolux gas boiler decreases, what is the problem?

- What is the problem if the Ferroli gas boiler shows error code F05, how to fix it

- Why did the Arderia boiler start giving error E2, how to fix it

- For what reason did the Ariston gas boiler constantly start turning on and off in heating mode?

- For what reason does the Baxi gas boiler not hold pressure?

- Why did the Bosch gas boiler start to issue error code C6, how to fix it

- The pressure of the Buderus boiler decreases, what is the problem?

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

- Why did the Arderia boiler often turn on and off when heated?

- What is the problem if the Ariston gas boiler shows error 607, how to reset it

- How to eliminate error code F28 on the Vailant boiler

- Why does the Visman boiler not function for hot water supply?

- How to eliminate error 43 on a Rinnai boiler

- This is why the Neva Lux boiler began to heat up and hum loudly

- Why does the Proterm boiler not work on hot water supply?

- How to eliminate error 01 on an Immergaz gas boiler

- For what reason does the Navien boiler not work in hot water supply mode?

- How to eliminate error E1 on an Electrolux boiler

- How to eliminate error code F37 on a Ferroli boiler

- How can you eliminate error 6A on a Buderus gas boiler?

- Why did the Daewoo gas boiler stop holding pressure?

- Why does a Bosch gas boiler not operate on hot water supply?

- What is wrong with the Baksi boiler if it gives error E01

___________________________________________________________________________

___________________________________________________________________________

- Beretta gas boiler does not hold pressure, what is the reason

- What is wrong with the Arderia gas boiler if it starts giving error A6

- The pressure in the Ariston gas boiler decreases, what are the reasons?

- For what reasons can the Rinnai boiler heat up and hum?

- Why did the Visman boiler constantly turn on and off when heating up?

- Why does the Arderia boiler not operate in DHW mode?

- For what reasons did the Ariston wall-mounted boiler begin to display error code 501?

- What is the problem if the Baksi boiler gives error E03, and how to fix it

- Why does the Buderus boiler give error 3C, how to reset it

- Why does the Proterm boiler often turn off and turn on when heating?

- What is wrong with the Ariston boiler if it shows error 607

- How can I eliminate error code 10 on a Navien boiler?

- What is the problem with the Electrolux boiler if it displays error code E3

- How to eliminate error F36 on a Vailant gas boiler

- What is the problem with the Proterm gas boiler if it gives error F25

- How to eliminate error code F5 on a Visman gas boiler

- What is the problem with the Ferroli boiler if it shows error code F05

- How to eliminate error E03 on a Baxi boiler

- What is wrong with a Bosch boiler if it shows error C6

- What is the problem with the Buderus gas boiler if it displays error code 3C

- What is the problem if the Rinnai boiler gives error 99, and how to fix it

- Why does the Beretta boiler display error A03, how to fix it

- Why does the Junkers boiler constantly turn off and on in heating mode?

- Why does the Daewoo boiler constantly turn off and turn on when heating?

- Why does a Bosch boiler constantly turn on and off when heating?

- Because of what the Thermon boiler often turns off and turns on when heating

- Why does the Celtic boiler constantly turn on and off when heating?

- What is wrong with the Westen gas boiler if it displays error E01

- How to eliminate error code A01 on a Corestar gas boiler

- How to eliminate error code F1 on a Senor Duval gas boiler

- How to eliminate error code A6 on a Celtic gas boiler

- What is wrong with the Elsotherm boiler if it starts giving error E1

- For what reasons did the Bugatti gas boiler begin to display error E01?

- How can you eliminate an error with code E2 on a Motan boiler?

- Why does the Immergaz boiler lose pressure?

- Why did the Kiturami gas boiler stop holding pressure?

- The pressure drops in the Korea Star gas boiler, what are the reasons?

- Why doesn't Mora's boiler hold pressure?

- The pressure in the Navien boiler is decreasing, what is the problem?

- The pressure in the Proterm gas boiler decreases, what are the reasons?

- Why does the Rinnai boiler not hold pressure?

- For what reasons does the Ariston boiler display error code 101?

- How to eliminate error F20 on the Proterm boiler

- For what reasons does a Daewoo gas boiler show an error with code E3?

- How to eliminate error code 16 on a Navien boiler

- For what reasons does the Electrolux boiler display error E2?

- How to eliminate error F20 on a Vailant gas boiler

- What is the problem with the Beretta boiler if it starts giving error A02

- How to eliminate error F2 on a Visman boiler

- For what reasons does the Neva Lux boiler show error code 02

- How can you eliminate error A03 on a Ferroli boiler?

- For what reasons does the Baxi gas boiler show error E02?

- How can you eliminate error E9 on a Bosch gas boiler?

- For what reasons does the Buderus gas boiler give error 2E?

- How to eliminate the E3 error on the Oasis boiler

- For what reasons does the Rinnai boiler show error 16?

___________________________________________________________________________

___________________________________________________________________________

- Heating boiler piping

- STS boilers

- KVT boilers for solid fuel

- Pellet boiler Peresvet

- Steel floor standing boiler Raton

- Solid fuel boiler Thermology

- Errors and malfunctions of the Termet gas boiler

- Termona boiler repair

- Boiler repair Nova

- Hermann boiler service

- Comparison of gas boilers Lemax Premium-20 and Danko-20s

___________________________________________________________________________

- Daewoo boiler maintenance

- Demrad boiler malfunctions

- Mora boiler malfunctions

- Westen boiler repair

- Malfunctions of Immergaz boilers

- Types of solid fuel boilers

- Models and design of combination boilers

- Liquid fuel and double-circuit boilers

- Cast iron boilers on coal

- Boilers with modeling burners

- Imported boilers for heating systems

Main models

Main characteristics of 11/23.3 MTV:

| № | Name, size | Boiler Protherm 11 MTV | Boiler "Proterm" "Gepard" 23 MTV |

| 1 | External dimensions of the boiler, mm | 742×410×315 | 742×410×311 |

| 2 | Thermal load, kW | 11.0 | 23.3 |

| 3 | Minimum load threshold, kW | 8.5 | 8.5 |

| 4 | Efficiency, % | 91.0 | 93.2 |

| 5 | Electrical load consumption, W | 130.0 | 147.0 |

| 6 | Power grid parameters, V/Hz | 220/50 | 220/50 |

| 7 | Limit value of pressure at the gas inlet to the boiler, mbar | 2.0 | 2.5 |

| 8 | Main fuel consumption volume, m3/h | 2.73 | 2.64 |

| 9 | Consumption volume of liquefied gas, m3/h | 1.12 | 1.02 |

| 10 | Maximum water pressure in the heating circuit, bar | 3.0 | 3.0 |

| 11 | Operating temperature range of heating, C | 36-80 | 36-80 |

| 12 | Pressure limit in the DHW network, bar | 10.0 | 10.0 |

| 13 | Hot water supply capacity, l/min | 1.0 | 1.7 |

| 14 | Operating temperature adjustment range, C | 36-60 | 36-60 |

| 15 | Chimney diameter, mm | 60/100 | 60/100 |

| 16 | Flue gas temperature, C | 126 | 122 |

| 17 | Heating area, m² | 80 −110 | 90-230 |

| 18 | Warranty period, months | 24 | 24 |

| 19 | price, rub. | 39 500* | 43 000* |

The thermostat for boiler automation based on the internal air temperature in the room is not included in the latest kit. The software has an option that allows you to connect a thermostat if the user buys one themselves. The circulation pump is equipped with an air vent that operates in automatic mode, and in addition, the latest modifications of the device have a post-circulation function that protects the pump from jamming.

Note! For those users who are looking for a highly efficient and environmentally friendly Protherm unit, you can pay attention to the Panther condensing model. With the same parameters, the device increases its efficiency by using the latent heat of flue gases, which previous models simply emit into the environment.

- F1 - you need to find the “restart” button, double-check whether the gas tap and the plug are turned on in the power outlet.

- F2 - it is worth checking the temperature sensor of the heating circuit and, if necessary, replacing it with a new one.

- F4 – the hot water supply sensor needs to be replaced; if the contacts are oxidized, they need to be cleaned.

- F5 – replacement of external temperature sensor.

- F6 - it’s worth checking the wires going between the sensors and the board, which could have broken, it’s also worth checking the ignition system.

- F7 – check all wires, they may break.

- F10 – in this situation, you will have to completely replace the NTC of the device.

- F20 – you need to check the temperature sensor for functionality.

- F22 - most likely, you will have to replace the sensor designed to measure the fluid pressure level. Most likely, you will need to add water to the system. It is worth double-checking whether the system is sealed, since the pressure level may well be reduced due to a leak. If it is present, eliminate it immediately.

How to regulate the burner power of a gas boiler

The useful thermal output of a gas boiler can be reduced by reducing the gas supply to the burner. They do this by changing the gas valve settings.

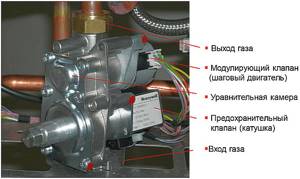

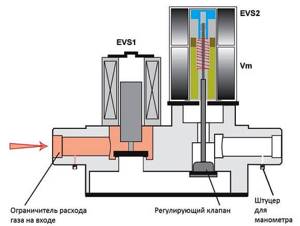

Gas valve Honeywel gas double-circuit boiler Protherm Gepard (Panther)

Access to the service menu of the Protherm Gepard boiler

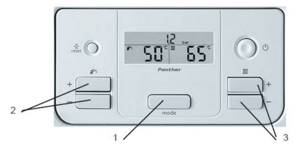

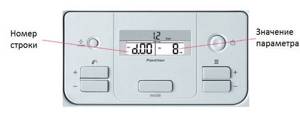

The Protherm Gepard boiler is controlled from the control panel through a publicly accessible user menu. How the owner can control the boiler is written in the operating manual. On the control panel you can call up another hidden menu - the service menu, intended for specialists. The service menu becomes available on the display screen after entering the code.

Access to the service menu of the Protherm Panther boiler (Panther)

The control panel of the Protherm Panther boiler has some differences from the Protherm Gepard boiler. The boiler control panel has a hidden service menu, which becomes accessible when the code is entered.

Description of some service menu commands

Line d.00 - maximum heating output (net power) of the boiler in heating mode, kW. The range of possible parameter values is from =9 to =23, factory setting = 15 (for Protherm Gepard). Line d.01 - run-on time of the circulation pump in heating mode, min., select a value between 2 and 60 min. Factory setting = 5 Line d.02 - Time delay after operation in heating mode for anti-cycling, min. Protects against frequent switching on and off of the burner in heating mode (this function is not applicable in DHW mode). Select a value between 2 and 60 min. Factory setting = 20 minutes. This delay (called anti-cycling time) prevents a rapid restart in heating mode after the burner has stopped due to the set temperature or the room thermostat TA. It depends on the coolant temperature setting: - at 80 °C, it is set for 1 minute and is not adjustable. - at 20 °C, it can be adjusted from 1 to 60 minutes using parameter d.02 in the service menu. At intermediate temperatures, between 20 °C and 80 °C, the delay varies proportionally in the range of 1 min. to the parameter d.02. d.18 - operating mode of the circulation pump; Operating mode options: = 0 - with burner: the pump operates together with the burner. =1 - continuous; with RT thermostat: the pump is activated by the command of the room thermostat. =2 - constantly in winter: the pump runs all the time while the boiler is in WINTER mode. Factory setting = 1. Line d.19 - circulation pump speed; Operating mode options: =0 - burner is running; speed in heating mode is selected automatically, maximum - in DHW mode, minimum - if the burner is turned off = 1 - min. speed in heating mode, max. – in DHW mode =2 – automatically selected in heating mode, max. – in DHW mode =3 — max. speed in heating and hot water mode. Factory setting =2 . Each time the burner is started in heating mode, the pump is switched on at a limited speed for at least 30 seconds. If the temperature difference between flow and return reaches 20 o K, the pump switches to maximum speed until the burner is turned off (even if the temperature difference has decreased). The same cycle occurs at the next ignition. Line d.35 - shows the position of the 3-way valve, heating/DHW (read only); =99 - hot water =0 - heating =40 - middle position Line d.36 - shows on the display the hot water consumption measured by the flow sensor, l/min. when dispensing hot water (read only) Line d.40 - shows on the display the temperature of the water leaving the boiler, in the direct pipeline of the heating system, o C. (read only) Line d.41 - shows on the display the temperature of the water entering into the boiler, in the return pipeline of the heating system, about C. (read only) Line d.44 - Control of ionization current. This parameter informs that the ionization current is in the optimal range. The displayed value does not represent the actual current value! Range of values: 0 – 10. In the range: =0 – 4 – ionization current is sufficient – flame is present; =4 – 8 – ionization current is slightly below a sufficient level – there is a possibility of flame loss; =8 - 10 - ionization current does not correspond to a sufficient level - there is no flame. Line d.52 - setting the minimum power of the boiler burner by shifting the minimum position of the Honeywell gas valve stepper motor. The range of possible parameter values is from =0 to =99. The lower the parameter value, the weaker the intensity of gas combustion. Line d.53 - setting the maximum power of the boiler burner by shifting the maximum position of the Honeywell gas valve stepper motor. The range of possible parameter values is from =0 to =-99 (negative values with a minus sign). The lower the parameter value, the weaker the intensity of gas combustion. Line d.62 - lowering the heating temperature at night. The setting range is 0 - 30 o C. If you connect a timer or even a manual switch to the boiler, you can switch the boiler into two modes: day or night. In night mode, the heating temperature setting is reduced by the amount set in d.62. Those. During the day, the temperature of the heating water and the temperature in the house are higher, and at night lower. You can set it the other way around. Line d.67 - Displays the time between boiler starts. This parameter displays the cooling time in minutes before the boiler is turned on again. The countdown of minutes begins at the moment the boiler turns off due to exceeding the maximum set operating temperature of the heating water on the boiler control panel and the room regulator is permanently closed. This parameter is important for the anticyclic function of the boiler, when the cooling time until the next turn on is calculated based on the set boiler heating water temperature and the configured anticycling time interval in line d.02. Line d.70 - Setting the position of the three-way valve. In this mode, it is possible to set the position of the three-way valve, regardless of the heating requirements for a particular circuit. Three-way valve position: =0 - the valve is controlled based on standard requirements from the control system; =1 - three-way valve is set to the middle position to empty the boiler (both heating and domestic hot water); =2 - three-way valve is set to the heating position. Line d.71 - Setting the maximum temperature in the heating system. Select a value between =45 and =80 °C. Factory setting =75 °C. Line d.88 - Protection against water hammer in cold water distribution (for KTV and KOV boilers). The ability to change the parameter eliminates the reaction to water hammer, which in some cases occurs in cold water pipelines. For example, when the automatic valve in the flush cistern of a toilet (or washing machine, or dishwasher) closes, a pressure surge (water hammer) may occur in the water supply pipes. The consequence of this may be a false activation of the flow sensor (turbine) of tap water, which will lead to a short-term unwanted activation of the boiler’s DHW mode. Factory setting =0 - activation of the ignition process for heating tap water at a flow rate of 1.5 l/min. Changing the parameter to value =1 - activation of the ignition process for heating tap water at a flow rate of 3.7 l/min. In this case, the flow duration must be at least 2 seconds. Line d.90 - Identification of the connected room sensor. Using this parameter, it is possible to verify that the room regulator is correctly connected, or that the communication between the room regulator and the boiler is working properly. Please note: this description only applies to controllers that support eBus communication. If a conventional regulator with a switching relay was connected, this function cannot be used. Display: =0 - the regulator is not connected or does not communicate with the boiler; =1 - the regulator is connected and there is communication between it and the boiler. Line d.96 - Setting the boiler to the parameters set at the factory. If the settings lead to incorrect operation or failures, it is possible to restore the boiler to factory settings. Setting: =0 - replacement with factory settings will not be performed; =1 - a return to factory settings will be made Note: when entering the setting of this parameter, the display always shows parameter “0”

The manufacturer offers two modifications:

How to connect to electricity

The electronics of gas boilers are demanding on the correct connection of the phase, zero and ground electrode.

If the contacts are reversed when connecting, the boiler will not start. Therefore, it is important to use a special plug and socket that does not allow you to connect the device in any other way. When running the cable, you need to check the correct distribution of the electrodes in the socket.

To check, use a probe screwdriver or other special devices.

Connecting a room thermostat

A room thermostat allows you to more accurately adjust the indoor microclimate . Its sensor checks the air temperature, which gives more accurate results than checking the extract air temperature, which is produced by the boiler electronics.

Using a room thermostat allows you to turn off the boiler when the set values are reached, when the device’s own sensors are not yet ready to give a command to stop heating.

The thermostat is connected to a special gap in the control board, the contacts of which are closed by default with a jumper.

To connect, turn off the boiler, open the lid and remove the jumper . Then the room thermostat is connected in the required order and a test switch is performed.

If the device operates normally, close the lid and proceed to further operation of the boiler with additional equipment. If problems are found, they are corrected immediately.

IMPORTANT!

Detailed instructions for connecting a room thermostat are available both on the device itself and in the user manual for the boiler. Under no circumstances should you act at random.

Error codes and malfunctions of the gas boiler Proterm Gepard

If you encounter problems when operating a gas boiler, a self-diagnosis system will help you. The built-in controller detects problems in the operation of equipment components and displays an error code for the Proterm Cheetah boiler on the display. Decoding the code indicates where to look for a fault and how to repair the device yourself.

Models

The most interesting models of the brand are:

"Cheetah"

This model of a dual-circuit type gas unit can be classified as a product with an affordable price. On the market you can easily find 2 popular modifications of the model - one with a conventional type of exhaust of fuel combustion products (MOV) and the second with a forced-type exhaust (MTV). There is control of the product by an internal temperature sensor or a special temperature sensor placed outside. The design includes an LCD screen, which controls the operation of the device. It does not need to be connected to a chimney, since the product has a coaxial type smoke removal system, where a chimney is not needed at all. The heat exchanger is made of steel; a separate sensor will monitor the pressure level in the entire system. Installation method: on the wall. The installation was made for heating residential buildings and heating water. Depending on the size of the building, you can choose one of 2 devices – 24 kW or 28 kW.

A low price and increased efficiency of 94% distinguish this model, while the consumption of combustible material will be very small. It has 2 operating modes: “economy” and “comfort”. Built-in electronics will provide automatic ignition. The unit is equipped with a 3-stage circulation pump, there is frost protection when the temperature drops by more than 5 degrees.

A wide range will allow you to choose a device from 6 kW to 18 kW. The electric boiler has a special power control system, operates quite quietly, and is suitable for heating oversized rooms. The installation is single-circuit, ideal for heating residential areas, efficiency up to 98%, must be connected to a 220 V network. Due to such an impressive number of functions, the device has the ability to control the system from a distance.

"Bear" 40 KLOM

This is one of the most popular models in the series of cast iron units, like the KLOM 20, 30, 40 and 50 products. This device is quite often used together with a device that runs on solid fuel, as a secondary heating device. Efficiency approximately 92%. The “Bear” modification has a separate 40 KLZ line; this device has a large 90-liter boiler; in addition, it is possible to replace individual sections in order to significantly reduce costs that may be associated with repair work.

"Panther"

It is used for heating office premises, residential buildings and providing them with heated water. There are models with a sealed or open combustion chamber. Water heating is 13-15 liters per minute, the largest heated space is 260 m2. The product can operate with a low level of pressure, it has high-quality frost protection and an increased degree of safety. Using the screen you can control the entire operation of the device. The design includes 2 heat exchangers, the first to create heat, the second to heat water. There is a special “comfort” mode; when it is connected, heated water flows from the tap in just a couple of seconds. Built-in self-diagnosis system.

"Jaguar"

The model is considered one of the most affordable gas boilers for heating small city apartments or suburban residential buildings. You can choose one of two options with a power of 11 kW or 24 kW; the device heats 10 liters of water in one minute. There is self-modulation of the flame, autonomous operation of 2 circuits is possible.

"Leopard"

According to the structure, the Leopard unit is a double-circuit unit with a bithermic copper heat exchanger and is placed on the wall. Two circuits allow this device not only to heat rooms, but also to heat water for domestic needs. This will help equipment owners save significantly on the purchase and installation of boilers, because this unit already has an excellent heat exchanger. Leopard products can be produced with both closed and open combustion chambers.

The power of Leopard installations varies from 9 kW to 23 kW. These installations can be with a traditional chimney or a turbocharged one. Since these products are quite compact, extremely affordable and completely safe, they are actively used in private households.

This is an excellent solution for heating country cottages, ordinary houses and apartments, as well as oversized warehouses and other buildings.