Gas equipment from the Vaillant brand, designed for heating systems, has a lot of significant advantages. Among them, the leaders are high-quality assembly and the use of reliable components that ensure proper operation. However, the resource of any equipment is not unlimited, and non-compliance with the rules does not have the best effect on the condition of the unit.

Even the most trouble-free devices gradually wear out and become unusable. You will find everything about how Vaillant gas boilers are repaired in our article. We will tell you how to identify the violation, identify the coding error and eliminate the cause of the breakdown.

You will receive detailed information about all types of damage and malfunctions that occur with heating devices bearing the Vaillant logo. You will learn how to distinguish information about the condition of the boiler from information about brewing or already formed defects. Our recommendations will help with preventive maintenance.

What malfunctions can occur in Vailant boilers?

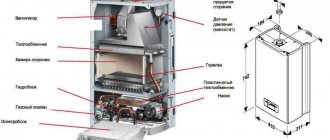

Malfunctions of the Vailant gas double-circuit wall-mounted boiler are divided into several groups, due to the occurrence of problems.

Groups:

- improper installation and operation;

- lack of prevention;

- breakdown of parts;

- failure of the electronic system.

If necessary, all problems can be resolved very quickly. To do this, it is enough to know the main malfunctions and error codes, which will be reflected on the electronic display.

Important! In the absence of the required experience, full-fledged repairs should be carried out by a specialist who will immediately identify the cause of the incorrect operation and eliminate it.

Vailant double-circuit wall-mounted gas boilers have several common problems:

- Error F22 – lack of water or insufficient water for operation. Eliminated by checking the pump, which may jam. You will also need to check the cable connection to the pressure sensor. This error also appears on the display when the circulation level is low.

- Error F28 - the equipment cannot be started. There are many reasons for this error, including incorrect connection or oversaturation with air. Most often it occurs due to improper installation, as well as neglect of the operating instructions. The solution to the problem is to completely check the installation and change the settings.

- F29 – the burner goes out or does not ignite at all. The most common causes include improper grounding and gas supply failure. The gas valve may be damaged or malfunction. In such cases, it is worth initially checking the pressure in the system, as well as the presence of air for ignition.

- F36 – combustion product exits the system into the room. Usually the source of the problem is poor ventilation or poor draft. In addition, such a failure occurs at elevated room temperatures.

- F75 – pressure does not increase, while the pump is running. This situation can occur if the pump or pressure sensors break down. In addition, air may accidentally enter the system or the expansion tank may not be connected correctly.

Important! When installing equipment, diagnostics should be carried out by a specialist or a person with experience, as this will help avoid most mistakes.

During installation, preliminary diagnostics must be carried out to identify all problems. This procedure is mandatory. Most problems are due to improper installation and operation. In addition, breakdowns are also more likely to occur under such conditions.

It is worth considering that problems can be caused by a variety of reasons, including mechanical damage or a failure in the electronic control system. Most problems will not appear with annual maintenance and proper operation.

It is also worth considering that in case of a number of breakdowns, the electronic scoreboard will not work. For each specific case, a different method of eliminating the negative factor is used. If you do not understand what the problem is, then it is better to contact specialists who will fix the problem without additional damage to the equipment.

You might be interested >> Description of the Proterm floor-standing gas boiler

Causes of error f75 Vaillant

Bypass valve

Its task is to protect the circulation pump mechanism from powerful hydraulic shocks. The valve has a spring, and in case of contamination it does not completely close the channel (half-open position). When the pump starts operating, the relay does not respond to a surge in pressure, which leads to error f75 Vaillant. There may also be deposits in the bypass itself: check, rinse.

Vaillant bypass valve

Expansion tank

Few people associate the correct operation of this device with error f75. But if the special tank is periodically not properly maintained, the pressure in the air chamber is below normal, it becomes one of the reasons for the appearance of such a fault code.

Rubber rubber gradually loses its elasticity, and deposits deposited from the system accumulate in the container body. The direct connection of the expansion tank with the hydraulic circuit of the boiler leads to the fact that part of the dirt gets into the Vaillant, to the pump.

The device of a closed expansion tank

Advice

Strainer

Vaillant boilers have a miniature cleaning element installed in front of the pressure sensor to protect its cavity from sediment. During maintenance, it must be changed annually, like any consumable. Gradual contamination of the mesh leads to the fact that the sensor does not respond to changes in pressure in the pipe, and the automation periodically issues error f75.

Vaillant boiler strainer

Pump

To accurately diagnose the condition, it should be removed from the Vaillant boiler. Error f75 indicates no shaft rotation or low speed. The result is the same - there is no coolant circulation or it is weak, and the sensor does not detect this. Testing the pump is quite simple.

Electrical part

Vaillant circulation pump wires are damaged

Mechanical part

Since error f75 is caused by a small pressure surge, it means that the operating Vaillant boiler pump does not create the required pressure. There are few reasons.

Salt deposits are removed by cleaning and washing. The damaged impeller is replaced. In service workshops, the functionality of the Vaillant boiler pump can be restored: they always have used products, and it is not difficult to find a replacement for any part. But it’s better to buy a new pump: it’s inexpensive.

Coolant

Many property owners, especially suburban ones, use antifreeze in heating systems. The special liquid loses its original properties over time - in professional slang it is called “rubber”. When the Vaillant boiler is started, the pump pumps the medium, which contains foam. As a result, voids (haverns) and the flow switch simply do not respond to changes in pressure. Hence the f75 error.

What is recommended

Expert advice

There are some expert tips to consider. In particular, a number of tips concern prevention and initial use of the boiler. Recommendations:

- the model must meet the needs of the heating system;

- connection must be made strictly according to the instructions;

- any small deviations from the operating cycle should be checked immediately;

- Before the first operational start, diagnostics must be carried out;

- Equipment installation is carried out by professionals; otherwise, problems may occur during the first operating cycles.

Important! Any type of boiler must receive full maintenance. Otherwise, the work cycle will begin to deteriorate over time.

Most users have questions during operation that only specialists can answer. Also, for every question there is an answer that allows you to solve the problem. Adviсe:

- If there is no response to turning on the water and a set of sounds that come from the equipment itself, it is worth checking the gas supply line, as well as the gas meter.

- When pressure jumps occur due to the expansion tank, you can simply pump it up.

- If the pressure sensor does not work correctly, error F75 appears. To eliminate this, you can simply press the supply tap.

- When switching off the equipment and supplying either hot or cold water, it is worth setting the minimum pressure.

- If there are delays in switching the boiler from one mode to another and sounds that resemble gurgling, it is necessary to pump out excess air.

- In addition to water, you can only use a coolant specially selected for the boiler. There should be no other liquids.

- When the equipment stops completely and the panel goes dark, you need to check the fuses.

- If the flame icon flashes and does not turn on, you need to clean the filters and check the sensors.

- If there is good pressure of cold water, but hot water flows poorly, then you will need to check and replace the heat exchanger.

It is worth considering one more nuance. The factory settings set the maximum value (not always, but often). If you have a smaller area, it is worth reducing the power. This procedure must be carried out after connection during the first diagnosis.

Different error codes may appear on the display, but the problem can be complex. An error is displayed that prevents the equipment from entering operating mode.

Once deficiencies are identified, they must be eliminated. Next, a full inspection of the equipment and configuration is carried out. After this, diagnostics are launched, which should check all modes and capabilities of the boiler.

Only after all the specified procedures can the equipment be put into operation. It is also important to carry out any necessary cleaning after repairs or troubleshooting.

There is an important nuance. If the boiler is not regularly maintained, problems may arise with the filters and the chimney. That is why the maintenance procedure involves not only changing parts, but also completely putting the equipment in order.

Most often, all problems during operation are displayed on the display. These signs are what you need to navigate first.

You might be interested >> Stages of connecting a double-circuit gas boiler

What caused the malfunction

Chimney

Error f33 is often encountered by property owners who do not adhere to the manufacturer’s recommendations for arranging the exhaust duct. Violations of the instructions have a negative impact on traction.

Illiterate design: discrepancy between lengths, pipeline cross-section, route slope angle, number of turns.

Violation of the tightness of the channel is the cause of error f33 of the Vaillant boiler. Check the connections, fix the flaws, and the code will disappear.

Wrong choice of installation location for the condensate collector or its absence.

The wind rose is not taken into account. With such a miscalculation, error f33 of the Vaillant boiler appears regularly when changing direction or gusts. The draft overturns, the unit “blows out”.

Connection of Vaillant to the chimney existing in the house. If the channel ensured stable operation of another boiler, this does not guarantee that the same will happen with Vaillant. When calculating, the type of heating installation and power must be taken into account.

Liquid in the pipe. A frequent case is when the chimney is removed from the building in close proximity to the roof drainage system. Moisture fills the channel, it becomes blocked, the boiler stops with fault code 33.

Error codes in Vailant boilers

The most common errors that appear on the display are F22, 28, 29, 36, 75. But in fact, there are a lot of errors that are displayed on the screen using codes. Most of the codes will not appear even during the entire long-term period of use, but there are several errors that can occur if used incorrectly. These include the following errors:

- F0 or F1 – requires checking the cable and NTC sensor, which controls the temperature;

- F2 – sensor malfunction or cable breakage;

- F5 or F6 - incorrect operation of the sensor, which removes combustion products in a safe way;

- F10 – short circuit on the line;

- F13 – the temperature limit of 130 degrees was exceeded, which led to a failure in the system;

- F32 – poor fan performance.

There can be many errors and codes for them, but everything can be found in the instructions. The Russian-language instructions contain a list of the most common codes. Less common, but still encountered, are the following errors:

- F11 – indicates that the temperature sensor installed in the return line has short-circuited;

- F12 – this type of error appears only if the water heater sensor is short-circuited;

- F15 – a short circuit has occurred in the external exhaust gas sensor;

- F20 - this type of error appears if the overheating sensor is poorly connected or is inoperative. The error indicates the overheating protection has tripped, which occurs in such situations;

- F23 - this code appears if there is not enough coolant in the unit and because of this there is a large difference between the readings of the incoming and return line sensors. To eliminate this problem, it is enough to check the correct connection of the sensors, the performance of the sediment, as well as its condition, since it may be damaged or blocked;

- F24 – insufficient amount of coolant in the boiler itself. In such a situation, the temperature increases sharply. This may occur due to insufficient pressure in the system itself, low pump performance or blockage;

- F61 – the supply of the control signal to the gas valves is disrupted. In such a situation, you need to immediately check the valves or electronics; they may be faulty.

If these and many other errors appear on the device display, you must immediately diagnose it and eliminate all errors in order to prevent its failure.

Error interpretation

There is some confusion in the Vaillant manufacturer's instructions and its interpretation. Regarding error f75, it is said that its causes may be a faulty pressure sensor or circulation pump. At the same time, the same table shows codes f73 and f74. The first indicates a problem in the signal circuit of the flow switch (short circuit, broken wire, poor contact), the second indicates a breakdown of the sensor itself.

Water pressure acts on the sensor membrane, which changes stroke when the pressure changes.

The peculiarity of the Vaillant electronic circuit is that it not only controls the operation of the pump, but also the moment it reaches mode. This is how German units differ from boilers of other brands. If within 20 seconds after start-up there is no pressure jump in the system by 50 bar (that is, normal fluid circulation), the automation regards this as a malfunction of the pumping device and issues an error f75, which blocks the Vaillant boiler.

First steps

Reset. This is done with a button on the Vaillant boiler panel or by turning off/on the power. Error f75 caused by power surge disappears.

Vaillant TEC pro-turbo8 boiler controls. “Troubleshooting” button to reset certain faults.

Diagnostics

Each Vailant boiler has a diagnostic system that is part of the electronic unit. Information about the state of the unit is displayed on the LCD display in the form of a code (including about past errors).

- Check all inlet and outlet connections for leaks (this includes outlets for carbon monoxide, condensate and domestic hot water).

- Check: there are no contaminants in the reduced pressure chamber.

- Check all electrical connections: whether the connectors and plugs are tight.

- Check the condensate drain and siphon for the presence of salt and limestone deposits. If necessary, clean.