What malfunctions can occur in Vailant boilers?

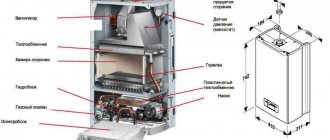

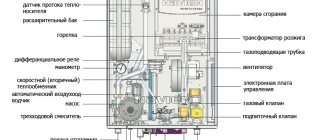

Malfunctions of the Vailant gas double-circuit wall-mounted boiler are divided into several groups, due to the occurrence of problems.

Groups:

- improper installation and operation;

- lack of prevention;

- breakdown of parts;

- failure of the electronic system.

If necessary, all problems can be resolved very quickly. To do this, it is enough to know the main malfunctions and error codes, which will be reflected on the electronic display.

Important! In the absence of the required experience, full-fledged repairs should be carried out by a specialist who will immediately identify the cause of the incorrect operation and eliminate it.

Vailant double-circuit wall-mounted gas boilers have several common problems:

- Error F22 – lack of water or insufficient water for operation. Eliminated by checking the pump, which may jam. You will also need to check the cable connection to the pressure sensor. This error also appears on the display when the circulation level is low.

- Error F28 - the equipment cannot be started. There are many reasons for this error, including incorrect connection or oversaturation with air. Most often it occurs due to improper installation, as well as neglect of the operating instructions. The solution to the problem is to completely check the installation and change the settings.

- F29 – the burner goes out or does not ignite at all. The most common causes include improper grounding and gas supply failure. The gas valve may be damaged or malfunction. In such cases, it is worth initially checking the pressure in the system, as well as the presence of air for ignition.

- F36 – combustion product exits the system into the room. Usually the source of the problem is poor ventilation or poor draft. In addition, such a failure occurs at elevated room temperatures.

- F75 – pressure does not increase, while the pump is running. This situation can occur if the pump or pressure sensors break down. In addition, air may accidentally enter the system or the expansion tank may not be connected correctly.

Important! When installing equipment, diagnostics should be carried out by a specialist or a person with experience, as this will help avoid most mistakes.

During installation, preliminary diagnostics must be carried out to identify all problems. This procedure is mandatory. Most problems are due to improper installation and operation. In addition, breakdowns are also more likely to occur under such conditions.

It is worth considering that problems can be caused by a variety of reasons, including mechanical damage or a failure in the electronic control system. Most problems will not appear with annual maintenance and proper operation.

It is also worth considering that in case of a number of breakdowns, the electronic scoreboard will not work. For each specific case, a different method of eliminating the negative factor is used. If you do not understand what the problem is, then it is better to contact specialists who will fix the problem without additional damage to the equipment.

You might be interested >> The operating principle of a turbocharged gas boiler

Codes that appear most often

Errors that appear on Vailant brand boilers are most often caused by incorrect installation and adjustment work. Thus, in order to adjust the burner and gas valve, it is necessary to use a special gas analyzer. Similar work needs to be done every time F28 appears on the monitor.

The most common types of failures:

- the circulation pump is in poor condition;

- modulation mode stopped;

- the heat exchanger is clogged.

If the setting is performed incorrectly, this will negatively affect the technological mode, which is prescribed by the manufacturer in the attached documentation. All documents are included with the equipment.

Most often the following are in poor condition:

- Gas shut-off valve.

- Control block.

- Igniter.

- Engine.

If an error occurs during boiler operation, information is displayed on the control panel.

Expert advice

There are some expert tips to consider. In particular, a number of tips concern prevention and initial use of the boiler. Recommendations:

- the model must meet the needs of the heating system;

- connection must be made strictly according to the instructions;

- any small deviations from the operating cycle should be checked immediately;

- Before the first operational start, diagnostics must be carried out;

- Equipment installation is carried out by professionals; otherwise, problems may occur during the first operating cycles.

Important! Any type of boiler must receive full maintenance. Otherwise, the work cycle will begin to deteriorate over time.

Most users have questions during operation that only specialists can answer. Also, for every question there is an answer that allows you to solve the problem. Adviсe:

- If there is no response to turning on the water and a set of sounds that come from the equipment itself, it is worth checking the gas supply line, as well as the gas meter.

- When pressure jumps occur due to the expansion tank, you can simply pump it up.

- If the pressure sensor does not work correctly, error F75 appears. To eliminate this, you can simply press the supply tap.

- When switching off the equipment and supplying either hot or cold water, it is worth setting the minimum pressure.

- If there are delays in switching the boiler from one mode to another and sounds that resemble gurgling, it is necessary to pump out excess air.

- In addition to water, you can only use a coolant specially selected for the boiler. There should be no other liquids.

- When the equipment stops completely and the panel goes dark, you need to check the fuses.

- If the flame icon flashes and does not turn on, you need to clean the filters and check the sensors.

- If there is good pressure of cold water, but hot water flows poorly, then you will need to check and replace the heat exchanger.

It is worth considering one more nuance. The factory settings set the maximum value (not always, but often). If you have a smaller area, it is worth reducing the power. This procedure must be carried out after connection during the first diagnosis.

Different error codes may appear on the display, but the problem can be complex. An error is displayed that prevents the equipment from entering operating mode.

Once deficiencies are identified, they must be eliminated. Next, a full inspection of the equipment and configuration is carried out. After this, diagnostics are launched, which should check all modes and capabilities of the boiler.

Only after all the specified procedures can the equipment be put into operation. It is also important to carry out any necessary cleaning after repairs or troubleshooting.

There is an important nuance. If the boiler is not regularly maintained, problems may arise with the filters and the chimney. That is why the maintenance procedure involves not only changing parts, but also completely putting the equipment in order.

Most often, all problems during operation are displayed on the display. These signs are what you need to navigate first.

You might be interested >> Gas double-circuit boiler Buderus

Error f29 appears:

- when the electrode is dirty. Clean it and the fault code will disappear;

- if the position of the sensitive element is violated. The distance from the wire to the metal of the burner is indicated in the instructions. As a rule, for all boilers no more than 8 mm. If the maintenance was carried out carelessly and the sensor is knocked down, error f29 is displayed;

Protherm boiler electrode

Advice

You cannot bend the wire - the metal is fragile and breaks. To change the position of the electrode, the plate is bent.

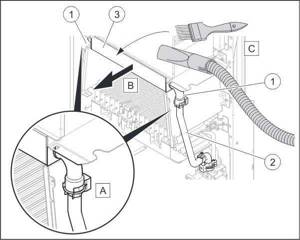

Burner condition

A decrease in gas pressure is caused by clogged nozzles. The combustible mixture does not enter the chamber, the flame dies out, the Proterm boiler stops with error f29. The holes through which the gas passes become clogged with dust and soot falling from the bottom of the heat exchanger housing. You don't need a professional to clean it - it can be done with a toothbrush and a vacuum cleaner. Be careful not to disturb the position of the ionization sensor.

Cleaning the boiler with a brush

Gas valve

The cause of error f29 is incorrect operation of the unit or breakdown. Malfunctions often occur when there are large pressure surges in the gas pipeline; Factory defects are a rare occurrence. Before making a replacement, experienced craftsmen advise cleaning the tube connected to the entrance to the unit (gas supply). It is made of copper, and salt deposits gradually accumulate in the cavity, reducing the pressure (pressure drops) or blocking the channel. Error f29 disappears after cleaning.

Protherm boiler valve

Advice

- Call a professional to replace the valve. Working with gas equipment requires skills, and after installing the unit in the boiler, its pressure setting is checked with a pressure gauge. It is impractical to disassemble the unit to remove dirt from the internal channels - even experienced service technicians will not undertake such work.

- After cleaning the tube, be sure to install a new gasket and check the joint in the traditional way - by soaping - for no leakage of “blue fuel”.

Proterm boilers (gas) are available in several modifications that have design differences. The article provides general recommendations for finding the cause of error f29. If you cannot remove it, contact an authorized service. Be sure to indicate the full name of the heating unit (printed on the nameplate), year of manufacture. A workshop representative will accept your application and at the same time tell you what to check additionally.

Error codes in Vailant boilers

The most common errors that appear on the display are F22, 28, 29, 36, 75. But in fact, there are a lot of errors that are displayed on the screen using codes. Most of the codes will not appear even during the entire long-term period of use, but there are several errors that can occur if used incorrectly. These include the following errors:

- F0 or F1 – requires checking the cable and NTC sensor, which controls the temperature;

- F2 – sensor malfunction or cable breakage;

- F5 or F6 - incorrect operation of the sensor, which removes combustion products in a safe way;

- F10 – short circuit on the line;

- F13 – the temperature limit of 130 degrees was exceeded, which led to a failure in the system;

- F32 – poor fan performance.

There can be many errors and codes for them, but everything can be found in the instructions. The Russian-language instructions contain a list of the most common codes. Less common, but still encountered, are the following errors:

- F11 – indicates that the temperature sensor installed in the return line has short-circuited;

- F12 – this type of error appears only if the water heater sensor is short-circuited;

- F15 – a short circuit has occurred in the external exhaust gas sensor;

- F20 - this type of error appears if the overheating sensor is poorly connected or is inoperative. The error indicates the overheating protection has tripped, which occurs in such situations;

- F23 - this code appears if there is not enough coolant in the unit and because of this there is a large difference between the readings of the incoming and return line sensors. To eliminate this problem, it is enough to check the correct connection of the sensors, the performance of the sediment, as well as its condition, since it may be damaged or blocked;

- F24 – insufficient amount of coolant in the boiler itself. In such a situation, the temperature increases sharply. This may occur due to insufficient pressure in the system itself, low pump performance or blockage;

- F61 – the supply of the control signal to the gas valves is disrupted. In such a situation, you need to immediately check the valves or electronics; they may be faulty.

If these and many other errors appear on the device display, you must immediately diagnose it and eliminate all errors in order to prevent its failure.

Causes of malfunctions

German equipment is designed for operation under normal conditions. European requirements for the quality of power supply, water and gas pressure are very strict, and the boiler operating mode is designed to meet the standard indicators of all systems. However, often the condition of the networks does not meet the requirements, which immediately affects the operation of the boiler.

The main problematic element is grounding - if the electrode is not connected to the circuit, or is missing altogether, the operation of the device becomes impossible. In addition, Vailant boilers are sensitive to supply voltage and react extremely painfully to low (or high) values, fluctuations or supply failures.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

All users are recommended to install a voltage stabilizer, and this must be done before connecting the unit to the network for the first time.

Another problematic factor may be the pressure and purity of the gas. If these indicators do not meet the standards, the operation of the boiler will be constantly interrupted by a self-diagnosis system that detects problems in the fuel supply system. Since the gas line poses a considerable danger, the reaction of the control unit can be quite severe - up to the complete blocking of the boiler.

Other possible malfunctions and ways to eliminate them

Note! Unfortunately, the boiler software does not allow you to detect internal failures in the operation of the board. And although the boiler will not be able to function, violations can sometimes be detected visually

Possible other error codes:

- F49 – bus voltage drop on eBUS due to short circuit.

- F63 – EEPROM, electronic control unit malfunction. If a failure occurs in the medium pressure, check the correct operation of the circulation pump and the condition of the expansion tank.

- F64 – the electronics do not work due to a short circuit in the pressure sensor on the supply or return pipeline.

- F65 – overheating of electronic boards. In case of failure or poor performance of electronic equipment, the software is tested, the condition of the contact groups, the operating parameters of the electrical network, and the functionality of the stabilizer are checked.

- F67 – violation of the burner flame control signal. When alarm signals appear from the burner device or the draft indicator in the firebox, first of all, clean the chimney and condensate drain, which may be clogged with limescale deposits.

Note! Before calling the service center, you can independently press the “Reset fault” button, on which the image of a “fire with a cross” is installed. If the unit does not work, then you should call a certified specialist, especially if the boiler is under warranty service

The arriving specialists will have to diagnose all boiler equipment, which will require disassembling the boiler. Next, the condition of the electrodes and electrical wiring supplying the electronic board will be analyzed, the reliability of the grounding circuit will be tested, and the gas fuel pressure and operation of the valve on the gas line in front of the boiler will be checked.

Boiler heat exchanger

Cleaning the Protherm Gepard heat exchanger

Probable Cause

Broken seam. Such a defect can be eliminated by soldering. The main thing is to find the location of the leak, since it is difficult to detect visually.

Recommendation: remove the Proterm Gepard casing, dismantle the device and block its pipes. When placing the heat exchanger in a tank of water, the problem area is determined by the air bubbles coming out.

Deposits that reduce the diameter of the coolant flow channel. Hence the overheating and error f20.

Recommendation to service the device.

The appearance of the Proterm Cheetah f20 error only in DHW mode indicates a problem with the secondary (plate) heat exchanger.