With the development of private housing construction, serious difficulties emerged with the lack of possibility of connecting centralized heating and hot water networks to some areas.

The problem is not so much the long distances as the deterioration of the highways and their full load, which does not allow the connection of new subscribers.

In addition, housing and communal services tariffs do not suit many users and force them to look for new ways to resolve the issue.

The optimal way is to create an autonomous heating system using a gas boiler as a source of thermal energy.

Let's consider the units of one of the most famous European companies - the Italian company Ferroli.

Ferroli double-circuit gas boilers

Ferroli is an Italian company founded in 1955 and managed to develop from a small workshop into a powerful manufacturing concern of global importance.

One of its activities is the production of gas heating boilers, manufactured using the most advanced technological methods . Double-circuit units have the most complete functionality - they provide heating for the house in parallel with the preparation of hot water for domestic needs.

They are compact, economical and highly efficient. Ferroli constantly conducts scientific and technical research to improve the quality and reliability of its products.

The result was the opportunity to significantly reduce the price of boilers with a slight limitation of functionality, which did not affect performance, but significantly increased demand.

Variety of heating equipment Ferroli

The brand's catalog includes equipment that runs on various types of fuel.

Gas

Wall-mounted gas boiler with a capacity of 60 kW

Ferroli wall-mounted and floor-mounted gas boilers meet European quality and safety standards. The main components of the units are made of corrosion-resistant materials. The burner and pump control are automated. You can regulate processes on the panel screen or from the remote control. Most models have two circuits, which allows you to prepare hot water for domestic needs. The units are available in a wide power range. They are designed for small apartments and spacious housing developments.

The most economical option for heating equipment is a condensing boiler. Its efficiency is 107-109%. The technology helps save energy resources and pollutes the environment less. Despite the many advantages of the technology, it cannot be used in all regions of Russia. This is due to the rules for operating boilers. The difference between indoor and outdoor temperatures should not exceed 20°C. Also, the disadvantages of the models include high cost.

Solid fuel

Non-volatile equipment is produced for domestic and industrial use. It is equipped with mechanical adjustments. Most models are produced with a cast iron combustion chamber. The fuel is coal, wood, and when installing a special burner, pellets. The most popular is the SFL series. When using it, installation of a direct insulated chimney is required.

Universal

The boiler produced by Ferolli, which operates on several types of fuel, is called universal. Equipment with an inflatable burner operates on gas/diesel. These are ATLAS series products. When using it, modifications with weather-dependent control are recommended. Solid fuel/oil boilers of the GF N series have a body protected from heat loss by a layer of insulation. The coolant temperature in the circuit is not lower than 60°C.

Electrical

Ferroli electric boilers heat water using a heating element. Equipment power from 6 to 24 kW. The boilers are compact in design. Control is carried out using the display. It is possible to program a weekly cycle. Models of the LED series can be combined with “warm floors” and an external boiler for hot water supply. The units are connected to a 220 V network.

Advantages and disadvantages

The advantages of Ferroli double-circuit boilers should be considered:

- High quality parts, elements and assemblies manufactured using modern technologies.

- Full functionality of boilers that allows you to heat rooms and provide them with hot water.

- Economical, relatively low gas consumption.

- Stability, stable operating mode.

- Availability of several types of design and functionality of units.

- Wide choice of power.

- Ease of Management.

- Availability of a self-diagnosis system.

- Compact, small size.

- Attractive appearance of the units.

The disadvantages of Ferroli double-circuit boilers are:

- Energy dependence. The need to use a voltage stabilizer and correctly connect the phase electrode. Mandatory grounding.

- Excessively high sensitivity of the electronics, often leading to failure of the expensive control board.

- A combined (bithermal) heat exchanger installed on some models requires the use of softening water filters; replacing it costs almost half the cost of the boiler.

Most of the shortcomings are not an exclusive feature of Ferroli double-circuit boilers and apply equally to all similar models from any manufacturer.

Although this does not reduce their negative value, such shortcomings should be treated as design costs.

IMPORTANT!

You can avoid harmful consequences by installing a voltage stabilizer and a softening water filter. This must be done from the first days of operation of the boiler. As a result, breakdowns and failure of the electronics and heat exchanger can be eliminated.

What types of Ferroli boilers are there?

Mounted condensing

Such devices clearly demonstrate the quality and advantages of Ferroli products. Their efficiency is 109%. The thermal energy of steam generated by gas combustion is used. The heated flue gases provide additional heat, which is used for work, rather than being pushed out into the chimney, as is common in a conventional design. There are single- and double-circuit condensing devices with a closed firebox. Their characteristics:

- Fuel is used economically. Flame modulation. Automatic adjustment of gas supply - depends on the set mode and weather.

- Thanks to the control system, you can set the heating level of your home - taking into account the time of day, a week in advance. Some modifications have outlets for “warm floors”. Automatic adjustment of coolant heating in two circuits - each has its own temperature.

- Dependence on electricity. Due to voltage surges, the microprocessor board burns out. If the network voltage drops, the equipment turns off and you have to turn it on again. This is perhaps the main drawback of Ferroli products.

- Operates at reduced gas pressure.

- The coolant can be water or antifreeze (antifreeze liquid).

Wall mounted with atmospheric burner

The classic design is an open combustion chamber. Air enters the burner from the room - through the natural movement of air masses. The main advantage is structural simplicity. Disadvantages - gas consumption is higher than that of condensing analogues, and productivity is lower.

Installation is no problem. The device is equipped with all the necessary components to ensure the operation of the system - circulation pump, expansion tank, gas valve. Ignition – electric or piezo.

Floor atmospheric

Non-volatile boilers are presented in various modifications, among which the Pegasus models are especially popular, differing from their analogues in the following technical details:

- Heat exchanger made of cast iron. With thermal insulation and shielding.

- By making some changes to the operation of the device, you can use liquefied gas as fuel.

- Some floor-standing versions are equipped with a built-in boiler - after opening the tap, hot water flows immediately, without delay.

- Power consumption is regulated.

- There is self-diagnosis - the display displays encrypted information about breakdowns and malfunctions. Operation and repair of equipment is simplified - once you know the error code, you can immediately find out the nature of the problem and perform the necessary maintenance.

- Safety is ensured by thermostats and a safety valve.

- The device is combined into a single system with all heating equipment. The operation of all devices will be controlled automatically.

- "Pegasus" is equipped additionally - if the buyer wishes, with temperature sensors and a remote control.

Kinds

There are different designs of Ferroli double-circuit boilers, differing in certain characteristics.

By installation type:

- Wall mounted . They are installed either on strong (load-bearing) walls or on a special support system - a ramp.

- Floor-standing. They are installed directly on the floor (or on a stand), so they can have more weight and power.

By heat transfer method:

- Convection . The coolant is heated in the usual way, in the flame of a burner.

- Condensation . Preheating of the OM is used using heat obtained by condensation of water vapor from the exhaust smoke. This allows you to reduce the intensity of the main heating and significantly save fuel.

By type of combustion chamber:

- Open or atmospheric . The air is taken from the room, and the smoke is removed using natural draft.

- Closed (turbocharged) . Air is taken from outside and supplied to the combustion chamber using a special fan. The smoke is removed in the same way, which ensures a stable operating mode independent of external factors.

The choice of the most successful configuration is determined by the needs of the user and operating conditions.

NOTE!

The use of condensing boilers in most regions of Russia is impractical, since the full functionality of the unit can only be achieved if the difference between external and internal temperatures is no more than 20°. This must be kept in mind when purchasing an expensive and useless unit under existing conditions.

Series and models

Ferroli double-circuit boilers are represented by the following series:

- Divabel. Turbocharged boilers with a capacity of 10, 13, 16, 18, 20 and 24 kW. Produced at the company's own enterprises in the Republic of Belarus.

- Fortuna. Atmospheric and turbocharged models with power from 10 to 40 kW. Produced for use in Russia at Chinese production facilities.

- Divaproject. Manufactured in Italy, the series consists of a single turbocharged model producing 24 kW.

- Divatech D. Series produced in Italy. Consists of three models with a power of 24, 32 and 37 kW. There are atmospheric or turbocharged burner options.

- Bluehelix Tech RRT. Condensing boilers with a capacity of 24, 30 and 34 kW.

- Domiproject D. Boilers with an open or closed combustion chamber. Two models with a power of 24 and 32 kW.

- Diva F. Turbocharged boilers equipped with a separate heat exchanger. Power is 11, 13, 16, 20, 24, 28, 32 and 37 kW.

All of the listed series of double-circuit boilers are wall-mounted. Of the floor-standing units, only boilers of the Pegasus DK 130 series, with a power of 30, 40 and 45 kW, are dual-circuit models.

Main series

At Ferroli, each type of gas boiler is represented in several series:

- Wall-mounted. Domina-N, Diva, Divatop Micro, Arena, Domiproject-D and others. Perhaps the most common type. Affordable price and simple design. The most popular is Arena. It has 2 circuits. The primary heat exchanger is copper, the secondary is stainless steel. The kit contains parts from other companies - for example, a valve from Siemens.

- Floor-standing. Atlas and Pegasus in different modifications - 56, 2S, F3N2S, D, DK. Cast iron radiators, with mounted or atmospheric burners. Electric ignition. You can connect a boiler. Reliable protection system - smoke control, various types of sensors, bimetallic indicators.

- Condensation. Econcept Tech, Energy Top and others. Save 30% gas.

Specifications

Let's consider the technical parameters of Ferroli double-circuit boilers:

| Parameter | Meaning |

| Boiler type | Gas heating |

| Functions | Heating and hot water preparation |

| Installation type | Wall-mounted or floor-mounted |

| Fuel type | Natural or liquefied gas |

| Heat exchanger type | Separate or combined (bithermic) |

| Combustion chamber type | Atmospheric or closed |

| Power range | 10-45 kW |

| Life time | Warranty - 2 years, operation - about 10 years |

| Power supply | 220 V 50 Hz |

Floor-standing Ferroli boilers for gas and liquid fuel with forced-air burner

In this category, Ferroli today produces five lines; there are several more discontinued (their technical characteristics are worse than those of the new ones). The units differ in design: the burner unit is located outside and is inserted into a hole specially provided in the door. The performance and technical characteristics of the boiler largely depend on the parameters of the burner, since it is responsible for the complete combustion of the fuel.

ATLAS (“Atlas”) is a cast-iron floor-standing boiler with a cast-iron sectional heat exchanger. It has a three-pass firebox structure: a labyrinth is arranged inside the firebox in such a way that the heated air, before exiting into the chimney, passes through this labyrinth and gives off the maximum amount of heat. This heat is then transferred to the coolant. These models have an analog control panel on which data is set using switches.

ATLAS D boilers have a different power range, a cylindrical firebox with a three-pass chimney duct, other powers, slightly lower efficiency. The control system is digital, the panel is LCD, you can connect a remote control, room and external thermostats, based on the readings of which the automation will regulate the power of the equipment. You can connect an external boiler to heat water (indirect heating) or use the ATLAS DK 100_130 model with a built-in 100 or 130 liter stainless steel tank.

Atlas floor-standing boilers with forced-air burners. Can work with gaseous or liquid fuels

High-power floor-standing cast iron boilers GN2 N and GN4 N also work with forced-air burners using liquid or gaseous fuel (natural or liquefied gas).

The body of the GN2 N units is assembled from several sections, which are connected using special steel pins and bushings. The housing is insulated on top, and a metal casing, painted using powder technology, is installed on top of the insulation. The boiler firebox is reversible, the geometry of the heat exchanger with a large number of fins guarantees high efficiency - above 90%. The updated control panel is located under a hinged lid.

Control panel for floor-standing boilers GN2 N and GN4 N

There is an on/off button, an adjustment thermostat, a thermohydrometer, and a restart thermostat. There is also space for installing an electronic adjustment and control unit.

Powerful boilers for heating private houses, offices, etc.

GN4 N have high power (220-650 kW). This line has a three-pass firebox with cooling. The boiler can operate in a normal or low-temperature circuit; it is possible to install external electronic control and cascade connection.

Today, the Ferroli concern also produces solid fuel and condensing boilers. Moreover, all solid fuel models can be converted into full-fledged pellet boilers by installing a burner, hopper and auger.

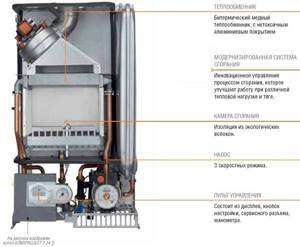

Device

Ferroli double-circuit boilers are designed based on the most efficient designs used in the global heating industry. The main elements are the gas burner, which is located in close proximity to the heat exchanger.

The hot coolant passes into the secondary heat exchanger, where it transfers some heat to prepare hot water.

IMPORTANT!

In models with a bithermal heat exchanger, both processes occur simultaneously.

At the exit from the secondary heat exchanger, the heating agent enters a three-way valve, where the hot and colder return flows are mixed in the required proportion to obtain the desired temperature, after which the liquid is sent to the heating circuit.

All processes are controlled by an electronic control board equipped with an extensive network of sensors.

They form the core of the self-diagnosis system, which constantly monitors the condition of the boiler components.

Owner reviews of Ferroli gas boilers: advantages and disadvantages

| Advantages | Flaws |

| High technical characteristics | Known reliability issues that often raise questions about the viability of the purchase |

| Intuitive and functional controls | Some owners note noise during operation; expensive models do not provide sound insulation |

| Almost a complete set of security systems, the models are also well adapted to domestic conditions | All models are volatile and require connection to an electrical outlet. |

| Low cost, starting from 25 thousand rubles. | According to owner reviews, problems with hot water supply in dual-circuit models are common. |

| A wide range of gas boilers, there are floor and wall-mounted, single-circuit and double-circuit, convection and condensation models with open and closed combustion chambers | Vulnerability of automation to voltage surges |

| Stylish and modern design | |

| Developed service structure, availability of competent specialists in almost all regions |

Connection and setup instructions

Connection and configuration of Ferroli double-circuit boilers must be carried out by specialists from service organizations with appropriate training.

All communications are connected:

- Heating circuit forward and return pipelines.

- Water make-up pipeline.

- Gas pipeline.

- Power supply.

After connecting the communications and checking the tightness of the connections, the boiler parameters are adjusted to the existing operating conditions.

The limits of gas pressure, water pressure, temperature in the heating circuit and DHW are determined. These settings are needed to obtain maximum gas savings .

All other adjustments are made by the user in a routine manner and only concern changing the room temperature or switching the boiler to summer/winter mode.

It is strongly not recommended to independently adjust the boiler parameters in order to avoid losing the warranty agreement and causing the unit to fail..

Download instructions

Download instructions for Ferroli double-circuit gas boilers.

Official website: where to view all models and operating instructions

In Russia, the official website of the manufacturer is located at https://service.ferroli.ru/

By going to the section “Equipment” → “Ferroli boilers” you can see all available models and their descriptions. For each model, in the “Documentation” tab, electronic copies of complete operating, installation and configuration instructions are attached. The manuals for each model describe the characteristics, installation diagram, algorithm for switching on and adjusting the operation, maintenance features, and contain clear schematic images.

Basic faults and main error codes

All malfunctions of Ferroli double-circuit boilers are immediately detected by the self-diagnosis system and displayed on the display as an error code.

The most common ones are:

| Code | Decoding |

| A01 | No flame (ignition attempt failed) |

| A02 | False presence of flame (voltage at the ionization electrode when the burner is off) |

| A03 | Boiler overheating |

| A06 | No flame after ignition cycle |

| A08 | Coolant temperature sensor malfunction |

| A09 | Gas valve malfunction |

| F04 | Smoke thermostat overheating |

| F05 | Smoke removal system failure or fan shutdown |

| F08 | Primary heat exchanger overheating |

| F10 | Break or short circuit of the exhaust temperature sensor |

| F11 | Break or short circuit of the DHW temperature sensor |

| F14 | Malfunction of sensor No. 2 direct line of the heating circuit |

| F34 | The supply voltage has dropped below 180 V |

| F37 | Pressure drop in the heating circuit |

| F40 | Excessive pressure in the heating circuit |

| F47 | Open or short circuit coolant pressure switch |

| F50 | Problems with the control board |

Price range

Prices for wall-mounted double-circuit boilers from Ferroli are in the range of 27-57 thousand rubles. for conventional models, and 40-80 thousand rubles for condensation structures. Floor-standing double-circuit boilers are much more expensive - 130-190 thousand rubles. depending on power and other specific features.

Industrial models can cost up to 5 million rubles, but, strictly speaking, they cannot be classified as dual-circuit models, since they can only work in conjunction with an external indirect heating boiler.

It is recommended to find out prices and the amount of additional costs in advance, since the cost of equipment largely depends on the region, distance from densely populated areas and other features of the area.

Useful video

In this video you will learn the advantages and disadvantages of a Ferroli double-circuit gas boiler:

Wall mounted

Fortuna

The most common dual-circuit model. It has extremely high technical characteristics, efficiency, depending on power, is in the range of 92.4-93.1%, and the maximum gas consumption of the most common version with a power of 24 kW is 2.72 m3/hour. The primary heat exchanger is made of more heat-conducting and corrosion-resistant copper, the secondary (for hot water supply) is made of stainless steel. The boiler implements the previously mentioned secondary heat exchanger preheating system, which significantly reduces the delay in the supply of hot water.

Available in 10, 13, 16, 18, 20, 24, 32 and 40 kW versions. Mostly in demand are modifications with a closed combustion chamber (F), but there are also cheaper and slightly less productive modifications with an open combustion chamber (C). There are also single-circuit models - Fortuna H, but their cost is only 5-10% lower. The production of Fortuna models is now carried out in China, and not in Italy.

We recommend: Stove heating of a private home, device options, how to choose the right stove, photo

Cost: 25,600-34,000 rubles.

Domiproject

An aging two-circuit model, discontinued, but still available in sufficient quantities in warehouses. Due to its obsolescence, it also has a corresponding, extremely affordable price, which is why it is in demand.

It differs from Fortna in being slightly less efficient, with a bithermal (double) heat exchanger, which is cheaper to manufacture, allowing the boiler dimensions to be made more compact, but is extremely difficult to descale. Otherwise, the design is as simple as possible; the most inexpensive materials are used, which, of course, also determines its price. There are versions with a power of 24 and 32 kW.

Cost: 15,800-23,000 rubles.

BLUEHELIX K

A noteworthy condensing model, one of the best and most trouble-free Ferroli gas boilers for heating a private home. The condensation principle of operation implies the presence of another additional heat exchanger that accumulates the heat of condensate formed from waste combustion products. Thus, a significant part of the heat no longer “flies into the pipe”, but is additionally accumulated and sent to heat the heating return line.

Efficiency is 109%, the heat exchanger is made of steel, but is made using a special technology without welding seams, which in theory and even in practice implies its durability.

The main difference is the presence of a built-in 50-liter boiler in the housing, which seriously increases the performance of heating hot water and increases operating comfort. Produced exclusively in Italy, but available only in 25 and 50 kW versions.

Cost: 96,000-125,000 rubles.

Floor-standing

Pegasus D

Single-circuit atmospheric gas boiler, almost problem-free compared to wall-mounted Ferroli models. It features a cast iron heat exchanger that is corrosion resistant and therefore durable. It also has good efficiency indicators - 90.9-91.7% and gas consumption that is simply excellent for an atmospheric floor-standing unit; the maximum natural gas consumption of the 23 kW version is 2.68 m3/hour.

The model has all the safety systems of mounted boilers: protection against overheating, freezing, pump blocking, etc. A safety valve and an air vent are pre-installed from the factory, which facilitates and minimizes the boiler piping. It is possible to connect underfloor heating and external control. Compared to other cast iron analogues, the boiler is quite lightweight - from 106 to 164 kg, which simplifies the requirements for the boiler room floor. Available in 23, 32 and 45 kW versions.

Cost: 60,000-93,500 rubles.

Pegasus 2S

Still the same atmospheric floor-standing boiler unit with a cast iron heat exchanger, with a similar device and technical characteristics, but much more power. Available in versions with a heating capacity of 56, 67, 77, 87, 97 and 107 kW, it is designed for heating large private houses and commercial premises; for its price it has not many analogues.

Unlike the previous Pegasus D, it is equipped only with overheating protection and an air vent; external control can be connected. There is automatic ignition, the burner is two-stage. In general, it is a fairly simple and understandable design.

Cost: 118,000-180,400 rubles.