Foil insulation for floors

The variety of products in construction stores is very large and it is extremely difficult not to get confused among the entire assortment and choose a truly high-quality, effective material, the use of which will not force you to soon redo all the repairs, but, on the contrary, will give you the joy of the fact that it was carried out using high-quality materials .

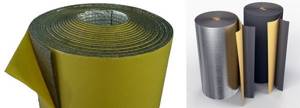

Foil insulation is a relatively new material on the market. Previously, the category of insulation for floors, walls, and roofs was represented by one single type - mineral wool, which had a lot of disadvantages. This material gets wet, and when in contact with water it loses most of its properties. At the same time, working with it was difficult due to unpleasant tactile sensations, and sometimes dangerous.

Foil insulation is a two-layer material, most often supplied in rolls, but is sometimes also found in the form of slabs. Layers are represented:

- directly with insulating material, such as polystyrene foam, polystyrene foam, penofol, etc.;

- foil on a layer of insulation, which has certain heat-reflecting qualities.

On a note! Foil insulation has special properties precisely due to the presence of a foil layer. It has the ability to reflect thermal energy and direct it inside the room, preventing it from escaping outside, strictly limiting the area of heat distribution.

Also, material covered with foil does not get wet, which means it also has certain water-repellent properties, although it cannot be used as a waterproofing coating.

Depending on the type of material from which this type of insulation is made, it can be thick or thin, retain heat worse or better, have pores of different sizes, which contain air in one quantity or another.

Foiled polystyrene foam

Izospan is foil-coated polystyrene foam produced in Russia. Its thickness is minimal when compared with mineral wool. However, thanks to the technical characteristics of the material, it can be easily used in a fairly wide temperature range - from -170 to +170 degrees. Such fluctuations occur quite rarely, so the material serves without any complaints for decades.

Izospan is the most popular insulation material on the domestic market, which is chosen when creating warm floors and thermal insulation of attic spaces. Izospan has the most effective heat reflection.

Properties of foil thermal insulator

Good insulation with a layer of foil has not only heat-insulating properties. It is distinguished by high levels of sound insulation, is not afraid of temperature changes, protects the room from moisture penetration, and has vapor barrier properties.

On a note! A heat insulator with a foil layer is in most cases an environmentally friendly material; it does not harm human health or the environment. It can be safely used in children's rooms, as it is non-toxic.

Foil insulation, especially from the category of materials made from penofol or expanded polystyrene, is resistant to mechanical stress - even heavy furniture can be placed on the floor under which such material is laid. The insulation will not lose its properties even in this case.

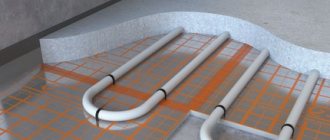

It is especially important to use foil insulation when installing heated floors. It will minimize heat loss, making the room warmer, and the cost of paying utility bills will be significantly reduced. The working insulating layer itself prevents cold air from outside from penetrating into the apartment, and the foil will ensure that heat is retained inside it.

At the same time, installation of foil insulation is very simple and it does not matter whether it is supplied in rolls or slabs. The material is easy to process - in order to cut a piece of a suitable size, you do not need to purchase any complex equipment. It is enough to have any cutting tool with you.

Attention! If no insulation was used during the installation of the floor covering or heated floor system, this is considered a gross mistake and a violation of the material laying technology.

Flaws

Foil products also have some disadvantages. This can usually be explained by insufficiently established manufacturing technology. However, there are several properties of foil products that everyone must know about.

All materials that belong to this group can be divided into two categories: insulation materials on which a metallized film is applied, and products directly with a foil layer.

The unpleasant properties of metallized film include susceptibility to the formation of rust stains. This circumstance imposes certain restrictions on the operating conditions of the insulation. It cannot be installed in rooms with high air humidity.

Insulation materials that have a foil layer do not have this drawback. However, even when purchasing such material, caution should be exercised. This is due to the risk of encountering a low-quality product from an unverified manufacturer. In this case, the foil may not be real. It will have the finest aluminum coating. However, such insulation materials have low heat-shielding abilities.

Advice! To avoid such unpleasant moments, you should buy only high-quality insulation materials. Proven materials include Izover and Izospan. This list also includes Rockwool.

Advantages and disadvantages

The main advantage of any insulation with a foil layer is its technical performance, which is significantly increased compared to similar materials, but without a foil layer. However, due to additional production costs and complicated technology, such a heat insulator is more expensive. In general, foil insulation has a lot of positive qualities.

Advantages of the material:

- sound insulation;

- safety from an ecological point of view in most species;

- resistance to temperature changes;

- moisture resistance;

- easy installation;

- high thermal insulation properties;

- durability.

The disadvantages of the material include softness, which prevents the use of foil insulation when laying some soft types of floor coverings, as well as high cost compared to ordinary thermal insulation materials.

Laying slab material

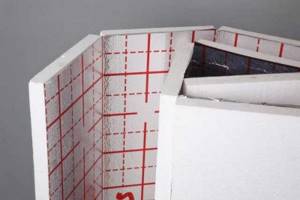

Reflective thermal insulation in slabs

Reflective thermal insulation in slabs is installed primarily under heated floors, although it can also be used as regular insulation. With foil mats, make a floating screed and lay them between the joists.

Floating screed

Step 1. The concrete surface of the floor slabs is leveled using putty and grinding. Clean from dust.

Repairing defects

Step 2. Using a level gauge, mark the screed pouring line on the walls.

Step 3. A damper tape is attached to the walls around the perimeter of the room and the base is primed.

Applying primer

Kermi damper tapes

Step 4. Plates are taken with a metallized coating, since aluminum is corroded by cement. Glue is applied pointwise to the base of the mats, after which the insulation is laid on the floor with the reflective layer facing up. When laying insulation, carefully adjust the joints so that gaps do not form.

Step 5. The joints are taped, and then the heat-insulating layer is filled with screed mortar. Level the mixture with a wide spatula or rule and leave until dry. After this, you can lay the finishing coating.

Video - Laying foil mats

Insulation by joists

Step 1. Remove the floor covering, clear the base of debris, check the integrity of the joists, and, if necessary, repair damaged elements.

Step 2. Place waterproofing material on top of the joists and secure it with a stapler on the inside of the beams, spreading the film well on the floor. The edges of the canvases are overlapped by 10-15 cm.

Step 3. The space between the logs is filled with foil plates, laying them in one or two layers. The slabs of the second layer must overlap the seams of the lower layer. A gap of 1.5-2 cm is left between the reflective coating and the upper edge of the logs. If it is not possible to leave a gap, a sheathing of 20x40 mm slats is placed on top of the logs.

Foil basalt mats

Foil basalt mats

Step 4. Further actions depend on the type of flooring. If it is linoleum or laminate, the rough base is covered with sheet material - plywood, chipboard, OSB. If the floor is made of boards, they are placed directly on the joists.

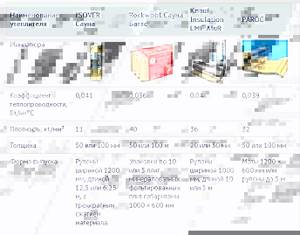

Table of the main properties of foil thermal insulators

| Name | Properties | Thermal conductivity | Where is it used? |

| Izolon | Elastic material, lightweight, waterproof and durable | 0.040 W/mK | As a substrate for laminate and linoleum, mounted under heated floors |

| Penofol | Flexible, thin material, environmentally friendly, waterproof | 0.037-0.049 W/mK | Can be used as a vapor barrier for conventional thermal insulation materials |

| Izover | Non-flammable, dense heat-insulating material | 0.041 W/mK | For insulation of concrete and wooden surfaces |

| Rockwool | Durable, non-flammable material, resistant to deformation | 0.39 W/mK | Insulation of floors on joists, heat and sound insulation of walls and ceilings |

| Foiled polystyrene foam | Resistant to temperature changes, durable | 0.037-0.041 W/mK | For insulating a warm water floor, insulating a floating screed |

How and where to use insulation with foil

Foil insulation can be used on almost all surfaces of the room, depending on its purpose. They are used for laying walls, roofs, ceilings and floors.

On a note! Foil insulation for floors is indispensable in rooms located on the first floors.

Where can foil insulation be used:

- when installing a heated floor system;

- to protect floors from penetration of cold from the basement;

- to ensure thermal insulation of walls;

- when installing a roof in a private house;

- when insulating balconies, loggias, verandas;

- when laying water supply and drainage pipes;

- in baths and saunas in order to preserve thermal energy indoors.

In general, the type and method of using foil insulation depends on the room in which the repair work is being carried out, as well as on the purpose of this room, the properties and microclimate of the building, etc.

Technology of ceiling insulation with foil insulation in a private house

Do-it-yourself attic insulation

And also because our Russians know what a greenhouse is and that every morning in the summer it must be opened. And they don’t realize that the entire living space needs to be ventilated. Dear Rusya is right as always. If you build wisely, like the French builders and use modern, cool materials, then you can build anything for a long time (for 100 years, otherwise why build anything at all). Another reason for my HATE for attics. — For the last 6 years I have been engaged only in roof structures and roofing materials. PS Fortunately, now only one out of three (clients) has to explain what condensate is.

Find out the cost of construction Photos Reviews

- home

- Construction

- Bath

- Cottage

- Pool

- Veranda

- Foundation

- Fence

- Gates

- Roof

- Roof

- Insulation

- Gazebos

- Priming

- Garage

- Brick construction

- Construction of a frame house

- Construction of a bathhouse

- Wooden houses

- SRO

Engineering systems

Warm floor Air conditioners Heating Septic tank Boiler room Chimney Gas supply Electrical installation Water heating Boiler Circulation pump Heating systems Thermostats Water heated floor Well Apartment renovation

Plasterboard ceilings Partitions

How to put foil insulation under laminate

...to properly lay drywall you need... plates...

...in order to lay tiles correctly you need to lay them evenly and cut them...

correct installation of foil insulation on the ceiling

how to properly put foil insulation under drywall

how to attach foil insulation under profiles

Which side should the foil insulation be placed against the wall?

Which side should the foil insulation be placed on the poured floor?

Which side should the foil insulation be placed on the poured floor?

Popular questions

How is the toilet connected?

Hello. I recently moved to a new apartment, and began to make repairs, when I got to the toilet I encountered such a problem as the toilet, I don’t know how to connect it.

How to add an extension to a wooden house with your own hands?

Good day to you. I would like to consult with you regarding the resolution of my case. It consists in obtaining information about such a concept as an extension.

Is a hygienic shower for a bathroom mounted to a regular faucet?

I bought a hygienic shower, but I was only able to purchase a hose and a watering can; a special wall-mounted mixer was not included in the package. I went around several stores, but nowhere.

Buy a house in Vologda?

Hi all! Please tell me through which company it is best to carry out projects and build a private house, and also do landscaping of the yard, and I am also interested.

How to change a country window?

Hello everyone, forum members! I spend a lot of time at the dacha, especially in the summer, almost every day. But for some reason I have one window that constantly lights up and I need to replace it.

Types of foil insulation for floors

In general terms, it is clear what properties a heat insulator with foil has, however, depending on the type of material, they may differ slightly.

Table. Types of foil insulation.

| View | Description |

| It is a rather voluminous and thick sheet of material with a layer of foil on one of the surfaces. It is produced using complex technology, during which individual polystyrene granules are fused into a single whole. This is a very durable material that is not susceptible to rotting and is not afraid of fungus and mold. Does not lose its qualities during sudden temperature changes ranging from -180 to +180 degrees. This material is used only for installing a thermal insulation layer on the floor. Most often - when installing a water heating system. As a rule, it is installed where there is high humidity and significant mechanical impacts on the floor covering are possible. | |

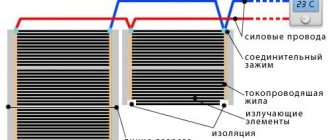

| Rolled material with a thin aluminum coating on one or both sides. The thickness of the heat insulator varies from 2 to 10 mm. It is usually used to insulate floors and walls, sewers or ventilation shafts. Interestingly, foamed polyethylene is also used in the shoe industry - insoles are made from it. It is easy to install, as it is light in weight and is often equipped with an adhesive layer on one side, which makes it easier to attach to surfaces. Technical characteristics: — specific gravity of a coating 5 mm thick – 60 kg/m; — thermal conductivity – 0.038 W/(mK). Foiled polyethylene foam includes penofol, ecofol, isolon and other materials. | |

| A type of insulation familiar to many. Mineral wool with foil is sold in the form of rolls or slabs and is usually used for thermal insulation of roofs, floors in bathhouses and on loggias or balconies. The foil layer is applied only to one side of the material. The thickness of mineral wool can vary from 5 to 10 cm. The base is a basalt slab or fiberglass. Unfortunately, mineral wool is far from being a material that is safe for health, and you should not use such insulation in an apartment. It can cause the development of respiratory tract diseases, as it releases a dangerous substance – phenol – into the air. When installing even in non-residential premises or outside the house, it is recommended to cover it with film. | |

| This type of insulation belongs to the category of materials based on mineral wool. It is not afraid of external environmental factors and can be used in the construction of gas stations, as it is non-flammable and can withstand temperature changes from -200 to +700 degrees without damage. It is also used in the construction of stoves and fireplaces due to its non-flammability. Used for thermal insulation of walls and roofs, floors between floors. |

Most often, penofol (ethylene foam) is used for installing floors. This material, depending on its qualities and characteristics, can be divided into 4 types:

- A – covered with foil on only one side, a classic and familiar material. Rarely used in rooms with high air humidity, but can be installed in such rooms when laying a layer of waterproofing;

- B – has a foil coating on both sides, a very dense type of heat insulator. No additional installation of a moisture-protecting layer is required;

- C – material that has a foil layer on one side and a self-adhesive layer on the other;

- ALP is a heat insulator with one layer of foil, but laminated with polyethylene. Used when installing an electric floor heating system;

- R – one side is embossed, the other is smooth;

- Super NET - among all types, has the maximum thermal insulation performance, can be used for many years and not lose its properties.

Thermal insulation of the floor can also be done using foam plastic covered with foil. It is also used to create the foundation during the construction of a building from scratch. For thermal insulation of floors, a thermal insulation mat can also be used, which has such qualities as high strength, ease of installation, lightness, and convenient fixation on the surface.

On a note! A good insulation material is polypropylene film, which has metal inclusions, due to which heat is evenly distributed over the entire surface of the floor and is retained for a long time.

Tepofol insulation: scope, characteristics, advantages, installation features

In order to save money on heating the home and to create a comfortable microclimate, the building is insulated with insulating material that has low thermal conductivity. A wide range of insulation materials allows you to choose the most optimal option for a specific design.

Among the innovative proposals that deserve attention is Tepofol. The article will discuss the properties and advantages of insulation.

Tepofol is a rolled type of insulation made from polyethylene foam. On one or both sides the canvas is covered with a foil layer (depending on the type of heat insulator). The thickness of the material is available in an assortment (from 2 to 150 mm). Due to its physical properties, Tepofol has the ability to reflect radiation up to 97%, due to which the effectiveness of thermal protection increases.

The new generation heat insulator has a number of advantages, one of which is durability. Tepofol is not subject to shrinkage or abrasion; it retains its properties throughout the operation of the entire building. Therefore, there is no need to plan to replace the heat-protective layer. Real savings on energy resources during the heating season are about 30%.

Manufacturers and prices

When choosing foil insulation, you have to pay attention to its cost, since when finishing rooms with large areas, the cost of the material can be significant.

Table. Cost of different types of insulation with a layer of foil.

| Material | Approximate price, rub. per sq. m. |

| Basalt cotton wool Rockwool 4.8 | 700 |

| Penofol | 100 |

| Izolon, thickness 3 mm | 200 |

| Basalt cotton wool Xotpipe | 100 |

| Porilex | 50 |

| Ecofol | 70 |

Before purchasing insulation, you need to consider several nuances. It is important to evaluate its elasticity, service life, resistance to deformation and thermal conductivity.

Properties and composition

This type of material should be considered as a new solution in the field of thermal insulation. They are an excellent choice when it is necessary to ensure high-quality insulation of the floor covering in a building. Often such products are chosen for insulating ceilings and walls. Its use is widespread in saunas and baths.

Foil insulation is mainly used to insulate floors and walls from the inside.

In appearance, foil insulation resembles a standard thermal insulation material made on the basis of mineral wool or expanded polystyrene. Its only difference is the presence of a layer of aluminum on top. Manufacturers often use metallized polypropylene film instead.

High thermal insulation performance is achieved by reflecting the generated thermal energy into the room. Although foil models are endowed with certain water-repellent properties, they cannot be considered as an effective solution for protecting structures from moisture.

The thickness of the metallized layer, as well as porosity, can be different. Often the material contains granules filled with air in the structure of the slabs. This feature has a positive effect on the thermal conductivity of the product.

This video will help you get acquainted with the characteristics and properties of foil insulation:

Nuances of fastening and installation

When laying foil insulation, you may need the following tools and materials:

- nails with large heads;

- stapler;

- hammer;

- construction tape.

When installing insulation with foil, it is important to avoid the mistake of laying the material with the shiny side down. In this case, the material will not perform its heat-reflecting functions. The foil side must “look” into the room in order to be able to return thermal energy to the room.

Advice! You can leave a small air gap between the insulation and the floor covering. Then the floors will be even warmer.

It is also important to remember that the insulation does not overlap. The sheets should be placed end to end and secured with tape or nails, depending on the type of base. Insulation with an adhesive layer may not be additionally fixed, but it is still recommended to secure it with fastening materials. All joints after laying the material are taped.

Work on laying insulation can be dry or wet. In the second case, the material will be filled with concrete screed. In the first one, it is advisable to install an additional waterproofing layer.

Features of operation

There are several subtleties of installing insulation with a foil surface. For example, when using such materials in living rooms, a ventilation gap is left.

The free space should be about 15-20 cm. This must be done because, as a result of prolonged heating, the aluminum layer begins to transfer the temperature to the back surface.

Heat transfer must occur to the air that exists between the insulation material and the facing surface. In this case, the heat will return to the living room. For this purpose, foil insulation is mounted with a special sheathing.

The overlap of the rows of material should be 15 cm. The connections are glued with a special film that ensures reliable insulation. Knowing these subtleties of installing insulation, you can create reliable insulation of the room.

By installing foil insulation yourself, you can save a lot on thermal insulation of various rooms. You can also reduce costs by choosing a suitable insulator.

Roll material laying technology

Step 1. The material produced in a roll must be laid on a surface cleared of debris. The base is swept, washed if necessary and dried.

Step 2. The insulation is cut into pieces of the required length and size.

Step 3. The material is leveled over the surface of the room.

Step 4. In small rooms, the insulation is attached along the walls and across with wooden blocks. Its individual sheets are glued together with tape.

Step 5. If the floor covering allows it (it is quite dense), then lathing is done on top of the laid insulation. This makes it possible to create an air gap.

Next, the floor is covered with a finishing coating or filled with concrete screed; work is also carried out on the installation of heated floors, if necessary.

Video - Laying roll backing

Insulation with a layer of foil is a good option for high-quality thermal insulation material. It will serve for many years if you choose it correctly in accordance with operating conditions, as well as with proper installation. It’s easy to avoid mistakes; the main thing is to carefully familiarize yourself with all the nuances of using the material.

Classification of insulation

1. Based on the base material of the insulation.

1.1. Foamed polyethylene.

- The most famous foil insulation materials are Izolon, Penofol, Tepofol.

- Low moisture absorption and thermal conductivity.

- Effective noise protection.

- Convenient self-installation. Such thermal insulation is lightweight (thickness from 2 to 10 mm), and the foil can be easily cut with ordinary scissors.

- For any surfaces. It is especially good to use as insulation for walls (when finishing them from the inside), floors (as a substrate for soft finishing materials), as well as pipes. The problem associated with sharp sounds during their resonance will be solved almost completely.

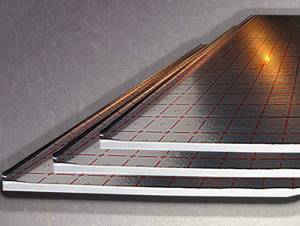

1.2. Foiled polystyrene foam.

- Sufficient mechanical strength.

- Almost zero moisture absorption.

- The temperature range at which the insulation does not change its characteristics is within ± 180°C.

The material is slab, therefore it is used mainly for floors when installing artificial heating or before plastering walls (with additional mesh reinforcement). The organization of wall insulation under siding is complicated by the exact dimensions of the slabs. You will have to reliably seal the joints between them and the edges of the sheathing cells. But taking into account minimal moisture absorption, foil is a good option as insulation for a sauna. The main thing is to correctly mount the supporting frame under the siding, maintaining its geometry over the entire area.

1.3. Foil basalt thermal insulation.

- Inertness to aggressive substances.

- Resistant to temperatures over a wide range – from -180 to +690°C.

- Ecological cleanliness.

- Elasticity.

This thermal insulation refers to rolled products, therefore it is used in the case of finishing ceilings or walls with siding. Often purchased for insulating baths, primarily steam rooms.

2. According to the linear dimensions of insulation with foil.

The categorization here is simple. The materials can be either in the form of mats (roll products) or slabs. A separate group includes products designed specifically for pipes, for example, Roxwool. They are designed for a certain diameter and are placed on the route, forming a protective “shell”.

3. According to the location of the foil.

- On the one side.

- From two.

4. According to the specifics of installation.

- With additional fastening on the base. This insulation is installed under the siding.

- Self-adhesive.

This is a general overview of foil insulation. Recently, the construction of bathhouses has been underway in the private sector (in summer cottages, local areas). And the question immediately arises - what exactly to buy for high-quality insulation? So that the cost does not “bite”, and the efficiency is high.

For lovers of bath procedures we can recommend Isover Sauna. What's good about it? This is cotton wool, the fibers of which consist of polymers. The foil is attached not to the base, but to a mesh covering the entire material. This ensures not only high-quality insulation, but also good vapor permeability of the walls. The dimensions of the canvases are standard, width - 1.2 m. Today - the best foil thermal insulation for saunas and baths.

Installation specifics

1. The most common question asked by “home craftsmen” when using this thermal insulation is which side should the foil insulation be placed on the walls? If we take into account that the main purpose of the metallized coating is to prevent IR rays from “escaping” the room, then it becomes clear that, regardless of the specifics of installation (under siding, plaster), the reflective layer should be facing inward.

2. In the event that for a number of reasons (climate features, location of the building, or other) the temperature inside during the warm season rises significantly, materials with foil applied on both sides should be used for insulation. They will ensure a constant microclimate in the house both in winter and summer, as they simultaneously reduce heat loss and prevent the penetration of infrared radiation from the outside.

https://youtube.com/watch?v=N233cxHH5Iw

Price

Prices mainly depend on the following factors: dimensions (including thickness) of thermal insulation, type of foil and specific application.

| Name | The basis | Type | What is recommended to insulate? | D | Thickness, mm | Roll, m2 | Retail price |

| rub/rul | rub/l.m. | ||||||

| Penofol | PE foamed | unilateral | walls, ceiling, floors | 3 | 30 | 790 | |

| 5 | 850 | ||||||

| 10 | 18 | 950 | |||||

| female-leeching | 3 | 2580 | |||||

| 5 | 2780 | ||||||

| 10 | 9 | 2300 | |||||

| double-sided foiling | 3 | 30 | 2990 | ||||

| 5 | 2590 | ||||||

| 10 | 18 | 2310 | |||||

| Izolon | one-sided | from 226 RUR/m2 | |||||

| Izover | fiberglass | baths, saunas | from 110 rub/m2 | ||||

| ROCKWOOL | stone wool | pipes | 18 | 30 | 134 | ||

| 21 | 137 |

*Applicable to the Moscow region.

Foil polyethylene foam ↑

Their density is slightly higher. Moreover, when the dynamic impact stops, the material “tries” to restore its original shape.

Areas of use ↑

Insulation of the concrete base

The insulation technology is similar to the previous one. But only in this case the self-adhesive foil thermal material is not used:

- We carefully prepare the concrete rough base: we fill cracks, holes and chips, clean, prime, and dry.

- We take measurements and lay the rolled foil material. We use ordinary stationery scissors to cut the strip to the required length.

- To prevent the insulation from slipping while laying the finishing coating, we fix it with rubber or acrylic glue.

- We lay the strips end to end and seal the seams with foil tape.

- If the concrete floor is too cold (for example, a loggia, balcony), then we additionally install logs on top, fill the voids with basalt wool or expanded clay, cover them with moisture-resistant plywood or stuff boards.

- We install the finishing coating.

Using suitable foil insulation for the floor is the best option to furnish your own home. Despite the fact that it costs more than other materials, such expenses are fully justified: there is no need to do unnecessary work, which will save not only time, but also finances.

Foil mineral wool ↑

Mineral wool itself already has very high thermal insulation characteristics. Foil, firstly, further increases the efficiency of insulation, and secondly, it is an additional way to protect hygroscopic material from the penetration of excess moisture and steam, which could have an extremely negative impact on its performance.

The material is sold in the form of compressed rolls, sectional or individual slabs, cylinders and half-cylinders.

Application ↑

Advantages and disadvantages

When choosing foil insulation, you should pay attention that its coating is made of aluminum. The main advantages of thermal insulation with foil are:

- high levels of noise insulation;

- environmental Safety. Their use for insulating surfaces in residential premises does not harm human health;

- resistance to temperature changes. They are insensitive to moisture;

- simple installation procedure;

- have high thermal insulation properties;

- have a long service life.

One of the disadvantages is their softness. This imposes certain restrictions on the list of finishing materials that can be used in conjunction with them. Another disadvantage is the high cost, so thermal insulation work will require serious expenses, even if the owner of the property does it himself.

Foiled from polystyrene foam ↑

This is a durable thermoplastic obtained by fusing polystyrene granules with aluminum foil on one side. This is a strong material that is resistant to significant mechanical stress and high humidity. It does not rot and is biologically stable. Retains its characteristics in the temperature range from -180˚ to 180˚.

The material is often used when laying heated floors. To facilitate this process, markings are applied to the slabs at the factory. When laying insulation, a layer of foil reflects the heat flow upward, warming up the finish coating.

What is foil insulation and how to install it inside the house

- Specifics of the material

- Varieties

Do-it-yourself insulation of a pile-screw foundation

Features of installation on vertical surfaces What to pay attention to

Specification of reflective thermal insulation

Modern technical solutions allow manufacturers to apply foil coatings to a wide variety of components. This contributes to a comprehensive increase in the heat-saving characteristics of even traditional materials used in construction. Let's consider which insulation materials most often serve as the basis for foil and what parameters they have:

- mineral wool and basalt wool are fireproof, environmentally friendly, resistant to any aggressive chemical influences; Available in slabs and rolls;

- expanded polystyrene - lightweight, mainly used for thermal insulation of floors;

- foamed polyethylene - the thinnest material, produced in rolls 2-10 mm thick; widely used for insulation of housing structures.

Although some craftsmen recommend using this material for outdoor work, it is often used indoors. The foil creates the effect of almost uniform heat distribution, acting on the principle of the so-called “thermal mirror”. This allows the use of such insulation in both industrial and private construction.

Application of polyethylene foam with foil coating

Not everyone knows what polyethylene-based foil insulation can be used for and how to install it inside a building. It is used in the following cases:

- thermal insulating screen for heating radiators;

- thermal insulation of floors;

- noise and heat insulation of pipelines and air ducts;

- thermal insulation of bath rooms;

- noise, hydro and heat insulation of roofs and walls.

Ease of installation and affordable price attract many who want to save on heating. When working on complex shapes of metal structures, self-adhesive material is used, which has high adhesion.

The use of insulation based on basalt wool

The industry produces this insulation in the form of mats, rolls or sheets. Most often, wool is installed to minimize heat loss on roofs and walls. Anyone who was interested in how to insulate their own home from the inside in the video could not help but notice that this material is especially valued when insulating baths. The following qualities of foil-coated basalt wool should be noted:

- high fire safety;

- strength;

- durability;

- resistance to various chemical influences.

Recommended video on the topic “How to insulate a house from the inside with foil insulation”:

https://youtube.com/watch?v=lJpeX_rfMxM

Installation on vertical surfaces

Installing a flexible and lightweight material based on polyethylene or foam on the wall is not difficult and can be done independently, just follow the following scheme:

- clean the wall surface from old coating or dust;

- treat the wall with an antiseptic and let it dry;

- glue the thermal insulation to the wall, with foil inside the room;

- make lathing for finishing.

As an option, you can assemble a wooden sheathing on which to secure the thermal insulation using a stapler. The next step will be the installation of the second sheathing for laying the exterior trim.

How to lay foil insulation inside the house: what to PAY ATTENTION to

Let's consider several important points that must be adhered to when working with insulating materials covered with metal foil.

It was already noted above that the reflective surface must be directed inward - this is a prerequisite! Otherwise, the whole meaning of such operations is lost. The connection must be made at the joint, and the joint itself must be glued with metal tape.

The next point is to make the foil insulation “work”: how to lay the sheathing for this? To obtain the expected result, an air gap of 15-20 mm is required between the finishing and the thermal insulation - only in this way will it be possible to retain heat as much as possible.

Regarding the question of how to secure the insulation. For materials that have a one-sided coating, it is quite possible to get by with polyurethane foam, sealant or double-sided tape. It is allowed to use adhesive based on acrylic or rubber (for example, Neoprene 2136, 88-NP, Acrol contact). The glue must be applied pointwise.

When choosing the type of foil, you need to take into account the conditions of its further operation. Polymer metallization on the insulation is not susceptible to the aggressive alkaline environment of concrete, so this option is best suited for organizing heated floors

Aluminum foil will simply collapse in such conditions; it will retain heat well if it is laid on the roof.

Application

Foil insulator can be used everywhere:

- for thermal insulation of ventilation air ducts, wells, wells;

- lining of pipelines (water supply, gas outlet, heating, etc.);

- for the purpose of reflecting heat emanating from heating radiators and other devices;

- when installing heated floors;

- to reduce heat loss in the room (installation on walls, floors, roofs).

It is advisable to use foil material when insulating the attic, roof ceiling and other internal surfaces of the building. The insulator operates in bathhouses, steam rooms, garages and other outbuildings. It is used for brooders and incubators and is used in crop production for growing seedlings.

The scope of application of foil insulation can be called unlimited due to its high performance qualities.

When choosing, it is recommended to take into account not only its cost, but also the following factors:

- All types of foil insulation have excellent noise-absorbing qualities, vapor and waterproofing properties.

- To reduce heat loss through the floor, preference should be given to a base made of solid polystyrene foam blocks.

- When finishing a bath/sauna, glass wool material is often used.

- A self-adhesive insulator will help create a reflective effect from radiators and batteries.