Good thermal insulation of a country house will not be superfluous in any case - whether you live in the country all year round or come only for the summer season. Equipped insulation makes staying in the home more comfortable at any time of the year. It also protects your home from excessive humidity and other external factors that can accelerate the process of destruction of the structure.

Expert opinion

Konstantin Alexandrovich

You need to start from the foundation. If the floors in the house are cold, heating will take a lot of time and energy. So, let's look at insulating the floor in a dacha without removing the old floor, and options if there is no subfloor.

Selection of materials for thermal insulation

The choice of building materials used for insulation work is varied. In addition to modern ones, traditional materials, which have long become familiar and have proven themselves well, are not losing ground among summer residents.

Expanded clay

The granules are lightweight and contain many pores that effectively retain heat. The material is not susceptible to attacks by rodents and insects and has a high level of environmental friendliness. In order for the thermal insulation layer to work with maximum efficiency, its thickness should be about 30 centimeters. In addition, the insulator must be reliably protected from possible exposure to moisture.

Sawdust and wood shavings

Natural material is quite inexpensive, and you can purchase it from any wood processing company. The shavings have excellent heat insulating properties, but are too susceptible to moisture and must be protected from water penetration.

Slag

This method of insulation can be implemented directly on top of the ground. Like many others, it requires waterproofing. The material has a significant service life, is not subject to fire and does not attract rodents.

Glass wool

Fiberglass-based wool has an affordable price, effectively insulates heat and muffles extraneous sounds. Not susceptible to damage by biological organisms. Among the disadvantages, we can note the likelihood of a decrease in the initial volume during operation and the need to use personal protective equipment when working with it. The latter is due to the fact that the fibers of the material are thin and easily damaged. They create an invisible suspension in the air, which can irritate the skin layer and mucous membranes of the respiratory tract.

Styrofoam

Very easy to install and resistant to moisture. Its service life is very long, but only if there are complete absence of rodents. Rats and mice have a particular weakness for this material and easily damage it.

Extruded polystyrene foam (EPS) or penoplex

Penoplex is available in a convenient slab format. They are resistant to moisture, are not afraid of temperature fluctuations, and do not freeze. The material is distinguished by high density, due to which its shape remains unchanged throughout its entire service life. The insulation is lightweight and has convenient locks to improve the quality of installation. Installing it is not difficult at all.

Penoizol

This type of insulation is applied to the floor surface without disassembling it, by spraying. The result is a seamless, high-density layer that actively resists the influence of external factors. The structure of the insulation consists of many pores, which reduces the level of loads on the building structure. Penoizol is ideal for thermal insulation of second floor floors, attics or attics. A significant drawback is the inaccessibility of applying the insulator yourself.

Ecowool

The insulation consists largely of cellulose fibers, and its thermal conductivity coefficient is very low. Ecowool is highly environmentally friendly and has excellent noise insulation properties. Installation of insulation into the space under the floor is carried out using a specialized installation.

Vermiculite

One of the types of insulation materials that have a loose form. Its structure consists of grains with scales. The weight of such material is less than that of expanded clay, and its sound-proofing and heat-insulating properties, on the contrary, are higher. If you compare it with mineral wool or extruded polystyrene foam, it turns out that vermiculite is not affected by microbes and biological organisms and is not interesting to rodents.

Warm floors are the key to health

Insulating “pie”

The need for insulation in a dacha can be caused by several reasons. Basically, this correlates with the forced decision to spend a year or two at the dacha, when there are problems with housing and arrangement.

Therefore, for a family, especially those with small children, the issue of insulation is not just a functional component for comfortable living, but also an opportunity to avoid health problems.

Therefore, due attention should be paid to floor insulation. This includes issues of thermal insulation, quality of finishing materials and flooring. Typically, in country houses, the floors are made of single-layer material and, as a rule, they are wooden

Typically, in country houses, the floors are made of single-layer material and, as a rule, they are wooden.

It is worth noting that wood itself can be an additional thermal insulation material. This also applies to linoleum, parquet boards or laminate.

To make the floor warmer, a layer of fiberboard or chipboard is laid underneath. But for better and more significant thermal insulation, you will have to make a lath. It is installed between the joists, and a layer of insulation is laid on top.

What is the best way to insulate a roof in a dacha?

In the process of insulating floors, it is important to use only high-quality materials, the characteristics of which include moisture resistance and reliability, light weight, strength and durability, low degree of thermal conductivity

And, of course, the materials used should not cause installation difficulties

Then your dacha will quickly be transformed and will have a heated floor.

And, of course, the materials used should not cause installation difficulties. Then your dacha will quickly be transformed and will have a heated floor.

Foam insulation

Suitable insulation materials:

- extruded polystyrene foam;

- expanded polystyrene or polyurethane foam;

- perlite

- Styrofoam;

- basalt wool;

- technical jam

- porous expanded clay;

- mineral wool.

All these materials certainly have a certain function. Basalt wool helps to cope with temperature changes; it does not have flammable properties and is quite durable.

Technical cork is characterized by a high degree of environmental friendliness, but this material is quite expensive.

As for mineral wool, it is quite popular today, as it has excellent thermal insulation properties.

It is also able to repel water well. Therefore, you can purchase this material in almost any hardware store, and it is sold both in the form of flexible mats and in the form of solid slabs.

Extruded polystyrene foam has a long service life and low thermal conductivity coefficient. Therefore, this type of material is often used in underfloor heating systems.

Laying insulation

Laying insulation

Choosing insulation for a country floor can sometimes be difficult. After all, he must:

- be light;

- retains heat well;

- do not absorb moisture;

- Mice don't like it.

The insulation is laid close to the joists.

Common options - polystyrene foam and mineral wool - do not fully satisfy these requirements. The first serves as a home for mice and is not entirely harmless. The second tends to accumulate moisture, which spoils the wooden elements of the floor. There is an alternative to these materials. This is expanded clay, glass wool, wood concrete - here it is a fairly loose wet mixture of cement and old sawdust.

Arbolite - wood concrete

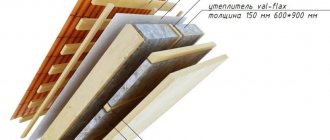

But no matter what kind of insulation is laid on the floor, the principle remains the same. A “pie” is formed, each layer of which serves a specific purpose.

- A membrane layer is laid on the subfloor to protect against steam from below.

- Insulation is placed tightly between the joists. All cracks in the insulation layer are carefully sealed, most often with construction foam. Check for a gap between the top edge of the joist and the top of the insulation; the insulation should lie slightly lower. If this condition is not met, additional bars will have to be placed on the joists.

- The entire floor overlaps the walls with a layer of vapor barrier to protect against steam penetrating from the room.

Laying wood concrete mixture

If everything is done exactly this way, the insulation will be carried out properly. The bottom membrane layer cannot be replaced with a completely waterproofing film layer. If you do this, moisture will gradually be absorbed into the insulation. It is especially dangerous to spill something on the floor, because the liquid will have nowhere to go. The only thing that can replace the bottom vapor barrier is cardboard or paper.

Thermal insulation in the case of a low underground

This technology is the most labor-intensive, since it involves dismantling the old flooring. This is due to the limited size of the underground space, which does not allow the thermal insulation material to be secured to the joists from below.

The steps themselves are as follows:

- The plinth and floorboards are carefully dismantled. Along the way, it’s worth labeling each element of the “mosaic” so that you don’t mess everything up when reassembling it.

- Inspect all joists for integrity. If necessary, all problem areas should be cut out and instead of damaged elements, solid beams of equal size should be installed. The extension is made using boards that are attached to the left and right sides of the joists. Use galvanized screws as fasteners (for obvious reasons).

- A cranial block is attached to the lower edge of each joist and the same on both sides. This will serve as support for the subfloor.

- In accordance with the distance between the logs, lumber is prepared, which will be used to form the rough flooring. In this case, the length of each section of the board should be 10-20 mm shorter than the step for installing the logs. Thanks to this, the flooring parts will be laid freely, but this will not interfere with the subsequent insulation of the subfloor.

- Now the actual formation of the subfloor is the laying of the prepared boards.

It is not recommended to join them tightly to each other, otherwise, due to the characteristic movements of the wood, mounds and steps will form.

Insulation options

In a country house, floor insulation is most often done in one of two possible ways:

- by lags;

- on a concrete base.

The first method is applicable for both wooden and concrete floors. It has one significant advantage: there is no load on the insulation, which allows you to choose any option.

When choosing the second method, serious pressure will be applied to the material designated as insulation, which imposes a number of restrictions on it; it must be strong and dense.

Optimal insulation for wooden floors

There is no point in discussing the best material for thermal insulation of a wooden floor. Almost everything is applicable, from grandfather’s dry leaves to expensive vermiculite. Floors in wooden houses are insulated using loose thermal insulation options, mats and slabs.

Since the list of requirements for any insulation consistently includes lightness, minimal water permeability, durability, and operational safety, all these qualities are quite satisfactory for builders and owners of wooden houses.

The choice mainly depends on the financial capabilities of the owner, the type of base and the method of installation. Owners who are not limited in funds will be able to purchase progressive, easy-to-install materials with detailed instructions on how to insulate the floor in a private house without the involvement of builders and with an accurate indication of the thermal properties of the factory product on the packaging. If you want to save money, you will have to tinker a lot with traditional insulation schemes.

Insulation for thrifty owners

Independent home craftsmen who do not want or do not have the opportunity to invest significant sums in insulation can use the following as a heat insulator:

- dry sawdust, which pleases with a minimal price, but requires reliable waterproofing on both sides of the insulating layer due to the tendency of the material to actively absorb moisture;

- sawdust granules, which are a more practical option, treated with an antiseptic and fire retardant;

- slag, which attracts cost, but is used primarily in floor insulation schemes on the ground;

- expanded clay, used to create a heat-insulating layer of considerable thickness, since its optimal thickness for our latitudes is considered to be 30 cm;

- simple mineral wool without foil and corrugated shells that increase thermal performance;

- roll insulation, created on the basis of glass fibers, slag wool;

- polystyrene foam, which requires measures to protect it from the encroachment of rodents and from fires.

If you follow the rules for installing thermal insulation using the listed materials, heat leakage through the lower ceiling will be eliminated. However, laying them will require impressive labor efforts.

Modernized, expensive insulation materials

If the owner of a country property does not have the main task of how to insulate the floor in a wooden house at low cost, then he has at his disposal:

- Vermiculite is a product of processing hydrated mica, which has excellent insulating qualities and long service life;

- Penoplex is extruded polystyrene foam produced in slab format with increased strength and excellent waterproofing properties;

- Various modifications of insulation with the brands Ursa, Thermolife, Isovent, Penofol, Izolyte, etc., which are mats and slabs with bases made of foamed polystyrene, glass wool and a basalt analogue, optimized by increasing wear resistance, minimizing water permeability, applying foil shells to reflect back heat rays and other methods.

In case of minor heat leaks, you can insulate a wooden floor with ecowool or polyurethane foam, but without special equipment it is impossible to blow in these materials.

This is a significant disadvantage, but the advantage is the creation of a dense water-repellent insulation layer that does not require a device to protect the insulation from steam.

Insulation of concrete floor

Concrete floors are renowned for their strength and durability. However, such bases have a significant drawback - they are cold. Insulation can save the situation, but not every home craftsman knows how to properly carry out such work.

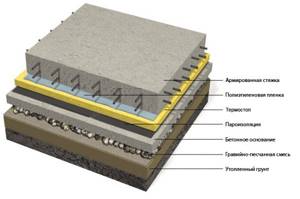

Multilayer structure of concrete insulated floor.

As mentioned above, concrete foundations can be insulated using logs. However, this technology is very labor-intensive, so most often home craftsmen lay heat-insulating mats under the screed. (See also the article Substrate under floor screed: features.)

This is done quite simply:

- Let's prepare the base. To do this, we clean it of debris and dust. You can use a construction vacuum cleaner to remove dust.

- Usually, uneven subfloors are visible to the naked eye. If you have not identified them, then check the slope of the base with a level; if it is present, the floor should be leveled.

- Leveling the floor is carried out by pouring a thin layer of screed. The base must first be primed.

- We cut beacons from the profile for plasterboard. They must be cut to fit the width of the room.

- We fix the beacons on the floor using small cakes of mortar.

We install beacons.

- When the beacons have set, you can start pouring the solution. Filling should be done exactly to their level.

- After leveling the floor, you must wait until the concrete is completely dry. (See also the article Warm floors for laminate: features.)

- We install a layer of waterproofing made of polyethylene film.

- We lay the foam slabs on the film as closely as possible to each other.

- We lay polyethylene film on the foam.

- A metal reinforcing mesh should be laid on top of the film, which will ensure high strength of the base.

- Now you can begin pouring the final layer of concrete, on top of which the finishing floor is laid.

Pouring reinforced screed.

What material is best for this?

Along with old materials for floor insulation in a country house, the modern market is replete with the latest developments in the chemical industry, in particular:

- Expanded clay.

- Wood shavings and sawdust.

- Styrofoam.

- Polyurethane foam.

- Penoplex.

- Penofol.

- Glass wool.

- Ecowool.

Important! If a country building is not used constantly, but only in the warm season, then the best solution would be to choose moisture-resistant insulation. Each material has its own advantages and disadvantages

Sometimes the question arises of how to effectively insulate a floor in a dacha with your own hands in the simplest way and at minimal cost. Expanded clay can be used for this work. It consists of lightweight porous granules that retain heat well

Each material has its own advantages and disadvantages. Sometimes the question arises of how to effectively insulate a floor in a dacha with your own hands in the simplest way and at minimal cost. Expanded clay can be used for this work. It consists of lightweight porous granules that retain heat well.

In addition, wood processing waste: shavings and sawdust are considered cheap and environmentally friendly materials. They retain heat well, but have poor resistance to moisture, and the shavings can harbor pests.

Polystyrene foam is easy to install and is a moisture-resistant material. In the absence of rodents it can last for many years.

Polyurethane foam has a porous structure, so it is lightweight, which allows you to insulate floors on the second floor or in the attic without increasing the operational loads on the floors.

Penofol is foamed polyethylene with a layer of foil applied. It is placed directly on top of the boards with the foil facing out, and the finishing coating is laid on top.

Ecowool has low thermal conductivity. It is blown into the underground space using special equipment.

Glass wool has an affordable price and retains heat well and is not susceptible to destruction by rodents. The main disadvantage is that it is prone to shrinkage, and during installation, the fragile fibers break and can penetrate the respiratory tract and irritate the skin.

Attention! When working with glass wool, you must use protective equipment. This will avoid unpleasant consequences

Ways to protect your dacha floor from moisture

The problem when installing a floor in a country house on a strip foundation is often its protection from dampness coming from the ground. The durability of the floor largely depends on good ventilation of the subfloor. Therefore, taking care of it begins with a project that necessarily provides for the arrangement of vents in the strip foundation. Vents are holes located oppositely. They are opened in the warm season and closed for the winter if the country house is intended to be used in winter.

Foundation ventilation

In areas where the groundwater level is high, simple subfloor ventilation may not be enough. Evaporation rising from the ground saturates the logs and leads to their rotting. Plastic film will help correct the situation. It needs to be spread under the entire area of the house and covered with a layer of regular sand. By taking these precautions, you can significantly increase the longevity of your entire floor structure.

Screw foundation

The floor of the house is on a columnar foundation. By definition, a columnar or screw foundation allows for free passage of air. The logs on such a foundation will never rot, but the lack of strapping and warm filling around the entire perimeter leads to the need for more serious insulation of the floor.

Floor in a house on a columnar foundation

Sequence of work

Laying expanded clay between joists for insulation

If a country house has one floor, insulating the floor of the first floor and the attic is sufficient. When it comes to a two-story cottage, the task becomes somewhat more complicated.

The process of insulating floors in a dacha is largely determined by their design. In most cases, the structure consists of one row of boards on joists. A finished floor covering is laid on top of the boards. As a result, even at high temperatures outside, cold comes from the ground into the house.

When the foundation of the house is a strip foundation, the design of the base implies the presence of vents. They are necessary for ventilation. In winter, it is recommended to close these openings with insulation, opening them in the summer.

The floor insulation process will be as follows:

- It is necessary to dismantle the old floor covering and the top layer of boards. Insulating materials are placed in the space between the joists. When insulating the floor with your own hands, you must not forget about laying a vapor barrier film above and below the insulation. You can secure it with a stapler; it should cover the entire surface of the floor;

- We close the structure with subfloors. It can be plywood or chipboard. As a piece of advice, professionals recommend replacing nails with self-tapping screws; they are more practical and durable;

- The work is completed by laying the flooring.

Now the country house is warm, cozy and comfortable. And the video material presented below will allow you to get acquainted with the work process in a visual way.

How to lay a floor on an earthen base

How to lay a floor on an earthen base

Sometimes country houses do not have a foundation, and the floor is laid directly on the ground. The covering is specially prepared, because it is impossible to lay the tree on ordinary soil. After removing the fertile layer, clay is laid as waterproofing. Then a layer of crushed stone and sand is poured. Each of these layers is carefully compacted. Clean sand is poured onto the leveled cushion. And logs, well treated to prevent rotting, are recessed into it for laying a wooden floor.

Insulate a concrete floor over the ground

If the dacha has a floor on the ground with concrete preparation, you can make a floor on joists (with or without insulation) and a floating screed on top of the insulation. The second option is more expensive, but also more reliable.

Construction of a concrete floor on the ground with insulation

Warm floor on a concrete base on joists

In some regions with inexpensive wood, it is easier and cheaper to insulate the floor of a dacha, if it is concrete poured onto the ground, by installing joists and flooring on them. Waterproofing is placed on the concrete slab - it can be a coating (mastic) or a weldable material. There may also be membranes and films, but it is unknown how long they will last. Therefore, it is better to focus on these types of waterproofing

Please note that the material should not conduct steam. Waterproofing should extend onto the walls at least to the height of the entire floor pie

Antiseptic logs are installed for waterproofing. Insulation is laid between them, which must be laid without gaps or cracks. If these are mineral wool slabs, then it is better to cut them 1-2 cm wider than the distance between the joists, so that they become tightly spaced. Then the cotton wool will “settle” and cracks may appear.

Lay an insulated floor on joists on a concrete base

The height of the logs is selected so that there is a gap of at least 2 cm between the insulation and the flooring. If the floor is made of edged or deck boards, gaps are possible. Then a vapor-permeable waterproofing membrane must be laid under the flooring. It will prevent water from entering the insulation, but will not prevent steam from leaving the mineral wool.

If the floor is planned to be solid - made of tongue-and-groove boards, a double layer of plywood, gypsum fiber board or other materials - then you can do without a membrane - there is practically no chance of pouring insulation.

Concrete floor with insulation

Those who have dealt with wooden floors often want to give them up. Wood is a very capricious material that needs regular maintenance. You can insulate a concrete floor in a dacha by laying waterproofing on the slab, and insulation on top of it. In this case, the waterproofing can be a film 150 microns thick, laid in two layers. Another option is to fuse roofing felt. At the same time, make good seams so that moisture does not pass through. Both of these materials belong to the inexpensive class, both do not allow water or steam to pass through. Ruberoid is, of course, more reliable, but it is also more expensive and more difficult to install. The waterproofing is again placed on the walls so that its edge is higher than the finished floor.

Option for a warm concrete floor on a concrete base

A layer of thermal insulation is laid on the waterproofing (or two layers with the seams separated - this is more reliable). It can be dense mineral wool or polyurethane foam. It is highly undesirable to use polystyrene foam. Over time, it will crumple, the floor will sag and will have to be redone.

If you will be laying polyurethane foam, fasten the boards together with tape. You can place reinforcement directly on it, place a damper tape (or its substitute) around the perimeter and then fill in the screed. You can immediately lay a floor covering on the screed - linoleum on a base, or fasten sheet material in two layers, and then put linoleum on it or whatever you chose. The second option is both better and warmer, but more expensive. But the insulation of the floor in the dacha will be done very well.

Insulation of floors using concrete preparation. Now you can lay either the floor covering or sheet material in two layers

If you decide to insulate the concrete floor of your dacha with mineral wool, you will need a layer of hydro-vapor barrier on top of it. It could be the same plastic film. But for this layer it is a very unreliable material. You will have to walk around and lay out the reinforcing mesh, but this is, after all, metal. So the film has little chance of remaining intact. And the holes in the film are wet insulation. Wet insulation is no heat insulator. So it is better to use a more durable hydro-vapor barrier material. Place a reinforcing mesh on it (100*100 made of 3 mm wire) and pour screed. Still, this option is not very good, since it is not entirely clear how mineral wool will behave in the thickness of concrete. If the waterproofing and vapor barrier are done well, everything will be fine. If moisture in any form seeps in anywhere, within a few years the floor will sag and/or become cold. And there won’t be much savings - you need a good vapor barrier, and it’s not cheap. So it’s better, after all, to use polyurethane foam.

https://youtube.com/watch?v=6eSa8gPCLsM

How to choose lags

Logs are rectangular bars laid parallel to each other as the base of the floor. Hardwood and coniferous wood are used. The main selection criterion is strength. Do not use material that shows signs of rotting. The presence of a large number of knots is not scary. For the logs of a country house, timber with dimensions of 50x150, 100x150 mm is suitable. The larger the room, the greater the requirements for the strength of the foundation. Sometimes it is enough to lay paired boards on edge.

How to choose lags

The location and height of the logs are selected.

The height of the log should provide a ventilation gap between the insulation and the finished floor. The dimensions of the lumber chosen as the floor frame and the thickness of the insulation must match each other. For example, with a log height of 150 mm, it is not always possible to lay insulation with a height of 100 mm. It is necessary to take into account that a few centimeters will go under the subfloor board and the skull block. The log can be increased in height with additional slats.

Insulation on wooden floors

If the floors in the dacha are very strong and smooth, and there is no desire to open them, you can perform insulation directly on the boards. The disadvantage of this method is that the ceiling height will decrease by about 8-10 cm.

Tools and materials

To work you will need:

- grinding attachment;

- jigsaw;

- building level;

- primer;

- wood putty;

- bars 50x50 mm;

- sheet material, for example chipboard;

- vapor barrier film;

- insulation;

- self-tapping screws;

- screwdriver;

- construction tape.

The bars will serve as lags, so they must be smooth, without defects, and well dried. Since the work process will take very little time, the bars should be pre-treated with antiseptic impregnation and dried.

Floor preparation

Step 1. Carefully remove the baseboards and clean the floor from dust. Check the horizontality of the surface with a level gauge.

Step 2. If there are protrusions on the floor, the surface is treated with a sanding attachment. The gaps between the boards and recesses are filled with putty.

Puttying a wooden floor

Step 3. Cover the working surface with two layers of primer mixture and allow the floor to dry.

Step 4. The beams are laid out on the floor in parallel rows with a step of 30 cm. From the outer beams to the walls the distance is 2-3 cm. Using a level and wooden wedges, the beams are aligned exactly horizontally and screwed to the base with self-tapping screws.

Laying and fastening lags

Step 5. The space between the beams is filled with insulation. Mineral wool and polystyrene foam are best suited for this. The resulting seams need to be blown out with foam.

Laying insulation in the space between the joists

Step 6. Cover the top of the insulation with a vapor barrier membrane, carefully straightening the material and securing the seams between the strips with tape.

Mineral wool is covered with a membrane

Step 7. For convenience, the sheet material is cut into squares and the flooring begins. Starting from the second row, the sheets are laid with the joints offset by 20-25 cm. The seams should be minimal, so fit the squares as tightly as possible.

Laying sheet material on joists

Step 8. If you plan to lay boards over chipboard, no additional treatment is needed for the subfloor. For thinner finishes, it is necessary to fill the joints and sand the entire floor with a sanding attachment. After this, remove the dust, apply a primer and wait until the floor dries.

The described options are the most practical for a summer residence; If you follow the technology, you won’t have to change the thermal insulation layer for at least 10 years.

An insulated floor in a country house will last at least 10 years

Comparative table of floor insulation

| Name | Advantages | Minuses | Thermal conductivity |

| Sawdust | Cheap, environmentally friendly material, lightweight | Flammability, susceptibility to rotting | 0.090-0.180 W/mK |

| Expanded clay | Eco-friendly, durable material, not subject to rotting, non-flammable | Heavy weight, fragility | 0.148 W/mK |

| Styrofoam | Does not rot, is waterproof, lightweight and easy to install | Low vapor permeability, cannot withstand high temperatures, releases toxins when melted | 0.035-0.047 W/mK |

| Mineral wool | Low thermal conductivity, easy to install, environmentally friendly, fireproof | When moistened, it shrinks and loses its insulating properties. | 0.039 W/mK |

Best way

An advanced method of insulating a wooden floor in a private home is the “warm floors” technology. Before insulating a wooden floor using artificial heating technology, it is necessary to make calculations to comply with a number of standards and safety requirements.

Thus, for heating, electrical appliances should be used that are difficult to access and that should not pose any threat. By installing a “warm floors” system, the user receives the following advantages:

- the user relieves himself of the problem of moisture getting into the insulators and damage to products;

- even in severe frosts, the floor covering remains warm, which saves fuel consumption with an autonomous heating system in a private house;

- the heating system constantly and – most importantly – dries the wood correctly;

- If the technology is followed, moisture cannot enter the underground space.

System elements

The main element of the system is a special heating cable, which is laid throughout the room. To turn on the heating, just connect the cable to the electrical power supply.

Installation of the system is simple and quick:

- the base is covered with aluminum foil;

- lay the cable on top;

- it is filled with concrete mixture to a depth of 3-6 cm;

- The top is covered with wood.

Wood flooring installation process

In the process of constructing a wooden floor covering, whether in a country house or in a brick cottage, there is nothing complicated: the work can be done with your own hands. However, in order to obtain a beautiful, strong and durable coating as a result of the work, it is necessary to take into account many nuances when performing it, and also to study well the theory of floor laying.

In a brick house, cottage or small wooden building, you can arrange the floors with your own hands in different ways. Let's look at the two most popular options:

- A floor covering created on a rough layer and with an additional layer of insulation (sound insulation), located on a base of soil or on overlapping beams;

- The floor is made of wood, built on a concrete base with an insulating layer.

In country houses, the first option is more often used. Moreover, this method creates floors on the first floor or basement, and it can also be used when arranging floor coverings on different floors of the building.

In the second option, the flooring design is built completely differently and can be modified and modified to reduce costs. More often, this method is used to make floors in brick cottages and apartments; it makes sense to lay floors in the kitchen on a concrete base.

Choosing thermal insulation material

The photo shows mineral wool slabs of various thicknesses.

First of all, let's look at how to insulate the floor in a dacha.

Today there are several types of insulation that are excellent for this type of work:

- Styrofoam.

- Mineral wool.

- Ecowool.

- Expanded clay.

- Polyurethane foam, etc.

Each of the above materials has its own advantages, but mineral wool and polystyrene foam are most often used for thermal insulation of bases. We will focus on these materials.

Advantages and disadvantages of mineral wool

Mineral wool is an insulation material that has replaced foam plastic from its leading position in the construction market. Possessing high technical characteristics, this material is affordable and flexible in use.

Advantages of mineral wool:

- Acceptable price.

- Excellent heat and sound insulation.

- Easy to install.

- Durability (about 30 years).

The only serious drawback of mineral wool is the fear of moisture. Even with minimal moisture, the material loses half of its high technical characteristics.

Characteristics of foam plastic

Foam boards.

Polystyrene foam is a traditional, wide-spectrum insulation material that can be used to insulate a dacha floor with your own hands without much difficulty.

Has the following advantages:

- Availability.

- Easy to use.

- An excellent heat insulator.

- Strength.

Flaws:

- Flammability.

- Poor sound insulation.

- Relative fragility (service life is 15-20 years).

Despite all the shortcomings, insulating floors in a dacha often involves the use of polystyrene foam.