The floor is the lowest part of the house, which is located in close proximity to the ground. Usually, heat flows out of the room through it, and cold and dampness penetrate inside. If you do not want to live in a cold and uncomfortable house, then the floor must be insulated. In the modern construction market, one of the leading places is occupied by isolon. This material has been used as insulation for many years and has actually shown its excellent thermal insulation properties. In the article we will describe in detail the characteristics and advantages of the material, and also dwell on how to insulate the floor with isolon in a wooden house, and highlight the intricacies of this work.

Izolon for floor insulation. Floor insulation with isolon

If you want to keep your home warm and minimize heating costs, then you can’t do without thermal insulation. Against the background of a wide variety of different types of insulation, isolon stands out favorably - a material made from polyethylene foam with a foil surface. Floor insulation with isolon significantly reduces heat loss both in a country house and in an apartment.

Thermal insulation with isolon.

Advantages and disadvantages of insulation with isolon

Izolon has an impressive list of advantages, such as:

- Light weight and slight thickness. With minimal heat loss, the thinness and lightness of the material makes the installation process much easier and saves free space in the room.

- Elasticity and resilience.

- Low coefficient of water absorption and vapor permeability. Izolon does not absorb moisture, which has a beneficial effect on the service life of the material, and also allows the installation of insulation without the use of a vapor barrier film.

- Environmentally friendly. This material is absolutely harmless to human health.

- Resistance to rotting and chemical influences.

- High reflective properties. The reflective effect allows you to significantly reduce heat loss in the room.

The disadvantages of using isolon as insulation include the following:

- A room insulated with isolon must have high-quality ventilation due to the vapor permeability of isolon.

- It is not advisable to use isolon in rooms with high humidity.

Insulation of a wooden floor

You can insulate a wooden floor using isolon in the following way:

- Dismantle the old covering.

- Install joists on the subfloor.

- Lay plywood panels or boards between the joists.

- Apply a layer of isolon. You can secure the material using a construction stapler or a screwdriver.

- Install the subfloor.

- Lay the floor covering.

Insulation of concrete floor

Thermal insulation of a concrete base can be done either with or without joists.

Work with the installation of logs is carried out in the following stages:

- Surface preparation. The floor must be cleaned of dust and dirt.

- Installation of lag.

- Installation of isolon. A layer of insulation is placed in the spaces between the joists.

- Laying the subfloor.

- Installation of flooring.

Without using logs, a concrete base can be insulated as follows:

- Prepare the base. Carefully fill all cracks and uneven areas. After the putty has completely dried, the surface must be sanded and cleaned of dust.

- Installation of isolon. The material is rolled out onto the prepared base and fixed with glue. The joints of the insulation are taped with foil tape.

With the right approach, you can always either insulate the floor with isolon or use this material as a substrate for laminate or parquet boards, and thermal insulation of the room. Izolon is an excellent insulation option that combines good value for money.

Can you believe everything they say?

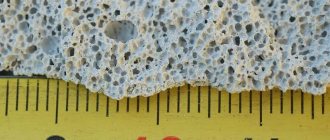

As mentioned above, many supposedly “similar” materials are not actually such. For example, for some time various brands of non-cross-linked polyethylene foam were widely advertised, which had not at all pleasant characteristics. They simply don't stand up to technical testing. After all, such materials quickly turn into a thin polyethylene film on the test bench.

According to the Research Institute, NPE polyethylene foams failed all tests as a soundproofing material. Therefore, you should not believe when they tell you that such insulating materials are no different from isolon. This is absolutely not true. Only isolon passed all the necessary tests, which confirmed its high characteristics.

How to lay foil insulation on the floor. Composition and properties of foil material

This insulation consists of two layers - a base and a reflective coating. Classic heat insulators are used as the basis - foamed polyethylene, expanded polystyrene, mineral wool and other materials. The reflective coating is a metallized polypropylene film or a thin layer of aluminum foil. The thickness of the insulation directly depends on the type of base.

Foil floor insulation consists of two layers

Types of insulation

Foamed polyethylene insulation has a thickness of 2 to 10 mm and is produced in rolls. It is usually used when installing “warm floors”, with further pouring of screed, and as an insulating substrate for some types of floor coverings. Self-adhesive material is especially popular, installation of which takes a minimum of time. Insulation has many varieties, of which the most popular are Izolon, Ecofol, Folgoizol, Penofol and Isoflex.

Insulation based on fiberglass and mineral wool has a thickness of 50 to 100 mm, and is commercially available in the form of rolls and slabs. It is used for insulation of interfloor ceilings, thermal insulation of baths and saunas. Basalt insulation with foil coating has increased heat resistance, but has one drawback: it contains phenol, which is unsafe for human health. The most popular brands of insulation: Knauf, Rockwool, Parok, Izover.

Rockwool foil insulation

Thermal insulation based on foamed polystyrene is produced in the form of rigid plates covered with foil. It is used when laying warm water floors, as well as for thermal insulation of surfaces subject to dampness and heavy loads. For the convenience of laying heating pipes, special red markings are applied to the foil coating.

Properties of insulation

Foil heat insulators have the following properties:

- high reflectivity;

- resistance to temperature changes;

- waterproof;

- excellent steam, hydro, sound and heat insulation properties;

- resistance to mechanical loads;

- durability;

- light weight;

- ease of installation.

Floors with such insulation will never become damp, will not require treatment with protective agents, and will last much longer. Most foil heat insulators do not contain carcinogenic components, so they can be used in any room; in addition, they reflect radiation, which is important now.

Aluminum foil perfectly reflects heat

The type of coating is of great importance. Aluminum foil perfectly reflects heat, but is destroyed by alkalis in concrete, and metallized film is not susceptible to such effects. That is why insulation with an aluminum layer is not used under concrete or cement screed. The thickness of the reflective layer is no less important: some manufacturers simply spray it on top of the heat-insulating base, which significantly reduces the effectiveness of the insulation. The thinner the layer, the easier it is for thermal radiation to pass through it.

Best answers

ordinary food will not work - it is metal and if it can “reflect” some part of the radiation, then part of the convective flow will still heat it up, and since aluminum is an excellent conductor... Insulation is needed under the foil! The walls need to be insulated themselves, for example .termoplex /korund.php?table=korund

Try to stick it with drool...

You'd be better off insulating it with polystyrene foam from the outside. and the floor can be insulated. You talk to those who do this.

I think you need to consult a construction store at the store or try installation

First, prime it several times with bentonite, and then glue, but it’s better with a heat-insulating layer, even PVA, but there are some that are sold as self-adhesive on a heat-insulating backing.

think about it, maybe galvanized iron, or better yet stainless steel, because foil is weak

oh, if the sticker is crooked, get a magnifying glass, with a focus like in ancient Greece they burned the fleet)

I use Termoizol - foil on foam, it’s easy to work with: I insulate steel baths - they turn out no worse than cast iron ones, they are warm. And food grade can be glued onto cardboard with slots for hooks for easy insertion.

Buy penofol, they are sold in different thicknesses. It can be self-adhesive, but if not, try double-sided tape!

If the foil is glued to the glass with egg yolk, then it will definitely stick to the concrete

.Moment. Apply in thin strips and glue

Anyone who has everything at home will keep it, just not the clerical one. Liquid nails or wallpaper glue work well

double sided tape is good

The most accessible and inexpensive BF-2, glues metal to organic matter.

Nothing but a stapler. It will fall off. Tested many times. And food won't work. Look for foil for baths and saunas, preferably on kraft paper, so you can glue it with glue. Do not stick clean foil.

and why? If for thermal insulation - foam is better, for sound insulation it is better than mineral wool

We invite you to familiarize yourself with: Vapor barrier for the roof: purpose, materials, installation, photos, videos

not glue, but pin. With slats, you put the isolon on it, lay the slats evenly on it, drill holes, and fasten it. And so every 50 cm. Well, or vice versa - first the slats have a “lattice” of insulation on them. Is it really so difficult to figure it out? Why is it necessary to “glue”? It is pointless to glue anything other than stone or concrete to concrete. Otvalitsa. Or it condenses and leaves.

Special opinion, by the way, is right - a lattice made of slats with mineral wool and covered with plasterboard or plywood on top. Much better.

There is also a self-adhesive one - prime the concrete with any interior primer, let it dry for 12-24 hours and stick it on - and if it is not foil-coated, then you need to buy a foil-coated one - if not, then glue for linoleum type 88 I don’t know what it’s called, but the effect is one thin layer on one and on the other surface and glue

You need to know the strength of the concrete slab. try turning to professionals who work with them slav-beton /index.php?id=2 I’m sure they will give you advice on how to do this, or they will do your work for you. Good luck to you

How to lay izolon on a wooden floor. Preparation

Before laying laminate boards, you need to thoroughly prepare the floor surface. The durability of the floor covering will depend on the quality of the preparatory work.

Preparation includes following these steps:

- The floor surface must be smooth, hard and dry. The first step is to dismantle the old coating and assess the condition of the existing screed. If there are many cracks and chips on it, it crumbles and peels off, then it needs to be dismantled and a new one created. If the defects are minor, then remove any existing chips and cracks using putty and level the surface.

- When choosing the material used to level the surface, it is necessary to take into account the depth of the unevenness. Measure the floor using a building level and calculate the difference between the highest and lowest points. If the obtained value is more than 3 cm, then it is advisable to use a traditional cement-sand screed. If the depth of the uneven surfaces does not exceed 1 cm, then you will have to use a self-leveling mixture.

- Before installing the laminate, the screed must be completely dry. You will have to wait about 14 days. To check the readiness of the surface, you need to use a simple method: place a glass jar with the neck pointing down. Wait a day and inspect the glass. If moisture has settled on it, then you need to wait a little longer, since the screed has not dried.

- If installation is carried out on a wooden base, then the condition of the surface must be assessed to detect the presence of unevenness, cracks and instability. If the condition of the floor is unsatisfactory, the boards will need to be re-laid. Minor irregularities can be eliminated by installing fiberboard sheets.

- Preparatory activities end with thorough cleaning of debris and dust. A vacuum cleaner will help you do this job.

Material characteristics

Due to its multi-functionality, Izolon has many applications, and not only in construction.

It is worth highlighting its many additional advantages:

- Elasticity, softness, low weight.

- Durability is associated with microbiological resistance (the material is not subject to rotting).

- Environmental Safety. The material is odorless, non-toxic, and is approved for contact with food and human skin. Therefore, using Izolon, you do not need to worry about animals and children.

- Chemical stability. Izolon has high oil and petrol resistance, compatibility with aggressive building materials (lime, gypsum, cement, etc.)

- Convenience, ease and simplicity of installation, the ability to perform work without special tools and construction skills. This allows you to significantly save money and reduce the construction and renovation time of the house.

Izolon is suitable not only for residential premises, but also for garages and warehouses

How to insulate a floor in a wooden building?

At the stage of building a house, the process of insulating the floor begins. First of all, the area under the floor is covered with sand to a depth of 5-6 cm, then expanded clay is poured onto it.

When choosing insulation, you need to take into account many points, for example, if you choose natural materials, then it is worth remembering that they are susceptible to combustion, and they rarely resist moisture, and various microorganisms and rodents can grow in them.

Sawdust and cellulose, treated for fire safety, are often used to insulate the base.

As for slab insulation, the following are considered in demand and of high quality:

- mineral wool;

- expanded polystyrene;

- glass wool;

- dry screed.

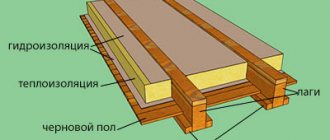

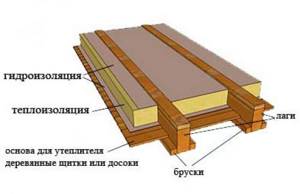

The finished floor is mounted on joists, with insulation installed in the gaps. The finishing coating can be installed over the screed. The screed is additionally insulated with expanded clay.

How to insulate the floor along the joists? To do this, the structure is assembled in increments of 40 -60 cm, while the subfloor must be well waterproofed from below. A vapor barrier is laid on top of the boards and joists. After this, insulating board material is laid in the gaps, the width of the boards is exactly 60 cm, and covered with a finishing coating - plywood, OSB or board.

If during construction it is decided to pour a rough screed, then it is better to do it using expanded clay. This will give the effect of additional thermal insulation of the floor. Then logs are installed on top of the screed, on top of which the finished floor will be laid, under which there will be a layer of heat-insulating material. Thanks to this cake, you will end up with perfect floor insulation.

If the floor in the house is wooden, then dry screed on the floor is well suited for insulation. To install such insulation, you need to fill the expanded clay along the leveled guides. Then slab gypsum fiber insulation is laid on the expanded clay. This method is simple, but is not applicable at high humidity.

Not long ago, a practical, durable and fireproof material appeared on the market - foam glass. The thickness of this material reaches 12 cm. These slabs can be laid not only on a wooden floor, but also on a concrete one.

Advantages and disadvantages

There are many advantages of this thermal insulation material:

- Low thermal conductivity coefficient.

- High thermal insulation characteristics.

- Isolon protects well from steam and moisture.

- Thanks to the closed cells, this material has a high degree of waterproofing.

- Although the protective layer of isolon is small, it has high shock and sound protection.

- The big advantage is the light weight of the material and its elasticity.

- The material also has high dynamic strength.

- Due to its high chemical activity, this material is not used in some areas.

- Izolon resists gasoline, oil and other chemical compounds well. And also does not react with flammable substances.

- The service life of such thermal insulation material can reach 100 years. This is a big advantage of isolon. This material can also be reused.

- Izolon is an environmentally friendly and safe material that does not pose any harm to human health and life.

The material also has some disadvantages:

- high cost of material;

- During transportation, isolon can be damaged;

- Thermal insulation device using isolon must be carried out according to technology. If this is not done, damage to the structure may occur and, therefore, the material will not perform its function;

- It is necessary to adhere to the rules for storing izolon.

Foil backing for plywood. backing for plywood

The plywood underlay allows, even without a “warm floor” system, to significantly increase the floor temperature. The substrate cuts off the cold. Prevents cold from penetrating into the room.

Plywood backing

The main task that the underlay performs is to prevent cold from penetrating into the room through the floor. It acts as a separating barrier between cold and heat. The floor covering accumulates heat and remains warm. The reflective layer prevents heat from escaping into the subfloor and thus heat is not wasted. The use of a reflective substrate allows you to increase the room temperature by up to 30%.

The underlay performs a waterproofing function, protecting the floor from the penetration of moisture and steam into it, both from above and from below. The substrate also levels the surface. When using material more than 2 mm, the substrate performs an acoustic function, reducing the amount of noise and vibration.

one of the options is what an insulated floor looks like; the void is often filled with mineral wool

Laying features

The substrate can be laid with the reflective side in any direction. The reflective effect will remain in any case. It must be laid with a continuous carpet and have the same thickness over its entire area. The individual panels are joined end-to-end, and the seams must be taped.

Operating procedure

- Preparing the subfloor

- Laying the insulation underlay

- Leveling layer of fiberboard, chipboard, OSB (in case of using a thick substrate)

- Flooring

More installation options

Material

The substrate/insulation consists of NPE with a closed cell structure; it is this structure that gives a low thermal conductivity coefficient, good elasticity and zero moisture absorption. The reflective layer consists of a composite of aluminum and lavsan, this combination gives the material unique characteristics - it does not conduct electric current, and is very resistant to concrete and alkaline solutions. The material has increased mechanical strength. The low density of the substrate allows the material to act as sound insulation.

The most important characteristics of the underlay/floor insulation

- Low thermal conductivity coefficient (0.037 W/m°C)

- high reflectivity (up to 95%)

- Resistance to temperature changes (from – 60 to +110 C)

- Good hydro- and vapor barrier properties (0 mg/m.h.Pa)

- Good sound insulation properties (0.04-0.14)

- Resistance to deformation (1.08 - 2.54 MPa)

- Environmental Safety

You can order or find out more by calling the toll-free number: 8-800, which is listed in the contacts.

Let's sum it up

will help make your home warm and cozy. We have been providing finishing and insulation services for wooden houses for more than ten years and have accumulated vast experience in this area, which we want to share with you. We will be happy to provide our services to residents of Moscow and the region. Leave your requests, and we will send a specialist to you for free to inspect and draw up a preliminary estimate of the work.

On the Contact page you will find detailed information on how to contact us.

Calculate the cost of painting and insulating your home right now

The building materials market is constantly expanding. A consumer who wants to insulate his own home sometimes finds it difficult to decide on a suitable heat insulator that is affordable and at the same time has decent performance characteristics. Recently, insulation with isolon has become popular. What this material is, what types there are, how to work with it - this will be discussed in the article.