Application of sealants

Sealing compounds are very popular during construction and repair work. They are a viscous or paste-like composition based on polymers. After application and hardening, sealants prevent liquid leakage through holes, gaps, openings and act as a waterproofing layer.

Most often, roofing sealant is used to seal joints and seams between sheets of base material. Sealing is especially in demand when arranging roofs with a small angle of inclination, from which water rolls off with difficulty. Sealants are also used to eliminate mechanical damage and other defects and to seal fastening points:

- chimneys,

- antennas,

- ventilation shafts,

- wooden poles,

- supports, piles.

Sometimes a strong wind tears off some of the sheets, they become deformed, and cracks appear on the surface. Cracks can also occur when trying to level the roofing material: even with high strength, the metal does not have sufficient elasticity and can be damaged by heavy loads.

Another possible reason for using sealant is a decrease in the protective properties of the anti-corrosion coating, because it also has its own service life, and after its expiration it deteriorates, peels off, and the surface begins to let moisture through microdamages. In such a situation, sealant becomes a temporary solution that will help you wait out the cold season until the roof is completely repaired.

How to carry out routine repairs correctly

If the roof has significant damage, then simply sealing the cracks on the garage roof with something will not work - you will have to partially replace the material. Sometimes there is no need to install a new coating, however, if bubbles appear on the surface, then first of all the top layers of material under which water has collected are removed.

To properly cover the slope with new sheets of roofing material, you will need:

- Dismantle old material. Remove 1 or 2 layers of used roofing felt, on which a large number of blisters and other defects have formed.

- On the bubbles that have formed on the surface of the roof, make a cross-shaped cut in the center with a knife, remove all moisture from them, and then allow them to dry.

- The layer of powder is removed from the base of the roof. To speed up the work, which is not enough, it is better to take a grinder with a special attachment. Keep in mind that all actions must be performed with extreme care so that holes do not appear in the roofing material.

- The prepared base is primed with bitumen mastic to obtain a sticky film - this will allow the new layer of roofing felt to adhere better.

- A few hours later, after the mastic has partially set, proceed to installing a new layer of roofing material. It is laid with a slight overlap of 10-15 cm. The inner base of the material, covered with fusible bitumen, is heated, and then pressed firmly against the old coating.

- The second strip of roofing material is placed at intervals from the first. If you don’t know how to coat the seams on the garage roof, then the same bitumen mastic will do.

Experts advise repairing garage roofs only in dry, calm weather and at ambient temperatures above 5 ℃. To avoid injuring yourself, follow safety rules and do not neglect insurance.

Why seal your roof?

Sealing significantly increases the reliability and durability of the structure. Over time, any structure will inevitably wear out and collapse if you do not take care of its waterproofing in advance. The sealant has the following effects:

- stops the flow of moisture into the roofing pie,

- prevents the insulation from getting wet,

- protects the rafter system,

- prevents the appearance of fungus, rotting,

- protects unprotected areas from aggressive substances falling with rain,

- increases the overall service life of the structure,

- normalizes the thermal conductivity of the roof, insulates the house,

- eliminates leaks,

- is an adhesive substance for water vapor barrier.

Types of sealants for metal roofs

Most often, metal is used for arranging roofs, which, in terms of technical characteristics and physical parameters, is well suited for this role. Despite its strength and aesthetic appearance, this material is susceptible to corrosion, which is accelerated due to regular temperature changes and the influence of atmospheric factors. Therefore, the roof sealant must be well suited to metal, be resistant to harmful effects and not peel off over time.

Based on the type of transition to the working state, there are two groups of sealants:

- Uncured. After application, they practically do not change consistency, so they penetrate into crevices and the smallest cracks. They can be used to seal any problem areas, apply them to the most complex structures, and repair large roofs. Sealants are available in the form of tapes and pastes. They can withstand temperature changes in the range of –60…+80 degrees.

- Curable. After completion, the seam hardens under the influence of oxygen, water, UV radiation, or as solvents evaporate. To prevent the polymerization process of the sealant from proceeding too quickly, curing inhibitors are added to the mixture.

Based on their composition, sealants are also divided into several groups, and they differ in strength characteristics and other parameters.

Polyurethane

Made on the basis of polymerized resin, they are a viscous, viscous mixture with high toxicity. Easy to apply to any substrate, they have many advantages:

- resistant to mechanical stress,

- work even at very low temperatures,

- are not destroyed by moisture and ultraviolet radiation,

- harden quickly

- serve for a long time,

- compatible with all roofing materials,

- may be painted.

Disadvantages of polyurethane sealants: they are quite expensive and toxic, as they are diluted with organic solvents.

Silicone

Silicone-based compositions are sold in tubes, pistol cartridges, and spray buckets. They are the most popular and have an affordable price. The products are multifunctional, resistant to temperature fluctuations, exposure to sunlight, and harden quickly. Silicone sealants are used for temporary and permanent waterproofing of roofs and other structures. There are acidic and neutral formulations on sale: the latter are more expensive, but more durable, non-toxic and odorless.

Polysulfide

Thiokol (polysulfide) sealants are made on the basis of modified resins and bitumen. They must be applied in a special way - in the form of several thin layers, and not one thick one, since oxygen and water vapor are needed for curing. Sealants are characterized by a universal purpose, serve for at least 15 years, and withstand differences from –40 to +140 degrees.

Polysulfide sealants also have disadvantages. They take a long time to dry - within 2-4 days, and the exact time depends on the thickness of the layer. The elasticity of sealants is low: their hardness resembles natural bitumen, so they cannot compensate for linear vibrations of materials. Under severe loads, there is a risk of microcracks appearing in the sealed seams, after which they begin to let moisture through.

Bituminous

They are also made on the basis of bitumen, but the latter undergoes a different technical treatment and is enriched with polymer compounds, and therefore acquires different properties. Such sealants are well suited for metal and soft roofs; they are viscous, durable, and can easily withstand low and high temperatures. Properties and capabilities of these tools:

- excellent penetrating ability,

- good elasticity and adhesion with most materials,

- protection of metal from corrosion,

- no cracks after drying,

- no reaction to UV radiation,

- preventing the proliferation of microbes,

- safety for humans, the environment,

- excellent moisture resistance.

Butyl rubber

Sealants of this group are made on the basis of isoprene and isobutylene, which form butyl rubber during copolymerization. The products are quite expensive, have excellent adhesion, elasticity, heat resistance, frost resistance, water resistance, and are characterized by a long service life. Butyl rubber sealants are sold in buckets, tubes, cartridges, and in the form of tapes.

Rubber

The products are made on the basis of artificial rubber and are considered universal, as they are suitable for different types of work. They withstand severe temperature changes, harden quickly, and are characterized by low toxicity. Many compositions are not very resistant to mechanical stress.

Acrylic

Acrylic sealants are characterized by their low price, long service life, and excellent quality. If you apply this composition to a dry surface, according to the instructions, the adhesion rate will be the highest, and with any type of coating. Acrylic sealants are odorless, environmentally friendly, and do not contain solvents. They are sold in different forms (cans, tubes, buckets, cartridges) and in a wide range of colors. The downside is that the water-repellent properties are not the highest, since the composition contains an aqueous dispersion. It is better to use together with sealing tape.

Two-component formulations

Such products can be made on the basis of different components: epoxy resin, urethane groups or silicone rubber. They are represented by two components: a base and a hardener, which must be mixed together before use, after which the suitability of the sealants will be limited to minutes or hours, depending on the specific type. Then polymerization of the base begins, it loses its fluidity and hardens.

Roofing mastic

Roofing mastics are very popular in construction. They are viscous plastic masses based on resins, rubber, bitumen with the addition of fine fillers: talc, graphite and others. Bitumen mastic is much cheaper than polymer mastic, but the latter has a high degree of adhesion and elasticity. Most often, mastics are used to strengthen and waterproof soft roofs.

Tape sealants

The easiest way is to use tape sealant, especially if a beginner is doing the work. The characteristics of sealing tapes are as follows:

- resistance to temperature changes, sunlight,

- possibility of quick application and replacement,

- high degree of tightness,

- sufficient mechanical strength.

Patches, wide or narrow strips are cut out of the sealant tape, depending on the need. The material is inexpensive, so the cost of sealing the roof will be low.

Nikoband product range ↑

The range of Nikobend brand products allows you to quickly and inexpensively solve most problems related to sealing elements of building structures, without resorting to more complex and expensive methods. plans to expand the production program of tapes at the expense of highly specialized materials. As of finally 2021, the Nicoband series offers three brands of products, differing in structure and purpose:

Nikoband ↑

Self-adhesive tape “Nicoband” after removing the protective film has two layers: an adhesive sealing bitumen-polymer layer and a protective one made of thick painted aluminum foil. The metal provides reliable protection of the bitumen composition from ultraviolet radiation. The operating temperature range in which Nikobend retains its properties is wide: from -40 ºC to +80 ºC. Such characteristics guarantee a long service life of the material outside buildings. First of all, this tape is intended for working with roofs, namely:

- Sealing of open junctions of any types of roofing coverings to chimneys and vertical walls.

Choosing the right sealant for different surfaces

Some compositions are considered universal, others are suitable only for a specific roofing material, but do not exhibit high adhesion to other coatings.

For metal roofing

For a product to be suitable for metal, it must have reliable adhesion to stainless steel, carbon steel, and alloys. A good sealant has high elasticity, is resistant to precipitation, and is not destroyed by vibration. Polyurethane, bitumen, and bitumen-rubber sealants are best suited for metal roofing. It is these compositions that are characterized by a sufficient degree of plasticity, and therefore serve for a long time.

Some products can even be applied to wet surfaces, which is very important when carrying out emergency repairs. Silicone acid compounds cannot be used for metal roofing: they provoke rusting.

For corrugated roofing

In order for the roof to serve faithfully, during installation you should follow the recommendations for the maximum slope (14 degrees), and also be sure to process the transverse joints of the corrugated sheets. Polyurethane sealant, which has high waterproofing properties, is excellent for this material. It is important to install or repair profile sheets when they are completely dry and clean. The sealant is applied in a layer of 3 mm; if necessary, the seam is covered with sealing tape.

For soft roof

Flexible tiles are the most inexpensive and popular type of material, which is especially often used for arranging country houses. For complete sealing, bitumen mastics and emulsions are used. For local repairs, products such as liquid rubber based on rubber and silicone are suitable. Seams and joints are sealed using sealant tape. All products, except bitumen mastics, are applied only to dry surfaces.

For metal roofing

Metal tiles are similar in properties and installation to corrugated sheets. Typically, silicone sealants with increased resistance to UV radiation are used to seal cracks up to 5 mm in size. Longitudinal and transverse joints are treated with bitumen or polyurethane compounds; the same means are used to seal the seams between the chimney, ventilation outlets, antenna and roof.

Where exactly are sealants used during roofing work?

Some areas are more susceptible to damage than others, so sealing compounds must be applied to them with special care.

Endovy

The structural elements of the roof, which represent the angle at the junction of two slopes, are the most complex units and are considered key in the arrangement of the entire roof. An error in the design and formation of any valley causes intense leaks, and when snow accumulates, it can lead to roof collapse.

Since all atmospheric precipitation converges in the valleys, they are subject to serious mechanical stress and are constantly exposed to climatic influences. Since the metal sheets in this area are cut, water can seep under individual elements. The overlap areas between the slats of the lower valley are well coated with sealant, which deflects water coming from the slopes. Without sealing, you can notice a leak in an area even if it is seriously damaged and there is a need for expensive repairs.

Chimneys, ventilation pipes, other engineering structures

In such places, you can do the sealing yourself, as it is not difficult. All joints around the perimeter are treated with the selected composition, without missing a single section. This will help prevent roof leaks in the most “popular” places: at the junction of the main material and overhead structures.

Drainage systems

There are gutters on every roof, and for maximum tightness of the areas connecting the gutters with the attachment point, it is necessary to use a specialized compound. The metal drainage system should be treated especially carefully in the area where it joins the roof.

Connections to vertical walls

There is a high probability of leakage in the area of vertical sections and the places where they connect with horizontal ones, unless these areas are first coated with a reliable composition. In addition to sealing, it is important to strictly adhere to the technology for constructing joints - using chipping or sawing of brick surfaces.

Cornice units

Sealants help glue the membrane to the metal strip, securely fixing and holding this material. When using a high-quality composition, the membrane gasket will not be torn off by strong winds, and water will not be able to seep under it. It is also necessary to coat the side junctions and overlaps of the joints of the corrugated sheets with the product, so that during slanting rain or spring melting of snow, leaks do not appear.

Repairing small cracks - what to fill with

If the cause of the leaks turns out to be minor cracks that appear on the roofing material due to temperature changes, then in this case there is nothing better than to fill the garage roof with bitumen in problem areas. Solid bitumen, which is melted before work, or liquid bitumen, ready for use, is suitable.

Cracks need to be repaired using the following technology:

- All debris and dust are removed from the roof surface;

- using a grinder with a grinding disc or sandpaper, remove the layer of protective coating in places where cracks are sealed;

- the base of the roofing material is degreased, for which you can use gasoline, acetone or alcohol;

- then take the prepared bitumen and slowly pour it into the crack;

- after the bitumen has hardened, this operation is performed one or two more times, until the damaged area in the roofing material is completely leveled.

- To avoid damaging the area being restored, it can be sprinkled with quartz sand or stone chips.

It is worth noting that to eliminate cracks it is better to use cold bitumen. Hot bitumen must be used with extreme caution and as quickly as possible, while cold bitumen is ready for use straight from the package. To get rid of small cracks, one can of such material will be enough.

Popular brands

There are many products on the market that are suitable for sealing roofs. The most famous:

- “Titan” - easily withstands frost, can be used with any materials, perfectly seals flat and seam roofs,

- “Sazilast” - it can be applied even at sub-zero temperatures, after hardening it exhibits a high degree of adhesion,

- SOUDAL Aquafix - suitable for wet and underwater surfaces, allows repairs in rainy weather, ideal for metal tiles and gutters,

- Ceresit is resistant even at abnormally low temperatures, after curing it resembles plastic, therefore it is not used on deformable substrates,

- RoofPlast is based on bitumen and is considered one of the highest quality sealants.

Subtleties of working with sealant

To carry out roofing work, you need to know the features of using a particular sealant. For example, two-component formulations must be mixed correctly: according to the instructions, in compliance with the proportions and timing. It is usually recommended to stir with a drill at medium speed for 10–15 minutes. It is advisable to carry out the procedure in a warm room, since in the cold the mass thickens greatly, and it is forbidden to dilute it with a solvent.

Sealants should not be applied to wet concrete or icy surfaces. The result will not be of high quality if you treat the lid with sealant at temperatures below –25 and above +50 degrees. The thickness of the layer of the composition should not be more than 3–4 mm, while sagging and tears are excluded. The easiest way to apply sealant is with a special gun, since manual extrusion often results in crooked seams. To ensure that the composition lies evenly, the areas around the seams can be covered with masking tape, and only then begin applying the composition. After the product has completely dried, the roof will be ready for use: it will be reliably protected from leaks for a long time!

Content

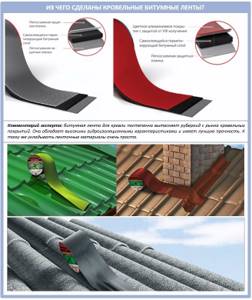

This building material is not called universal for nothing: bitumen tapes are used to seal not only the roof, but also pipes, boats and in general everything that needs to be repaired on the farm! Why not? If the entire repair process only takes half an hour!

To the touch, the bitumen tape will remind you of a self-adhesive underlayment, which is usually used when installing soft tiles. But, unlike a carpet, the top layer of the tape is reliably protected from ultraviolet rays and is metallized. The tapes themselves are produced from 5 to 30 cm wide.

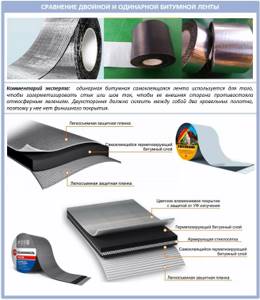

The technical characteristics of bitumen tape are practically the same among different manufacturers. After all, the main requirement for it always remains the same: adhesion, durability and reliability. Basically, tapes are single- and double-sided:

Coated or uncoated:

Let's list their main advantages: cost-effectiveness, weather resistance, excellent adhesion and ease of installation. You will probably be interested to know how such a roofing element is made.

During the production process, self-adhesive bitumen-polymer binder is applied to the UV-resistant foil film. It consists of bitumen, a polymer modifier and adhesive additives. This binder is covered with an anti-adhesive polymer film on top to protect the bitumen component from contamination before installation.

Another important point: the use of bitumen tape does not involve the use of fire, which is very important when working at height. There is also a nice bonus: bitumen tapes have a “self-healing” effect, when an accidental puncture heals itself due to the viscosity of the material. Thanks to this, not only will it only take you a few minutes to fix the roofing problem, but in general, even after a couple of years, you will no longer need to remember about such a patch.