6231 0 0

Michel July 28, 2016Specialization: plumber with 10 years of experience, computer repair specialist, powerlifting coach. I have extensive experience in construction, interior decoration, and making homemade furniture. Hobbies: sports

This article is devoted to what the layout of heating pipes can be like in a wooden house or a modern apartment building. I am going to talk about diagrams for connecting circuits to an elevator, risers to a heating circuit, and methods for inserting individual heating devices into the circuit. So, let's go.

Heating system installation.

What it is

Let's start with a description of the general principles of operation of the heating system.

Heating of heating devices is ensured by the circulation of coolant through them (process water, antifreeze, ethylene glycol, etc.). Circulation requires a differential created between the input and output of the device.

This difference can be achieved in several ways:

- By connecting through the elevator unit to the heating main, where a pressure difference of 2 - 3 kgf/cm2 is maintained between the supply and return lines.

A nuance: after the elevator, the difference between the mixture and the return is much smaller - 0.2 - 0.3 kgf/cm2. Exceeding this value would make the circulation excessively fast. The consequences are noise in the pipes and increased temperature of the return pipeline.

- Circulation pump.

- The difference in the density of hot and cold coolant in so-called gravity (gravity) systems.

Obviously, in all cases it is necessary to ensure that each heating device is connected to the common system with two connections. This can be done in several fundamentally different ways.

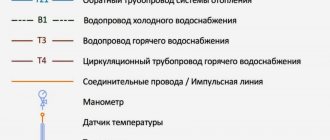

| Scheme | Short description |

| Single-pipe | Heating devices are connected to a common ring circuit |

| Two-pipe | Heating appliances are connected between the supply and return pipelines running along the entire perimeter of the heated premises |

| Collector | Each heating device is equipped with its own pair of connections connected to a common manifold |

It’s curious: mixed radiator connection schemes predominate in apartment buildings. The presence of dedicated supply and return heating outlets makes the system a two-pipe system; at the same time, within the riser, batteries are often combined in series.

Classification

A two-pipe heating system, in turn, can be classified according to several additional characteristics.

Orientation

The vertical scheme is used only in multi-storey buildings. Each radiator is a jumper between the supply and return risers running nearby.

The horizontal scheme can be used both in apartment buildings (the example with two bottlings was mentioned in the paragraph above) and in cottages.

Passing and dead-end

In the associated circuit, the coolant in the supply and return flows along the ring in one direction; in a dead end - in opposite directions. A dead-end scheme is in demand where doorways or panoramic windows make installation of a full ring of pipes problematic.

Bottom and top filling

Until about the 70s of the last century, houses with top filling predominated in the USSR: from the elevator unit, the supply pipeline rose to the attic; From there, the coolant flowed through the risers into the return pipe located in the basement.

The use of such a scheme had several practical consequences:

- The attic, willy-nilly, was heated and had dimensions sufficient for maintenance and repair of shut-off valves.

- During repairs, each heating riser had to be turned off at two points - in the basement and in the attic.

- When starting up the reset system (both the entire system and individual risers), it was necessary to bleed air from it. For this purpose, the supply bottling was mounted with a slight slope, and an expansion tank with a vent was installed at its upper point. Accordingly, the launch of the house was accompanied by a visit to the attic.

However: in some cases, the dump still led to the basement through all the floors. When the discharge cross-section was small, air was displaced through it at the front of the water flow.

With the advent of flat roofs and the development of panel housing construction, upper filling was practically replaced by lower filling: both supply and return migrated to the basement. The risers began to be connected in pairs in the apartments on the top floor. After reset, each of them needs to remove the air plug; For this purpose, Mayevsky taps or ordinary valves are installed in the apartments on the upper floor.

Please note: the bottom filling circuit is more vulnerable to accidents in the cold season. Relieving air (especially in the absence of access to all air vents) takes a long time; At low temperatures, it is not uncommon for some of the risers to freeze.

About the centralized heating system and schemes for its implementation

The central heating system of a multi-storey building has never been particularly efficient - up to 30% of the heat is still lost on the way to the consumer, which is paid for by the consumer. Therefore, many apartment owners abandon the central heating system in favor of an autonomous system due to its greater efficiency and cost-effectiveness. But how does centralized heating of apartments work, and can it be improved?

The system for distributing pipes around the house is schematically very complex, plus the supply of pipes to a residential building, and the distribution of heat across areas. In just one individual house, the circuit includes hundreds of valves, taps, drains, fittings, distributors and flanges that work on the central equipment - the elevator unit, which regulates the distribution of heat throughout the house.

Elevator unit

Schemes for supplying coolant to a separate apartment from an elevator unit are different. Thus, the bottom-spill scheme uses the principle of supplying coolant in the direction from bottom to top. Those who live in “Brezhnevka”, “Khrushchev” and “Stalinka” buildings know how it works.

In a multi-storey building with such a coolant supply scheme, the supply and return pipes are installed around the perimeter of the house, starting from the basement, and act as jumpers between the heating mains. This scheme is a closed cycle with the beginning and ending in the basement of the house. The highest point of this piping is the highest apartment(s) in the building.

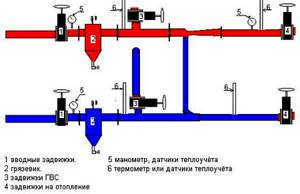

General house heat metering unit

- The main drawback that this heating system in an apartment building has not gotten rid of is the mandatory bleeding of air at the highest point of the wiring when starting the system. For this purpose, Mayevsky taps or conventional valves are used. If the air is not vented, then the air lock will definitely shut off the system at some arbitrary point, cutting off heating to the entire house.

- Another disadvantage of the bottom-spill scheme is that half of the house is heated by hotter radiators (from the coolant supply pipe), and the other half of the residents receive a slightly cooled coolant (mostly from the return), and nothing can be done about it. The temperature difference is especially noticeable on the lower floors of the house.

Advantages

What, in fact, is good about a 2-pipe heating system?

Its main advantage is that it allows you to ensure a more or less constant temperature of heating devices throughout the building.

With a single-pipe heating system, the battery connections at the beginning of the single filling rings will have a supply temperature (typically 70-75 C). at the end - return temperature (50 C). Here, each radiator will receive a coolant with a temperature slightly different from that provided by the supply boiler or the elevator unit after the mixing unit (elevator).

In addition, in the case of a large house with a significant number of batteries, a 2-pipe heating system simply has no alternative: not a single single-pipe ring configuration will cover all the rooms of an 80-apartment building.

Anticipating objections: yes, a manifold circuit can more than replace a two-pipe system. However, its selling price will be tens of times higher due to the enormous consumption of pipes; in addition, a large total length of the connections will mean huge non-target heat losses.

Problems

It couldn't have happened without them either.

Expenses

Obviously, with the same diameter, two pipes will always be more expensive than one. If the area of the heated building is small, the benefits obtained will not compensate for this difference: it is easier to compensate for the temperature spread by increasing the number of radiator sections at the end of the single-pipe ring.

Balancing

The cottage's two-pipe heating system needs balancing.

First, let's outline the essence of the problem.

Imagine that two pipes go from the heating boiler deep into the house. Through the first, water flows to the radiators, and through the second, it returns. Moreover, each radiator is a jumper between these pipes.

What's the problem? Yes, the fact is that each heating device will dampen the difference between the supply and return. If on the first battery it is equal to, say, 0.2 kgf/cm2, then on the second it will be 1.75, on the third it will be 1.5, and so on.

Private houses, apartments from the developer

The last remark, in fact, brings us close to the next section of the article. Its topic is heating diagrams for a private house: pipe routing and insertion of heating devices.

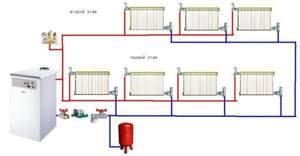

The upper and lower filling schemes described above are quite applicable for a two- or three-story cottage. However, they are not always optimal in terms of material savings, fault tolerance and temperature distribution. Well, let's explore the alternatives.

Horizontal wiring differs from standing (vertical) in that heating devices located at the same level are connected to each other. If there are two or more floors, the outline of each of them is drawn horizontally.

Horizontal wiring for two floors.

Wiring from a boiler or other heat source can be:

- Single-pipe . All devices are connected into the gap of a single ring encircling the perimeter of the room, or (which is much more reasonable) parallel to it. There can be several such rings - according to the number of rooms or floors;

The simplest one-pipe scheme.

- Two-pipe. Each radiator is a jumper between the supply and return threads. It is believed that two-pipe wiring allows for a more uniform temperature distribution.

Section of two-pipe wiring with radiator connections.

In practice, however, it is quite capricious, since it requires throttling of the devices closest to the boiler and precise adjustment of the chokes. The price of non-compliance with this recommendation is defrosted distant heating devices: without chokes, the entire coolant begins to circulate through nearby radiators.

Each radiator in a two-pipe system must be equipped with throttles for adjustment.

It is worth noting that the problem of balancing a two-pipe system is very elegantly solved in the so-called Tichelman loop . In fact, it consists of several parallel contours of the same length.

Another solution that allows you to evenly distribute the thermal load is collector wiring . In this case, each device is connected by a pair of connections to collectors responsible for turning off or adjusting the temperature. This scheme involves laying pipes in screeds or grooves: hardly a dozen parallel pipes on the walls will decorate the design of your home.

Collector and series wiring can be combined in one heating system.

Finally, a two-pipe distribution can be dead-end (when the direction of movement in the supply and return is opposite) and parallel (the movement of the coolant in two lines is parallel, the system is a vicious circle).

Which scheme is better for a studio apartment or a small cottage?

In my opinion - single-pipe (“Leningradka”), plinth (installed at the bottom of the walls), with radiators connected parallel to the main ring and embedded in a “bottom-down” pattern . It attracts with its absolute fault tolerance, ease of launch and undemanding balance.

I'll elaborate on this statement a little:

- Defrosting any individual section of the circuit is impossible in principle as long as coolant circulates in it. The ring, however;

- The operation of a separate device (air lock, shutdown, throttling) does not have any effect on the operation of the remaining batteries. Circulation in the ring will continue in any case;

- To start the ring, just open the valve or gate valve. All air will be forced into the batteries located above and can be vented at any time through Mayevsky taps or automatic air vents. Moreover, it will not interfere with the operation of the batteries even without bleeding: circulation will go through the lower collector of the device.

Useful little things

- When balancing with chokes, the time interval between changing the throttling mode and stabilizing the temperature of the heating devices reaches 6 - 8 hours.

- For a cottage with an area of up to 100 m2 with forced circulation of coolant in a two-pipe system, a reasonable minimum filling cross-section is DU2, up to 200 m2 - DU25.

- In a gravity system, filling cannot be made thinner than DN32 when using polymer pipes and DN40 when using steel pipes . In addition, gravity systems are used on an area of no more than 100 m2: in a large room, the hydraulic resistance of a long circuit simply will not provide the minimum required circulation rate.

Features of the upper heating distribution

What is such a highway scheme like? A typical top filling heating system differs from the bottom one in the location of the supply pipe. It is located under the ceiling of the room or in the attic (for a one-story house).

Its use may be relevant in several cases. First of all, there are problems with installing the lower horizontal pipes. This is explained by the impossibility of laying a highway. Another option when a two-pipe heating system with top wiring would be optimal is to install a gravity circuit. In this case, the water pressure from the supply riser will be evenly distributed over the connected heating radiators.

Experts highlight the following advantages of a heating system with overhead wiring:

- Minimal heat losses . The temperature in the upper part of the room is always higher than in the lower part. Therefore, heat transfer from the surface of the pipes will be compensated by increased heating of the air. As a result, most of the thermal energy will flow into the radiators;

- Simplified installation . It is noteworthy that a single-pipe vertical heating system with overhead wiring can be installed directly under the ceiling or in the attic. But at the same time, you need to take into account the location of the furniture - it is undesirable for it to cover the supply pipes;

- Improved hydrodynamic performance of the system . A properly designed top-drain heating system has a minimum of branches and corners.

However, you need to know the disadvantages of such a scheme. Laying the pipelines will require more material than when using a system with bottom routing. As a result, the total volume of coolant increases, requiring the installation of a boiler with increased power characteristics.

For a single-pipe vertical heating system with installed top wiring, the main problem may be the appearance of air locks. Therefore, Mayevsky taps must be installed on each radiator.

Connecting batteries

The sectional radiator can be connected in three different ways.

Three possible connection diagrams for a sectional radiator.

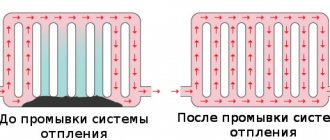

- The side connection is optimal when the number of sections is no more than 7. All of them will be heated evenly, but the end sections will require periodic washing;

- A diagonal connection is suitable for long radiators and equalizes the temperatures of the first and last sections. Flushing is required and performed through a tap installed instead of a blind bottom plug;

- The bottom connection differs favorably from the diagonal one in that the radiator does not require flushing at all. The sludge is carried away by the coolant circulating through the lower collector. However, due to the uneven distribution of circulation between the lower and upper collectors, the device loses 10-15% of thermal power.

With a bottom connection, you can forget about flushing.

Single-pipe heating system with overhead wiring

In what cases is it important to install a two-pipe vertical heating system with overhead wiring? Most often, a similar scheme is applicable for small houses with an area of up to 100 m². Let's consider an example of organization for the most common system with natural coolant circulation.

Depending on the method of connecting the radiators, the heating scheme with top filling and natural circulation is divided into two types - with parallel and counter movement of the coolant.

Counter scheme

It is characterized by sequential connection of radiators and different directions of water movement in the main and return pipes. In this case, the heating system is single-pipe with overhead wiring, the design of which has a number of features, and is distinguished by the following parameters:

- Inability to adjust the degree of heating in each radiator;

- Dependence of heating of the coolant on the length of the pipeline. The further the radiator is installed from the boiler, the lower the temperature of the water entering it. To normalize the temperature in all rooms, batteries with a different number of sections should be installed;

- Compliance with the angle of inclination of the upper supply line. On average per 1 m.p. the inclination towards the movement of liquid should be 5-7 mm.

An expansion tank must be provided for top filling in the heating system. It is located at the highest point and performs several functions. The main thing is to stabilize the pressure when heating water in the pipes. If an open type tank is installed, coolant can be added through it.

You can increase the water pressure using an accelerating manifold - a vertical pipe installed immediately after the boiler. However, the minimum height of this element must be 3 m, which makes its installation in apartments impossible.

Associated movement of water

In this case, the direction of movement of the hot and frozen coolant is the same. To improve the performance characteristics for the upper and lower heating distribution, experts recommend installing a bypass for each radiator. This is a straight piece of pipe connecting the inlet and outlet pipes of the radiator. The bypass package must include shut-off valves. As an additional control element, you can install a thermostat. In this case, not the entire volume of coolant may reach the battery. Adjustment is carried out using shut-off valves. Such a single-pipe heating scheme with overhead wiring has the following positive qualities:

- Ability to carry out repair work without stopping the system. To do this, the entire water flow is directed through the bypass;

- Installing a thermostat together with a three-way valve forms a system for automatically regulating the degree of heating of the radiator.

House heating scheme

It was already mentioned above that most modern houses in cities are heated using a centralized heating system. That is, there is a thermal station in which (in most cases using coal) heating boilers heat the water to a very high temperature. Most often it is more than 100 degrees Celsius!

Water is supplied to all buildings connected to the heating main. When connecting a house to a heating plant, inlet valves are installed to control the process of supplying hot water to it. A heating unit is also connected to them, as well as a number of specialized equipment.

heating unit operation diagram

Water can be supplied both from top to bottom and from bottom to top (when using a single-pipe system, which will be discussed below), depending on how the heating risers are located, or simultaneously to all apartments (with a two-pipe system).

Hot water, entering the heating radiators, heats them to the required temperature, ensuring its required level in each room. The dimensions of radiators depend both on the size of the room and on its purpose. Of course, the larger the radiators, the warmer it will be where they are installed.

Two-pipe heating system with overhead wiring

Installing a two-pipe heating system with overhead wiring minimizes or completely eliminates many of the disadvantages described above. In this case, the radiators are connected in parallel.

Its installation requires significantly more materials, since two parallel lines are installed. Hot coolant flows through one of them, and cooled coolant flows through the other. Why is this top vent heating system preferred for private homes? One of the significant advantages is the relatively large area of the room. The two-pipe system can effectively maintain a comfortable temperature level in homes with a total area of up to 400 m².

In addition to this factor, the following important operational characteristics are noted for a heating scheme with top filling:

- Uniform distribution of hot coolant over all installed radiators;

- Possibility of installing control valves not only on the battery piping, but also on individual heating circuits;

- Installation of a water heated floor system. A collector hot water distribution system is only possible with two-pipe heating.

The optimal capacity of an open expansion tank is 5% of the total volume of water in the system. Moreover, it should only be 1/3 full.

To organize forced top filling in the heating system, it is necessary to install additional components - a circulation pump and a membrane expansion tank. The latter will replace the open expansion tank. But the location of its installation will be different. Membrane sealed models are mounted on the return line and always on the direct section.

The advantage of such a scheme is that it is not necessary to observe the slope of the pipelines, which is typical for the upper and lower heating distribution with natural circulation. The required pressure will be created by a circulation pump.

But does a two-pipe forced heating system with overhead wiring have any disadvantages? Yes, and one of them is dependence on electricity. During a power outage, the circulation pump stops working. If the hydrodynamic resistance is high, the natural circulation of the coolant will be difficult. Therefore, when designing a single-pipe heating system with overhead wiring, you need to perform all the required calculations.

You should also take into account the following installation and operation features:

- When the pump stops, reverse movement of the coolant is possible. Therefore, in critical areas it is necessary to install a check valve;

- Excessive heating of the coolant can cause the critical pressure to exceed. In addition to the expansion tank, air vents are installed as an additional protective measure;

- To increase the efficiency of a heating system with top-pipe distribution, it is necessary to provide automatic replenishment of the coolant. Even a slight decrease in pressure below normal can lead to a decrease in heating of radiators.

Regardless of the chosen scheme of a heating system with top filling, it is necessary to provide for two types of adjustment of the degree of water heating - quantitative (using shut-off valves) and qualitative (changing the boiler power). Then the heating operation will be not only efficient, but also safe.

The video will help you clearly see the difference for different heating schemes:

Central (or centralized) heating is a system for providing heat to a large number of residential properties.

It is most often used for heating apartment buildings, office buildings, and industrial facilities.

you understand the essence, structure and principle of operation , as well as understand the types of central heating systems.

Equipment

So, we are going to install water heating with our own hands. What main elements will our scheme include?

Boiler

Domestic gas heating boilers are the cheapest to operate. In the Moscow region, the cost of heating a 200 m2 house with main gas does not exceed 3,000 rubles per month.

Boilers can be volatile (with electronic ignition) and non-volatile (using piezo ignition and a pilot burner). The former are noticeably more economical - the pilot burner consumes up to 20% of the total amount of gas.

In second place in terms of efficiency are solid fuel boilers. Coal and firewood will be an excellent solution where there is no main gas. However, using solid fuel requires frequent loading: you will have to light the boiler at least twice a day.

There are, however, a number of ways to solve this problem.

- Gas-generating solid fuel boilers split the fuel combustion process into two stages. Initially, it smolders with limited air access, forming flammable pyrolysis gas; then this gas is burned in its own furnace. A gas generator boiler is capable of operating on one load not for 2-5, but for 8-12 hours.

- Top-burning devices use the smoldering of a thin top layer of coal or wood. A coal boiler can operate for up to 5 days without maintenance or cleaning.

- A simple and universal solution is to use a heat accumulator (a thermally insulated container with a volume of 300-2000 liters). Working at full power, the boiler heats the water in the tank after lighting. Over the next few hours, the accumulated thermal energy is gradually released to the heating devices.

Finally, solar and electric boilers differ little in heating costs. They provide the maximum cost per kilowatt-hour of heat. In addition, it is not possible to provide the power required for heating with electricity everywhere.

Pipes

Their choice is determined by whether we are talking about central or autonomous heating.

The optimal material for central heating is steel pipes of several types.

- Black steel is cheap but susceptible to corrosion. In addition, steel risers and connections require a lot of time and effort for installation. Connections are most often made by welding.

- Galvanized steel is protected from corrosion by a zinc layer; It would be correct to assemble a galvanized liner ONLY on threads. Welding breaks the protective coating, including inside the pipe.

- Finally, a wonderful material is corrugated stainless steel. The pipes are connected using compression fittings with silicone seals and are easy to bend.

Why steel? Because in the central heating system you are not protected from exceeding the design temperature and water hammer. It is better to overpay when installing heating, and not when eliminating the consequences of a dirty boiling water leak.

But autonomous heating means that all parameters are constant and under your control. Hence the choice of materials:

- Metal-plastic with press fittings.

Important: it is better not to use compression fittings with union nuts on heating and hot water. After several heating and cooling cycles, they begin to leak.

- Polypropylene. Preferably reinforced: reinforcement not only increases the tensile strength of the pipe, but also reduces its thermal expansion.

- Cross-linked polyethylene. In addition to strength, these pipes have another advantage: they are flexible and are supplied in coils up to 500 meters long, which is useful for radial distribution with laying pipes in a screed.

Heating devices

And here it is worth separating central and autonomous heating.

In central heating systems, it is better to use steel tubular radiators, steel convectors and bimetallic radiators. Aluminum is not desirable.

And not only from the point of view of strength: the instructions for the use of aluminum radiators specifically stipulate the ability of this metal to accelerate destruction in combination with copper water supply. Metals form a galvanic couple.

Since you can’t know what your neighbors’ eyeliners are made of, it’s better not to take risks.

But for autonomous heating, aluminum radiators are undoubtedly the best choice.

Safety

- Expansion tank. It accommodates excess coolant during its expansion accompanying heating.

- Safety valve - additional insurance against circuit overflow. The valve is activated and releases excess coolant when its pressure reaches a preset threshold value.

- A pressure gauge or thermomanometer is installed for visual monitoring of parameters.

- An automatic air vent or a manual air vent is mounted at the highest points of the circuits and in air pockets.

Central heating: what is it?

The structure of centralized heating consists of several interconnected elements.

Heat source and heat exchanger

CHP plants or can act as a source of thermal energy . The combined heat and power plant heats the coolant using thermal energy generated by steam from water in steam turbines.

With the help of a heat exchanger, the already heated water transfers heat to the cold water. In boiler houses, thermal energy is obtained from hot water.

It is believed that one thermal power plant can replace several boiler houses , but the latter also remain in demand.

Heating networks

They are a system of interconnected pipelines for transferring heat to residential buildings. Heat supply networks can be located both underground and above it, and thermal insulation measures must be observed in both cases.

Heat consumer

This is equipment for receiving and distributing heat throughout the facility.

The operating principle of a central heating system is based on the principle of circulating hot water (or steam) through supply and return pipes, which can be top- or bottom-filled. Both of these pipes can be located in the basement of the house, or you can install the water supply pipe in the attic or a specially equipped technical floor, and the return pipe in the basement.

When can a bottom or top spill scheme be installed?

A pipe system with bottom filling consists of a pair of risers connected by jumpers . Such a system can be installed either on the top floor of the property or in the attic.

Top filling pipe systems are installed on the technical floor.

An air vent and special valves must be connected here , which would allow each individual riser to be closed.

This option is considered more advanced and in demand when installing central heating, but has a number of nuances:

- As hot water moves downwards, its temperature decreases , which means that on the lower floors of a heated building it will be colder than on the upper ones. Therefore, when installing such a system, you should think about increasing the number of radiators or the area of convectors.

- When discharging hot water from a certain riser, you must first locate and shut off this riser on the technical floor, and then also find and turn off the valve for this riser in the basement, which is considered a rather complicated procedure.

Heating system design

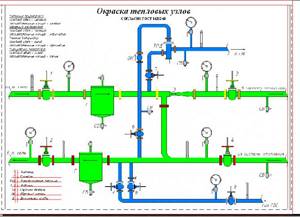

Elevator unit

The heating system of residential buildings begins with inlet valves that cut off the house from the route. It is along their flange closest to the external wall that the division of the areas of responsibility of housing and heating workers passes.

Further towards the house heating circuit are located:

- Hot water taps on the supply and return pipelines. The implementation may be different: each pipeline may have one or two tie-ins; in the second case, a flange with a retaining washer is mounted between the taps, creating a pressure difference to ensure continuous circulation. This is necessary so that the water in the DHW risers is hot around the clock, and the heated towel rails powered by hot heating remain hot.

Useful: in winter, when the supply temperature is below 90C, the DHW in this case is connected between the connections on the supply, and above - on the return. In summer, the circulation mode of the hot water supply system is from supply to return.

- The heating elevator itself is a key component that provides heating for a multi-story building. In it, hotter water from the supply, due to greater pressure, is supplied through a nozzle into the socket and, through a suction, draws part of the water from the return pipeline into a repeated circulation cycle through the heating circuit. It is the diameter of the nozzle that regulates the heating in an apartment building - it determines the real difference inside the heating system and the temperature of the mixture, and therefore the heating devices.

- House valves allow you to cut off the heating circuit. They are open in winter and closed in summer.

- After them, discharges - valves for draining or bypassing the system. In some cases, the heating system of a residential building is connected through a valve to the cold water supply system - solely to ensure that the radiators can be filled with cold water for the summer.

Spills and risers

The word “bottling” among professionals refers to both the direction of water circulation and the thick pipe through which water flows to the risers.

Typical heating of a 5-story building is made with bottom bottling. The supply and return pipes are routed along the outer contour of the house in the basement. Each pair of risers is a jumper between them. The risers are connected to each other upstairs - in an apartment on the top floor or in the attic.

- Jumpers placed in the attic are pure evil. It is almost impossible to ensure ideal thermal insulation of the attic and maintain a constant positive temperature in it. Any stop of heating means that after half an hour there is ice in the jumpers instead of water.

- An air vent is mounted at the top point of the jumper. In typical Soviet-built houses, it is a simple and extremely fail-safe design - the Mayevsky tap.

Bottom filling is associated with a problematic start of circulation after each discharge: the jumpers become air-filled, and for normal operation of all risers it is necessary to bleed air from each jumper. It can be problematic for locksmiths to get into all apartments, to put it mildly.

The heating system in a nine-story Soviet-built building is often somewhat different: the supply bottling is located in the attic. An expansion tank with an air valve is also mounted there; there is also one of a pair of valves that cuts off each riser.

After stopping and resetting the heating, problems with defrosting are extremely rare:

- When the bottling is laid at the correct slope and the vent is open, ALL water from the bottling and the top of the risers is discharged in a matter of seconds.

- Despite thermal insulation, bottling losses are large enough to warm up the attic even with minimal thermal insulation of the room.

- Finally, bottling is a pipe with a diameter of at least 40-50 millimeters with great thermal inertia, which, even with water without circulation, will not freeze in five minutes.

Top filling has a number of other features:

- The temperature of radiators decreases linearly from floor to floor, which is usually compensated by their large size. It is clear that below, already cooled coolant enters the heating devices; Therefore, heating of the first floor is usually carried out with the maximum number of radiator sections or the total area of convectors.

In addition: the temperature in the basement is usually lower than in apartments. Losses through the ceiling on the outer floors are usually much greater.

- Starting the heating is very simple: the system is filled; both house valves open; then the vent on the expansion tank opens for a short time - and ALL risers are involved in circulation.

- Removing a separate riser, on the other hand, is more difficult and involves a lot of movement. You first need to find and turn off the required riser in the attic, then find and shut off the second valve in the basement, and only then unscrew the plug or open the vent.

Principle of operation

First, the residential property that needs to be provided with heat is connected to the heating network from the boiler house or thermal power plant. valves are installed in the pipelines of the facility , from which thermal units run. Then they install mudguards - devices that will prevent the accumulation of dirt and metal oxides in the pipeline.

After installing the valves and mud traps, the main unit of the entire heating system is installed - the elevator . Its function is to cool water overheated from the thermal power plant to the optimal temperature.

The fact is that the water entering the thermal power plant for heating is overheated to too high a temperature - 130-150 degrees Celsius, and to prevent the liquid from turning into steam, optimal pressure is created in the heating network. Therefore, it became necessary to cool the overheated water using an elevator.

Photo 1. This is what an elevator looks like - a mixing unit for heating a house, which works as a circulation pump and mixer.

Based on the condition of the elevator, you can also determine the level of temperature difference in the heating network: when this happens, the elevator nozzle changes diameter.

The heating elevator is followed by another valves, with the help of which the heating in residential buildings is turned off and on.

Installation of vents is another important detail of a central heating installation. Resets are special valves designed to restart the system. Last but not least, heat meters are installed to determine the amount of heat transferred to the object.

Connection on a balcony or loggia

Connecting a central heating system to a balcony or loggia is a very controversial phenomenon . The fact is that the connection work plan will need to be agreed upon with the BTI. In addition, freezing water in pipes is also not pleasant. To heat the balcony, it is better to use an electric heater or have a heated floor.

Garage installation - no polypropylene

It is possible to install central heating in a garage if it is equipped with a heating system main. If there is no highway, then you can equip it.

It is important to choose the right material for the pipeline. It is not recommended to use polypropylene as a material for pipes.

But this is possible when the garage is attached to a residential building. If the garage is a separate building an autonomous boiler room next to it , which will heat its premises, however, this will take a large amount of money.

Advantages and disadvantages

A centralized heating system has both advantages and disadvantages.

Among the advantages are:

- reliability and quality of service due to constant monitoring of the system by technical services;

- relatively inexpensive fuel;

- environmentally friendly equipment;

- ease of use.

As for the disadvantages, they are as follows:

- pressure drops in the heating system;

- dependence of the work schedule on the seasons of the year;

- expensive equipment;

- inability to independently regulate the temperature on heating devices;

- colossal heat losses during its transportation through pipes and units.

On what basis is water heating divided into types?

Depending on certain factors, there are several types of centralized heating systems.

- By thermal energy consumption mode

- year-round - requires constant heat supply;

- seasonal - requiring heat only in the cold season.

- By type of coolant :

- air - a system that not only heats the building, but also ventilates it; due to expensive equipment it is used extremely rarely;

- water - intended only for heating a residential property; widely used for heating apartment buildings and is easy to operate;

- steam system - provides the building with heat and water vapor, is actively used in industrial facilities.

- 3. According to connection method :

- independent - heating system in which the coolant heats water in a heat exchanger;

- dependent - the coolant is heated in the heat generator and immediately supplied through the heating networks to consumers.

- 4. According to the method of connection to the water supply system:

- open - a system in which hot water is supplied directly from the heating network;

- closed - water is supplied from the water supply and then heated in a heat exchanger.

What is heating like?

When it comes to heating an apartment building, one cannot boast of a large selection. All houses are heated according to approximately the same scheme. In each room there is a cast-iron heating radiator (its dimensions depend on the size of the room and its purpose), into which hot water of a certain temperature (coolant) coming from the thermal station is supplied.

example of a cast iron radiator

However, the entire water supply circuit may vary depending on what kind of heating distribution is provided in a particular building - single-pipe or two-pipe. Each of these options has certain advantages and disadvantages. To better understand this issue, you need to know exactly everything about the first and second. So let's briefly describe them.

- Single pipe heating system. Its design is simple, and therefore reliable and cheap. But still she is not in great demand. The fact is that, when entering the heating system of a house, the coolant (hot water) must pass through all the heating radiators before it enters the return channel (also called “return”). Of course, by heating all the radiators one by one, the coolant loses temperature. As a result, when reaching the last user, the water has a relatively low temperature, which is why in the last room it can differ significantly from the temperature in the one it arrives at first. This often causes discontent among residents. Therefore, the described heating system for a multi-storey building is used relatively rarely.

- Two-pipe heating system. It is free from the disadvantages that are inherent in the heating system described above. The design of this system is significantly different. Hot water, having passed through the heating radiator, does not enter the pipe leading to the next radiator, but directly into the return channel. From there it is immediately sent back to the thermal station, where it will be heated to the required temperature. Of course, this option requires significantly higher costs both during installation of the system and during maintenance. But this heating system design makes it possible to ensure the same temperature in all heated buildings. Example of a two-pipe heating system

It also makes it possible to install a heating meter. By installing it on a heating radiator, the owner can independently regulate its heating level and, accordingly, reduce the cost of paying heating bills. This option is not possible in a single-pipe heating system. By reducing the amount of hot water passing through your radiators, you can thus cause a lot of trouble for your neighbors, to whom the coolant reaches after passing through your apartment. That is, the heating rules in this case will be openly violated.

Of course, it is impossible to change the type of heating system in an apartment; this requires titanic efforts and a huge amount of work that will affect the entire house. But still, knowing about the pros and cons of different types of heating systems will be useful for every apartment owner.

This video provides a broad overview of various heating systems.

Is it possible to abandon the centralized system and connect an individual one?

It is quite possible to turn off the centralized heating system in your apartment if you do it legally , in compliance with the law, which, by the way, does not prohibit it.

There are several reasons for disabling:

Turning off central heating in an apartment building is not an easy procedure.

The fact is that this is a closed system, and the release of any element from it leads to its destruction. In the future, a complete reconstruction of the system will be required.

Therefore, you should take this matter seriously and under no circumstances disconnect from heating networks without permission .

First, you need to notify all homeowners of your intention, hold a general meeting , and then contact the relevant authorities with a package of documents, most often the management company.

Required documents

- Statement.

- Technical passport of the apartment in which it is planned to turn off the central heating.

- Ownership of the apartment.

- Consent of all residents to turn off the heating.

- Conclusion on the re-equipment of the heating system.

- Heating conversion project , which must be developed by engineers and verified by the relevant authorities.

If disabling the central system is approved, then it will be necessary to dismantle the system : remove the batteries, install autonomous heating, etc.

Attention! All work should be carried out only by experienced specialists. to take on this matter on your own, without experience in this area .

Development of a heating system project

The heating device, starting from the inlet system and ending with heating radiators, is created immediately after the skeleton of an apartment building is built. Of course, by this time the heating project for an apartment building must be developed, tested and approved.

And it is at the first stage that a number of difficulties often arise, as with any other very complex and important work. In general, the heating system of an apartment building is complex

The power of your heating system can depend on the strength of the wind in your area, the material from which the building is constructed, the thickness of the walls, the size of the rooms and many other factors. Even two identical apartments, one of which is located on the corner of the building, and the other in its center, require a different approach.

After all, a strong wind in the winter season cools the outer walls quite quickly, which means that the heat loss of a corner apartment will be much higher.

Therefore, they need to be compensated by installing larger heating radiators. Only experienced specialists who know exactly how all the equipment is designed and how it works can take into account all the nuances and select the optimal solutions.

A beginner who decides to calculate the heating system in an apartment building will be doomed to failure from the very beginning. And this will not only lead to a significant overexpenditure of resources, but will also put the lives of the inhabitants of the house in danger.