Why do you need long-burning wood-burning boilers for your home? When constructing private housing, there is always a need to build an autonomous heating system. It is good if gas is supplied to the construction site. Otherwise, you can, of course, use the electric option, but electricity is too expensive. The second option is a regular wood-burning stove with a water circuit, but to heat a large area you will need too much firewood, which is also not cheap. However, if you use long-burning wood-burning boilers for your home, most problems can be avoided.

Long-burning solid fuel boilers are a good solution for efficient heating of a private home

Operating principle

The operation of heating equipment can be based on two different principles:

- Fire spreads from top to bottom. As a result, combustion time increases;

- when using the pyrolysis method, the released gases are not immediately removed to the outside, but are ignited again. This method allows you to obtain maximum heat transfer.

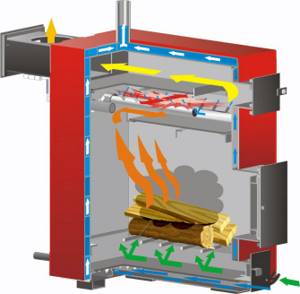

The air flow enters directly into the combustion area. In a heating boiler, wood oxidizes. It is affected by high temperature and insufficient oxygen. When wood chars, carbon dioxide is released.

A similar process is recreated in the combustion chamber, in limited space. Wood does not burn, but slowly smolders. The combustion duration increases. The lack of thermal energy is compensated by the combustion of the released gases.

How do CDGs work?

Most solid fuel stoves use the top supply of oxidizer (oxygen contained in the air) to maintain combustion. In addition, immediately before entering the firebox, it is heated to a certain temperature, which promotes better oxidation and minimization of combustion waste: ash, soot, etc.

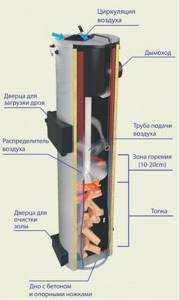

Oxygen in them, unlike a fireplace, is supplied from the top input, and then falls into the lower part of the combustion chamber.

Thanks to this organization of air movement, at the initial stage, only the top layer of solid fuel located in the chamber volume is effectively burned. After the reserves of this layer are exhausted, the supply of oxygen to its lower part is turned on. As the next layer burns out, the air flow penetrates deeper and deeper into the firebox. Thanks to this, each subsequent portion of wood is disposed of only when its order arrives.

This approach allows you to save on the volume of fuel consumed and at the same time clearly control the combustion process. The described features of the technology made it possible to classify boilers operating on its basis into the category of long-burning heating equipment. Due to the specific nature of their operation, these units are economical and guarantee a high level of environmental friendliness when recycling all types of fuel.

Construction of heating units

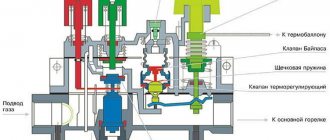

Long-burning wood-burning boilers contain the following elements:

- combustion chambers. In the first section, wood is burned. In the second, combustion of carbon dioxide is maintained. For more efficient operation, the structure is lined with fireclay bricks;

- automatic control system. A special device is used to control the flow of air into the heating structure. Due to this, the combustion temperature changes. In simpler devices, a slide valve is used for manual control;

- The combustion chamber includes a coil. The coolant circulates through it. In a cast iron design, the water jacket is located around the combustion chamber;

- heating batteries with supply and return outlet. They are united into a common outline;

- the chimney consists of broken transitions. This design accumulates heat better

Most heating units include enlarged loading chambers. This design allows you to increase the battery life up to 12 hours. Some models are capable of operating without additional fuel loading for several days.

Review of popular models and their costs

When choosing models, reviews from users and experts were taken into account. The list includes both domestic and foreign devices.

"Bourgeois-K STANDARD-20"

The technical characteristics of this model significantly exceed those of the classic “potbelly stove”. This pyrolysis boiler is 4 times more economical when compared with similar installations. To keep the house warm around the clock, it is enough to heat it 2 times a day. During combustion, a minimal amount of soot and carbon dioxide is released. The boiler power is 20 kW, it is 1.5 times more affordable than imported models.

Key benefits:

- high energy efficiency;

- works on different types of fuel;

- the presence of an automatic thermostat;

- energy independence.

Among the disadvantages, one can note only the large mass of equipment. You can buy this model in Moscow at a price starting from 62,000 rubles.

Buderus Logano G221-25

The Buderus boiler can operate on any solid fuel. The burning time is ensured by the spacious chamber. If necessary, the temperature of the coolant is adjusted. The equipment can be installed in a system with natural circulation or with a pump.

The maximum power of the Buderus boiler is 25 kW, so it successfully copes with heating rooms up to 250 m2. The heat exchanger, made of cast iron, allows you to heat water to a temperature of +90 °C. This is a non-volatile installation with an efficiency of 78%. The unit performs excellently in working conditions in a private home.

Advantages:

- a volumetric firebox that can accommodate firewood up to 68 cm long;

- reliable and high-quality assembly;

- energy efficiency;

- easy installation;

- simple maintenance.

The only disadvantage of the boiler is its high cost. It will cost 119,000 rubles.

Prices for Buderus boilers

boiler Buderus

"Don KS-T 16 R"

This efficient and reliable model is produced in Russia. The body is made of steel. The unit is suitable for operation in open and closed systems. Any type of fuel is loaded into it - pellets, coal, firewood, and so on. The 16 kW model is ideal for heating a house with an area of 160 m2. The only negative is the unpresentable appearance.

Boiler advantages:

- easy to use;

- allows you to connect a gas burner;

- It's inexpensive.

The Don unit will cost customers 20,800 rubles.

"Week KO-90"

This production model is also produced in Russia. The operating power varies from 15 to 45 kW, there is automatic control and adjustment. Using the “Nedelka” device, you can heat rooms with an area of 150 to 400 m2. This could be: a large country house, a cottage, a service station or a car wash.

The ability to load 300 liters of fuel will allow the boiler to operate for 7 days. In addition, this equipment is omnivorous, so choosing the right material is easy. To achieve long-lasting combustion, it is recommended to use coal grades T, SS and A.

Equipment advantages:

- made of 5 mm steel grade 09G2S;

- produced using patented technology;

- every stage of production is strictly controlled;

- Together with the boiler, the buyer receives all the necessary documentation confirming the fire safety and reliability of the equipment.

The cost of the device is from 164,900 rubles.

"Lemax Forward-16"

It is characterized by a simple design, where there is nothing superfluous, therefore maintenance of this model is not required. Decorative metal panels are used to make the body. Next comes the thermal insulation, under which a housing made of 4 mm steel is hidden. The volumetric fuel chamber is protected from overheating, which is provided by a water jacket.

To increase strength, the manufacturer reinforced the heat exchanger with a channel. The lower part of the device is equipped with a heat-resistant grate, under which there is a box for ash. Firewood or brown coal is used to operate the boiler. If necessary, loading can be done from above. Power - 16 kW.

Advantages of the boiler:

- Any solid fuel is suitable;

- compact dimensions;

- availability of top and end loading;

- availability.

The price for this model starts at 18,190 rubles.

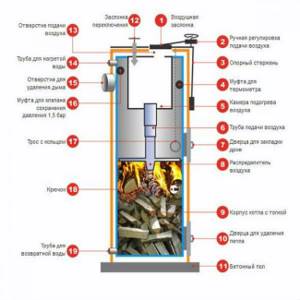

STROPUVA S40

The unit is best suited for industrial premises. The combustion chamber can hold up to 50 kg of firewood. It takes about 70 hours for them to burn. The thermal power of the equipment is 40 kW, which means that it can be used to heat rooms up to 400 m2.

Of course, you can install the unit in a private home, but to do this you need to be a wealthy person, because the price of the model is quite high. The boiler is equipped with a steel heat exchanger and an open combustion chamber, where, in addition to firewood, wood briquettes can be placed.

Advantages:

- high thermal power;

- relatively compact dimensions;

- simple controls;

- long duration of fuel combustion;

- independence from electricity;

- The coolant can heat up to +95 °C;

- presence of a safety valve.

The price of a long-burning solid fuel boiler is from 127,000 rubles.

Prices for STROPUVA boilers

boiler Stropuva

"NMK MAGNUM KDG 20 TE"

This is a domestic development, created taking into account the climatic characteristics of Russia. It accepts only coal as a heating material, which can burn for about 5 days, giving an efficiency level of 75 to 80%. Essentially, this is the “golden mean”, taking into account the power indicators, reliability of the boiler and the complexity of its maintenance. There is a combustion control system, although it is quite simple.

Advantages:

- accessibility, since the devices are produced by a domestic manufacturer;

- high-quality assembly;

- There is a heat adjustment.

The cost of the model is from 32,620 rubles.

Advantages and disadvantages

The main advantage of heating devices is the possibility of long-term autonomous operation. The combustion intensity is regulated by an automatic system. It increases or decreases the flow of air masses into the firebox. When operating boilers with manual control, it is not necessary to use additional energy sources. They are most often used in heating circuits with natural circulation. But if you reduce the combustion intensity, the efficiency of the heating device decreases noticeably.

The battery life of a conventional long-burning boiler does not exceed 8 hours. According to manufacturers, some models are capable of maintaining the combustion process without additional loading of firewood for more than 30 hours.

Fuel used

The advantages of long-burning heating equipment include the ability to use different types of fuel, which allows its owner to choose the most economical type. The following types of solid fuel are suitable for loading into the CNG:

- firewood or coal;

- natural peat and artificial pellets;

- regular or pressed sawdust.

The sizes of combustible products placed in the chamber can be different, which simplifies the order of their storage within the boiler room.

The ability to use a variety of types of solid fuel once again confirms the versatility of automatic boilers, which can also be used in domestic conditions.

We calculate the required heater power

Using a wood boiler you can heat a fairly large room. Its area can reach up to 500 m2. Power is determined in the following order:

- calculate the total area of the room;

- calculate the power of the heating system, taking into account that heating 10 m2 of space will require 1 kW of thermal energy;

- if there is a hot water supply system, another 20% is added to the obtained value.

Such calculations are of an average nature and are more suitable for central Russia.

Voting: which solid fuel boiler is the best?

What would you choose from solid fuel boilers or would you recommend purchasing?

Stropuva S40U

31.25% ( 5 )

Candle S-18kW

18.75% ( 3 )

Buderus Logano S171-50 W

12.50% ( 2 )

ZOTA Optima 20

6.25% ( 1 )

Sime SOLIDA EV 5

0.00% ( 0 )

Protherm Beaver 40 DLO

0.00% ( 0 )

Bosch Solid 2000 B SFU 27

6.25% ( 1 )

Kentatsu ELEGANT-03

6.25% ( 1 )

Kiturami KRM 30R

0.00% ( 0 )

ZOTA Mix 20

6.25% ( 1 )

Design Features

Heating devices are divided into several types, depending on the presence of certain design features:

- firebox designs. You can use vertical or horizontal loading of heating material. A vertical combustion chamber is more suitable for wet firewood. In this case, bottom combustion is used. During the burning of the lower layers, the wood located at the top is dried;

- To regulate the operation of heating devices, mechanical or manual dampers are used. Using an automatic control system, the used air is forced into the firebox, and the exhaust gases are removed. A controller and thermostat are used to control the room temperature. Such systems are more often used for heating industrial premises;

- Heating structures with a built-in boiler storage tank have one heating circuit. With its help, the coolant and water in the hot water system are heated.

Features of operation

When heating premises using long-burning boilers, the amount of wood used is significantly reduced. Savings can reach up to 40%, and efficiency approaches 90%. In order for the heating device to work as efficiently as possible, certain rules must be followed:

- when initially igniting the wood, the damper should be opened;

- The boiler can be switched to main mode only after the combustion temperature reaches 600°C;

- It is not recommended to use wood that is too wet. The moisture content in them should not exceed 20%;

- care should be taken to ensure that the temperature of the coolant does not fall below 65°C;

- when burning, it is better to use hard wood: beech, stock, oak or aspen;

Correct loading of firewood

When placing firewood in the firebox, large pieces are selected. They should be located close to each other. The formation of voids should be avoided whenever possible. The logs must be shorter than the dimensions of the loading chamber.

Dry splinters are used for ignition. It is strictly prohibited to ignite the firebox using gasoline or other flammable materials. From time to time, special briquettes should be used instead of wood, which help remove tar deposits on the walls of the heating boiler.

Installation of the heating unit

During installation work, it is necessary to follow the general rules that apply to wood-burning boilers and take into account SNiP standards:

- As a base for the heating structure, you should choose a durable, non-combustible material. Adjacent walls are equipped with additional protection;

- when laying the chimney, they are guided by fire safety standards. If its surface comes into contact with a wall that contains flammable material, the contact points are insulated with fire-resistant insulation elements. A steel sheet is attached to the top;

- to connect water heating, use special taps located on the heater body;

- if the boiler output exceeds 40 kW, it should be installed in a separate room;

- Volatile equipment must be connected using a stabilizer or an uninterruptible power supply. For protection, automatic devices are used that connect directly to the electrical panel.