We're sure you're not a fan of unexpected expenses. And you probably don’t want to replace a completely new boiler because of a problem that was not resolved in time. Meanwhile, problems appear even in devices that work for the first day. In the article we wrote about errors in Kiturami gas boilers and their codes. Read it. Even if you do not have heating equipment of this brand, it is better to learn more about it - you will understand whether it is worth buying it in the future.

You will learn to recognize errors in Kiturami boilers. Find out what causes them, in addition to the main reasons. For convenience, we have presented their codes in ascending order. Immediately after them, other failures and problems that do not have codes were indicated. Read the article and you will know what to do if a malfunction occurs.

Boiler errors are determined through codes. They differ among manufacturers. On Kiturami devices, combinations of numbers from 01 to 98 pop up. The decodings are the same for all boilers of this brand that run on gas. They can differ only because of the names of individual modules.

Design and principle of operation of Kiturami boilers

The South Korean company Kiturami produces boilers that run on various types of fuel. Gas double-circuit floor- and wall-mounted units, solid fuel or biofuel, wood-burning, pellet boilers, fueled by pellets, diesel boilers - designed to run on diesel fuel.

The company also produces combination boilers that can use solid fuel - wood, coal, household waste and liquid fuel - diesel fuel. Such boilers are equipped with two combustion chambers, separate for each type of fuel.

The boilers use a high-tech burner design patented by the company, a turbocyclone, thanks to which the units can operate at reduced gas pressure. What this means is that the burner completely burns the fuel, thanks to the combustion gas return device and the addition of a secondary flow, thereby ensuring one hundred percent ignition.

Kiturami HiFin gas models are equipped with a capacitive heat exchanger and a hot heating circuit, which is located in the expansion tank block. It is this technology that allows you to simultaneously use hot water and heat the room. Solid fuel and combined boilers use low-carbon technologies, which are the original development of the company.

Pellet boilers use original technology, thanks to which the boiler does not need to be cleaned; the ash leaves the device along with the condensate through a pipe made of stainless steel. The latest 4th generation models can be heated even with completely wet wood, the excess moisture released during the combustion process is removed outside using a special device.

The boilers are equipped with a built-in transformer that protects the equipment from damage during power surges, an automatic self-diagnosis system, an anti-freeze system, various safety sensors, some models are even equipped with seismic sensors that provide a high degree of safety in seismically hazardous areas.

Kiturami boiler transformer

Kiturami units can operate in different climatic conditions, at particularly low temperatures (in Arctic conditions), are resistant to increased vibrations, and operate stably with low fuel quality. The power of the boilers has a wide range from 10 to 460 kW, which makes it possible to use them both in residential premises and in production areas of up to 4000 sq.m.

During operation of the boiler, malfunctions and errors may occur, which are displayed on the device display.

Problems in the operation of Kiturami boilers

Not all problems have their own code, so we will consider them separately.

“Network” indicator does not light up - check the power in the outlet and the fuse on the ignition transformer. If there is no voltage in the electrical network, call an electrician; if there is, call the service department.

The indicator on the control unit lights up for insufficient water - there is no water in the device or the level is too low. Damage to the black wire of the boiler and the red cable of the sensor can also cause a problem.

The room temperature sensor works normally, but the radiators are cold - the circulation pump does not disperse the coolant through the pipes or does so too weakly. Inspect the locking parts on the heating pipes. Check the pump itself.

"Overheat" light comes on - the heating system is not working properly. Check her out.

If the problem persists, do the following:

- Adjust the shut-off valves on the heating pipes.

- The strainer may need cleaning. Examine it.

- Check the circulation pump, repair or replace if necessary.

The “Safety” diode lights up - gas enters the boiler burner in small quantities or does not enter at all. Inspect the valves and open them if necessary. The problem remains - call the gas workers.

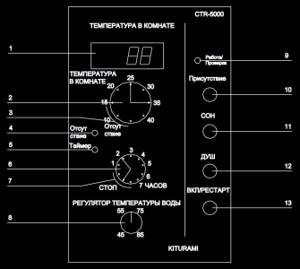

Schematic representation of a room remote thermostat: it has 5 main modes, including presence, absence, shower, sleep, water heating control

The pump has been running for too long. The water temperature indicator on the control unit is constantly on - the heating system is not working properly or there are air pockets in it. Release the air.

The boiler takes longer to heat up - look for a problem with the gas pressure and the condition of the filters.

The burner vibrates when turned on - the size of the chimney is not enough for normal gas removal.

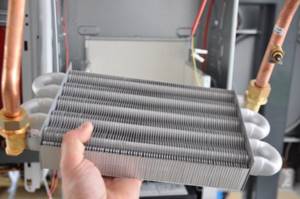

The efficiency of the device in terms of hot water supply and heating has decreased - bad water or dirt from the heating system enters the boiler. Chemical treatment of the circuits and heat exchanger will help.

Basic error codes for gas boilers

Let's look at the main error codes of the Kiturami gas boiler and methods for eliminating them.

01

Error 01 (ep 01) or E01 appears when there is no ignition when starting the boiler.

If the boiler gives this error, check:

- Is the gas valve unscrewed, unscrew it all the way;

- the system is airy, bleed the air;

- grounding may be done incorrectly or broken, ground the unit, note that the grounding wire must be buried in the ground at a distance of at least 30 cm;

- gas pressure, if it does not correspond to that specified in the instructions, contact a specialist;

- serviceability of the ignition transformer, check, if necessary, replace with a new one;

- ignition cable and ignition socket for mechanical damage, eliminate them;

- if the burner is clogged with soot, clean it;

- electrode, its angle of inclination, whether it is clogged, adjust the inclination in accordance with the instructions for the device, clean it of soot and burning, check for short circuits and breaks;

- gas valve, if faulty, replace;

- serviceability of the flame control photocell, if not working, replace it;

- control board, wires suitable for it, if the board is faulty, replacement is required.

02

Error 02 or E02 means a flame defect before gas supply or a false flame.

Occurs in the following cases:

- if the flame control photocell is faulty, it must be replaced;

Kiturami boiler control board - if there is a malfunction in the operation of the electronic control board, check the connection of the contacts; if the board is faulty, replace it;

- in case of a short circuit between the electrode and the control unit;

- When the electrode touches the burner jets, it is contaminated with soot, clean and adjust its position.

03

Error 03 or E03 appears when the flame goes out constantly, several times within 1 minute.

To troubleshoot, check:

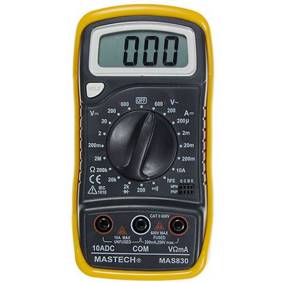

- check the fan for correct operation by measuring the resistance with a multimeter; if it is not working, change the fan;

- if the chimney is clogged, clean it;

- the presence of natural ventilation in the room where the unit is installed, open the doors and vents;

- gas pressure, if it is low, call a specialist from the gas service;

Gas pressure regulator - serviceability of the flame sensor; if it is faulty, replace it.

04

Code 04 or E04 appears when the heating temperature sensor does not operate correctly.

Check:

- mechanical connection of wires approaching it, in case of breakage or oxidation, clean and connect them;

- sensor for short circuit and open circuit, replace the sensor;

- the electronic board is in good working order, replace it if it is not working.

05

Error 05 or E05 means a malfunction of the overheating sensor.

Check:

- in models where a seismic sensor is installed, check it for short circuit and open circuit, if faulty, replace the sensor;

Tester - the amount of scale in the heat exchanger, clean it according to the instructions in the instructions;

- water pressure in the system, add water;

- thermostat for short circuit and break; if faulty, replace it.

06

Error 06 or E06 appears when the fan malfunctions.

To troubleshoot, check:

- check the wires leading to the fan for breakage or oxidation, clean and connect them;

- the fan blades are worn out, the fan will have to be replaced;

- sticking contacts of the differential relay; if the fault recurs when unsticking, replace the relay;

- mains voltage, if the voltage is inappropriate, install an autotransformer;

Checking the network voltage with a tester - If the chimney is clogged, clear it of any obstructions;

- fan rotor for short circuit and break; if faulty, replace the fan;

- Hall sensor is faulty, replace it.

07

Error 07 or E07 indicates a problem with the chimney system.

The reasons may lie in the following:

- the fan operates at too high or too low speeds, check its serviceability;

- accumulation of condensate, frost or snow in the chimney pipes, remove it.

- strong wind, if this problem is constant, you need to redo the chimney taking into account the wind rose.

Chimney cone

95

Error 95 (er 95) or E95 appears on the device display when the pressure in the heating system is low.

What to do when this code appears:

- inspect the filters and wash them if they are clogged;

- check for leaks in the radiators, at the joints, eliminate the leak;

- check the heat exchanger and expansion tank for leaks, eliminate the leak;

- inspect the membrane on the expansion tank, it may stretch and become coated, replace it;

- add water to the system to the nominal pressure.

96

Error 96 or E96 - the occurrence of this code means that the temperature sensor has tripped and the coolant has heated up above the permissible value of 95 degrees.

The cause of overheating may be:

- a large amount of scale in the heat exchanger, remove and wash the heat exchanger according to the instructions for your device;

Heat exchanger of a domestic boiler - Incorrect operation of the circulation pump, check, if the pump is faulty, replace it;

- Thermostat is faulty, check it for short circuit and open circuit; if a fault is found, replace the thermostat;

- Electronic board faulty, replace.

97

Error 97 occurs when there is a gas leak or when the system is airy. In this case, you need to turn off the gas valve, turn off the unit and call a specialist.

98

Error 98 occurs when there is insufficient fuel. It is necessary to check whether there is enough fuel entering the boiler.

Errors and malfunctions

What to do if there is an error on the display? Look at the instructions. Usually the manufacturer indicates the decoding of the values. Another thing is that it is not always clear to the user. We will tell you how to fix the problem.

Also run diagnostics:

Some boilers include a seismic sensor. During an earthquake, it blocks the operation of the device. Check it for serviceability.

Inspect the fan blades, wiring, and connection tightness. Check the differential relay, its contacts for sticking, and the Hall sensor.

Remove any scale from the radiator tubes.

Malfunctions of WORLD 5000 models

When the device is turned on and the CTR-5700 controller is started, the device does not respond. The lights don't come on and it doesn't start.

The CTR-5700 external regulator is functioning, but the batteries are cold.

The coolant probably does not move well through the system:

Problems with WORLD PLUS, WORLD 5000 models

The “Network” diode on the control unit does not light up.

The light comes on to indicate that there is not enough water.

The LED lights up to indicate overheating. The gas boiler is not working.

The “Safety” LED came on. Reason: pressure in the line has dropped. Fuel does not enter the burner.

Long pump operation. The temperature light on the panel lights up.

The burner is functioning, but the temperature rises very slowly.

When the burner starts up, vibration is heard. Incorrect chimney section. Combustion products are poorly removed. Carry out correct installation of the structure.

Weak heating of heating fluid and hot water supply. Clean the radiator from scale. Deposit prevention should be carried out every year. Connect cleaning filters.

Boiler won't start? Now you know what to do. If you do not dare to repair the equipment yourself, contact a service center.

Basic error codes for diesel boilers

01,02,03

Error 01, 02, 03 occurs when there is no ignition in diesel boilers Kiturami Turbo 13, Kiturami Turbo 17, Kiturami Turbo 30.

If this situation occurs, check:

- whether diesel fuel enters the unit, whether the shut-off valve is open;

- the filter may not allow fuel to pass through, contact a specialist;

- whether air enters the unit, whether the blinds are open, ensure free access of air;

- If the chimney is clogged, clean it.

04

Error 04 indicates a malfunction of the temperature sensor in the heating circuit.

Check:

- connecting the wires approaching the sensor for a break;

- thermostat for a short circuit or break; if a fault is detected, replace it.

05

When error 05 appears, the signal from the temperature sensor does not reach the electronic unit of the device. The reason lies in a malfunction of the sensor or a breakdown in communication between the sensor and the board. In this case, you should turn off the unit and call a specialist.

95

Error 95 appears when the pressure in the heating system is low.

Check:

- are there any leaks in the heating radiators and connecting joints;

- check the serviceability of the air valve; if it is not working, replace it;

- add water to the nominal value.

What are the differences between Kiturami heating boilers and what can cause them to break down?

The species diversity of Kiturami boilers affects the troubleshooting technology, so consideration of the types of their energy supply and design features is very important.

According to the type of fuel used, Kiturami boilers are divided into:

- diesel (Turbo, KSO series);

- gas (Twin Alpha, World Plus, KS);

- biofuels (KRM).

Construction of a gas double-circuit boiler Kiturami Twin Alpha

In addition, the company also produces solid fuel (KF), condensing heating boilers that can operate on combined fuels. Regardless of the type of device, they all have similar equipment, which includes 5 levels:

- an air system, which includes a chimney and inlet;

- hydraulics, whose main function is to perform heat exchange of the coolant;

- automatic control, with sensors and regulators;

- the fuel system, through which the fuel enters the injector and is transferred by the pump;

- electrical component.

All these levels interact with each other and provide the technical component (passport) of the device, so they must work uninterruptedly. That is why, if problems are detected, repair of Kiturami boilers must be carried out comprehensively. After all, even if the gear panel sensor shows a system failure, it will not indicate the real reason for the deviations in operation: be it a lack of grounding or a simple lack of fuel.

The main causes of problems include:

- violation of operating rules;

- incorrect installation;

- depreciation of equipment;

- untimely service.

Basic error codes for pellet boilers

03

Error 03 in a pellet boiler means that the engine through which pellets enter the boiler has turned off.

What should you do in this case:

- check for a wire break;

- measure the sensor for open and short circuit;

- Check the serviceability of the engine itself; if it is not working, replace it.

07

Error 07 appears when the fan operates at too high or too low speed.

To determine, check:

- It is possible that foreign objects have gotten into the fan housing, remove them;

Kiturami boiler fan - there is a strong wind outside;

- The fan is faulty, check the rotor for short circuits and open circuits; if a discrepancy is found, replace the fan.

97

Error 97 appears when the pellet filling level is low. It is necessary to fill the pellets to the level of the bottom of the holes in the burner plate.

Questions about malfunctions of Kiturami diesel boilers

___________________________________________________________________________

- Diesel boiler Kiturami Turbo

- Pellet boiler Kiturami

- Repair of gas boilers Kiturami

Question:

Kiturami turbo 13R, in presence mode everything works, it is triggered by both the room temperature and the water temperature. In shower mode, the temperature shutdown does not work, the boiler begins to boil. It doesn't give any errors. What could it be? Answer:

It is necessary to reduce the DHW temperature. Everything is described in detail in the boiler passport. If there is extraneous noise, there is likely salt deposits in the boiler itself. Question:

In the second year of operation of the Kiturami Turbo 21, an exhaust smell appeared. After the boiler is turned off, air blows from the inlet air manifold, i.e. reverse thrust is formed. A coaxial chimney into the wall is used. What is the problem and how to solve it? Answer:

If the chimney is installed in an area of wind pressure, when there is wind, when the burner is turned off, the exhaust may enter the room. It is necessary to remove the chimney from the wind pressure zone. Question:

Which injector should be installed in the Kiturami Turbo 13P - 0.5x60 or 0.5x80 (this was the one in the new one)? And what will be the effect of installing 05x60 in this boiler? Answer:

60 and 80 are the degree of fuel atomization. After these values comes the letter S, P, H - corresponds to hollow, half-half and solid spray. For a low-power boiler, almost any nozzle will do. We recommend adjusting the air supply (with a gas analyzer). Question:

Diesel boiler Kiturami Turbo100R. CTR5000 - shows t +92 and is not reset. The burner does not turn on. How can I fix this and can I turn on the burner without this block? Answer:

Most likely the boiler control panel is faulty. The boiler can operate without a control panel; to do this, you need to disconnect the control panel wires from the boiler. The only problem is that the boiler will reach maximum power. Question:

Problem with kiturami turbo 30 r. On natural gas. Shows error 01. From the previous answers it follows that there is a problem with the ignition. Some kind of flame sensor. How to fix the error? Where is this sensor located? Answer:

The flame control sensor is located on the burner; two wires go to it, two yellow or white and orange. Question:

Tell me about the ksog and tgb kiturami floor-standing boilers - do they have a built-in boiler and do they have electric ignition? Answer:

These boilers are boiler type; a heat exchanger in the form of a coil is used for hot water supply; electric ignition is used. Question:

Please tell me on the kiturami 13 the fan motor does not start the first time, if you knock lightly it starts. What could be the reason? Answer:

There may be several reasons: low supply voltage, failure of the electric motor capacitor, interturn short circuit, moisture ingress into the bearings. Question:

Kiturami stso13 after error ep01, how many minutes later does it restart on its own? Is this an error and the boiler completely stops until it is restarted manually? Answer:

The boiler performs two test runs; if the start does not occur, it goes into error mode. Most likely there is not enough gas pressure or low voltage, the air supply is not adjusted, etc. Question:

Boiler 13 STSO the first start gave error 01, after repeated startup attempts error 01 is repeated. Some owners write to clean the photocell, tell me where it is installed and how to clean it correctly. Answer:

Error code 01 - the flame control sensor does not detect the flame. The flame control sensor is located on the burner (two yellow wires and a black plastic cylinder). you need to carefully pull it out of the mount (turning left and right) and wipe it with a clean, dry cloth. Question:

I have a kiturami turbo 17 diesel, it gives error 01 and stalls immediately after starting. What needs to be done to fix this? Answer:

Error code 01 - no combustion. If ignition does occur, it is necessary to remove the flame control sensor located on the burner from the burner and wipe it with a dry cloth until it is in perfect condition. Question:

Diesel boiler KITURAMI Turbo R21, room temperature controller CTP 5000, house area 98 sq.m., radiant heating system, number of radiator sections 120, coolant volume about 100-120 liters, 2-story house is quite well insulated, chimney runs through the house on the roof, a container with fuel in an insulated room.

Now the question is, it seems to me that the boiler’s power is excessive for such conditions, is it possible to change the burner to R13? Will this reduce kerosene consumption? Will it be necessary to change the fuel pump? Answer:

According to your description, the power is somewhat excessive. It is not necessary to change the burner, fuel pump, etc. It is necessary to install an injector with a lower capacity and adjust the fuel pump to this injector. You will achieve a reduction in power and, accordingly, a reduction in fuel consumption. Question:

Kiturami boiler stso 13. Constantly produces error err01. I worked on summer diesel fuel, could this be the reason? And yet, the fine fuel filter is only half full. It should be? Answer:

Error code 01 - no ignition. There may be several reasons: poor fuel supply (check the fuel supply to the boiler), the nozzle is clogged (the nozzle needs to be cleaned), the photocell is dirty (the photocell needs to be cleaned). Do not forget that the fuel tank must be higher than the level of the boiler fuel pump, then the fuel filter will be completely filled. Question:

Kiturami R50 diesel boiler. Is it possible to clean the BFP 52K R5 gear fuel pump, if so, how to do it? The boiler starts, turns off after a few minutes, displays error 01. I changed the nozzle, fuel filter, completely cleaned it of ash, but no fuel comes from the pump. What could be the reason? Answer:

It is necessary to remove the fuel pump by first unscrewing the three mounting screws and the fuel supply pipe to the hydraulic cylinder. Unscrew the four hexagon screws from the end part and remove the cover. Under the cover you will see places where dirt is deposited, drops of water, and also a mesh filter. All this needs to be washed and dried.

The program plate does not need to be removed. It is necessary to remove the two valve solenoids with coils, and also wash and wipe them. It is extremely important to check the coils for breaks. Reassemble in reverse order. Question:

There is a Turbo 13R boiler. I want to connect it to a UPS. Which UPS to choose? Answer:

We recommend using a UPS of at least 400-500W. Teplocom UPSs have proven themselves quite well. Question:

Kiturami turbo diesel 13 R, why does it work for an hour or two and shows error 01.03 and so on constantly. It started in the cold. How to solve this problem? Answer:

It is necessary to check the flame control sensor, fuel filters, airiness of the fuel line, supply voltage if there is a shortage - a stabilizer is required. Question:

Problem with kiturami p13 boiler. Its fuse burned out - we replaced it, after that it turned on and started working, but nothing lights up on the control panel, only blinks occasionally. And the unit works, does not turn off - I even got the impression that the circulation pump does not turn on. What to do? Answer:

Check the power supplied to the remote control panel, it should be 12-17 Volts. Check the voltage supply circuits to the circulation pump, whether the fuel heater in the fuel filter is connected (sometimes such models are found).

When the remote control is turned off, the unit will operate at full power, limited only by the overheating temperature sensor (failure of the remote control). Question:

Boiler Kiturami 17 Turbo. Recently, the pressure of hot water supplied from the boiler in the mixer has been much weaker. Could it be that the coil is clogged and how can I clean the coil on my own? Answer:

A decrease in DHW flow is a fact of clogging of the heat exchanger. To eliminate the defect, chemical flushing of the heat exchanger is necessary. Chem. reagents use various mixtures of acids, selected in such a way as to react as little as possible with the copper tube, sometimes even washed with a solution of citric acid. Question:

Boiler Kiturami Turbo 30R. It gives error 98. The branded tank is missing, the plug to the fuel tank is not connected. We replaced the CTX-1500 unit with a known good one. After a cycle, the error repeated itself, but the boiler is working properly. A day later the error disappeared, but after two more days the error occurred again. What could be the reason? Answer:

Error code 98 - lack of fuel. This error code only occurs with a faulty control unit (if there is no capacity). We recommend trying to change the pressure on the fuel pump and try to de-air the fuel system. Question:

Is it possible to use a kiturami turbo 13p boiler without a circulation pump, in a simple gravity system with an expansion tank? Answer:

If the natural circulation of the system is sufficient, then the boiler can be used without a circulation pump. There may be some difficulties when using DHW. When using DHW, it will be necessary to turn off one of the supply or return taps in order to obtain the required amount of hot water (remove the self-circulation effect while using DHW). Question:

Unit 21R (error 95) - the error has disappeared, the water level is normal, but black smoke is still coming out of the pipe and the boiler (by sound) is working somehow differently. What could it be? Answer:

The boiler needs urgent maintenance. To do this, you need to turn off the boiler, remove the burner device, remove the chimney, remove the basket, pull out and clean the turbulators from soot and deposits.

On the burner device, it is necessary to wash the fuel filter, fuel pump, remove, disassemble and wash the nozzle. It is necessary to clean the combustion chamber of soot and deposits (carefully pour a fire-resistant layer at the bottom). It is necessary to achieve uniform combustion (the burner can be turned on in the open state, the flame should be short, reactive to the entire volume of the stabilizing pipe).

Question: The Kiturami Turbo diesel boiler constantly operates in this mode: it heats up for 10-15 minutes and goes into error E01. Only after a restart it turns on, and soon the same error occurs. The boiler is almost new. What could have happened to him? Answer: The flame detection system does not work, and this is a common occurrence for oil boilers when the diesel burner was not adjusted during installation. The fact is that the factory settings usually do not correspond to operating conditions.

Individual adjustment of the burner with a gas analyzer is required. This device allows you to see the combustion picture in many parameters and configure it correctly, taking into account the given fuel and air flow in a given boiler room. Question: Kiturami Turbo 13 has turned off and is showing error 95. What does this error mean? Answer: Error 95 means low water level in the boiler. The coolant should be added, the pressure will rise to an operating value of 1.5 atm, and the boiler will start. If this is not actually the case, then you should check the serviceability of the water level sensor. You also need to check the system for leaks and air pockets. Question: The Kiturami boiler heats up to 40° and stops with error 01. What should we do? Answer: The error indicates the absence or insufficient traction. Either the boiler is clogged with soot, or there is no flow of fresh air into the boiler room. The burner settings for the following parameters could also be lost: flue gases, temperature, efficiency and other indicators. Question: The boiler began to show an error: something is connected with the ash pan, and the red emergency lamp is on. What needs to be done to fix this? Answer: It is necessary to inspect the boiler and diagnose problems. Preventive maintenance before the start of the next heating season is necessary for the boiler every year. In your case, the firebox is 100% clogged, and the chimney also needs to be inspected. A firebox heavily contaminated with soot can be cleaned by you yourself. Question: The Kiturami device has been working perfectly for several years without any intervention. What needs to be done to ensure that it continues to work no worse? Answer: To maintain boiler equipment in good working order, annual preventative maintenance is necessary. This concept includes cleaning the inside of the boiler, mandatory replacement of the nozzle and filter, checking the automation and condition of the chimney. Question: The Kiturami 17 diesel boiler has stopped, error 01 is flashing. I’m thinking of cleaning everything myself. What should you do first? Answer: First of all, you need to check the condition of the firebox and chimney to see if they are clogged with soot. You can do this yourself. Then check the cleanliness of the injector and the serviceability of the fuel pump. At least once a year you need to clean the outside of the heat exchanger.

Question: The Kiturami Turbo 30R liquid fuel boiler is new, but it works very poorly, often goes out, lights up for a few minutes and turns off again. What about the factory settings of the burner? Answer: Factory settings correspond to the factory operating conditions of the boiler. At your home they may be completely different. It is necessary to configure the burner with the following characteristics: condition of the chimney, gas pressure, presence of air flow into the room. The cleanliness of the firebox is important, and it can clog in just a week if the fuel is of poor quality. Question: The unit is new, it has been running for only 2 months, and suddenly it stopped. The indicator indicates that the burner is working, but it does not work. It doesn't show any error. What is the reason? Answer: Perhaps the boiler automation is set to a certain operating mode - for example, to a time-limited mode when the burner will not turn on. This is especially true for boilers with an outside temperature sensor, when the boiler goes into summer mode on its own. In this case, the indication remains. If there were problems with the burner or the flame, an error code would definitely appear. Question: The Kiturami diesel boiler suddenly puffed out when ignited, white smoke began to appear, and it no longer turns on. Recently we cleaned the injector from carbon deposits. What's wrong with the device? Answer: Cleaning the nozzle is not enough for the boiler to operate correctly. Diesel boilers must undergo a preventive inspection at least once a year, including setting up the burner with a gas analyzer. It is impossible to adjust the burner without the device. At the same time, carbon deposits 2.5 mm thick reduce the efficiency of the boiler by 25%, and this is excess fuel wasted. Question: The Turbo 21R boiler consumes an average of 270 liters of fuel per month, heating 100 sq. m area. I was told that this is a lot. How to reduce consumption? Answer: This boiler is too powerful for the heated area. Also, many factors influence fuel consumption: fuel quality, fuel combustion quality, condition of the firebox and chimney, degree of insulation of the house and others. Question: The Kiturami Turbo 30 R has started to smoke a lot: very black smoke is coming out of the chimney. Fuel consumption became enormous - almost a ton of diesel fuel burned in three months. Need to do something. Answer: Your boiler needs to be cleaned and the burner adjusted using a gas analyzer. As you know, 2 mm of soot on the heat exchanger reduces the boiler efficiency by 15%. Question: I want to change the nozzle to a smaller one in the Kiturami Turbo 21 diesel floor-standing boiler in order to save money. Mine requires 3 liters of diesel fuel per hour, and the nozzle from Turbo 17 requires a liter less. This can be done? Answer: Simply changing the injector to a smaller one will not solve your problem. It will be necessary to reconfigure the pump to a different pressure, and the savings will be insignificant. A more rational solution is to adjust the burner. Question: The Kiturami 21 floor-standing boiler suddenly stopped - it seems there is no ignition. A month and a half ago they cleaned him, what could have happened to him? Answer: First of all, the question is: where is diesel fuel located, what is its storage temperature? If everything is in order with this, further inspection of the equipment is necessary and determination of problems in the ignition mechanism. Question: The Kiturami 2-circuit floor-standing unit does not start - there is no ignition. No matter what I did - cleaned it, changed the ignition electrodes - it was useless. It doesn’t write any errors and doesn’t work. What to do? Answer: If there is a fuel supply and there is a spark, but the boiler still does not start, then it is necessary to adjust the equipment. Normal ignition can be hampered by both a lack of oxygen from the outside and excessive air flow.

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

- Malfunctions of the AOGV-23 ZhMZ boiler

- Parameters and design of gas boilers AOGV and AKGV

- Boiler automation Baxi Luna-3 Comfort

- Installation and installation of the Baxi Slim boiler

- Adjustments and maintenance of the Beretta Chao boiler

- Determination of error codes and malfunctions of Rinnai boilers

- Errors and malfunctions of the Termet gas boiler

- The meaning of error codes and malfunctions of Vailant boilers

- Determination of malfunctions and errors of Visman boilers

- Questions about servicing Navien boilers

- Questions about malfunctions of Kiturami diesel boilers

- Junkers boilers - Experts answer user questions

- Experts answer questions about Electrolux boilers

___________________________________________________________________________

___________________________________________________________________________

- Answers from Nova boiler repair experts

- Questions about Hermann boiler service

- Answers from Daewoo boiler service technicians

- Questions about servicing Ferroli boilers

- Questions from users regarding the repair of electric boilers Evan

- What causes an AKGV gas boiler to light up and immediately go out?

- What is wrong with the Alpha Color boiler if it shows error code E01

- Why does the AOGV boiler light up and go out quickly?

- How to eliminate error E01 on the Baltgaz boiler

- What is the problem if Dani’s boiler lights up but immediately goes out?

- Why does a Danko boiler light up but quickly go out?

- The Demrad boiler has stopped holding pressure, what is the problem?

- Why did the Gaslux boiler start to get hot and make noise?

- What is the reason if the Keber gas boiler lights up but quickly goes out?

- How to eliminate error code 01 on the Kiturami boiler

- What causes a Conord boiler to light up but immediately go out?

- What is the reason if the Lemax boiler lights up and goes out quickly

- Why does a Mimax boiler light up but suddenly go out?

- Why does the Hearth boiler light up but immediately go out?

- Why does a Ross gas boiler light up but go out quickly?

- What is the problem if the Siberia boiler lights up and goes out suddenly?

- Why does the boiler Signal light up and suddenly go out?

- What can cause a Termet boiler to make noise and get hot?

- Why does the Termotechnik gas boiler light up but suddenly go out?

- How can you eliminate error E01 on a Thermon boiler?

- For this reason, the Electrolux double-circuit boiler began to hum and heat up

- For what reasons does a Ferroli gas boiler display an error code A01?

- For what reason does the Immergaz boiler not operate on hot water supply?

- Why does the Navien gas boiler constantly turn off when heating and then turn on immediately?

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

- Heating boiler piping

- STS boilers

- KVT boilers for solid fuel

- Pellet boiler Peresvet

- Steel floor standing boiler Raton

- Solid fuel boiler Thermology

- Errors and malfunctions of the Termet gas boiler

- Termona boiler repair

- Boiler repair Nova

- Hermann boiler service

- Comparison of gas boilers Lemax Premium-20 and Danko-20s

___________________________________________________________________________

- Daewoo boiler maintenance

- Demrad boiler malfunctions

- Mora boiler malfunctions

- Westen boiler repair

- Malfunctions of Immergaz boilers

- Types of solid fuel boilers

- Models and design of combination boilers

- Liquid fuel and double-circuit boilers

- Cast iron boilers on coal

- Boilers with modeling burners

- Imported boilers for heating systems

Other faults

Code 08 in a diesel unit occurs when communication with the control unit is broken. You should check the length of the wires connecting the CTR-5000 device to the unit; it should not exceed 10 m.

The operation of this device may be affected by the close proximity of electronic devices; remove them from the boiler. If the code does not disappear after resetting, call a specialist.

Error 98 appears in diesel devices when the fuel level is insufficient. Add fuel, if the code lights up and then contact a service center.

Conclusions and useful video on the topic

Details about repairing the control unit after error 06:

Maintenance of the Kiturami boiler by gas workers:

You have read about malfunctions in the operation of Kiturami gas boilers and their symbols. Most of the errors indicate a temporary failure without risk to the entire device, but be prepared for the fact that the device may not work for several hours or days.

Fix any problem step by step. Monitor the pressure in the device and heating system, network voltage, and external conditions. Avoid gas or water leaks. Eliminate them as quickly as possible. Do not touch the gas communications inside the boiler and those leading to it.

Write comments on the topic. Tell us about the most common errors on your boiler and its brand. Write down whether it had to be repaired and how many times. Are you satisfied with your technology? The contact form is located below the article.