Basement ventilation

Nowadays, a basement room in a private house is far from uncommon. Very often, storage areas are placed there for unnecessary things and for storing screws. Or, following a newer and more fashionable trend, they will equip space for gyms and swimming pools. But the purpose of such a room is not so important. In order for such a room to be suitable for something and become truly comfortable, it is first worth considering a system for the proper functioning of the basement in the house with all communications connected. And one of the most important is ventilation.

Features of basement ventilation

The presence of the basement floor in the layout of the house makes it actually the foundation. Therefore, it is quite obvious that enormous pressure is exerted on the walls and ceiling from all sides. For the proper arrangement and rational functioning of such a room, it is necessary to take into account the following factors:

- Calculation of loads on walls and its uniform transmission;

- Thermal insulation of the entire room;

- Optimal ventilation;

- Air quality, which directly depends on the composition of a particular soil;

- Hydro- and gas insulation.

- Temperature and humidity levels;

- Electricity supply.

As stated above, the air quality in the basement directly depends on the soil where the house is located. Very often, during irreversible organic reactions, harmful gases, including radon, accumulate in the basement.

Harmful impurities cannot be determined by smell or other indicators, but after a long stay in such premises, a rather serious illness appears in the body. And with prolonged exposure and the development of the worst variants, serious diseases can form.

Therefore, it is necessary to consider the basement ventilation system in the house. The most optimal ceiling height in the basement is 2.1 m. It is important to take into account that the room should only be partially underground. To be able to install windows. But not for natural light, but for the most primitive ventilation system - ventilation.

However, such a system cannot be perceived as a full-fledged option. Very often it is taken for granted that even on the hottest days of summer, basements are quite cool. Of course, this is very convenient, especially when the room was intended for storing supplies. But unfortunately, this is one of the proofs of an insufficient ventilation system. In addition, if you do not approach the issue properly, moisture may form in the room, followed by bacteria, mildew and mold.

In a private house

Based on the above, it becomes clear that ventilation in any basement is simply necessary. In this regard, it is worth carefully considering the question of what kind of ventilation system will be used there:

- Natural. The arrangement of such ventilation should be thought out in advance, even at the stage of creating a house project. It is a regular pipe that is ducted outside and air circulates due to the pressure difference between the street and the room. The effectiveness of such a system is quite relative and depends on many factors, including wind strength and weather conditions. For small basements it will be a very good option;

- Forced. In this case, the name speaks for itself. Air movement occurs due to special fans, which, during their operation, pump air from the street and remove stagnant air from the basement. Ideal for any room;

Of course, technology has moved forward a long time ago. Therefore, the heating system can even be responsible for the room temperature and air humidity. But such installations are very expensive and difficult to maintain because they have a multi-stage filtration system.

While you can install a natural or forced system using a fan yourself and maintain it yourself. However, another important factor is that you need to carefully fence off the ventilation openings with special grilles. They do not prevent air from getting inside, but will protect against rodents and street debris.

In an apartment building

Ventilation in an apartment building is also divided into forced and natural. It is located in each riser and goes into the kitchen and toilet. That is, those places in apartments where the highest concentration of unpleasant odors is.

Special hoods are installed on such systems and can only be serviced by qualified specialists. In new houses there are complex split systems that are responsible for temperature conditions. Older buildings often have conventional fans to circulate air.

Natural ventilation in an apartment building is presented in the form of a special channel leading to the toilet and kitchen of each apartment. There are also holes coming out of the basement, the number of which directly depends on the area of the basement.

DIY hood in the cellar

The ventilation scheme depends on the parameters of the house, the purpose of the basement and the location with climatic conditions. To set up a conventional system, you will need two pipes (one for supply, the other for exhaust), which will be responsible for air circulation in the storage.

The ventilation system in the cellar can be made natural or forced with your own hands. In forced air, the main role is played by fans that will circulate air in the room.

Also, when choosing special equipment for ventilation, you need to pay attention to the resistance of the equipment to work in conditions with high humidity.

You will find more information about installing ventilation in the basement yourself in the video.

Materials for production

Existing ventilation schemes in the cellar include the use of various types of pipes. Among the large assortment, the most common are asbestos cement and low-density polyethylene.

Products based on asbestos cement are similar in appearance to slate, but according to their characteristics they have the following qualities: reliability, high level of strength, resistance to adhesion, durability. In hardware stores they can be purchased in long lengths, which will have a beneficial effect on the integrity of the structure. Polyethylene pipes most often have to be welded together, which requires special tools and work skills.

Metal pipes are rarely used to install a ventilation system, since they are subject to corrosion and quickly rot in the ground. To prevent such impacts, it can be treated with anti-corrosion enamels or waterproofing materials can be used to protect it from moisture.

When using any material, the openings for the exhaust and supply pipes must be reliably protected from moisture and debris. For such purposes, you need to install a grille and a special cap on it, which can be made from any material.

Fan types

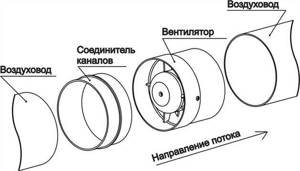

For proper air circulation in the storage facility, you can use several types of fans, which, based on their operating principle and location, are divided into axial and duct (Figure 4).

Figure 4. Types of fans for basements

The duct fan has a medium power level and can be mounted anywhere in the ventilation pipe. The energy consumption of this type of fans is insignificant, which is suitable for saving money. Some of the most efficient duct fans are amplitude-type devices.

Axial fans are installed in close proximity to exhaust or supply openings. According to their operating principle, they can produce stronger air circulation, but at the same time they require electricity. Together with the fan, a special valve is installed on the outlet pipe of the system, which will not let cold air inside.

Possible problems in the absence of supply and exhaust ventilation

As mentioned earlier, lack of ventilation in the basement of a residential building can lead to many problems. Of course, the worst case scenario is health problems due to constant exposure to radon gas. In large quantities it is a highly radioactive substance that has serious health effects.

But besides this, it is worth thinking about smaller problems. If the ground floor was intended as a storage room for unnecessary things or a warehouse for supplies, then in the absence of natural supply and exhaust ventilation it will not be able to serve such purposes. Firstly, dampness and high temperature. In a couple of days, it will completely destroy the supply of a good harvest. Twists also cannot be stored for a long time in such conditions. Of course, all things will rot and become unusable over time.

There is a high probability that fungus, mold and harmful insects will appear. And, of course, such conditions can cause serious damage to the foundation and floors.

Requirements for size, number and location

Calculation of the air exchange characteristics of a basement room is carried out at the initial stage of a residential construction project. Based on the given parameters of the area of the premises, the number, position and diameter of vents capable of providing the required natural ventilation regime are established.

Next, determine the height at which you need to place the holes . In central Russia, they must be installed 600 mm above the soil level so that snow does not block the ventilation and melt water does not flow into the basement.

In accordance with SNiP, the entire cross-sectional area of vents in basement rooms must be no less than 1/400 of the total ventilation area. Therefore, for a household in a 10x10 m plan, the total cross-sectional area of all openings will be 0.25 m2.

The configuration of such air ducts can be any; usually it is a circle or a rectangle.

An example of calculating the number of vents for a 10x10 m building, with a total area of 0.25 m2:

- the maximum distance from the corners is set to no less than 1 m, one hole is installed for every 2 m;

- it is assumed that by stepping back 1 m from the corners, you can install five holes on each side, for a total of 10 units on two opposite walls;

- determine the area of one hole: 0.25 m2: 10 = 0.025 m2;

- if circular vents are installed, the minimum diameter is determined using the circle area formula: d = √4*0.025:3.14 = 0.140 m or 14 cm.

Other ventilation methods

A situation may well arise that, given the presence of a basement, it was not possible to develop a natural system. Either it does not cope with its task or a mistake was made during the design. In any case, you can’t do without forced air exchange.

In order to install a forced ventilation system in the basement of a private house, you must:

- Install supply fans in the wall;

- Connect fans to the exhaust ducts;

- Or, as an alternative, use a very ordinary fan that needs to be placed near the air duct.

It is important to take into account that the pipes in such a system should be of a smaller diameter, because the air moves through them much faster than during natural air exchange.

For an efficient installation, please consider the following:

- The exhaust pipe should be longer and located above the ridge;

- The diameter of the air outlet can be used to regulate the intensity; the larger the diameter, the more active it works;

- If the room is damp, then quicklime will help with this. Place in a large container indoors for a couple of days so that it absorbs excess moisture;

- It is best to ventilate the basement in bad and windy weather.

If the entire system is installed correctly, the basement will function normally. The most optimal temperature will be 16-21 degrees, and humidity 50-60 percent.

Cases when a ventilation system is not needed

If you have waterproofed, no vents are required.

So, an air movement system is not needed if:

- The underground soil is covered with a vapor-proof membrane or bitumen roll materials. In this case, there must be sufficiently large overlaps to ensure the tightness of the joints.

- If the underground space is used as storage and it has a direct connection with the premises of the house.

- If a high-quality forced ventilation system is installed in the basement space, and the foundation is well insulated.

According to modern research, it is best to fill the underground space and install a concrete screed. This option guarantees a high degree of reliability.

Filling with sand and filling the screed eliminates the need to worry about ventilation

Expert advice

Ventilation of a strip foundation is an extremely important aspect that must be taken into account when building a private house. To avoid corrosion of the foundation materials and the basement itself, it is better to refrain from shutting off the air in the vents even at low temperatures. The soil itself will prevent the room from freezing, and good insulation materials can help as an auxiliary option. If the basement floor was planned as a storage room, the issue of comfortable temperature is secondary. The main thing is to set up a ventilation system so that dampness does not appear. Subsequently, it is very difficult to get rid of it, but it is very easy to breed mold bacteria in the room.

Therefore, even if there is some kind of homemade damper system in the vents, it is worth making sure that in winter the room is first of all well ventilated.

Protecting air from rodents

Unprotected vents can be an easy way for rodents to enter your home. Mice, rats and even snakes can use first the underground and then the house as their refuge. This problem is relevant both in the city and in rural areas, and worsens in the fall, during cold weather. To avoid visits from uninvited guests and to protect your home, vents must be covered with mesh or bars.

The easiest and most effective way is to purchase a construction grid. Its sections should not be larger than 5-7 millimeters, otherwise they will not become an obstacle for mice. You can make the mesh yourself from strong wire.

The grate is cut into pieces that correspond in size to the vents, and another 1-1.5 centimeters are added. After this, frames are made from tin - you can even use canned food for this. The material is cut into strips, two of them are bent and pieces of the lattice are inserted inside. The elements are connected to each other by tapping with a hammer. When the frame is ready, the mesh is installed on the vents and secured with screws.

How to ventilate the basement of a private house?

The arrangement of ventilation is of decisive importance for creating comfortable and safe living conditions. Often during design and construction, attention is not paid to such an important element as the ventilation of the basement floor of a private house, as a result of which many difficulties arise during the operation of the building.

Features of organizing air exchange in the basement

Lack of ventilation in the basement leads to the formation of dampness and mold, and also creates favorable conditions for the spread of pathogenic bacteria. Therefore, even at the construction planning stage, it is recommended to provide for the creation of a moisture content control system.

Ventilation of the base should be carried out taking into account the characteristics of the structure and the characteristics of the site: when designing it, they take into account the area of the ventilated space, the type of building foundation, soil properties and its humidity, average annual temperatures, etc. Various types of systems are used for the basement floor: natural, supply and exhaust or forced ventilation can be installed in this part of the building.

Ventilation installation diagram

Organization of air exchange in the basement of a residential building involves the creation of special openings (vents and vents). The presence of these elements can ensure natural ventilation of the basement of a private house. The arrangement of openings is carried out along the perimeter of the facade every 2-4 m. If construction is planned in a lowland, gratings must be installed in double quantity. The main advantages of this option include:

- lack of equipment operating from the electrical network;

- efficiency;

- simplicity of arrangement and operation.

As practice shows, vents cannot always provide effective air exchange and maintain a favorable microclimate in the basement. When arranging spaces in the basement that will be used for sports, recreation (for example, a billiard room) and other needs, there is a need to organize fresh ventilation.

Natural supply and exhaust ventilation

Supply and exhaust ventilation is designed both to remove air from the basement premises and to ensure the supply of clean air masses. This type of air exchange is called natural supply and exhaust ventilation. This type of basement ventilation operates based on the difference in temperature inside the building and outside. Evidence that during the development of the project all the nuances were taken into account and its organization was carried out correctly is effective air exchange and the absence of drafts.

It should be noted that the supply and exhaust system in the basement can be installed either by professionals or independently, without the involvement of specialists. If you have a certain level of knowledge and skills, its creation is not difficult. The disadvantage of the supply and exhaust option is the impossibility of functioning in the summer season, since there is no temperature difference. Also, this type does not allow you to regulate the volume of air that must be removed.

Ventilation grates

Reliable ventilation of basement rooms is an important process that ensures the standard operational life of the house and creates the necessary microclimate in the house at any time of the year. The purpose of the grille is to protect the underground area from small animals and rodents.

Installation Requirements

In order to close the ventilation pipes installed in the basement wall structures from the street, special grilles are installed on the outside of the structure.

They decorate the ventilation outlet, provide regulation of the intensity of air exchange and protect the air ducts from precipitation.

When choosing a type of grille, you need to know that it is not recommended to install plastic products outdoors; they are accessible to rodents. The best option for basement structures is metal adjustable grilles that can set the required ventilation mode depending on climatic conditions.

For example, in the warm season they open completely, but at sub-zero ambient temperatures they partially overlap.

Varieties

- configurations

- sizes,

- source material,

- color design.

They come in round and rectangular shapes; you can find designs made in the form of an oval and a polygon. The first 2 variations are the most common, however, they have a serious drawback: the correct shape of the outlet hole contributes to the creation of vortex flows at the outlet, which negatively affects the process of outflow of air flows.

According to the method of functioning, grilles are divided into supply and exhaust . The first, through which there is an influx of air, and through the second, the outflow of exhaust air. The following grating designs are also produced:

- with fixed plates,

- invoices,

- on hinges

- capable of opening

- adjustable,

- with installation of a check valve.

Depending on the type of material used, products are made of plastic, wood and metal. Metal gratings are available in aluminum and steel.

The former are limited in size, since when installed on channels with a large cross-section, they bend easily under the influence of loads. Steel structures are the strongest and most popular option among developers .

Installation process and technology

The most reliable and common option for attaching a ventilation grill is using bolted connections. It is used on almost any type of external walls.

Fastening with bolts is carried out according to the following algorithm:

- First, the location where the grille will be installed is marked;

- drill holes for the screws using a drill, so that the head of the inserted screw fits exactly along the contour of the grille;

- Next, apply the grille to the required contour and secure it with screws.

When choosing the fastening method using hot glue, it is applied with a gun along the contour of the ventilation hole and the grille is firmly pressed to the wall. After fixing the structure to the wall, seal the cracks with foam for installation. After the foam has hardened, the excess is carefully removed and the joints are puttied with a solution.

Installation of natural ventilation

The supply and exhaust system consists of 2 pipes: one of them provides air flow, and the other removes it from the room. It is recommended to place pipes at different heights and on opposite sides for more efficient air exchange. Warm air accumulates in the upper part, so the pipe designed to remove air is located under the ceiling. The fresh air supply pipe is located below, near the floor. If there is a fireplace, the exhaust pipe should be located close to it for more efficient ventilation.

Pros and cons of different types of ventilation

With non-stop air circulation, the temperature and humidity conditions will be stable, however, during the cold season, freezing of the room may occur.

1. The channel is necessary to remove moisture, odor and toxic compounds.

2. The supply pipe ensures the flow of fresh air into the interior of the cellar.

3. A single-pipe system is the simplest method, which has its pros and cons:

- the positive side is that the hood is cheap and relatively easy to install;

- The disadvantage is that full air exchange is problematic due to the weak inflow.

If the cellar is small in size, then it is recommended to install this option. The air duct must be divided into separate ventilation openings.

4. Installation of a two-pipe type is preferable due to the possibility of ensuring greater safety of food and things located underground, but it requires large financial expenses.

The correct design completely changes the air in the room approximately 2 times per hour. The circuit diagram with natural circulation is included in the project at the initial stage of its creation.

In what cases can you get by with one pipe and determining the diameter?

In a separate cellar with a small area, as well as in a garage or barn located under a garage, a single-pipe system is installed. Its top should extend at a distance of at least 80-100 mm from the ridge of the roof.

- In a structure with a perimeter of 2x3 or 3x3 m, it is necessary to erect a structure whose cross-section is at least 150x150 mm, with a wind catcher at the end.

- The hood must be divided in half by a vertical partition running along its entire length.

- In one compartment the air enters the room, in the second it comes out of it, so a separate damper is made for each part, which closes.

- Before completing installation, you need to check the circulation. To do this, you can smoke the underground and monitor the pace of cleaning.

In order for the system to function correctly, it is necessary to accurately calculate the diameter of the air ducts for ventilation.

- The underground area should be proportional to the cross-section of the pipe and be 1m2/26 cm2.

- The diameter of a pipe of 1 cm is equal to 13 cm2 of cross-section, hence: (Splace x 26 cm2)÷13. If S of the basement is 9 m2, then it turns out (9x26)÷13=18, which means that the size of the cross section should be at least 18 cm.

- ventilation pipes are taken 1-2 cm larger than the obtained value. For S=9 m2, you need to take material with a cross-section of 19-20 cm.

On the street side, the channel is located in places accessible to strong wind currents, otherwise it will be inactive.

Which channel to close for the winter, nuances of a hood with two pipes

The use of a two-pipe design to form a full-fledged supply and exhaust system requires the most accurate calculation, so it is advisable to first create a diagram.

- For uniform air exchange, channels with equal cross-sections are installed. If it is necessary to drain the cellar or get rid of a musty smell, then the diameter of the outlet should be large.

- The fewer bends and turns, the better the ventilation will be.

- Optimal temperature conditions and circulation are achieved by maximizing the distance between the hoods and each other. It is preferable to place them at different ends of the room.

| View | Installation | Nuances |

| Exhaust | The lower end is located at a distance of 150 cm from the floor, as close to the ceiling as possible. To enhance traction, the outlet channel is closed with a mesh or a deflector is attached to it. | 1. The ventilation holes of the pipes must have a height difference of at least 100 cm. 2. The underground supply duct on the street is located below the exhaust duct. 3. Air masses form condensation: when winter comes, it cools down and turns into frost. The street end requires mandatory insulation. 4. To remove condensate, a drain valve is installed in the lower part of the exhaust pipe. |

| Supply | The hood should be at a height of about 30-50 cm from the floor. The outer end rises above the roof by a maximum of 25 cm. If the duct is installed in the ceiling of the basement, then a grille is attached to it from the outside to protect against the penetration of rodents. |

In order to regulate the intensity of air movement, you need to open and close the dampers installed on the ends of the hoods located inside the room.

Forced ventilation

Often, organizing air exchange in the basement requires the installation of forced ventilation. Common reasons why its organization is required are:

- location of the building in a lowland (in an area of high humidity, in a swampy area, etc.);

- location or appearance of groundwater sources under the house;

- use of the basement floor for storing certain categories of products (cheese storage facilities, wine cellars, etc.), which require maintaining humidity levels and maintaining temperature conditions.

Forced air exchange is provided if the natural system cannot cope with its functions. The operation of this option is based on the same principles as the operation of the supply and exhaust system, but the inflow and removal of air does not occur in a natural way, but through the use of mechanical equipment. Also, this type of air exchange is organized when living rooms are placed in the basement.

Many owners of buildings with a basement are interested in the question of how to make ventilation of this type. Forced systems are purchased ready-made in stores (they are equipped with a supercharger and a valve designed to stop the air supply when the mechanism is turned off). When arranging this type of air exchange, a fan is built into each of the pipes installed as a supply and exhaust option.

If it is necessary to ensure constant temperature maintenance, a thermostat is additionally built into the system, and a hygrometer can be installed to control the humidity level. To heat the air that comes from the street in the autumn-winter period, air heaters are used. The installation of forced ventilation in the basement of a private residential building will ensure stable operation of the system and guarantee a favorable climate regardless of weather conditions and other factors.

Vents in the finished foundation

What to do if vents were not installed during construction, or their size is not enough for proper ventilation? The most effective, but not the easiest way is to drill holes or increase their size.

Diamond drilling in a finished foundation

The most difficult thing is to do them in a concrete foundation. In this case, you can order diamond drilling and entrust the work on the vents to specialists.

If there are already holes in the concrete, but their size is not enough, you can deal with this yourself. Around the existing vent, small funnels are drilled with a large drill, which are gradually connected to each other. After this, the new air duct is polished and given the desired shape.

Vents in the finished foundation

In the case of a brick foundation, you can break the mortar at the joints to be able to remove excess bricks. This must be done carefully so as not to damage adjacent elements and not to compromise the integrity of the foundation. In foam concrete blocks, ventilation can be easily done manually. Along the perimeter of the future vent, you need to drill holes at a short distance from each other, and then connect them in such a way that you get a vent of the required size.

There are also ways to improve ventilation without expanding the vents. You can run a pipe from one of the vents to the roof or improve the insulation of the basement. If your home uses stove heating, you can install the stove so that air is drawn from the basement.

Basement floor ventilation: natural supply and exhaust and forced system

Did you know that basement ventilation is a point that must be taken into account at the initial stages of building construction? If, when designing a house, you do not pay enough attention to the system for controlling the moisture content in the air of the basement, the operation of the building is guaranteed to result in a number of difficulties.

Among the undesirable consequences, we note the formation of excess dampness, the appearance of mold and other pathogens. Let's figure out how ventilation in the basement can be done with your own hands without the help of professional builders.

Features of organizing air exchange in the basement

Having visited any home, it is easy to understand how effective the air exchange in the room is. A heavy and musty smell, condensation on the surface of the walls, all this indicates problems with ventilation .

If the house design involves the construction of a basement floor, you should immediately plan in its walls the presence of special openings (vents and vents) designed to provide natural ventilation.

Ventilation in the basement of a private house should be planned taking into account a number of factors, including the type of foundation and soil on which it is built, the area of premises in the basement, average annual ambient temperatures, wind direction, soil moisture, etc.

Most often, for complete ventilation of the base, one vent located every 4 meters along the perimeter of the outer wall is sufficient. If the house is located in a low area, ventilation grilles are installed on the base in double quantity.

Natural supply and exhaust ventilation

Construction design statistics indicate that vents designed to provide ventilation may not be sufficient. For example, if the basement is used as a warehouse, workshop, gym or billiard room, you will need to use supply and exhaust systems that not only remove polluted air, but also provide fresh air from outside.

This type of ventilation is natural, since its operation is based on the temperature difference between the outside and inside of the basement. If the calculations when designing such systems are carried out correctly, natural ventilation ensures high-quality air exchange in the complete absence of drafts.

A supply and exhaust natural ventilation system can be ordered from specialized companies or can be assembled independently. Essentially, the system consists of two pipes, one of which is supply and the other is exhaust.

To ensure optimal performance of the system, the pipes are distributed on the sides, for example on opposite walls. In addition, to ensure optimal air exchange, the pipes must be located at different heights.

Considering that warm air is concentrated in the upper part of the room, literally under the ceiling, it is advisable to install the exhaust air pipe as high as possible. Conversely, cold air is located below, so it would be better to place the pipe for supplying fresh air from the outside closer to the floor.

In addition to the correct placement of pipes, it is necessary to take into account their sizes and configuration. As a rule, to ensure air exchange in the basement of an individual residential building, plastic pipes with a cross-sectional diameter of 100 mm are sufficient.

Installation of natural ventilation

The instructions for setting up the system are as follows:

- At the top of the wall we mark the diameter of the hole, which on each side should be 10 mm wider than the diameter of the pipe.

Important: When marking, make sure that there are no hidden wiring in the wall. To avoid trouble, drilling should be performed after cutting off the electricity supply to the room. During this time, you can power the power tool from the next room using an extension cord.

- We make through holes along the perimeter of the drawn circle. For this work, we use a hammer drill with a drill longer than the width of the wall (usually 60 cm is enough).

- After the holes are drilled in a circle into the hammer drill, we insert a chisel and begin to gradually cut out the inside of the future hole.

Of course, there is a simpler and less labor-intensive way - ordering diamond cutting of concrete. But the price of this service will negatively affect the cost of the result, so we save and continue to work with our own hands

- After the hole is ready, cut 1 meter of pipe and insert this piece into the hole.

Subtleties of the forced exhaust device

This type of ventilation system is structurally similar to the natural one described above. But what makes them different is the presence of fans and other additional equipment, which increases, and radically, the efficiency of exhaust hood in basement rooms.

Forced ventilation is considered a costly method of eliminating contaminated air masses.

And yet, such a disadvantage is offset by the lack of dependence on natural conditions, the complex configuration of the basement floor, and mistakes made when creating natural hood. That is, from everything that makes the system ineffective.

The simplest forced exhaust system is quite simple to set up - just install a duct fan in the exhaust air duct.

The forced exhaust system is similar to the natural one (described above), the only difference being the presence of fans. Which are mounted in air ducts in the manner shown in the picture

If the basement floor is divided into several rooms, and everything needs to be forcedly ventilated, then there will be little exhaust equipment in one room.

As a result, you will have to get out of the situation in the following ways:

- creation of air channels laid under the ceiling in all necessary rooms, which are formed from metal or plastic pipes;

- installation of exhaust and supply fans.

Supply fans will help solve the problem in particularly difficult conditions. Usually they are used exclusively in conjunction with exhaust hoods.

Forced ventilation of the desired basement floor is carried out if natural exhaust capabilities are insufficient. For example, this happens when the floor area is too large, there is significant humidity or gas formation. But the only important difference between this air exchange technology and the natural one is the presence of a duct fan, which significantly increases efficiency

Since the fan is the basis for high-quality ventilation of any forced-air system, you should familiarize yourself with the technology for its selection. Since not every product will cope with the task, and many will even pose a danger to the life and health of users.

Necessary equipment to assemble the system

The following can be used to provide forced exhaust:

- fans;

- Humidity sensors, their more outdated analogues, which are hygrometers.

- thermostats;

- heaters.

Most often, fans are used to obtain the desired result. The most important characteristic of such equipment is performance and it will have to be calculated in each specific case.

But this is not difficult to do, since all you need is to use a special formula for calculation. According to which, the optimal fan power will be the derivative of the building volume of the required room and the multiplicity of the amount of air volume exchange for each hour.

Fan performance for a forced ventilation system is the most important performance characteristic on which efficiency depends. And if it is not enough, then forced air exchange is similar to ordinary natural one. In addition, such a product must be safe, and if the base is habitable, then silent

In addition, important performance characteristics of any exhaust fan are: safety, noiselessness, functionality. It is advisable to use a waterproof device.

Humidity sensors allow you to generate a signal to turn on/off the equipment in use. For example, the same fans. This will allow you to eliminate dampness, without overpaying for electricity. After all, ventilation devices will work in situations where this is necessary.

Thermostats are designed to keep the temperature in the basement stable. They are used to provide a command signal to turn on/off the air heater and other equipment used to heat the supply air.

This allows not only to maintain a given temperature, but also to create a pressure difference to ensure the required performance of a ventilation system without fans.

Stages of installation of a forced system

The installation of a forced ventilation system is carried out in several stages.

Which include:

- Calculation of the area of vents and their quantity. These operations are similar to those performed when designing a natural hood (listed above).

- Fan performance calculation.

- Creation of air ducts in compliance with the requirements specified for natural exhaust.

- Installation of fans and additional equipment if necessary.

- Functionality check.

All calculations are made at the design stage of the basement floor.

When arranging ventilation for the basement, it should be remembered that the main goal of such a procedure is to create effective air exchange, without stagnant zones. Therefore, it is necessary to comply with the norms of the profile joint venture, which state that the area of the exhaust openings should not be less than 1/400 of the area of the floor itself. The only exceptions are situations with increased background radiation.

How to choose basement ventilation for a private house

The humid air of the basement is an ideal environment for the development of harmful microorganisms, mold and various fungal formations. The activities of these organisms have a destructive effect on materials, both of organic origin and building structures. Also, the waste products of such a biological environment, entering the human lungs through the air, can cause severe pulmonary diseases.

That is why the question of regular ventilation of enclosed spaces such as basements, basements and various types of underground spaces arises. Ventilation of the basement of a private house is arranged in two ways:

- Natural ventilation;

- Forced ventilation.

Natural ventilation

Developers often ask the question: why do you need to install basement ventilation? The evaporation of the soil foundation poses a threat of accumulation of moisture and vapors from the soil foundation in the basement. This creates an aggressive environment that negatively affects the condition of the building structures.

The consequence of lack of basement ventilation is mold in the basement

What are the consequences of lack of ventilation in the basement? The fact is that evaporation from the soil base, having no outlet, begins to fall in the form of dew on the surface of surrounding structures. As a result, conditions are created for mold to grow. The waste products of bacteria and mold formations destroy the structure of building structures and have a detrimental effect on human health.

In addition, radon gas is released from the soil base, the inhalation of which can cause significant harm to human health.

In order to avoid these phenomena, underground ventilation is arranged. There must be vents in the basement. Vents are ventilation openings that provide constant ventilation to the underground of a house.

Natural ventilation of the basement of the house occurs due to the difference in air temperatures outside and inside the basement.

Ventilators come in different designs depending on the design of the base. When laying brick walls, large openings are left. In the base made of monolithic concrete, during the formation of the formwork, sections of asbestos pipes are laid. The dimensions of the openings depend on the volume of the ventilated space.

Sections of asbestos-cement pipes with a diameter of 150 mm in increments of 2 meters are laid in monolithic reinforced concrete. The area of openings and the frequency of their location in other types of underground fences depend on the volume of ventilated rooms.

Vent covered with grate

I cover the ventilation holes with grilles to prevent the entry of small animals: rats, mice and other rodents. Grilles come in the form of meshes made of polymer materials, metal louver type and other designs.

There are no exact methods for determining the number of vents, their sizes and varieties. In this matter, much depends on the wind rose and seasonal changes in temperature conditions. However, based on practical experience in arranging ventilation for the basement, the developer can always choose an effective layout of the vents in the basement of a private house.

Ventilation holes are also installed in the walls of the ground floor and basement.

Vents in the internal walls of the basement or basement are placed in such places that the air flow is not refracted, thereby ensuring maximum ventilation of the room.

Ventilation in the foundation of a house - how to ensure air circulation and get rid of condensation

To ensure ventilation of the underground space, various methods are used:

- special vents are made at the base of the structure. Excess moisture is removed thanks to natural air circulation. With the correct selection of the cross-section and location of the channels, a draft occurs that does not allow condensation to form;

- organize the extraction of air masses from the space located under the floor using a ventilation pipe. It is brought to the roof level, and air access is provided through a pipeline running inside the room. In this option, the ventilation ducts of the base are not installed.

Many “self-builders”, having equipped their own home with a good ventilation system, completely forget about ventilation of the foundation, which is the basis of any structure

The intensity of air exchange is also affected by the location of the building:

- for air circulation in buildings located on flat terrain, it is enough to make a pair of channels with a diameter of 150 mm. They must be placed on opposite sides of the tape base;

- the base of a building located in a lowland, where air flow speed is low, should be ventilated more intensively. For this purpose, additional channels are provided along the contour of the base.

There are proven solutions to reduce condensation. They provide:

- thermal insulation of the foundation, which is additionally protected by a waterproofing coating;

- insulation of the basement floor using modern thermal insulation materials.