Home » Heating and water supply » Installation of a wall-mounted gas boiler

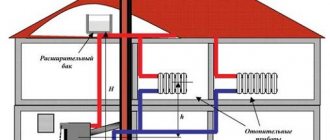

In our country, the installation of gas boilers is carried out exclusively by certified specialists, who demand a fairly high fee for their services, although most of the work can be performed by any home craftsman. This publication will provide detailed instructions on how to install a wall-mounted gas boiler with your own hands and what is needed for this.

…

- 1 Stages of installation work

- 2 Preparatory work 2.1 Project

- 2.2 Selecting a room

- 3.1 Stage one: mounting the boiler

Istrinsky district, KP "Istrinsky Plyos", complex of engineering systems

Technical task:

Complete set and installation of heating, water supply, sewerage systems in a private house with an area of 550 m2.

Result:

The boiler room in the cottage village "Istra Plyos" is made using the most modern equipment and materials: the heat source in this case is a cascade installation consisting of gas floor-standing boilers Buderus Logano G234 WS (RU TOP)

, total power 110 kW. To prepare hot water we use a boiler from the Belgian manufacturer ACV Comfort series; pumping and mixing modules from the German manufacturer Huch EnTEC ensure efficient circulation of coolant through radiator heating systems and water-heated floors, as well as water supply to four bathrooms and laundries located on the first, second and ground floors of the building. A Rosinox stainless steel chimney was installed, Reflex expansion tanks, a Watts safety group, and Framco dirt removers were installed. The wiring throughout the house and the water heated floor system are made with Rehau Stabil and Rautherm S pipes, the radiator heating is equipped with steel panel radiators from the German manufacturer Kermi, our company’s specialists installed 37 radiators of various types and sizes, as well as several installations from the manufacturer Geberit.

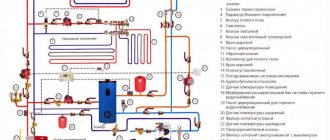

Buderus boiler connection diagrams

There are standard classic diagrams, illustrated in the installation instructions for Buderus boilers of one series or another. However, in practice, the diagrams almost always undergo changes to optimize the wiring, adjust to the geometry of the furnace room and the relative position of individual components of the heating system.

The heating systems of country houses, although similar to each other, are only in general terms. In reality, no matter how diverse the areas and layouts of buildings are, their heating systems are just as different. Departures from standard schemes can also be caused by:

- connecting the pool heating heat exchanger,

- placing a volumetric buffer tank to which you plan to connect alternative heat sources: solar collectors, solid fuel boiler or fireplace insert with a water circuit.

Complications of the circuit cannot be avoided when implementing the connection scheme for Buderus cascade boilers, when the system is designed to use several gas boilers operating together or alternately. A modern approach to building such systems is the use of special units - hydraulic arrows, which ensure equalization of temperatures and pressure of the coolant in several circuits connected to it.

Shchelkovsky district, KP "Verezhki-2", heating of townhouses with a total area of more than 550 m2

Technical task:

Separate heating and water supply for 2 twin townhouses using original equipment from leading European manufacturers, incl. Buderus automation, which allows you to remotely control the boiler room from anywhere in the world using a mobile application.

Result:

As the main boiler equipment we use a wall-mounted condensing gas boiler Buderus Logamax plus GB162

with a power of 70 kW, with a coaxial pipe exiting to the roof of the building, an indirect heating boiler from the Belgian manufacturer ACV of the Smart Line series with a volume of 240 liters was used to prepare hot water, which has a patented “tank-in-tank” technology - as a result, we are able to heat a larger amount of water in a shorter period time. To circulate the coolant through the system, we use pumping and mixing modules with Grundfos pumps, a manifold and a hydraulic separator made of German main components and assemblies made of copper, as a result we obtain a reliable, but at the same time compact system with increased productivity and heat transfer. The wiring throughout the house was made using Rehau Rautitan stabil pipes; when completing the water-heated floor system, pipes from the Swedish manufacturer Uponor were used; the radiator heating system was represented by panel steel radiators from the manufacturer Kermi.

Common faults and repair tips

A malfunction is considered typical if it can occur in a boiler of any modification - these are problems with the burner, combustion chamber, fuel supply, security system, electronics, sensors, etc.

Some problems can be solved simply by cleaning, tightening contacts or reinstalling a part; you can fix them yourself. If repairs require more serious repairs, we recommend contacting a service center.

Burner does not turn on after maintenance

Often, after repair work, the boiler does not want to turn on, ignition does not occur, and no errors are indicated on the display.

If you decide to flush the pipeline or change the radiators, and to do this you turn off the boiler and drain the coolant, then after filling the system back with water, attempts to turn on the boiler may fail

It's all about the emergency thermostat. We'll tell you how to repair and turn on a Buderus gas boiler after a forced shutdown.

The Logamatic control system contains a safety temperature limiter STB. It is located to the left of the water regulator, under the cap. To return the limiter to its working position, you must remove the cap and press the button, then restart the unit

If after pressing nothing has changed, you need to change the overheating sensor - preferably at a service center, with a guarantee for the work performed.

There are other possible reasons for equipment downtime.

What can be done:

- turn on the start and emergency switches;

- check the operation of the circuit breakers; if faulty, replace them;

- check whether the combustion product control system is functioning correctly; after it is blocked, restart it and wait 15 minutes.

Modern devices have a reset button. It is always recommended to use it when various types of malfunctions occur.

Many units do not require intervention and restart themselves. When performing repeated idle autostarts, the equipment must be shown to service workshop workers.

No spark or flame when igniting

If the startup process occurs in operating mode, but the flame does not appear due to the lack of a spark, you need to disconnect the ignition cable, turn it on again and listen.

The absence of a sound, a kind of click, indicates a breakdown of the ignition transformer, which needs to be replaced. If there is sound, but the spark does not fly out, replace the pilot burner or electrode.

Original AE ignition device for the Buderus gas boiler. The cost of a new service kit is 8,400 rubles. To save money, you can buy a Chinese equivalent, but the quality will be lower

Perhaps the reason is simple - they simply forgot to turn off the gas valve. Open the valve and try starting again.

Air pockets can also prevent ignition. It is recommended to bleed the air from the radiators and the system through the Mayevsky valves, inspect the automatic air vent device, and then try to light the burner again.

Problems with ionization current

The unit will not work if L and N are accidentally mixed up during connection, or if voltage is established between PE and L. It is recommended to reconnect the wires and check the grounding; if necessary, install an isolation transformer.

Perhaps the problem is a weak connection - during the period of operation, the terminal connections often become loose and the wiring falls out. Tighten all connections or replace the defective element

Due to damage, a short to ground may occur; the damage to the ionization electrode must be repaired. If the ionization current does not reach 1.5 mA, cleaning is required - remove contamination from the ceramic part or core of the ionization electrode. The pilot burner may need to be replaced.

Extraneous noise in the unit

If you can clearly hear the sound of boiling, you must thoroughly clean all components and parts in contact with the coolant. Usually, with regular cleaning, which is done once a year, this problem does not occur.

To a greater extent, contamination by mineral formations occurs in the heat exchanger, where hot water constantly circulates. Scale is deposited on literally all elements of the unit

What should be done:

- remove the unit lining;

- dismantle the heat exchanger;

- clean all elements from scale with a special means;

- install the part in place.

In order to reduce the amount of sediment to a minimum, we recommend installing filters that reduce the concentration of salts in the water.

If water noise is heard during heating that lasts longer than programmed, you should check the settings. Perhaps the problem is that the pump is not working properly - you need to check how the turbine functions and adjust the rotation speed.

Novogorsk, DSK "Lad", a complex of engineering systems in a cottage with an area of 350 m2

Technical task:

Turnkey installation of heating, water supply and sewerage systems, installation of a boiler room and chimney.

Result:

A heating and water supply system was installed for a private house with an area of 350 m2 in Khimki, Moscow region, Novogorsk district. The boiler room is mounted on the basis of a floor-standing atmospheric boiler Buderus Logano G234 WS (RU TOP)

, with a power of 55 kW, standard automatic control MC110 and automatic expansion TECH i3, which allows you to control three heating circuits, as well as remote control of the boiler from anywhere in the world. Pumping and mixing modules, manifold and hydraulic separator manufactured by Huch EnTEC, Reflex expansion tanks, Itap shut-off valves, piping of main components and assemblies with Viega copper. The heating system consists of several circuits of a water-heated floor made of Rehau Rautitan pink pipes of 16 and 20 diameters, Kermi panel radiators, and Grota manifold cabinets. The water supply and sewerage system was installed using Uponor aqua pipes and rehau rautitan his.

Chekhov district, KP “Brilliantovy Bereg”, heating and water supply of a private house with an area of 220 m2

Technical task:

Complete set and installation of all main utilities: boiler room, radiator/convector heating, water heated floor, water supply and sewerage.

Result:

An example of the production of a full range of work on HVAC systems, using the highest quality materials and modern equipment: the heart of the house’s engineering is the boiler room, made on the basis of the Buderus Logano G124 boiler (RU TOP)

with a power of 24 kW, equipped with a remote control system for heating circuits, a boiler from the Belgian manufacturer ACV of the SmartLine series was used to prepare hot water, pumping and mixing modules from the German manufacturer Huch EnTEC, Reflex expansion tanks, a domestically developed Shtil inverter stabilizer were installed, and a Rosinox chimney system was installed. The heating system is represented by water heated floors based on Rehau Rautherm S 17 pipes, convectors from the manufacturer Varmann installed in the window sills, as well as panel radiators from the German manufacturer Kermi.

Rublevo-Uspenskoe highway, Borki village, boiler room in a private house with an area of 300 m2

Technical task:

Complete set and installation of a boiler room in a private house, based on a wall-mounted condensing boiler.

Result:

In addition to the condensing wall-mounted boiler Buderus Logamax plus GB172i

with a power of 42 kW, a Protherm electric boiler with a power of 9 kW is installed in parallel, capable of providing a house of 300 m2 with a positive temperature in the event of a complete shutdown of gas, even during winter frosts. To prepare hot water, an indirect heating boiler from the Belgian manufacturer ACV of the Smartline series is installed; circulation of the coolant through the heating system is provided by pumping and mixing modules, a manifold and a hydraulic separator from the German manufacturer Huch EnTEC. The boiler circuit piping is made of Viega copper, Reflex expansion tanks are installed, a Watts safety group is installed, and products from the Italian manufacturer Itap and the German Oventrop are used as shut-off valves.

Pushkinsky district, KP "Green edge", a complex of engineering systems for a private house with an area of 400 m2

Technical task:

Complete set and installation of all major engineering systems: boiler room, heating, water supply, sewerage, chimney.

Result:

All major engineering systems were designed and installed for a private house in the Pushkinsky district. The boiler room is made using a floor-standing atmospheric boiler Buderus Logano G234 (RU TOP)

with a power of 55 kW, an indirect heating boiler from the ACV SmartLine series with a volume of 160 liters is responsible for the preparation of hot water. Thanks to the patented “tank in tank” technology, water heating is carried out much faster and more efficiently than with boilers from other manufacturers. The project provides for a heating system based on radiators and water-heated floors throughout the entire area of the building. Steel panel radiators from the manufacturer Kermi were chosen as heating devices. The collector water supply circuit ensures uniform flow of water through all plumbing fixtures. To implement this project, Rehau brand pipes and fittings, Oventrop distribution manifolds and Viega emergency drains were used.

Volodarskoe highway, KP "Orlov", private house with an area of 320 m2

Technical task:

To provide heat to a townhouse located in the Orlov cottage village, to supply and install boiler equipment, a radiator heating system and water-heated floors.

Result:

As a heat source we use a floor-standing gas condensing boiler Buderus Logano plus GB102

power 42 kW, indirect heating boiler Huch EnTec, volume 200 l, pumping and mixing groups, manifold, hydraulic separator from the same German manufacturer. The radiator heating system is represented by Rifar bimetallic sectional radiators, Rehau Rautitan pink floor heating pipe with a diameter of 20 mm, for more efficient and uniform heating of the surface in the form of tiles or laminate. A feature of this system is the increased efficiency of a floor-standing condensing boiler, as well as its low weight and relatively small size, as well as the diameter of the chimney compared to traditional atmospheric boilers of any manufacturer.

Rublevo-Uspenskoe highway, KP "Uspensky Forest", estate complex with a swimming pool and hammam

Technical task:

Complete set and installation of heating, water supply and sewerage systems in an estate with an area of more than 1500 m2.

Result:

Buderus Logano G334 WS was chosen as the basis for the boiler room

each with a power of 135 kW, the total system power is 270 kW.

Cascade automatic control Buderus Logamatic 4321

and

Buderus Logamatic 4322

allows you to control six heating circuits + a hot water circuit; an indirect heating boiler

Buderus Logalux SU1000

, providing hot water to 11 bathrooms, a shower room, a laundry room and a hammam. We used floor pump groups and a manifold from the German manufacturer Meibes V-UK and M-MK with mixers, a Watts hydraulic pump and other components from leading European manufacturers. The boiler piping is made of ferrous metal, a twin chimney made of Rosinox stainless steel is installed. Radiator heating is implemented using products from various manufacturers: at the moment we have installed 48 bimetallic 10-section Rommer radiators, 18 steel tubular radiators Arbonia, we have also prepared places and “looped” terminals for the subsequent installation of Varmann floor convectors. The wiring and system of water heated floors throughout the house is made using several types of pipes, incl. Rehau rautitan Stabil, Pink and Rautherm S, Oventrop shut-off valves were used, Grota manifold cabinets were installed, TECE installations were installed in the bathrooms.

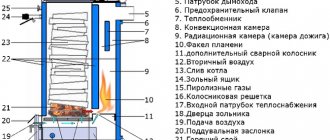

Review and installation of the boiler Buderus

Buderus long-burning solid fuel boiler: Installation, characteristics and review. HI ALL!!! my name is PEOPLE'S BUILDER ANDRYUKHA, I am building a house from MONOLITHIC SAWDUST CONCRETE (ARBOLITE) alone if you are interested in this topic then LIKE and SUBSCRIBE TO THE CHANNEL youtube.com/user/Android4981?s... we will build together :)) —————— ——————————————————————————————————————

Thank you for watching my video! Thanks for watching my video!

Please — Like, Comment…Subscribe to my channel Like! subscribe to my channel

Group in contact vk.com/club77010908

Advertising on the channel: vk.com/topic-77010908_30724499

YOU CAN BUY HONEY, SUPPORT THE PROJECT AND THANK ANDRYUKHA here: vk.com/im?sel=89813493&w=p…

My HOME youtube.com/user/Android4981 My family! youtube.com/channel/UCtXh1g98V… Danil's channel youtube.com/channel/UCSToyLptl… Timofey's channel youtube.com/channel/UCL0pS5NRp…

I became a YouTube partner. And you can too. air.io/?page_id=1432&aff=8…

——————————————————————————————————————————————

All My Videos About Construction youtube.com/user/Android4981/v…

CONSTRUCTION OF AN ENERGY EFFICIENT HOUSE!!!youtube.com/watch?v=i2Qc_TM5Ie…

HOW TO BUILD A HOUSE (efficiency)youtube.com/watch?v=HCFT9UIm3s…

ROOF WITH YOUR OWN HANDSyoutube.com/watch?v=fZe1NWqmU2…

WINDOWS AND DOORS IN MY HOUSEyoutube.com/watch?v=JcbBjJiKCo…

HEATING WITH YOUR OWN HANDSyoutube.com/watch?v=EATzBjrYx0…

MY TOOLyoutube.com/watch?v=H29MaKYl38…

Answers to questions from subscribers.youtube.com/watch?v=10ZCtFF6l9…

Tips from the PEOPLE'S BUILDERyoutube.com/watch?v=NB-DMoODz-…

DIY BEEKEEPING))youtube.com/watch?v=4zm2WVS3HG…

Vlog or MY PERSONAL LIFEyoutube.com/watch?v=gaHg0Ib1dm…

ENJOY WATCHING!!!

——————————————————————————————————————————————

For those who want to help the development of my project: Webmoney wallet: R427959508083 - rubles Z128343445713 - dollars Yandex wallet 410011489332148 THANK YOU IN ADVANCE!

Simferopol highway, portal car wash "Lespromkhoz"

Technical task:

Implement heating for a portal self-service car wash and provide heated water to six washing stations at any time of the year.

Result:

The boiler room was installed and launched using the Buderus Logano G315 WS

with a power of 170 kW, running on diesel fuel. This unit provides heat and hot water to the portal sink and the adjacent areas. In addition to high-tech automation that controls five heating circuits, the system contains a hydraulic separator, pumping and mixing modules with Grundfos generation G2 pumps, a high-carbon steel manifold, copper piping of the main components and assemblies, as well as shut-off valves from the Italian manufacturer Giacomini.

Assistive devices

Auxiliary devices are also required for the heating system to function.

Air balloon

These are different types of devices that help remove air pockets from the system. During operation of the boiler, small pressure drops may occur, as a result of which air, which is forced into the upper part of the system, can disrupt circulation. This will affect the heat transfer of the entire system.

Of all the variety of air vents, it is best to choose an automatic one. By installing such an air vent, you will forget about air jams, because it will independently release the air that accumulates in the system.

Sump

Piping heating boilers with natural water circulation does not require the installation of such devices. Gas and solar boilers do not like pollution very much. They are equipped with thin heat exchanger channels and a dirt-sensitive impeller. In such cases, installing a mud trap is simply necessary.

Leningradskoye Highway, self-service car wash complex “Black Mud”

Technical task:

Provide heating and hot water for a self-service car wash.

Result:

The boiler room was installed and launched in a technical room, at one of the self-service car washes, not far from the village of “Chernaya Gryad” - 33rd km of the Leningradskoye Highway. The heat generator in this case is a floor-mounted pressurized boiler Buderus Logano G215 WS

with a power of 78 kW, it provides heat and hot water to six posts and a utility room in which the equipment is located. To prepare hot water we use a boiler from the Belgian manufacturer ACV of the Comfort Line series. Pumping and mixing modules from the German manufacturer Huch EnTEC ensure continuous circulation of the coolant and supply of hot water to the stations; a 2000-liter buffer tank is installed, which allows accumulating osmosis (prepared water for finishing the car body) and ensuring its uninterrupted supply even when all six stations are operating simultaneously, for quite a long time.

Error codes and instructions for eliminating them

Modern gas boilers are able to inform the user about a malfunction, and fix some breakdowns independently by stopping and restarting.

If the unit does not cope and an error is displayed on the display, you should act according to the instructions, and if necessary, contact the technical service

Error codes are alphanumeric characters that indicate the type of fault. Among them there are simple ones that require a reboot or cleaning, but there are also complex ones that require diagnostics of all components of the unit. Let's look at the most significant and frequently occurring errors.

0Y – temperature increase above operating settings (at a norm of +95°C). If the boiler does not turn off automatically, turn it off manually, check the serviceability of the sensors and the settings.

You should also check the pump and connect it to the main regulator. Adjust the pump power.

2P – sharp increase in DHW temperature. Check that the pressure corresponds to the operating parameters, check the operation of the pump, and make repairs if necessary.

H11 – problems with the hot water sensor. Check the functionality of the temperature sensor, as well as the contacts of the connecting wires. Replace faulty parts.

3A – the fan does not start. Check contacts and wire connections. If the unit is faulty, replace it.

3U – fan speed is too high. Check the operation of the smoke exhaust duct and clean it if necessary.

4C – heat exchanger overheating. Carefully inspect the cable and sensors, bleed air from the system, check the pressure in the network. If everything is normal, the problem is in the radiator water unit or pump; disassembly and repair are required.

6A – no ignition, no flame. Unscrew the gas valve to the maximum, check the pressure.

If you suspect a lack of draft, check whether there is any in the chimney. You can use a lit match - an even flame indicates contamination of the chimney, a fluctuating flame indicates good draft

It is also recommended to diagnose the flow switch, check and, if necessary, clean the electrode contacts, remove deposits from the burners with a brush, and if the burner malfunctions, install a new unit.

6C – the system detects a flame when the boiler is turned off and the gas is turned off. You should check whether the chimney is working and whether the contacts are oxidized. Perhaps, due to condensation, moisture has appeared on the board, which needs to be dried, and at the same time check the cleanliness of the condensation siphon.

9L – malfunction of gas fittings. A thorough check of fittings and wiring, repair and replacement is required.

After replacing some components - for example, a fan or pump - the unit must be put into operating mode. After repairing a Buderus gas boiler yourself, it is not always possible to get it to work correctly due to “off” settings. We advise you to call a technician who will check the correct connection and reconfigure the unit.

Simferopol highway, self-service car wash complex

Technical task:

Provide a self-service car wash complex with heat and hot water and install an anti-icing system.

Result:

Our company’s specialists have fully equipped and installed a boiler room that supplies heat and hot water to a self-service car wash complex located in the south of the Moscow region. It is based on a floor-mounted pressurized boiler Buderus Logano G215 WS

with a power of 78 kW, it serves as a heat generator for heating the boiler and water heated floors. To control and monitor the system, a weather-dependent controller with an LCD display is installed, which allows for separate control of heating circuits, a burner from the German manufacturer Giersch running on diesel fuel, Huch EnTEC pumping and mixing modules, a Watts safety group and thermomanometers, and a Meibes water-heated floor collector. As a material for installing a water heated floor system, we use Rehau rautitan pink pipe, with a diameter of 20 mm.

Kaluzhskoe highway, KP "Yesenino", boiler room in a private house with an area of 350 m2

Technical task:

Installation and piping of a boiler room using a wall-mounted condensing boiler Buderus Logamax plus.

Result:

Buderus Logamax plus GB172i acts as a heat generator for heating a house with an area of 350 m2

with a power of 42 kW, an indirect heating boiler

Buderus Logalux SU200

; pumping and mixing modules and a Huch EnTEC hydraulic separator ensure the circulation of coolant through the circuits, Reflex expansion tanks are installed, the piping of the boiler circuit to the distribution manifold is made of Viega copper, then polypropylene, resistant to temperature changes. Ultimately, we get a modern and inexpensive boiler room with increased efficiency, and at the same time made in a single color style, successfully combined with the interior and exterior of the building.

Mytishchi district, KP "Aksakovo", townhouse with an area of 320 m2 + bath complex 120 m2

Technical task:

Supply of equipment and a full range of works on heating, water supply and sewerage systems. Also, one of the tasks is to supply heat to the bath complex with an area of 120 m2, located at a distance of 30 m from the main building.

Result:

During the work done, our company’s specialists equipped and installed a boiler room based on the Buderus Logano G234

with a power of 55 kW, original automatic control system

Buderus Logamatic 4211

Logalux SU200

is installed for the preparation of hot water supply , coolant circulation through the system is provided by pumping groups and a manifold manufactured by TE-SA, Reflex expansion tanks are installed, piping of the main boiler units and units are made of copper pipes, a chimney made of Jeremias stainless steel is installed. The heating system is represented by bimetallic sectional radiators from Rifar and Varmann convectors. The wiring throughout the house is made with a Rehau Rautitan Stabil pipe; the water supply and sewerage systems, as well as the heating mains supplying heat to the heating devices of the bath complex, are produced by the Swedish manufacturer Uponor.

Familiarization with technical characteristics

Below we discuss the main parameters of the products of the most popular “Logano” series. The information is provided in the form of a comparative table to make it easier to make a choice. All models are made of steel or cast iron, as these materials have the most suitable properties.

Logano G221 products presented.

Having made preliminary calculations of the heating system for the building, you can familiarize yourself with the technical data of the boilers.

| Products | Power in kilowatts | Efficiency in percent | Pressure in bars | Material |

| S111-2 | 12-45 | 86 | 2,5 | Steel |

| S121-2 | 21-38 | 85 | 2 | Steel |

| G221 | 20-40 | 78 | 3 | Cast iron |

| G221A | 25-30 | 80 | 4 | Cast iron |

The Logano S121-2 boiler is demonstrated.

Recommendation! When operating boilers operating on solid fuel, it is necessary to use firewood whose humidity does not exceed 20 percent. Otherwise, the power of the devices will be noticeably reduced.

Novorizhskoe highway, KP "Luzhki", boiler room in a private house with an area of 550 m2

Technical task:

Place the boiler equipment in a limited space, connect to a previously installed and narrowed chimney diameter.

Result:

During the installation process, our company’s specialists focused on the convenience of further operation of the boiler equipment. Inflatable boiler Buderus Logano G215 WS

with a power of 78 kW was installed on a horizontal indirect heating boiler

Buderus Logalux L200

, distribution combs with quick-installation pumping groups of the seventh generation Meibes were mounted on the opposite side of the room.

The boiler circuit piping is made of high carbon steel. A Cuenod two-stage gas burner was installed, and a compact Jeremias silencer was installed for greater comfort. The system is controlled by weather-dependent automation Buderus Logamatiс 4211

, with multifunctional modules FM442 integrated into it.

Task assessment and budgeting

Our engineer carries out all the required measurements and calculations, takes into account the predicted energy consumption, the number of consumers, the number of heating circuits, possible heat losses of the building, and the individual technical features of the heated premises. A layout plan for the main components and assemblies of the boiler equipment is being developed, and the need to purchase additional components for the heating system is being assessed. Based on all the actions described above, an individual estimate and specification are drawn up, in accordance with which the facility is completed and installation/commissioning work is carried out.

Connection to the gas main

The process of connecting a gas boiler to a gas pipeline must be carried out exclusively by qualified specialists from the gas service or another organization licensed to carry out this type of work. Independent connection to the gas main is illegal and, at best, threatens the owner of the premises with a considerable fine, and at worst, it can lead to tragedy.

The first stage in the process of gasification of a facility is contacting the gas service. After submitting all the necessary documents, individual technical conditions (TS) will be developed for you, the fulfillment of which is necessary to connect to the gas main.

Once you have the specifications in your hands, you can safely start looking for a certified specialist who, in accordance with the requirements of regulatory authorities, will design a gas pipeline and connect your heating boiler to it.

Photo 5: Connecting a wall-mounted boiler to the gas main

Gasification of the premises can be carried out using underground and above-ground methods. For the underground section, corrosion-resistant polyethylene pipes are used, and the above-ground part is made of steel pipes, which enter the room directly at the location of the gas heating boiler, at a distance of 1.2-1.5 m from the floor.

Attention!

When using several heating devices, gas supply to each of them is carried out separately. Laying gas lines indoors is strictly prohibited.

When accepting installation work, you should pay special attention to the fact that all connections must be sealed using tow or paint. The use of sealing tape or FUM is not allowed due to the low degree of tightness of the connection. A gas filter must be installed on the shut-off valve to protect the heating boiler from small debris and condensate. It is recommended to connect the gas boiler directly to the shut-off valves using steel pipes. It is possible to use a special corrugated stainless steel hose, but pipes are still preferable, since their use does not reduce the cross-section of the gas channel.

For more information about connecting and piping wall-mounted gas boilers, see the following video:

Its service life, operating efficiency, and the safety of its owner depend on how correctly the wall-mounted gas boiler is connected. We hope that our short overview of the main stages of connection and strapping was useful to you.

FAULTS AND REPAIRS

REPAIR OF GAS HEATTER

BOILER SPARE PARTS

Installation and piping of the boiler room

This term refers to all actions necessary to ensure the full functioning of the heating system and the subsequent transportation of coolant to radiators, water-heated floors and other heating devices. There are no universal solutions suitable for absolutely any case, and cannot exist; in each specific case, a specialist performs calculations individually.

Today, piping a boiler room using copper pipes is quite popular, which is quite logical and understandable:

- Simplicity and reliability of installation. Of the specialized equipment, a specialist only needs a soldering iron and mastery of this tool;

- Heat resistance. Piping of boiler units and units made with copper provides reliable protection against expansion and deformation of the pipe when it is heated or overheated during the movement of the coolant;

- Copper actively resists the formation of salt deposits inside the pipeline, so the speed of movement of the coolant is stable throughout the entire operational period of such material. Note that traditionally manufacturers claim a service life of fifty years or more, and with proper installation and soldering - 100 years or more;

- Good heat transfer from copper - heating of rooms is carried out not only with the help of the radiators themselves, but also due to the movement of the coolant. Copper heats up well and does not require a large amount of thermal energy;

- Copper is not subject to corrosion. Over time, copper pipes may become coated with a thin layer of oxide, but this does not in any way affect performance;

- Copper piping is not afraid of freezing. Piping the boiler room with copper pipes eliminates the difficulties associated with freezing of the coolant. In this case, steel and propylene pipes simply burst. Copper is more ductile, so it can withstand freezing loads without losing integrity.

Connecting a wall-mounted boiler to the electrical network

Most modern wall-mounted gas boilers are equipped with sophisticated automation. It controls many processes, turning the heating boiler into an autonomous mini-boiler room, the operation of which requires virtually no intervention from the owner. Obviously, the control unit and various sensors require an electrical connection.

Double-circuit wall-mounted boilers are available in two versions: with a conventional socket and with a cable for connecting directly to the machine. In any case, they must be powered from the mains through an individual machine. If you purchased a model with a plug, then the individual socket for the gas boiler should be located next to it, but in no case under it. This is one of the safety requirements so that in the event of a coolant leak, a short circuit does not occur.

Photo 3: Installing a voltage stabilizer for a wall-mounted boiler

A gas boiler requires mandatory grounding. For these purposes, you can purchase a point grounding kit. It is installed in the basement or next to the house and occupies a small area of about 0.25 m².

Boiler automation is very sensitive to the quality of the supply voltage. If the level of the sinusoid at the input is insufficient or the shape is not ideal, the devices quickly fail. To prevent frequent breakdowns and extend the service life of the unit, it is necessary to connect voltage stabilizers for gas boilers. To avoid shutdowns of heating equipment in the event of power outages, you should additionally purchase an uninterruptible power supply.

Additional equipment and components for the boiler room

Ensuring the highest possible level of safety is as important an aspect of boiler installation as doing the installation correctly. Additional equipment and components help to achieve the highest level of efficiency:

- Collectors - such equipment contributes to the uniform distribution of coolant heated to the desired temperature along numerous circuits;

- Sensors for fuel leakage, the appearance of smoke, liquid fuel, stability of working pressure - such devices help to significantly increase the degree of safety, since they are able to promptly signal a danger;

- Temperature sensors, automation systems - help facilitate the processes of managing the heating system, making it possible to automate the vast majority of technological processes;

- Shut-off valves - provides the ability to distribute coolant flows within the system depending on the user’s wishes;

- Quick installation groups are a ready-made heat distributor along circuits, which can be correctly installed in the boiler room, connected to the boiler and to the heating system, water heated floors, boiler and power supply;

- Hydraulic separator - necessary for hydrodynamic balancing of the heating system and serves as an additional unit. This device makes it possible to protect boiler heat exchangers made of cast iron from possible thermal shocks.

To combine all of the above elements into a single operating system, you will need to use the services of several specialists with many years of practical experience in the configuration and installation of boiler rooms and heating systems. By contacting us, you make the right choice!

Preparatory work

…

The first thing a home owner should do before installing a wall-mounted heat generator is to obtain technical support. conditions that will become the basis for carrying out all work on connecting heating equipment to the main gas pipe and putting the heating system into operation.

To obtain technical conditions, the home owner must submit an application to the gas service, indicating the fuel consumption in a specific room. Based on the standards regulated by SNiP 31-02, clause 9.1.3, the average daily gas consumption for one apartment located in central Russia is:

- For cooking – 0.5 m3.

- For hot water supply – 0.5 m3.

- For heating (depending on the volume of the room) – 7-12 m3.

After reviewing the application by specialists from the local gas company (the process lasts from 7 to 30 days), the applicant is given technical information. conditions that are actually permission to carry out installation work.

Project

Installation of a wall-mounted gas boiler cannot be carried out without a competently drawn up and approved project, which is developed on the basis of technical specifications. conditions.

Important! The creation of the project should only be carried out by specialists who have permission to carry out such work.

After the project has been developed, all documentation with equipment specifications, technical data sheet of the boiler installation and instructions for its operation are submitted for approval to the organization responsible for controlling the gasification of a specific site. After receiving a positive approval result, you can proceed to work, taking into account all the requirements for the installation of wall-mounted gas boilers.

…

Find out about domestically produced gas boilers Look at Reviews of German boilers Buderus 24 kW

Read about Gas boiler with an open combustion chamber

Selecting a room

The design features and purpose of the boiler installation influence the choice of equipment installation location.

- installation of equipment and installation of a wall-mounted gas boiler with an open combustion chamber (atmospheric boiler) must be carried out in a separate room, equipped in accordance with the norms and requirements of the Code of Rules SP 60.13330.2012 (according to the old SNiP 41-01-2003); SP 112.13330.2011 (Click to download - according to the old SNiP 21-01-97); SP 30.13330.2012 (according to the old SNiP 2.04.01-85); SP 62.13330.2011 (formerly SNiP 2.04.08-87).

- installation of wall-mounted gas heating boilers with a closed combustion chamber can be carried out in almost any room of the home, if it meets fire safety requirements and has a volume corresponding to the power of a particular boiler.

As a rule, a kitchen is used as a room for installing a wall-mounted gas boiler installation, which must be equipped with:

- An exhaust ventilation system with air exchange at least 3 times per hour. When installing an atmospheric heat generator, the supply ventilation must replenish the volume of air taken in by the exhaust hood and ensure normal operation of the boiler unit burner.

- Chimney. If an atmospheric boiler is used, an individual combustion product removal system is required. Turbocharged heat generators are equipped with a coaxial chimney, which, as a rule, comes complete with the equipment.

- A window whose area should correspond to 0.03 m2/m3 of the room.

- Engineering systems: plumbing, heating circuit, electricity.

In addition, the installation instructions for a wall-mounted gas boiler strictly regulate the volume of the room for its installation.

- For heaters with a power of up to 30 kW, a room with a volume of 7.5 m3 is sufficient.

- For heat generators with a capacity of 30-60 kW, a boiler room with a volume of 13 m3 or more is required.

- Installations with a power of 60 kW or more require a room with a volume of at least 15 m3.

Note! These requirements are valid for boiler rooms with ceiling heights from 2.2 to 2.5 m.