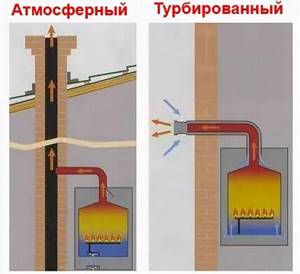

The huge selection of gas boiler models is currently quite extensive. They vary depending on the functions performed, the characteristics of the installation process and, of course, cost. To make the final decision on choosing an atmospheric or turbocharged gas boiler, it is necessary to pay special attention to the features of each type of the above equipment and analyze the nuances. Also decide which type will be optimal for you.

Differences between an atmospheric gas boiler and a turbocharged one

Gas equipment, on the basis of which autonomous heating systems are built, is presented in two options on the market. The consumer can now purchase either a turbocharged or naturally aspirated (chimney) type.

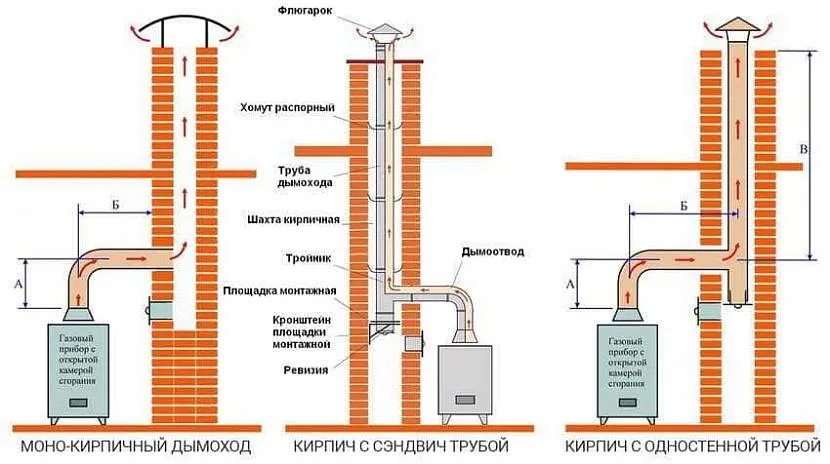

The first group is equipped with a coaxial chimney, as well as a closed combustion chamber. Due to the minimum requirements for the ventilation system, it can be installed in apartment buildings. To operate an atmospheric boiler, a traditional chimney is required. It is installed in low-rise private buildings.

The main differences between atmospheric and turbocharged boilers lie in the design and operating principle of the gas burner

The main working unit of the atmospheric gas boiler, which is of the open type, takes air from the room. The combustion process with the traditional release of its products occurs openly, therefore, to install atmospheric equipment, a boiler room is installed, separated from the living area of the house.

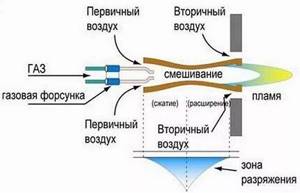

An atmospheric burner is a set of small nozzles through which gas passes under pressure. During combustion, the required amount of air enters the chamber, which intensifies the flame. As a result, when heating water in the system, an atmospheric boiler consumes a minimum of fuel. Smoke is exhausted through a stainless steel chimney.

An open burner burns oxygen from the air mass of the boiler room during operation. Even if we take into account that this is a priori a non-residential premises, a powerful ventilation device is required. After all, a constant supply of air is required for normal combustion

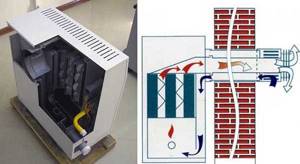

A turbocharged boiler has a closed combustion chamber. Oxygen is driven into the chambers through a coaxial pipe by a fan. Installation of equipment is possible anywhere.

The peculiarity of the wall-mounted turbocharged boiler is that the combustion chamber is made of copper, which limits the power to 35 kW. In floor-standing boilers it is made of cast iron, which allows you to significantly increase power.

Atmospheric varieties of gas boilers require connection to a standard chimney with a vertical duct. Turbocharged ones can be equipped with a coaxial chimney - it is easier and cheaper to install

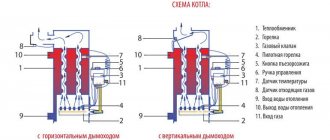

Device

A double-circuit boiler consists of a reservoir and a boiler.

These two elements are closely interconnected and operate in a closed loop. In addition, a water supply system is connected to the boiler - this ensures a constant supply of hot water, regardless of the position of the tap handle. All gas turbo boilers resemble a boiler room. In summer, the heating system is turned off, but the hot water supply does not stop. This technique significantly reduces the consumption of blue fuel. This is the main advantage of turbo boilers. The structure itself consists of the following elements:

- fan;

- sensor and electronic unit;

- gas valve;

- expansion tank and heat exchanger;

- combustion chamber and pump;

- pressure gauge

Fan

Double-circuit boilers are equipped with a single-speed fan with a built-in combustion product pressure switch. The forced air system works as follows:

- the fan pumps in oxygen;

- the resulting decomposition products are removed from the device.

The forced system removes harmful gases through a coaxial pipe, so there is no need to use a chimney.

Heat exchanger

The gas heater has a double-circuit heat exchanger. This is the main part of the boiler, due to which the entire system operates. Supply and exhaust pipes are connected to the heat exchanger, supplying the device with water.

The liquid passes through the main internal circuit, is heated to the desired temperature (regulated by the sensor) and is discharged back into the system and the heating circuit. This is how water is heated and the living space is heated.

Gas valve

This small part performs an important role: regulating the fuel supply. In modern turbocharged boilers, valves with a flame modulation function are installed.

When choosing a heater for your home, you should pay attention to the functionality of the gas valves and give preference to parts with the ability to modulate

The electronic unit

The electronic board in wall-mounted turbo boilers is located at the bottom of the device. It is hidden in a durable plastic case, which is secured with latches.

There are no screws or additional parts in the mount. This provides quick access to the electronic board.

Expansion tank

Double-circuit turbocharged boilers are equipped with an expansion tank. This is an additional container of water that serves as a reserve reservoir in case of excess liquid. When the pressure in the pipes increases (due to an increase in the volume of water), the incoming valve becomes open and allows water to enter.

As the temperature drops, liquid flows out of the tank and fills the radiators. The standard volume of the expansion tank is 6-8 liters.

Combustion chamber and pump

The gas double-circuit boiler has a low power of 35 kW. The device is equipped with a closed combustion chamber. With the help of a fan, air is supplied through a coaxial pipe, which supports the combustion of the gas.

The combustion products also leave the turbine. The standard combustion chamber is made of copper alloy, and cast iron is used for floor structures. Standard models use a three-speed pump. It has a built-in “air vent” and a drain valve.

Features of units with a separate heat exchanger

Separate-type gas wall-mounted appliances are optimal for hard water. In this case, a plate heat exchanger is installed in turbocharged double-circuit equipment and an internal type circuit is used to prepare the coolant. Such wall-mounted gas turbo units have a high degree of reliability and can operate for a long time in water supply and heating systems with hard water.

Rice. 2 Boiler with plate heat exchanger

Due to the rather simple design of the gas appliance, its repair is cheaper. But such dual-circuit turbocharged models have dimensions slightly larger than bithermic ones.

The principle of operation of the boiler and its design

Image 1. Hydraulic diagram of a double-circuit boiler in heating mode.

Gas appliances with two heating circuits have the following operating principle. The heat of the burned natural gas is transferred to a heat exchanger, which is located above the gas burner. This heat exchanger is included in the heating system line, that is, the heated water in it will circulate through the heating system. Water circulation is carried out using a pump built into the boiler. To prepare hot water, the dual-circuit device is equipped with a secondary heat exchanger.

The presented diagram in IMAGE 1 shows the ongoing work processes and equipment design:

- Gas-burner.

- Circulation pump.

- Three-way valve.

- DHW circuit, plate heat exchanger.

- Heating circuit heat exchanger.

- D—inlet (return) of the heating system for heating;

- A - supply of ready-made coolant for heating devices;

- C - cold water inlet from the main;

- B - output of ready hot water for sanitary needs and domestic use.

The principle of preparing water for DHW is as follows: the heated water in the first heat exchanger (5), which is located above the gas burner (1) and is designed to heat the heating circuit, enters the second plate heat exchanger (4), where it transfers its heat to the DHW circuit.

As a rule, double-circuit boilers have a built-in expansion tank to compensate for changes in coolant volume.

The double-circuit boiler circuit allows you to produce hot water and heat it for heating only in separate modes.

Design of a double-circuit gas boiler.

It is impossible to use the boiler simultaneously for domestic hot water and heating at a certain point in time. For example, during operation of the device, the heating system is heated at a given temperature, the process of maintaining the temperature is controlled by the boiler automation, and the circulation of the coolant through the heating network is carried out by a pump.

At a certain moment, the hot water tap for domestic needs opens, and as soon as the water begins to move along the DHW circuit, a special flow sensor installed in the boiler is triggered. Using a three-way valve (3), the water flow contours in the boiler are reconfigured. Namely, the water heated in the heat exchanger (5) stops flowing into the heating system and is supplied to the plate heat exchanger (4), where it transfers its heat to the hot water system, that is, the cold water received from the pipeline (C) is heated through the pipeline (B) served to consumers of an apartment or house.

At this moment, circulation occurs in a small circle and the heating system does not heat up while the hot water is being used. As soon as the tap at the DHW water intake is closed, the flow sensor is triggered and the three-way valve opens the heating circuit again, further heating of the heating system occurs.

Most often, the design of a double-circuit gas boiler involves the presence of a plate heat exchanger. As already mentioned, its purpose is to transfer heat from the heating circuit to the water supply circuit. The principle of such a heat exchanger is that sets of plates with hot and cold water are collected in a package where heat transfer occurs.

The connection is made hermetically: this prevents the mixing of liquids from different circuits. Due to the constant change in temperature, processes of thermal expansion of the metal from which the heat exchanger is made occur, which contributes to the mechanical removal of the resulting scale. Plate heat exchangers are made of copper or brass.

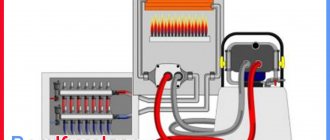

Connection diagram for a double-circuit boiler.

There is a double-circuit boiler scheme that includes a combined heat exchanger.

It is located above the gas burner and consists of double tubes. That is, the heating circuit tube contains a hot water supply tube inside its space.

This scheme allows you to do without a plate heat exchanger and slightly increase the efficiency in the process of preparing hot water.

The disadvantage of boilers with a combined heat exchanger is that scale is deposited between the thin walls of the tubes, as a result of which the operating conditions of the boiler deteriorate.

Advantages of turbo boilers

The use of turbocharged gas boilers is associated with both positive and negative aspects.

The advantages of the equipment include:

- easy installation in any convenient place;

- air intake from the street, which does not affect the indoor climate;

- the presence of a modulating burner device adapted to operate at low fuel pressure;

- switching to liquefied gas is possible;

- the presence of automation that regulates the combustion mode depending on the weather;

- smoke removal without the possibility of harmful gases entering the home.

In general, turbocharged gas installations have no analogues in terms of economy and efficiency.

Main characteristics

The key characteristics of gas-fired boiler systems include:

- power;

- dimensions and weight;

- Efficiency of the heating device.

The power of a gas boiler with an atmospheric burner is determined by the characteristics of the equipment. The maximum performance of a wall-mounted unit is 36 kW, while this parameter for floor-standing models is several times greater than for wall-mounted counterparts. The overall characteristics of the installations also vary depending on the design features. Thus, a wall-mounted atmospheric gas boiler weighs about 50 kg, while the weight of a floor-standing heating device can reach 100 kg.

The efficiency of devices with an atmospheric burner varies between 80-90%. This means that 10-20% of the energy generated is not used for its intended purpose. Improved models of units in the expensive segment are equipped with a high-tech gas supply regulator, which allows for the highest possible efficiency values.

Review of turbocharged gas boilers

For heating small apartments and offices, a turbocharged gas boiler is the best choice. It is safe, easy to operate and trouble-free. Consistently provides consumers with heated water in the volume they need.

Its advantages over atmospheric:

- if the power is up to 60 kW, the installation location does not matter;

- air is not taken from the premises for combustion;

- combustion products are removed by a fan to the street through the chimney;

- high efficiency allows you to use less fuel.

Turbine-type boilers are completely safe and can be installed in any room.

The closed burner of a gas boiler is much safer than the open version. During its operation, gaseous fuel processing products do not enter the premises. Oxygen is not burned out

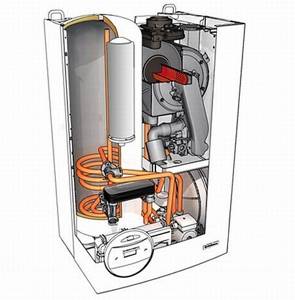

Design and operating features

The main structural components of a boiler with a closed burner option:

- gas-burner;

- fan;

- DHW heat exchanger;

- built-in expansion tank;

- heating heat exchanger;

- circulation pump;

- temperature sensors;

- gas valve;

- security systems;

- coaxial chimney;

- electronic control unit.

The installation of such a boiler should be carried out on the outer wall of the house or near the ventilation shaft. Despite the fact that the cost of a turbocharged model is higher than that of an atmospheric model, you can save on equipping the boiler room and installing a traditional chimney.

Most dual-circuit units stop heating the room while hot water is supplied. Contrary to the opinion of the majority, the coolant does not have time to cool down and the temperature in the apartment remains unchanged.

Turbocharged boilers are equipped with a “Summer” mode. In this case, hot water is supplied independently from the heating system - this is a strong argument in favor of purchasing a model with a closed burner.

Advantages of turbocharged boilers:

- Air intake for heating is carried out not from the room, but from the street:

- sealed combustion chamber;

- no need to install a chimney;

- there is no need to build a boiler room (installation can be carried out in any room);

- compact dimensions;

- high efficiency and low energy consumption;

- high productivity (on average 10 liters of water are heated per minute);

- automated operation and electronic control system;

- high security;

- ease of operation.

Disadvantages include the high cost of equipment and parts for repairs and dependence on electricity supplies.

Models with closed burner type

A single-circuit boiler is used to supply heated water to heating radiators. Dual-circuit models have a second heating circuit designed to prepare hot water. A boiler with a power of over 20 kW will allow you to heat the room and heat water.

However, the floor-standing unit is of low power, so it should not be “overloaded”. It is better to heat water with a gas water heater. According to the standards, it is allowed to install two separate boilers in one boiler room: wall-mounted and floor-standing. One of them will supply sanitary water, and the second will supply coolant.

Double-circuit models are divided into boilers with a bithermal heat exchanger and a separate one. The first is used for heating and hot water. Its disadvantage is sensitivity to bad water. Scale quickly forms on it and productivity decreases.

During operation, it is recommended to use descaling powder. A separate heat exchanger performs the same functions as a bithermic one, but is less sensitive to water.

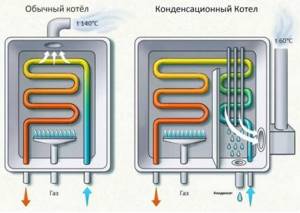

The high efficiency of condensing boilers is explained by the intelligent use of condensate, the heat of which is transferred to the heating circuit

Condensing boilers, in addition to the usual heat generation, additionally use the energy released during operation of the equipment during condensation of water vapor. Essentially, these models collect condensate to transfer its heat to heating devices. Such boilers allow you to save up to 17% of gas, and their efficiency reaches 108%.

Would you say that the efficiency of any type of heating equipment cannot exceed 100%? Maybe this is what condensation models confirm. They partially reuse the energy released during the combustion of one portion of fuel.

Condensing boilers have two heat exchangers. One of them heats water or coolant, the second collects and prepares condensate for subsequent use

Review of atmospheric gas boilers

Main characteristics of atmospheric gas boilers:

- power - from 20 to 60 kW;

- large dimensions and weight;

- productivity - up to 30 l/min;

- average efficiency - 79-92%;

- electronic control panel.

This model is equipped with an open combustion chamber. Oxygen is taken from the room where the equipment is located, and combustion products are removed through the chimney. Leaks in the combustion chamber result in some of the gases entering the environment and can cause poisoning.

Gas boiler equipment with an open burner is absolutely not suitable for installation in residential premises. Even with a flawlessly functioning chimney system, the risk of toxins entering the air mass cannot be excluded

Therefore, a special room with good ventilation is equipped for atmospheric boilers.

Selecting a location for installation:

- the structure is installed in a technical building;

- powerful and large models require a building with a foundation;

- to ensure sufficient draft, a close location of the chimney with minimal bending is necessary;

- it is important to provide communications for the output of the coaxial chimney.

The operation of an atmospheric boiler is based on heating the heat exchanger material with a gas burner. It then transfers the resulting energy to the coolant or water prepared for use.

Burner design:

- nozzle;

- head;

- air regulator;

- ejection tube.

With partial, part of the gas enters directly, and the other part with air. At full - before entering the combustion chamber, complete mixing of gas with air occurs. In the CIS countries there are no models with full mixing.

Gas boiler burner and its operating principle. Before the air reaches the nozzles, it mixes with the gas. Mixing can be complete or partial

Burners are available in one and two-stage types, with smooth switching of fuel supply speed and modulating. Cost savings depend on the complexity of the design. Some models allow the use of diesel fuel. But the price of such boilers is much higher.

The burners are equipped with CO2 and flame level sensors. If the draft is insufficient, the flame may go out, which will lead to gas pollution in the room. A similar problem is observed in home-made structures that are converted from solid fuel boilers.

Advantages of atmospheric gas boilers:

- stable operation even with low gas pressure (it follows that in this case the fuel supply elements fail faster);

- No additional air supply is required for efficient combustion of the mixture;

- silent operation;

- ease of operation.

There are also significant disadvantages. The most important thing is the possibility of carbon monoxide leakage and fire. Therefore, boiler equipment with an open type of gas burner requires a separate room (impossibility of installation in apartments).

Types of atmospheric gas boilers

Heating equipment differs from each other:

- dimensions plus weight directly related to dimensions;

- power;

- Efficiency

The maximum power of wall-mounted models of atmospheric boilers is 36 kW. This indicator is due to the design features.

To select the optimal power, you should take into account the area of the room and factors of possible heat loss (windows, cold floors and walls). It is recommended to choose a boiler that can heat an area 25% larger than the actual one.

The boiler power is selected so that for every 100 sq.m there is a minimum of 10 kW plus 25% of the result obtained

In addition to power, when choosing a boiler, you should pay attention to efficiency. This indicator shows how much energy is required to heat water and how much is burned. Average figures for atmospheric boilers are 80-90%. More expensive models provide maximum effect - up to 97%.

Condensing boilers have 100% efficiency. The fact is that the exhaust gas heats up to 110°C. In turbocharged units this figure is 55 °C. In condensation rooms - 30°C.

Kinds

Wall-mounted single-circuit boilers are produced in various design options, which can be divided according to the following characteristics:

By type and material of heat exchanger:

- steel. Stainless steel is used, which has average capabilities and efficiency. Such units are usually installed on units in the middle and low price range.

- copper. This unit demonstrates increased heat transfer, durability and efficiency. Installed on expensive models from the most famous manufacturers.

On single-circuit boilers, as a rule, one structural type of heat exchanger is used - tubular. It is a spiral of steel or copper tube, which is heated by a burner flame.

The coolant passing inside manages to get a high temperature and exits to the next nodes completely ready for further work.

By type of burners and combustion chambers:

- atmospheric. These are open type burners that use air directly from the room. To remove flue gases, they need to be connected to a traditional type chimney with natural draft;

- turbocharged. These units are closed, so a turbofan provides fresh air and smoke displacement. Their combustion process is more stable, and there are never problems with smoke removal. The only problem may be a fan failure or a power outage.

According to the method of energy transfer:

- convection These are boilers that operate on the usual principle of heating the coolant using a burner.

- condensation A relatively new design, which uses a two-stage method of heating the coolant. First, it is heated from the heat obtained from the condensation of flue gases, and only after that it enters the heat exchanger, where it finally receives the set temperature. This technique allows you to significantly reduce gas consumption, since the coolant is already heated and does not require too intensive preparation. However, for the operation of condensing boilers, specific conditions are required - the condensation temperature must exceed the return flow temperature. This is only possible on underfloor heating systems, or when the temperature difference between inside and outside is no more than 20°. This is impossible in Russia.

NOTE! When purchasing a condensing boiler, you should not trust the declared efficiency, which is 107-109%. This is a common marketing ploy

We must first understand how this unit works.

Advantages of an atmospheric boiler

Chimney gas boilers are the most common option for organizing autonomous heating. They are relatively inexpensive, easy to operate, and have a long service life. The operating principle of an atmospheric boiler provides for the evacuation of combustion products by natural draft, which is organized by the chimney. Among the advantages of the equipment are the following:

- low price;

- There are completely autonomous models, without electricity;

- the presence of a draft sensor guarantees safe operation of the combustion chamber.

Top popular and inexpensive models

Among gas atmospheric boilers, Vaillant products are characterized by a successful combination of price and quality. The two most popular lines - Vaillant Turbo TEC and Vaillant Atmo TEC - have proven reliability and performance.

The manufacturer Baxi offers inexpensive products; each line includes examples with an open and closed combustion chamber. The LUNA and FOURECO series have the most attractive prices.

Viessmann boilers are known for their quality.

Types of natural gas boilers

The division into wall-mounted and floor-standing boiler models is clear - the first are made in a mounted version, the second are placed on the floor. Both are divided into types according to the principle of operation:

- Atmospheric. They are equipped with an open combustion chamber, into which air enters from the room where the gas hot water boiler is located. The name suggests that the combustion process takes place at atmospheric pressure in the firebox.

- Supercharged (aka turbocharged). They are distinguished by a closed chamber into which air is supplied by forced injection (supercharging) through a fan.

- Condensation. These are turbocharged heat generators equipped with a special circular burner and a ring-shaped heat exchanger. The goal is to burn fuel as efficiently as possible, removing thermal energy from the water vapor released during combustion, causing it to condense.

Both wall-mounted and floor-standing gas boilers are equipped with steel and cast iron heat exchangers, where the coolant for the water heating system is heated with a burner. In addition, heaters can be equipped with a second circuit for heating water for household needs, providing hot water supply to a private house or apartment.

There is another division of heating units - into single-circuit and double-circuit. To understand which boiler is best to choose for heating your home, we suggest first familiarizing yourself with their strengths and weaknesses.

Operational safety

Despite the safety of a double-circuit gas turbo boiler, any equipment can fail, so if a gas smell appears in the room, the following precautions must be taken:

- Immediately open the windows and ventilate the room;

- Close the ball valve on the gas supply line;

- You should not turn on lights or electrical appliances in the room, or use mobile phones;

- Call the emergency gas service.

Piping of a turbocharged double-circuit gas boiler Baxi ECO Four.

Important! The design of a turbocharged boiler almost completely eliminates gas from entering the room, however, despite this, it is recommended to organize additional ventilation in the room where the boiler is installed. This applies to all gas-powered equipment.

Installation specifications for these boilers

Here, the installation depends on the type of boiler: wall-mounted or floor-mounted.

Installation of floor-standing versions is carried out in several stages. Before they are carried out, be sure to prepare the site on which you plan to install the boiler.

Next you need to install the pipes. They are necessary to eliminate the results of combustion. The bracket that will fix the boiler is being fastened.

Upon completion of the work, the boiler is fixed in its final position.

The installation of the wall-mounted version has some differences. Before installation work, holes are created in the wall. Coaxial pipes will be stretched through them. After which this gas modification is attached and connected to the wall. At the final stage, a coaxial outlet is arranged

It is important here not to fit into all the criteria specified in the documentation for the equipment.

Thus, a turbocharged boiler with two circuits running on gas is simply a must-have appliance in the house. It is especially necessary when heating failures often occur in the house, and hot water flows intermittently. The price of the presented boiler is impressive, but this does not stop many buyers. They understand perfectly well that such expenses pay off very quickly. The key point here is its installation. It is better to entrust it to professionals.

The price aspects of turbocharged models with two circuits largely depend on the brand of the product, equipment, technological specifics of the equipment, etc. Today, representatives of many brands are entering the market, some domestic, some foreign models. Nowadays, boilers from the Italian giants “Baksi” and “Ariston” are in special demand.

Models from Baksi

The Italian concern specializes in the production of wall modifications. They also operate on a piped principle and have two circuits (heating and heating). They implement innovative design ideas. The regulation of all work is entrusted to sensitive automation.

This manufacturer constantly modifies and develops the internal mechanism of this equipment. The reforms affected the control unit, heat exchanger, and burner.

Wall-mounted double-circuit turbo boilers "Baksi" are characterized by the presence of a wide range of functions and small physical parameters.

Example of the Baxi model:

Turbocharged gas boiler baxi

These units are easy to operate. The control is intuitive. The design specifications for baxi gas boilers are as follows:

- There are steel and copper heat exchangers. The first performs the function of rapid and efficient heating of the coolant in the heating network. The second one heats the water. This device uses a flow-through heating technique.

- Availability of an integrated storage boiler. As a rule, almost all variations with two circuits suffer from a very long period of water heating. The Baksi concern has installed the indicated boiler in its products. It joins the recycling network. It represents a buffer capacity. She quickly supplies hot water. Thus, from the moment you open the tap until the heated coolant enters the DHW network, only a few seconds pass.

- Suggested combustion departments for domestic wall-mounted versions: naturally aspirated and turbocharged. The former are also called open, the latter – closed. The differences here lie in the absorption and non-absorption of air from the rooms where the boiler is located. The former do this, the latter do not. The second, as expected, are connected to the coaxial chimney. Through it, the results of combustion are eliminated and air penetrates the burner.

The installation requirements for this boiler are minimal. Such a boiler is allowed to be installed in city apartments (in standard high-rise buildings).

Flaws

Among the disadvantages of turbocharged gas boilers are:

- use of electricity. Boiler controls and turbines depend on electricity;

- With regular power surges in the network, the automation may fail;

- there is condensation. Since the temperature of the exhaust gases does not exceed 120°C, condensation occurs in coaxial chimneys, which can block the channel if it freezes.

To solve the latter problem, the chimney is usually insulated and a condensate collector is installed.

The most popular manufacturers and their brief descriptions

The leading manufacturers of floor-standing single-circuit boilers are European companies, although domestic designs are optimal for Russian conditions.

The most famous companies are:

- Viessmann. A German company, one of the most famous and reliable companies producing thermal products;

- Protherm. A company from Slovakia that produces a wide range of heating boilers. ALL series are named after animals of different species;

- Buderus. “Daughter” of the world-famous concern Bosh, which fully characterizes the quality and reliability of the products;

- Vaillant. Another German company whose boilers are considered the highest quality and most reliable;

- Lemax. Russian manufacturer of energy-independent floor-standing gas boilers. When developing the project, all the features of working in difficult conditions were taken into account;

- Navien. Korean boilers that successfully combine high quality and affordable prices.

The list of manufacturers can be continued for a very long time. All currently operating companies care about the quality and reliability of their products, trying to surpass competitors and reach the maximum number of users.

Gas boilers for heating systems from ALFATEP

Choosing a gas boiler for the heating system of a house or apartment is a very important decision, and one of the best places for this is our online store, which offers a wide selection of atmospheric and turbocharged models from leading domestic and foreign manufacturers. Our specialists are ready to provide all the necessary advice and help you choose equipment, taking into account the features of the system, the area of the house, and installation options. You can also order from us work on the design of heating and hot water systems at home and installation of equipment, which is carried out by qualified craftsmen.

All clients of our online store can use the services of a transport service that will deliver the goods to the specified address at a convenient and pre-agreed time.

What to consider when choosing an installation

A gas boiler is a heating installation in which, when natural or liquefied gas is burned in a burner, the water circulating through the heat exchanger circuit is heated. Such devices are classified according to several criteria.

Single-circuit and double-circuit boilers differ in the number of circuits for coolant circulation. A single-circuit installation has one heat exchanger and is designed to heat the coolant for the heating system. If the power of the unit is sufficient, special outlets can be provided at the output, allowing parallel connection of a storage-type boiler for hot water. A double-circuit boiler contains two independent heat exchangers that allow water to be heated to different temperatures. They provide heating and hot water.

Depending on the installation method, the installations can be wall-mounted or floor-mounted. The wall-mounted boiler is lightweight and small in size, which allows it to be mounted on the wall, saving usable space in the room. The floor-standing unit has significant dimensions, which allows for a significant increase in power. It is mounted on the floor in a special room (boiler room). Medium-power units with universal installation are also available. They can be attached to the wall or floor.

Based on the design of the combustion chamber, installations with open and closed fireboxes are distinguished. When using an open chamber, a chimney with natural exhaust is installed. Complete removal of combustion products is ensured by a closed chamber equipped with a coaxial chimney.

Gas boilers can use standard (atmospheric) or modulating burners. In the first option, when the pressure changes, the combustion mode is changed by manually setting the regulator to a different position. Modulating burners are able to maintain constant operating conditions automatically.

Criterias of choice

The choice of a gas boiler for a home is made taking into account the following parameters:

- Power. It determines the heated area of the room. The following condition is taken into account: for every 10 m2 of area, a power of 1 kW is required (with a room height of no more than 2.9 m). For houses with poor insulation, high ceilings, and cold regions, a power reserve of 25-40% is taken. To connect a boiler to a single-circuit boiler, an additional 30% of power is required.

- Hot water capacity. It is important for dual-circuit installations, because determines the possibilities of hot water supply. For a family of 2-3 people, 5-6 l/min is sufficient; for a large family, more than 12-15 l/min is required. When connecting storage boilers, the volume of the tank is important.

- Efficiency determines the efficiency of gas consumption. In highly efficient and economical installations it exceeds 92%.

- Ignition principle. The simplicity and safety of starting the unit depends on the principle of igniting the gas in the burner. Ignition can be provided manually, electrically or using a piezoelectric element.

- Electricity demand. Gas boilers can be energy-dependent or non-volatile. In the first case, the design includes pumps, fans or other electrical devices, which makes the boiler dependent on the electrical network.

Equipment assessment is also carried out to ensure temperature conditions. In this direction, the following indicators are important:

Maximum heating temperature of the coolant (water). The heating system requires heating to 80-90 degrees. The hot water system does not require temperatures above 60 degrees. Inertia, i.e. duration of heating to the maximum temperature when starting up the equipment. It is considered normal if it lies within 0.5-2 hours

The time it takes to retain heat after stopping is also important. Setting and maintaining temperature. The temperature regime can be set by a mechanical or electronic control system

Regulation can be stepped or smooth. The mechanical type of adjustment is based on manual installation of the regulator taking into account the pressure. The electronic circuit ensures automatic maintenance of the mode within specified limits.

Complete guarantee of safety is considered the most important evaluation criterion. The best boiler has a multi-stage protection system, including automatic shutdown in emergency situations (interruption of gas supply, flame extinction, problems with the chimney, etc.), control of overheating and hypothermia.

How to choose a boiler?

When choosing a gas boiler, three main parameters are analyzed: all technical characteristics, a reliable and trusted manufacturer, and cost. Be sure to analyze the room in which the equipment will be installed. The first thing you should pay attention to is the power and functionality of the equipment.

Criteria for choosing wisely

Important characteristics:

- Performance. The calculation is made after analyzing the area of the room and possible heat loss.

- Number of serviced circuits. If space heating and hot water supply are required, choose a double-circuit boiler with a pair of heat exchangers. If DHW is not needed, then a single-circuit boiler is sufficient. The new double-circuit heating devices provide a “Winter/Summer” mode.

- The material from which the heat exchanger is made. Steel or cast iron is used for the primary circuit, and copper and aluminum for the secondary circuit. The service life, thermal conductivity and cost depend on the material.

- Automation. It is provided in a double-circuit turbocharged boiler. There are two types: standard and weather-dependent. New models have built-in remote control units. The model can be additionally equipped with remote notification. Gas consumption depends on the number of automation functions.

The best models of gas boilers are produced by German companies. Italian and French products are in second place in popularity. Russia also began to supply competitive boilers that are low cost.

The most reliable boilers are Baxi, as well as Vaillant Turbo TEC, Viessmann, Vaillant Atmo TEC. In second and third place are models from Neva Lux and Arderia. Korean products from Navien, Hydrosta, Daewoo and Kiturami have low reliability and build quality.

Installation requirements

The highest demands are placed on the installation of atmospheric boilers. Installation and connection are carried out only by representatives of the gas company, with which an agreement is concluded for further maintenance and technical inspection of the equipment. All connecting nodes must be made perfectly, extremely tightly.

You can install a turbocharged boiler yourself. But you need to take into account that the slightest violation will lead to a decrease in performance, and the manufacturer will refuse warranty service

Turbocharged models are not so demanding, but manual connection is also not particularly recommended. Especially if, due to the fault of an inexperienced contractor, water gets into the gas pipeline. There is an important condition - perfect removal of smoke exhaust ducts to the street.

Rating of TOP 5 wall-mounted single-circuit boilers

Among single-circuit wall-mounted boilers, the following models stand out:

Buderus Logamax U072-18

world famous concern Bosh. Experts note the high quality of the products, which is not inferior to the products of the parent company. The Buderus Logamax U072-18 boiler is a single-circuit unit with a power of 18 kW, which is suitable for heating a house of 160-180 sq. m. m.

The manufacturer warns that if the water hardness is more than 16°dGH, you will need to use softeners or special filters.

Boiler parameters:

- coolant temperature - 40-82°;

- pressure in the heating circuit (max) - 3 Bar;

- dimensions - 400/299/700 mm;

- weight - 32 kg.

The unit can be connected to an external indirect heating boiler, which will provide the home with hot water.

BAXI LUNA-3 1.310 Fi

The BAXI company is considered Italian, although the enterprises are scattered throughout Europe, and the head office is located in the Netherlands. The LUNA-3 1.310 Fi boiler is a convection unit with a power of 31 kW.

This is a solid device capable of heating a residential building or office with an area of up to 310 square meters. m. High efficiency (93.1%) ensures fuel savings and allows you to get maximum performance from the boiler.

Characteristics:

- coolant temperature - 30-85°;

- gas consumption - 3.52 m3/hour;

- pressure in the heating circuit (max) - 3 Bar;

- dimensions - 450x763x345 mm;

- weight - 40 kg.

According to the manufacturer, the service life of the boiler is at least 10 years with a 2-year warranty.

BAXI LUNA Platinum+ 1.32

Another representative of the Italian company is a condensing single-circuit boiler with a capacity of 34.8 kW. Its efficiency is 105.7%, which is nothing more than a clumsy marketing ploy.

A preheating stage has been added to the design of the unit, which allows reducing the intensity of the burner and saving fuel. However, the physical possibility of condensation with the release of heat is possible only under certain and rather narrow conditions, which are impossible in Russia.

Unit parameters:

- coolant temperature - 25-80°;

- gas consumption - 3.49 m3/hour;

- pressure in the heating circuit (max) - 3 Bar;

- dimensions - 450x760x345 mm;

- weight - 37.5 kg.

The price of the BAXI LUNA Platinum+ 1.32 condensing boiler averages 76-80 thousand rubles.

Considering the uselessness of an additional heating stage in most regions of Russia, the need for such a purchase should be carefully weighed.

MORA-TOP Meteor Plus PK24SK

A product from Czech manufacturers with a power of 23.7 kW. This is the optimal value for a room with an area of 220-240 square meters. m., which corresponds to the size of most cottages.

It is a single-circuit gas wall-mounted atmospheric type boiler. Requires connection to a common stove-type chimney.

Its characteristics:

- coolant temperature - 30-80°;

- gas consumption - 2.6 m3/hour;

- pressure in the heating circuit (max) - 3 Bar;

- dimensions - 400x750x380 mm;

- weight - 27.5 kg.

Users note the high performance and reliability of the unit, stability of operation.

Protherm Panther 25 KTO (2015)

The Protherm brand is the brainchild of the Vaillant Group, and was created specifically for the production of inexpensive, high-quality gas boilers. Initially, the products were aimed at the market of Russia and the CIS countries.

The Protherm Panther 25 KTO (2015) boiler has a power of 25 kW, which is suitable for heating 250 sq.m. It features low fuel consumption and stable, trouble-free operation.

Main characteristics:

- coolant temperature - 30-85°;

- gas consumption - 2.8 m3/hour;

- pressure in the heating circuit (max) - 3 Bar;

- dimensions - 440x800x338 mm;

- weight - 41 kg.

When connecting an external boiler, it becomes possible to provide the room with hot water, which makes the unit a fully functional device.

How to choose the right place to install atmospheric and turbocharged boilers

The location for installing the boiler is selected based on the following parameters.

- Floor or wall construction (floor structures are usually placed in separate technical rooms).

- Boiler power and weight (large models may require separate foundation preparation).

- For atmospheric models, the close location of the chimney is important; the finished structure can have a minimum bending angle to ensure sufficient draft.

- Turbocharged boilers require communications to vent a coaxial chimney to the outside.

| It is important to know! Due to the tightness of the combustion chamber, turbocharged boilers do not require installation in a separate room. |

Floor and wall types of equipment

The floor structure is distinguished by its high weight - up to 100 kg. Its installation requires a lot of space, and installation is labor-intensive, complex and expensive. Most floor-standing atmospheric boilers do not heat water to be supplied to mixers. During operation, the floor-standing unit makes a lot of noise, and the chimney requires regular cleaning.

Positive sides:

- high power;

- durability;

- lack of electronics.

Wall heaters are smaller in size and weight (up to 50 kg). Such boilers are predominantly double-circuit. The model is easier to install and does not take up much space. The boiler can be placed anywhere in the room. Wall-mounted atmospheric boilers are single-circuit and double-circuit.

Both floor-mounted and wall-mounted boilers are produced to serve one or two circuits. However, if space allows, it is better to take two: a floor-mounted single-circuit one for heating and a column for preparing hot water

Disadvantage: a wall-mounted boiler depends on electronics. If something burns out, you will lose hot water and heating. Boilers are installed mainly in small apartments and houses.

Differences in the operation of heating units

There are two types of devices for creating a heating system:

- Turbocharged.

- Atmospheric (chimney).

A turbocharged unit is characterized by the presence of a coaxial chimney. There are minimum requirements for ventilation; such devices are installed in multi-apartment buildings. Open type equipment requires a traditional chimney; this type of device is suitable for buildings with a minimum number of floors.

Equipment for space heating Source teplo-klimat.com.ua

An atmospheric boiler is an open type device; oxygen enters the working unit from the environment. Combustion and waste removal are carried out openly; to install this type of equipment, it is necessary to equip a full-fledged boiler room. The operating principle of the chimney unit burner is based on gas entering the system through nozzles. Combustion is supported by the supply of an air mixture, so it is important to ensure a constant supply of oxygen and install a powerful ventilation system. Heating water results in minimal fuel costs.

Wall-mounted gas boiler Source ignis-pro-kotly.ru

Wall-mounted closed-type equipment is equipped with a copper combustion chamber, its power is limited to 35 kW. Equipment that is installed on the floor surface has greater power, as it is equipped with cast iron chambers. This material is durable, but due to temperature differences it can crack at the water entry point and in the heating zone. Corrosion can be prevented by installing a four-way valve. Stainless steel installations are durable, resistant to thermal shock, and are characterized by increased corrosion resistance, but are expensive.

Operating principles of chimney devices

During operation of the atmospheric heating unit, the burner heats the heat exchanger, and water or other coolant is heated. Before entering the nozzles, the gas combines with air, which ensures combustion.

Fuel economy is determined by the complexity of the heating equipment design. Some boilers run on diesel fuel.

The burners are equipped with carbon dioxide and flame level sensors. If there is a lack of draft, the flame will go out, which will lead to gas entering the room. This mechanism of action is possible in homemade heaters.

Advantages of atmospheric units:

- Energy independence. Most of these models are used during power outages.

- Affordable price.

- There are autonomous models; they can function without electricity.

- Traction sensors ensure safe operation.

- A chimney with a slight bend angle is placed next to the atmospheric units, this will provide the necessary draft.

Working burner of a gas boiler Source engelys.myguru.ru

Traditional removal of gases using natural draft is typical for many types of units. The difference between the pressure of the air and gas mixture promotes the flow of air, which leads to the displacement of heated flue gases and combustion of fuel. Thrust is formed; the higher the difference between pressure indicators, the stronger the thrust.