Recommendations and safety precautions

Before you start creating a homemade unit, you need to make sure you have the necessary tools and evaluate your skills in using them. For example, if a person has never done welding, it will be difficult for him to assemble a structure with his own hands. In this case, it is better to purchase the device in a store. After all, its individual parts can be joined together only thanks to a welding machine.

Below are a few important things to know:

- It is prohibited to connect the device to the main line yourself without the knowledge of the gas service.

- Permission can be obtained by calling specialists to your home or delivering the assembled unit to their office.

- If installed without permission, gas may leak, which will lead to fire and even explosion.

- Welding work is performed only in special clothing, gloves and a mask.

- Each item must be purchased only in a special store and have a passport.

- The creation of the device must be carried out in accordance with the drawing.

Installation rules for a condensing type boiler and constant installation errors

Installation of a condensing type boiler should be carried out taking into account the following rules and requirements:

- it is better to select a well-ventilated room for installing the boiler that meets all the necessary fire safety needs: ceiling height of at least 2.2 m, room volume - from 7.5 m 3, ventilation window area 0.025 m 2;

- the placement of the boiler must be vertical;

- before mounting, the main thing is to outline the location for installation in order to provide the necessary communications in advance and weigh the installation steps;

- the boiler must be mounted on a specialized frame, which is included in the delivery set (exclusively for the highest class of equipment), or on a mounting rail;

- the chimney must be made of heat-resistant plastic or corrosion-resistant steel;

- the horizontal part of the chimney from the boiler should go with a slight slope towards the room;

- Condensate drainage can be organized in the following ways: into a centralized sewerage system or into a separate container for further disposal.

Connecting a condensing type boiler without the skills to carry out similar work can lead to the following errors:

- The condensate is drained outside the heated space. In the cold season, this can be dangerous due to the formation of an ice plug in the tube, which will increase the likelihood of boiler failure.

- The condensate is drained into a container not intended for this purpose or is completely unorganized. This is considered a big mistake, since the condensate contains toxic or caustic substances that require specialized disposal.

- The design touches the heated part with flammable or combustible substances, which leads to a violation of fire safety rules.

- The gas connection was made without the use of specialized sealing pads, and gas filters were not installed. The results may be as follows: a gas leak or a dirty burner in the middle of the firebox based on this. Working with such errors is prohibited, as the level of explosion hazard in the room increases.

- The inclined angle of the boiler, which is specified in the installation requirements by the manufacturer, is not observed. This will lead to disruption of condensation and circulation modes and may cause very high gas consumption or a decrease in heating power.

- Installation of a gas meter that does not meet the power properties of the boiler. In these cases, either the gas flow will be insufficient, or the meter itself will break down with the possibility of leaks.

Calculations and creation of drawings

Before you create a device, you need to find or make your own drawings. They should contain information about what the future unit is, how to connect it, cool it, how the chimney and deflector are installed.

When making a device, you need to take into account how much heat is lost in each room where the battery will be located. Its quantity differs even for rooms in which the footage is the same. Calculations are carried out with a reserve. Add 10% for dimensions. 10 m² requires 1 kW of energy.

Gas emits 6.55 kW. You need to divide your daily energy consumption by this value. This gives the required volume of the boiler. A self-made tank holds the amount of liquid needed to heat a house.

Condensation Formation

The resulting condensate is no longer pure H20, but is a mixture of various inorganic acids with a relatively low concentration. However, due to the constant increase in the temperature of internal components, it is classified as an aggressive composition. To prevent the development of deformation due to exposure to condensates, boiler structures are made from acid-resistant materials. They can be used as:

- stainless steel;

- simulin (aluminum-silicon alloy).

In most cases, heat exchangers have a cast construction, and manufacturers refuse welded seams. This is due to their vulnerability to corrosive damage.

Steam condensation should only occur in the secondary heat exchanger. If it goes further into the chimney, it will reduce the thermal potential of the installation and also negatively affect the pipe material. Because of this, it is also common to use stainless steel or plastic for the production of chimneys, and individual horizontal units are placed at a slight angle so that the condensate drains back into the boiler and does not come out. It is important to understand that the gases that leave the condenser are cooled to incredibly low temperatures, and everything that has not condensed in the boiler will begin to condense directly in the chimney.

At different times of the year and day, a certain amount of heat is required from the boiler installation, which is regulated by the burner. This element can be either modulated, supporting a smooth change in power, or unmodeled, in which the power indicators are fixed in a certain range. The latter option involves adjusting the burner switching frequency based on the owner’s preferences. However, modern residential boilers use simulated burners.

Having obtained a general understanding of air-conditioned heating boilers, the principle of their operation, as well as the types of burners, you can take a more serious approach to the issue of purchasing a system and subsequent installation. But in most cases, the basic information is not enough to make sure that the upcoming choice will be worth it. Therefore, many people want to study in detail the main advantages and disadvantages of condensing boilers.

What you will need

When a project is selected, it is necessary to calculate how much material is required. If the instructions suggest that you need cast iron, do not buy cheaper aluminum, otherwise the device will quickly fail. It is better to purchase a thermostat and deflector ready-made than to make it yourself.

It is important to consider several points when making the device:

- It is advisable to choose a programmable thermostat, so you can set a controlled temperature.

- It is better to install the deflector above the chimney pipe, thereby ensuring exhaust. It may look like an umbrella with a cone. The material is only stainless steel.

- The device must have automation, which includes control over flame, overheating, and draft. The presence of a blast valve is also important.

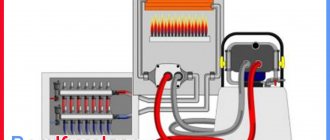

Basic diagrams and how water heating works in a garage

This heating system is simple and reliable and provides good efficiency. The principle of operation will be approximately as follows. A boiler running on different types of fuel heats a water tank. Through a closed system of pipes and storage tanks, hot water circulates inside the system, giving off heat outside. At the last stage, the already somewhat cooled water returns to the boiler, where it is reheated. Correct pipe routing and selection of the necessary boiler parameters are the main points in creating such a system.

Important details:

The system definitely needs a small circulation pump, which will ensure the flow of water. Partially this purpose will be served by a slight slope in the pipe routing, but equipping it with a pump will be much more efficient. The choice of material for the system also determines its effectiveness. Traditional metal pipes and radiators have been replaced by modern analogues. They heat up much faster, but also cool down quickly. Heating of the metal occurs much more slowly, but the heat transfer will take a long time. If the garage is attached to a residential building, it will be easier and cheaper to connect it to an existing heating system. To save money, you can use fewer radiators, but this option will be the most optimal. A nearby building can also be heated by diverting pipes from the house, but in this case it is necessary to carefully insulate the external environment to avoid the risk of the system freezing. The location of radiators has its own laws. This should be a minimum distance to the floor - 15 cm, and also 2 - 4 cm from the walls. To eliminate the possibility of freezing of an unused system in severe frost, the water in the pipes can be replaced with a special antifreeze. Water heating in a garage will be a waste of time and money if you do not provide adequate insulation of the structure

Particular attention must be paid to high-quality floor screed, from which heat loss most often occurs. The garage must also be equipped with working ventilation. The principle of serial connection of consumers is most often used. This is much easier to do yourself, but does not “work” as efficiently as parallel piping. You can make an expansion tank yourself

A fairly large metal or plastic container is suitable for this. If necessary, this will help to easily add water to the system and avoid overheating of the boiler.

This is much easier to do yourself, but does not “work” as efficiently as parallel piping. You can make an expansion tank yourself. A fairly large metal or plastic container is suitable for this. If necessary, this will help to easily add water to the system and avoid overheating of the boiler.

Schemes of a water heating system for a garage are varied and are easy to find freely available on the Internet. Further installation, as well as the list of necessary tools, will depend on the type of materials used. Before installation, it is also necessary to analyze additional energy costs, which increase in proportion to the size of the garage. For a car, this issue is not fundamental, because sufficiently dry and ventilated air will help avoid body corrosion. The question of heating the room is relevant when performing long-term work or if the garage is combined with a workshop or other outbuildings.

Here are some of the most classic examples, and an example with heated floors.

———————————————————————————————————-

———————————————————————————————————-

Instructions for making a homemade boiler from scratch

It is better to choose a floor-standing model that can be placed in the garage, in the boiler room, or on the street. The base on which the device is installed must be specially prepared. You need to dig a hole 80 cm deep. Its width is equal to the size of the unit. A pillow should be installed at the bottom of the pit. After this, crushed stone is poured.

The frame is formed from reinforcement and formwork is made. The latter needs to be filled with concrete. After a day, it is removed, and sand and gravel mixed together are poured in its place. Now tar is placed to insulate moisture. A brick wall is formed to protect the building from the heat of the boiler. Then you can start assembling it.

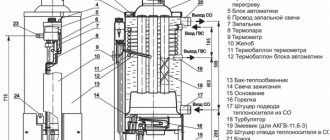

The unit should be cooked using the drawing. The heat exchanger is made of steel. To do this, you need to use a pipe 40-50 cm in diameter. The tank must have appropriate openings at the top and bottom. The end of the pipeline should be sealed with a fitting. When the device starts working, the burner will heat the copper spiral, which transfers heat to the container, and from it to the water. The deflector is installed above the chimney - this is an exhaust hood.

The automation is assembled from control units for flame, overheating, draft, and safety valve. Otherwise, the device will not work correctly.

After completing the base, the unit is installed on it. At this stage you need to weld the chimney to it. This is an iron pipe that removes carbon monoxide. Its diameter should be at least 20 cm. It rises 30 cm above the roof. In order for carbon monoxide to escape faster, you need to make an exhaust hood using a grille and a fan. These elements are installed inside the pipeline.

If there is a possibility of a power outage, you should consider installing an uninterruptible power supply. It can also protect the device from power surges. You can buy a ready-made block or assemble it yourself.

Operational Features

Certain important little details about the operation of condensing boilers:

- it is not allowed to reduce the burner power below 10% of the total power, since due to continuous switching on and off, it will break down much earlier than the design period;

- increasing the heating temperature at the boiler outlet above +50 0 C is not recommended, since gas consumption will significantly increase;

- The condensate can be drained into the sewer under dilution conditions in a ratio of 10:1, and also into a settling well if it is neutralized.

Connection and placement

Before connecting the finished device to the gas pipeline, you need to obtain permission from the relevant organization. After this, 2 American taps are purchased, which are installed on the forward and reverse pipelines. Such shut-off valves will help dismantle the unit if an emergency occurs.

A filter must be installed on the pipe through which the coolant will move back to the boiler. It will protect the device from mechanical debris. It is necessary to install shut-off valves on the gas pipeline. It looks like a faucet and acts as a filter.

Now all that remains is to connect the gas pipe through which the fuel will move. Each joint and connection point of elements must be sealed. The boiler must be connected to a water supply with cold water, as well as hot if it is a double-circuit one.

Place the device in a specially prepared place, on a pillow. The installation location can be a garage, boiler room or street.

Rating of condensing boilers

The rating of condensing-type boilers is distinguished by manufacturers and models, depending on the type of construction: wall-mounted or floor-mounted.

The most common wall-mounted types of boilers:

- De Dietrich PMC-M 24/28 MI Plus is a double-circuit mounted boiler with cast, alloyed aluminum, a heat exchanger and a plate heat exchanger for connecting to a hot water supply, as well as an 8-liter expansion tank. Heating power is 6.1-24 kW, the largest heating area is 248 m 2, the weight of the structure is 29 kg.

- Ariston Genus Premium Evo 30 is an elite-class double-circuit boiler, equipped with radial and plate heat exchangers and weather-dependent automation. Designed for a power of 3.3-30 kW and a room area of up to 311 m2, the weight of the structure is 35 kg.

- Viessmann Vitodens 100-W is a double-circuit boiler with a very technological Inox Radial heat exchanger and a secondary plate type for DHW, modulated by a Matrix burner in the range from 20% to 100%. Power range - 11-35 kW, calculated for an area of up to 350 m 2, weight 44 kg.

Boiler

condensing type Viessmann Vitodens 100-W

Rating of common floor boilers:

- Vaillant ecoVIT VKK INT 366 is a single-circuit boiler with a power of 34 kW, which is designed for heating rooms up to 340 m2. Equipped with a digital control system DIA-System, electronic ignition and modulating burner. Designed for heating and hot water production.

- Viessmann Vitogas 100-F GS1D870 is a single-circuit boiler equipped with an open firebox, a reliable and durable ignition system with pre-mixing, and precise automation. Calculated for a power of 29 kW and a heated area of 300 m2.

- Buderus Logano G234 WS-38 is a single-circuit boiler with a power of 38 kW, which is designed for heating rooms up to 380 m2. The design is thermally insulated, supports the connection of additional automation, is durable and reliable in operation. Designed for heating and water heating for domestic hot water supply.

Installing condensing-type boilers in modern heating systems is considered quite cost-effective, even without paying attention to their high price. They are not dangerous in operation, undemanding in maintenance, maintainable, productive and universal in use. are considered an excellent alternative to direct combustion boilers due to their high efficiency and economical gas consumption.

How to increase efficiency

Under no circumstances should safety precautions be neglected. If you decide to save on something, you can lose much more. For example, you should not connect a gas pipe to the basement or ground floor.

You shouldn’t skimp on automation either. Otherwise, the system may overheat, causing a rupture in the pipeline. Lack of water circulation can lead to an accident. Therefore, automation must provide control over the operation of the pump, filter, and thermostat.

You can save on the coolant supplied to the batteries without losing temperature. To do this, you need to insulate the walls and windows by sealing the cracks. Savings are calculated at the assembly stage, and not when the device is ready for use, because after the last soldering nothing can be changed.

Types of heat exchangers

Boiler operation diagram

They come in 3 types:

- Steel structure - used in economy class boilers.

- Stainless steel products are widely used in wall-mounted applications.

- Cast iron heat exchangers are the most reliable models that are mounted in a floor-mounted version.

Steel heat exchange systems are inferior to others in terms of technical characteristics, but are significantly cheaper. Cast iron boilers and stainless steel design options are approximately equal in power.

A cast iron boiler has a high heat capacity due to its impressive mass and wall thickness. Stainless steel heat exchangers are more modern high-tech products. But a boiler for heating a private home, made of cast iron, can reliably serve much longer than other devices.

Therefore, when installing a gas heating system, it is preferable to choose cast iron units. One of the main advantages of such equipment is its practicality, reliability and durability. It is quite possible that in the future you may simply not need to repair such a boiler, and occasionally you will only need to carry out its maintenance.

Other options

There are two more options for homemade boilers, when the units are obtained by remaking a gas water heater or stove. This can significantly save on installation costs.

Based on a gas water heater

The alteration involves replacing the nozzle or block responsible for gas combustion if a liquefied mixture is used. You will need to purchase an atmospheric burner that fits the combustion chamber. The ignition is mounted inside it.

To connect a fan burner, you will need to purchase an additional heating circuit. It consists of a security system unit, an expansion tank and pump, an air vent and a Mayevsky valve. This type of burner is more expensive, since it will also require a pressure gauge, an automatic air bleeder and a coaxial chimney.

Conversion from a gas stove

It is almost impossible to make such a boiler. There is only one available way: install a metal container with coolant on the burner, which will heat up and then move through the pipes to the batteries. The volume of the tank depends entirely on the power of the stove. It does not exceed 100-150 liters.

The return pipe is welded from below, and the direct supply is connected from above. Hot water rises and moves to the radiators. The cold liquid returns through the lower pipe.

Such a homemade device does not require a safety valve and an air vent, since excess water in the form of steam bubbles will escape through a loosely closed tank lid.

You can install a gas boiler yourself. You just need to follow the exact instructions and remember safety precautions. Before connecting, you must remember to obtain permission from Gorgaz.

Types of condensing boilers

Condensing boilers are classified according to the following parameters:

- according to installation option: floor or wall;

- by number of circuits: single- or double-circuit.

Floor-standing condensing boilers are not only large in size, but are also usually equipped with remote pumps and other equipment that require a separate room for installation. In most cases, they are single-circuit and are intended for heating large areas. Their good qualities are the possibility of repair and structural simplicity.

Condensing wall-mounted boilers differ from floor-mounted ones due to their compact size and relatively low weight. All components and assemblies are located in the middle of the case; there are no remote components. Available in single- and double-circuit versions, they are easy to connect and undemanding to operate.

Boiler

condensing type single-circuit floor-standing

Single-circuit heating boilers for heating rooms are used not only in heating systems, but also for systems with hot water supply, provided there is a storage water heater. They are distinguished by their design simplicity, affordable price, in comparison with a double-circuit, high efficiency and heating power, and economical fuel consumption.

A double-circuit gas condensing

boiler Can be used for heating or heating water without the need to purchase a separate storage water heater. Small, easy to install and maintain, installation is done on the floor or wall.

Insulation of the house

The degree of insulation of a house or apartment is of significant importance in saving gas. If the building is not insulated, and the doors and windows are ventilated, a significant part of the heat will go outside. The material of the walls of the house also matters. For example, wood and block transmit heat faster than double brickwork.

Good insulation of the ceiling, floor and walls will save a lot of fuel. It is advisable to replace old frames with energy-efficient double-glazed windows, and wooden doors with a more airtight modern analogue. A well-insulated building will save up to 30% on gas.

Particular attention should be paid to insulating the attic and basement, since a lot of heat also escapes through them.

Note! To increase the energy efficiency of your home, you can install reflective screens made of aluminum foil between the radiator and the wall; they will allow you to return some of the heat to the room.

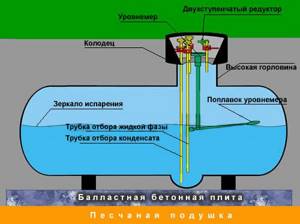

Gas holder for propane heating

It is a sealed container of large volume with a system for receiving and transmitting propane. The gas holder can be installed on the surface or underground. In the latter case, only the service hatch cover will be visible. This design will provide a large volume of gas for heating not only the propane garage, but the entire house.

To install it, the following conditions must be met:

- The minimum distance from the gas tank to the foundation of the house is 10 m;

- The external pipeline must have safety elements, and it is necessary to use special pipes for gas transportation;

- When planning to heat a house with propane using a gas holder, access paths to it are provided for a refueling vehicle;

- Filling the container yourself is prohibited. To do this, you need to use the services of a specialized company.

The advantages of using a gas tank include a long service life of structures. It is also recommended to select a container of such a volume that refilling is carried out once every 2-3 years. Compared to cylinder heating, which method of storing propane is more expensive - this is due to the initially high cost of the equipment and the cost of its maintenance. To reduce them, two or three houses can be connected to one gas holder.