Chimneys for boilers and geysers

Modern chimneys - types and differences How to place Connection - existing limitations

If you have a water heater or gas boiler in your private home, you are fully responsible for the use of the heat-generating device. Gas service employees place strict demands on gas equipment being put into operation. If you do not comply with these requirements, you will not be able to obtain permission to connect your equipment to gas. Let's consider the rules for installing chimneys of gas boilers and water heaters on our own.

Modern chimneys - types and differences

You should choose the size, determine the diameter and design of the chimney, taking into account the type of heating equipment chosen. A heat-generating gas appliance always has high efficiency. In this regard, combustion products moving through the smoke removal system are distinguished by a relatively low temperature - usually it does not exceed more than 200 degrees. Celsius.

Chimneys for gas boilers can be:

— Single-circuit stainless steel. Advantages: ease of installation and low price. The chimney is laid using cylindrical single-circuit pipes. Such structures can only be installed from the inside;

-Stainless steel sandwiches. The use of sandwich systems is also not prohibited by gas workers. In this case, each pipe will have several layers of steel and a layer of insulation. The solution is suitable for both external and internal installation schemes;

— Flexible made of stainless steel. They resort to the use of metal corrugated pipes, which have a high level of flexibility. It is possible to install a chimney of complex configuration;

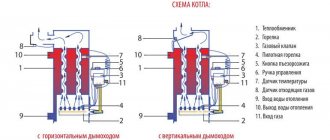

- Coaxial. Installing a coaxial chimney is the most modern and safe method of removing combustion products. The design consists of two tubes inserted into each other. Smoke is discharged outside along the internal circuit. Air is forced into the firebox through an external circuit.

Important! Before purchasing a chimney, you should read its instructions. It is here that the operating temperature withstood by the pipe, the optimal diameter, and the requirements for the materials of the system channel are indicated.

The safe operation of gas heating equipment depends on how well the smoke exhaust duct is installed. Laying pipes and connecting the system should be done by professionals! Their recommendations are as follows:

— Smoke exhaust ducts should be laid inside the system. Use the internal main walls of the structure;

— The size of the boiler inlet pipe must be equal to the diameter of the chimney pipe. Avoid using products with smaller/larger diameters. Otherwise, maximum sealing of the elements is impossible;

— A minimum of 5 centimeters must remain between the non-combustible wall finishing and the outer wall of the pipe. If there is no fire protection on the wall, the distance increases 5 times. Sheet metal or asbestos can be used to protect walls;

— The section of pipe where the connection is made to gas heating equipment must have a vertical orientation in space. The vertical segment of the chimney should not be shorter than 0.5 meters;

— Install the structure strictly vertically. Moreover, proper installation allows for a slope of up to 30 centimeters. When laying, you can create no more than three turns of the structure. The total length of horizontal turns should not be more than one meter;

- 5 meters minimum - an indicator of the total length of a gas-powered chimney. It should rise above the roof level by at least half a meter;

— The presence of an element with windows for inspection is a prerequisite. In addition, the design must have a condensate collector, as well as a tee. If any of these elements are missing, installation is prohibited.

Important! In order for the chimney to function effectively, the connections of the pipe segments must be as tight as possible. When installing the system, you should use heat-resistant sealant and steel clamps.

Poisoning people with carbon monoxide, gas explosions, fires in residential buildings and cottages - all these are the consequences of incorrectly installed chimneys. When installing equipment in an apartment building, neglecting safety standards is strictly prohibited. Remember that not only you, but also your neighbors can suffer.

— Connecting more than 2 gas-powered appliances to one chimney system. When installing a common chimney for several boilers, installation should be carried out at different levels. 1 meter is the minimum distance between equipment entry points;

— When installing a smoke exhaust duct, it is prohibited to use porous materials, such as cinder blocks. The optimal solution would be to choose a chimney pipe made of stainless steel that is not afraid of high temperatures;

— The chimney should be laid in a separate room (boiler room); installing a gas chimney in living rooms is prohibited. If a coaxial pipe is installed, leading through the wall to the street, there is no need for a boiler room;

- The chimney pipe of a gas appliance should not be led into a living room, into a poorly ventilated room, into an entrance or corridor, into a glazed loggia or a common area;

— Chimney pipes that do not have thermal insulation cannot be installed externally. You can protect the structure from low temperatures in winter by wrapping it with non-flammable insulating materials. A brick mine can also help.

xn--31-6kclv.xn--p1ai

Features of installing a chimney in an apartment and private house

The installation of a smoke exhaust duct in an apartment is directly related to the presence of a stationary duct for smoke removal. As a rule, such ducts run through the walls and form the ventilation system of a multi-story building. Installation of a heating system in an apartment requires a chimney supply from a gas water heater to such a channel. In the absence of stationary ventilation, it is recommended to install coaxial smoke exhaust.

There are other nuances of installing chimneys for a gas water heater in an apartment that are worth paying attention to:

- the communication design, which is necessary to remove combustion products, must comply with SNiP standards. The chimney should not have narrowings or be pinched, as this may cause smoke in residential premises ;

- smoke exhaust pipes must have a smooth inner surface that facilitates throughput;

- As a rule, the installation of a chimney in an apartment is carried out in a vertical plane;

- the permissible number of bends in vertical communications is no more than 3;

- the channel must be well sealed.

It is not recommended to use aluminum corrugated pipes for indoor installation of chimneys. This is due to the fact that such pipes fail very quickly (burn out). The most suitable option for an apartment is considered to be galvanized steel communications.

Installing a chimney in a private house is a more complex undertaking. First of all, it should be noted that exactly when this communication will be installed plays a big role. If the installation of a smoke exhaust duct will be carried out during the construction phase of the building, it is recommended to arrange a brick shaft in a vertical plane and place a galvanized steel pipe inside it.

Important! The heating system and the gas water heater must have different shafts to remove combustion products.

If a private house has already been built, a galvanized pipe for a geyser equipped with the necessary thermal insulation is best suited. There are two options for installing a smoke exhaust duct in a private house:

The chimney must be mounted so that, if necessary, it can be easily reached. And the end of the chimney structure must be located above the roof at a distance of at least 0.5 m. The main thing to remember is compliance with building codes and regulations when installing a chimney structure - the main requirement, following which you can avoid many troubles in the future.

Devices and requirements for a chimney for a gas boiler or water heater

The chimney, rising above residential buildings, is the only visible element of a complex smoke removal system responsible for removing combustion products from the firebox. The presence of a gas boiler or water heater in a private home places increased responsibility on the owners for the safety of using heat-generating devices. The gas service imposes strict requirements on gas equipment being put into operation, without which owners cannot obtain permission to connect. In this article we will figure out how to properly install a chimney for a gas boiler or water heater, and how to do the installation yourself.

Types of chimneys

The design, diameter and dimensions of the chimney pipe depend on the type of heating equipment used. Heat-generating devices operating on gas have a high efficiency, so the combustion products of “blue” fuel moving through the smoke exhaust duct have a relatively low temperature, not exceeding 200 degrees. The chimney for a gas boiler is selected from the following options:

- Single-circuit stainless steel. This is the simplest method of smoke removal and has the lowest cost. To lay the chimney, single-circuit cylindrical pipes are used. Only internal installation of such structures is allowed, since when placed externally the pipe freezes in winter. Single-circuit stainless steel pipes

- Sandwich chimney made of stainless steel. The requirements of the gas service allow the use of sandwich systems, the design of which differs from a single-circuit one in that each pipe consists of 2 layers of steel and 1 layer of insulating material between them. This option is suitable if an external or internal installation scheme is used. Sandwich pipe installation diagram

- Flexible chimney made of stainless steel. The design of a flexible chimney is different in that it uses special corrugated metal pipes. They are highly flexible, making installation and installation of a smoke exhaust duct of complex configurations easy. Flexible chimney for geyser

- Coaxial chimney. A more modern and technologically advanced way to get rid of combustion products is a coaxial chimney. When installing this equipment, all safety requirements are observed. A device of this type consists of two tubes inserted into one another; smoke is discharged into the atmosphere along the internal circuit, and air is forced into the firebox along the external circuit. Scheme of operation of a coaxial chimney

Note! Information about which chimney for a gas water heater or boiler of your model is best suited is contained in the instructions for the device. It contains requirements for the material of the smoke exhaust duct, the recommended diameter and operating temperature that the pipe must withstand.

Recommendations for placement

An important part of installing gas equipment is installing a smoke exhaust duct. The safety of those living in the house depends on this element of the heating system. Therefore, pipe laying and connection are entrusted to professional craftsmen who know better where and how to place chimneys for boilers in the house in order to comply with the requirements of the gas service. They recommend adhering to the following recommendations:

- For laying smoke exhaust channels for gas heating equipment, an internal layout is better suited. Pipes should be placed along the internal main walls of the structure.

- The diameter of the chimney pipe must correspond to the size of the boiler inlet pipe. You cannot use products whose diameter is larger or smaller to maintain maximum sealing between the elements.

- The section of the chimney where the connection to the gas heating appliance is made must have a vertical orientation in space. The length of the vertical segment must be at least 0.5 m. Rules for installing a chimney for gas equipment

- The distance between the outer wall of the pipe and the non-combustible wall finishing material must be at least 5 cm, but if the surface is not protected from fire - at least 25 cm. Craftsmen recommend protecting the sections of the walls where the chimney for a gas boiler passes with screens made of sheet metal or asbestos.

- It is better to install the chimney strictly vertically, although during installation a slope of up to 30 cm is allowed. When laying, you can make no more than 3 turns of the pipe, the total length of the horizontal sections of which does not exceed 1 m.

- The total length of the gas chimney must be at least 5 m, rising 0.5-1 m above the roof ridge.

- The chimney must include elements with inspection windows, a tee and a condensate collector. Installation is prohibited if any of these parts are missing. The correct scheme for attaching the pipe to the wall

Important! The main condition for the effective functioning of the chimney is the tightness of the connections between the pipe segments. They are connected to each other using pipe-to-pipe fastening. However, when performing installation, it is better to coat the seams with a heat-resistant sealant that can withstand temperatures up to 1000 degrees, and also secure the joints with steel clamps.

Connection restrictions

An improperly installed chimney causes fires in residential buildings, gas explosions and carbon monoxide poisoning. If installation is carried out in an apartment building, then neglecting safety requirements endangers not only the owners of one apartment, but also their neighbors. To avoid problems when operating gas equipment, it is prohibited:

- Connect more than 2 gas appliances to one chimney. If a common chimney is being installed for 2 boilers, then the connection is made at different levels, the distance between the equipment entry points must be at least 1 m.

- It is not allowed to use porous materials, including cinder blocks, to construct a smoke exhaust duct. The best option is a chimney pipe made of heat-resistant stainless steel. Requirements for the height of the pipe relative to the ridge

- For laying the chimney, a separate room called a boiler room is equipped. Since installation of a gas chimney in residential premises is not allowed. When installing a coaxial pipe leading outside through a wall, a separate room for installing the boiler is not required.

- The chimney pipe of gas appliances must not be routed into residential premises, into poorly ventilated rooms, into glazed loggias, corridors, entrances, or common areas.

- External installation of chimney pipes without thermal insulation is not allowed. To protect against low temperatures in winter, the chimney is wrapped with non-flammable insulation or a brick shaft is constructed. Standards for placing a coaxial chimney

Note! Protective umbrellas, deflectors and other devices are not placed on the head of the gas boiler pipe, as they only interfere, reducing the level of draft in the chimney.

Examples of correct and incorrect ways to connect a chimney pipe

Video instruction

krovlyakrishi.ru

In what cases is it necessary to install two boilers?

The decision to install a second boiler most often arises in cases where the base boiler cannot independently carry the entire heat load of the in-house heating system. This scheme will eliminate the problem of power shortages in boiler equipment.

However, there are other reasons for connecting two boilers into one heating system to ensure sanitary temperature in the room:

- Incorrect preliminary calculation of the thermal power of heating installations.

- Increased heated area of the house.

- The need to increase the functionality of the heat supply source, for example, installing a hot water supply system or heating air in heating units.

- Increasing the period of autonomous operation of a heating source when using different types of energy carriers, for example, solid fuel during the day and electricity according to diftariff metering at night.

- The lack of reserves of the main fuel allows the use of two boiler units operating on different types of fuel.

Requirements for chimneys for gas boilers and water heaters

Requirements for chimneys for gas boilers and water heaters are rarely observed by developers or are completely ignored.

This happens for the reason that few people study the standards before starting installation and do all the work themselves, without the involvement of specialists.

Now I will tell you the basic requirements for chimneys for gas boilers and water heaters:

- they must comply with building codes; — each device must have its own channel. But there is an exception here. It is allowed to connect two devices into one channel but at a distance of 750 mm or more; - the chimney must be sealed to prevent carbon monoxide from leaking into the house. So, for example, a brick chimney cannot guarantee 100% tightness; - resistance to condensation. Due to the low temperature of the exhaust gases, the steam contained in it does not evaporate and condenses on the walls of the chimney. This can cause destruction of the walls and, as a result, leakage of carbon monoxide; — do not reduce the draft in the channel. A round chimney is considered ideal. There should be no roughness or irregularities in it that interfere with traction; - size matters. If the outlet on the boiler, for example, has a diameter of 150 mm, then the chimney should be 150 mm and in no case less; — the chimney must be warm. By insulating the chimney you thereby reduce the formation of condensation;

- must be vertical, go straight into the sky without any coverings or canopies. Deviation from the vertical is allowed by 1 m and up to 30°.

prostostroy.com

Installation procedure

Installation of an exhaust pipe for a geyser made of any material begins with taking measurements and preparing all the necessary elements. In the case of corrugation, the work procedure is very simple. It is enough to take a pipeline of the required length, put it on the smoke exhaust pipe of the water heater and clamp it with a clamp. The free end is inserted into a decorative ring and fixed in the opening of the smoke channel. The main thing here is to ensure that the diameter of the corrugated pipe matches the size of the outlet hole of the column.

For all other materials, you need to prepare the required number of straight and rotary elements that will be inserted into each other, forming the desired chimney configuration according to the principle of a designer. Rotation angles are standard or made individually for specific sizes.

During assembly, ensure maximum tightness of connections. The entry of one element into another must be at least half the diameter. For better sealing, heat-resistant sealant is used. The joints are fastened with clamps and are located outside the ceilings and are freely accessible.

Due to the limitation on the number of permissible turns, the number of possible chimney configurations is quite limited. There are three main options depending on the location of the exhaust vent. Two more can be obtained by mirroring the previous ones.

All requirements and recommendations stated above apply to devices with an open combustion chamber. The standards also allow the removal of combustion products through an external wall without a vertical smoke duct from geysers with a closed combustion chamber and forced release of exhaust gases. In this case, installation is carried out according to the manufacturer's instructions in compliance with the standard distances and lengths of the coaxial chimney specified in SP 42-101-2003.

Exhaust pipe for a geyser - features of choice

One of the most common devices that can provide uninterrupted hot water supply to a home is a gas water heater. It does an excellent job of heating any volume of water in the shortest possible time. At the same time, modern modifications allow you to clearly set the required temperature and automatically turn on and off in accordance with the operating mode of the water point.

Gas-powered instantaneous water heaters are quite economical and safe to use. The only inconvenience is the need to organize high-quality removal of combustion products. This problem can be solved once and for all only with the help of proper installation of an exhaust pipe for a geyser. When choosing the parameters and configuration of the smoke exhaust system, you must be guided by the manufacturer’s instructions and current regulatory documents.

Regulatory requirements

According to the table of definitions NPB 252-98, the exhaust pipe for a gas water heater is the connecting pipe for the smoke exhaust pipe of the device and the smoke duct. Accordingly, it transports gas combustion products and must meet the requirements for chimneys. Failure to comply with them can lead to gas pollution in the room and carbon monoxide poisoning.

All requirements for chimneys are set out in the following regulatory documents:

- NPB 252–98;

- Rules for the production of pipe and furnace works VDPO;

- SP 42-101-2003, Appendix G

- SP 60.13330.2012, which is an updated version of SNiP 41-01-2003 (replacing SNiP 2.04.05–91).

The main provisions that directly relate to smoke removal from household gas water heaters boil down to the following points:

- The cross-sectional area of the exhaust pipe is taken to be no less than the cross-section of the outlet pipe of the unit;

- It is necessary to ensure complete tightness of the chimney, its resistance to corrosion and high temperatures up to 200 °C;

- Laying connecting pipes through living rooms is prohibited;

- The vertical section of the exhaust pipe at the outlet of the column must be 500 mm high, in some cases it can be reduced to 250 mm;

- Connecting pipes should be up to 3 m long in new buildings and up to 6 m in existing ones;

- It is allowed to use no more than 3 turns with a bend radius no less than the diameter;

- The exhaust pipe is installed at a distance from the ceiling or wall made of non-combustible materials of at least 5 cm, if they are combustible or difficult to burn, then at least 25 cm. The distance can be reduced to 10 cm by taking protective measures in accordance with SP 42-101-2003;

- If the connecting pipe for a gas water heater passes through an unheated room, then thermal insulation must be used;

- The exhaust pipe must be laid with a slope of 0.01 or more towards the appliance.

Important! Removal of combustion products is possible only through smoke ducts or specially installed chimneys; the use of ventilation ducts is strictly prohibited.

Smoke ducts are installed in walls made of non-combustible materials and are insulated, if necessary, to prevent condensation. If there are no suitable walls or the building in use does not have channels for removing combustion products, then install a top-type or root-type chimney.

Each fuel-burning device must have a separate smoke duct or pipe. In some cases, it is allowed to remove exhaust gases from the column and boiler into one chimney with an increase in the cross-section of the pipe. In this case, the combustion products must be introduced into the channel at different levels at a distance of at least 0.75 m or at the same level using a cut with a height of 0.75 m and a thickness of 0.12 m.

The chimney must be strictly vertical and have at the base a removable pipe or pocket 250 mm deep with a door for cleaning soot. If it is necessary to bypass existing obstacles, a deviation of up to 30° from the vertical is allowed, while the cross-sectional area is maintained, and the offset should not exceed 1 m.

Note: the round or rectangular hole under the entrance to the smoke channel is intended for cleaning soot and must always be accessible for maintenance. When doing general cleaning in the kitchen, do not forget to open the door and clean out soot, leaves and other debris.

The height of the chimney is a key factor in creating good draft. It is this that is decisive in the issue of high-quality removal of combustion products. The height of the chimney must be determined in accordance with the diagram given in SP 42-101-2003 (Appendix D).

If there are taller buildings or trees nearby, then it is necessary to additionally check the height of the wind pressure zone and, if necessary, increase the height of the chimney. In any case, the elevation above the adjacent part of the roof must be at least 50 cm, and with a combined (flat) roof - at least 200 cm.

After installation is completed, the tightness of the smoke exhaust pipe and the presence of draft must be checked. To avoid the risk of loss of draft as a result of freezing of the tip or its blocking by foreign objects, it is prohibited to use nozzles on chimneys in the form of umbrellas, deflectors, etc.

Note: in rooms with hermetically sealed windows, the gas water heater may periodically turn off due to insufficient air flow. The automation stops the operation of the water heater to prevent reverse draft, which may occur due to rarefaction of air in the room. To eliminate the problem, it is enough to keep the kitchen window in micro-ventilation mode while the column is running.

Selection of pipeline material

When going to purchase an exhaust pipe, you need to carefully study the installation conditions, know the model of the gas water heater, the diameter of the smoke exhaust pipe and the required lengths of the pipeline sections. It is advisable to stock up on a diagram of the location of the water heater indicating all the distances; this will help you better navigate when choosing the necessary elements and, if necessary, obtain specialist advice.

According to SP 60.13330.2012, connecting and chimney pipes must be made of non-combustible materials with an equivalent internal surface roughness of no more than 1.0 mm. In addition, they must be tight with tightness class B and prevent air leaks at the connections and in places adjacent to the smoke duct. The use of materials such as ceramics and stainless steel is recommended.

SP 42-101-2003 allows the use of roofing or galvanized steel with a thickness of 1 mm or more, flexible metal corrugated pipes and standardized elements supplied with the unit.

It is very important that the material of the exhaust pipe is resistant to corrosion, since condensation can destroy it quite quickly. The smoother the inner surface, the less soot will accumulate on it. The roughness of the outer surface is not standardized, but from the point of view of ease of cleaning, a smoother material for the connecting pipe will be more practical.

However, corrugated pipes are quite popular for connecting a gas water heater to a smoke duct. They are easy to work with and very convenient in tight spaces. Their use allows you to successfully avoid obstacles and carry out hidden installation, hiding equipment in cabinets and covering the pipeline with removable panels.

The main disadvantage of corrugated pipes is the possibility of burning out under the influence of high temperatures. Therefore, for fire safety purposes, it is recommended to use stainless steel corrugation rather than cheaper aluminum.

Galvanized steel 1 mm thick is an acceptable material, but there is an opinion that when heated strongly, galvanizing can release harmful substances. Accordingly, its use is undesirable for models with high flue gas temperatures.

Exhaust pipes made of steel coated with heat-resistant enamel have proven themselves quite well. White shiny pipes look quite nice in the kitchen and can fit into almost any interior.

The ideal material in terms of durability, aesthetics and compliance with all requirements is stainless steel. It is not at risk of corrosion, burnout, dust accumulation, or accidental damage. Quite naturally it turns out to be the most expensive.

Installation procedure

Installation of an exhaust pipe for a geyser made of any material begins with taking measurements and preparing all the necessary elements. In the case of corrugation, the work procedure is very simple. It is enough to take a pipeline of the required length, put it on the smoke exhaust pipe of the water heater and clamp it with a clamp. The free end is inserted into a decorative ring and fixed in the opening of the smoke channel. The main thing here is to ensure that the diameter of the corrugated pipe matches the size of the outlet hole of the column.

For all other materials, you need to prepare the required number of straight and rotary elements that will be inserted into each other, forming the desired chimney configuration according to the principle of a designer. Rotation angles are standard or made individually for specific sizes.

During assembly, ensure maximum tightness of connections. The entry of one element into another must be at least half the diameter. For better sealing, heat-resistant sealant is used. The joints are fastened with clamps and are located outside the ceilings and are freely accessible.

When attaching an exhaust pipe for a gas water heater, you should eliminate the possibility of deflection, as well as contact with electrical wiring, gas pipes and other communications. To pass through floors and roofs, it is necessary to use additional thermal insulation or a special unit - cutting.

Due to the limitation on the number of permissible turns, the number of possible chimney configurations is quite limited. There are three main options depending on the location of the exhaust vent. Two more can be obtained by mirroring the previous ones.

All requirements and recommendations stated above apply to devices with an open combustion chamber. The standards also allow the removal of combustion products through an external wall without a vertical smoke duct from geysers with a closed combustion chamber and forced release of exhaust gases. In this case, installation is carried out according to the manufacturer's instructions in compliance with the standard distances and lengths of the coaxial chimney specified in SP 42-101-2003.

Conclusion

Thus, installing an exhaust pipe for a geyser has many important nuances. Considering the great danger that may arise from non-compliance or partial violation of regulatory requirements, it is necessary to approach this issue with the utmost seriousness and, if possible, entrust all work to professionals.

High-quality installation of the connecting pipe is the key to safe operation of the geyser. Strict compliance with all requirements of regulatory documents will ensure stable operation of the device and allow owners to use a convenient water heater without fear of carbon monoxide poisoning.

znatoktepla.ru

Piping diagrams by type of boiler

It is quite simple to link the operation of two units of the same type, but real operating conditions do not always allow this. More often it is necessary to combine the operation of units not only with different power, but also with different energy carriers.

The most popular pairs of two-boiler schemes:

- gas fuel and electricity;

- gas and solid fuel;

- firewood and electricity;

- propane and electric power;

- heating oil and electricity;

- pellets and electricity.

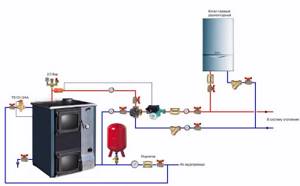

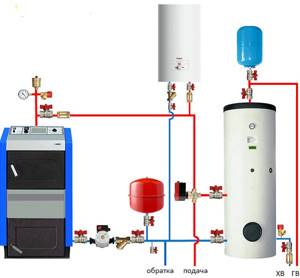

Connecting a gas and floor-standing solid fuel boiler

This is the most technically complex method of piping two boilers, since it requires the implementation of a smoke ventilation system and compliance with the dimensions of the room for the installation of large fire-hazardous objects.

It is best to entrust the development of the diagram to a design organization, since it must take into account all the rules of safe operation for both gas and solid fuel boilers.

The optimal mode in the heating network is achieved when installing a multi-circuit system; in this case, it is necessary to connect boilers with two independent circuits.

Considering that solid fuel devices are practically impossible to regulate the temperature of the coolant, an open heat supply system with the installation of an expansion tank should be used.

Moreover, a closed heat supply system using gas and solid fuel boilers is unacceptable and is a serious violation of fire safety rules.

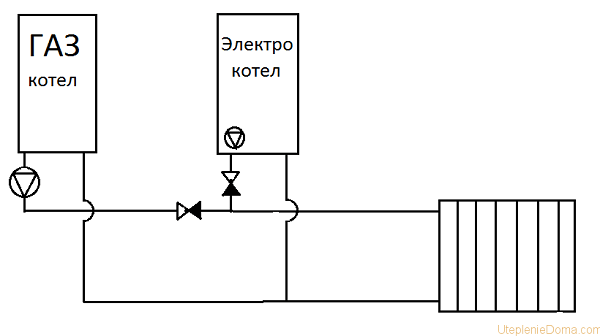

Electric and gas

A very effective and easy to manage scheme. By combining gas and electric boilers in one heating system, it is possible to achieve a much greater thermal effect, and with the correct combination of operating modes of the units, the scheme is more economical than traditional gas boilers.

The leading function in this pair is usually performed by a gas boiler unit, which has the lowest cost of thermal energy. The electric boiler is switched on at night using the cheapest tariff for electricity metering.

When choosing the thermal power of equipment, it is necessary to focus on this boiler piping scheme. The gas unit must be more powerful, and the electric boiler must have peak power to operate at night or at peak heat demand. There are no prohibitions on the joint operation of this pair of boilers in regulatory materials. However, their installation will require approval of the boiler house design from both the gas service and energy supervision.

Connecting a solid fuel and electric boiler

Connecting a solid fuel and electric boiler is also an effective implementation of a combined heat supply source. The basic boiler is solid fuel, which is capable of operating at one load for at least 8 hours. It warms up the heat supply facility well.

After the fuel burns out and the coolant cools down to 60 C, the electric boiler is switched on in the mode of maintaining the temperature schedule. For greater energy efficiency, it is advisable to have a hot water storage tank, which is heated by an electric boiler during the night economy mode.

The solid fuel boiler itself is difficult to regulate due to the inertia of the combustion process; it will produce almost nominal performance until the fuel burns out.

In this case, working to heat the primary circuit in the storage tank, adjustment of the heating mode will be carried out in the secondary heating circuit from the storage tank through a three-way valve by mixing cold water from the return coolant with hot water from the supply line.

What kind of corrugation is used for chimneys

Combustion products in an apartment building are discharged into the ventilation duct, in a private apartment - to the street. Depending on where the gases are discharged, the pipes are divided as follows:

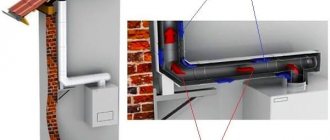

- Coaxial - the pipe exits through the wall or roof of the house to the street;

It is a structure of two pipes, the larger of which is put on the smaller one. Oxygen from the street is supplied to the fire through the free space between the pipes.

- Chimney - with connection to the ventilation duct.

Chimney pipes, in turn, can be smooth steel or corrugated.

- Smooth steel pipelines. Covered with white heat-resistant enamel or galvanized. Maximum length -1.5m. Made from sheet steel with a minimum thickness of 0.6mm. Due to temperature differences, condensation forms in the pipes and freezes in winter. Therefore, the structure must be carefully insulated.

- Flexible corrugated air ducts. Corrugated pipes are the best choice for removing waste gases from the column. They are convenient, reliable, and inexpensive. Due to their low weight and flexibility, they are easy to install.

The standard diameter of corrugated pipes is 11 and 13 cm. Maximum length – up to 3m. If you need to mount a longer section, the parts are connected with metallized tape. It can also be used when repairing corrugation.

When choosing a pipe for exhaust, it is necessary to take into account the temperature of the exhaust gases. Usually in the column it reaches 200-300°C, so the operating temperature of the corrugation should be at least 350°C.

Corrugated chimneys are made from stainless steel or aluminum.

In the case of gases venting through the wall, a special hole is prepared in it with an installed passage pipe, isolating the wall and the pipe from each other.

Let's look at the features of each material.

Stainless steel chimney:

- Withstands heating up to 900°C.

- Stainless steel is a durable and corrosion-resistant material;

- The corrugation bends in any direction and does not require additional fittings.

- The multilayer structure made of aluminum foil and reinforcing wire is not inferior in flexibility to stainless corrugation;

- The temperature of the exhaust gases should not exceed 400° C;

- Aluminum is lighter than stainless steel and has better stretchability;

- These products are inferior to their stainless steel counterparts in strength.

The use of aluminum pipes is not prohibited, but, as practice shows, inspectors in most cases require replacing aluminum with another material.

In any case, you should purchase only certified products.

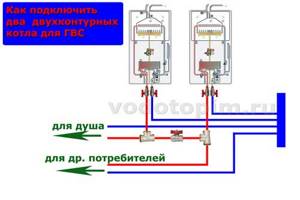

How to connect two double-circuit boilers to produce hot water?

Well, there is another option where two boilers in one system operate on hot water supply. In such a scheme, it is best to have one boiler heat water for one group of consumers, for example, for a shower; the second one is for everyone else:

Then the person taking a shower will be spared the troubles experienced when there is only one wall-mounted boiler: when opening and closing other hot water taps at the same time (for example, in the kitchen), there will be no temperature fluctuations in the shower room.

Note in the diagram that there is a ball valve between the hot circuits. This is in case of repair/prevention/replacement of one of the boilers, when the remaining one will heat water for all consumers

Only after the repair you need to remember to open the tap.

Well, I think I said everything about two boilers in one system.

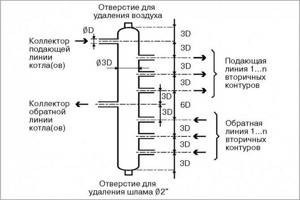

Hydraulic arrow in a parallel connection system

A hydraulic arrow is a device that provides hydraulic isolation of flows supplied to individual circuits of the heating system.

It plays the role of a buffer tank, receiving the flow of coolant heated by the boilers and distributing it to consumers in a branched system. Often the volume of coolant required for them differs, the speed of movement of the heated water and its pressure differ. And in the situation under consideration, the movement of heated water from each of the boilers also stimulates its own circulation pump.

When the powerful pump is turned on, the coolant is unevenly distributed throughout the circuits. So, the task of the hydraulic gun is to equalize this pressure. Due to the fact that there is virtually no hydraulic resistance inside it, it will freely receive and distribute coolant flows from both boilers.

Let’s figure out whether it is really necessary in a parallel system for connecting 2 boilers, especially since if you buy and install a hydraulic separator with the help of a specialist, and not with your own hands, the total amount will be unpleasantly surprising.

The device is a piece of pipe with pipes, hollow or with filter meshes to remove bubbles and filter out incoming contaminants. It can be placed in any position, but more often vertically, with an air vent on top and a shut-off valve on the bottom for cleaning. A hydraulic arrow is installed between the boiler and heating circuits

In the classic connection scheme, a hydraulic separator is usually not required, since the conflict of 2-3 pumps can be equalized without this device. Accordingly, if you have 2 boilers that are used exclusively as a backup and there are no more than 3-4 pumps in the system, there is no particular need for it.

But if there are more forced circulation circuits or heating boilers operate simultaneously at full power, it is best to install this device. Again, it is unknown whether you will use the second boiler permanently or only in backup mode, so it is better to be safe.

Advantages of a two-boiler system

The main positive aspect of installing two boilers in one heating system is the continuous maintenance of heat in the room. A gas boiler is convenient because it does not need to be constantly maintained. But in case of an emergency shutdown or in order to save money, a wood-burning boiler will become an indispensable heating addition.

The heating system of two boilers can significantly increase the level of comfort. The advantages of a double thermal device include:

- selection of the main fuel type;

- the ability to control the entire heating system;

- increasing the operating time of equipment.

Connecting two boilers into one heating system is the best solution for heating buildings of any size. This solution will allow you to continuously maintain heat in the house for many years.