Water floor structure

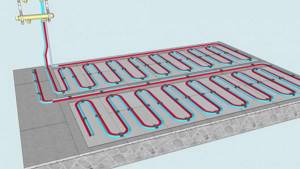

A typical floor system with water heating can be divided into two parts, one of which will be the heating unit itself, and the second will be the control infrastructure. The working part with the coolant contains the following elements:

- A substrate on a rough surface that forms the structural basis for laying the heat distribution circuits.

- Waterproofing with damper tape.

- Thermal insulation that prevents heat from escaping to the rear.

- Heat-conducting pipes.

- The final layer of structural coating.

Regulation of the operation of heat-conducting circuits is ensured by means of a water heated floor control unit, which also consists of several functional parts that deserve special attention.

Servo drives for manifold

For underfloor heating, the pipeline is connected to the collector. The equipment has outlets for hot coolant and for cooled liquid, which is pumped into the boiler. The number of outlets in the manifold corresponds to the number of water heating circuits. A coolant of a certain temperature is supplied to the main line. Servo drives are designed to regulate it through valves located on the manifold.

We recommend: How to install damper tape for underfloor heating?

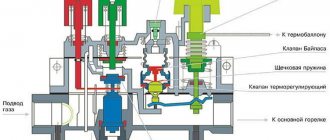

The underfloor heating control unit has the following components:

- spring made of nichrome; Electric current passes through it;

- container with thermal fluid; it is heated by a nichrome spring;

- a rod to which the cold circuit valves are attached;

- temperature sensor; the device is installed on the liquid circuit of the heated floor;

- thermostat; it is programmed for a certain mode; a temperature sensor and a servo cable are connected to it.

The thermostat sets a specific heating mode. If the floor temperature exceeds the set parameter, the thermostat closes the servo drive circuit. The spring, which is located in the thermal fluid, begins to heat up.

The liquid expands and presses on the rod, which opens the valve for the cold circuit. In the mixing chamber, hot coolant and cooled water are mixed. Warm liquid enters the floor line.

When the set temperature decreases, the thermostat opens the servo drive circuit. The spring begins to cool, the thermal fluid cools and contracts. The rod rises and closes the outlet for the cold circuit. A heated floor system is being installed in Moscow to heat country cottages.

When using a servo drive, the thermal fluid heats up and cools down quickly. The system changes operating mode in 1-3 minutes. The thermal head on the mixing unit turns off the heating system within 15 minutes. The automatic floor heating machine can be controlled remotely using servo drives using electronic gadgets.

Control node device

The heating floor with a water pipeline is supplied with a mixing and heating unit, which, depending on the design, can be connected to one or more heating circuits. Its basis is formed by a heating element with a power of 1000 to 1500 W, a collector group and a circulation pump. In addition to this unit, you can connect an intelligent control system for water heated floors.

Advice from experts: the regulation system should be made as segmented as possible in terms of levels of connection of shut-off valves. This means that control must be provided by both mechanical control elements and a combined thermostat. Moreover, it is advisable to place shut-off and start-up valves along all circuits in a separate order, which will make the system more cumbersome, but will increase the reliability of control in emergency modes.

Adjusting water heated floors

How to fill a heated water floor

If we consider how to regulate a water-type heated floor, we can immediately note the complexity of the techniques used, in comparison with electric heating. In particular:

- a method of smoothly adjusting the water temperature in the system is used, since sudden surges lead to airing;

- there are several schemes for mixing hot coolant into the heating circuit;

- it is assumed that a separate circulation system will be installed for each control zone of the apartment or house;

- There is an option to use semi-automatic means of maintaining the temperature of the coolant simultaneously with thermostats.

Let's look at several control schemes for water-heated floors, starting from the simplest.

- Changing the coolant flow mechanically. This adjustment system is (from the user's side) a simple faucet. By opening it or incompletely closing it, the overall heat transfer is changed. In fact, the mechanical control system is more complex than a faucet, but the control principle is similar to its operation. The above diagram is of little use if the house has one main circulation pump. The mechanical system will affect the heating efficiency of all rooms.

- Supercharger control. By turning the circulation pump on and off, the required parameters of the coolant in the pipes are maintained. Switching can occur both according to the signal from the thermostats and in accordance with the parameters of the sensor installed in the heating circuit. In order to achieve separate microclimate regulation in a single room, you will have to equip your own water passage structures in each of them, equipped with blowers. If this is not done, the main circulation pump at some points in time can turn off the heating in the entire house.

- The thermal head can act as an effective semi-automatic means of temperature control. It is more inconvenient compared to a wall-mounted thermostat; it works on the following principle: it opens the supply of heated water if the temperature in the control circuit drops and, vice versa, it shuts it off when the set limit is reached. The thermal head controls the three-way valve.

The listed techniques refer to the so-called single-point control schemes. They regulate the operation of a separate circulation path or zone of the heating system. More advanced methods include servo-driven distributors. Depending on the indicators of the sensors, such devices can redistribute the flow of heated water into separate controlled zones.

Circulation pump function

The working process of a water floor begins with the delivery of water from the central water supply and raising its temperature in the heater. Next, the finished coolant must be distributed along the laid circuits. This task is performed by the circulation pump. In the water heated floor control system, this equipment has its own auxiliary tasks that go beyond regulating the speed of flow distribution. For example, a pump can be equipped with water flow sensors, record critical pressure indicators and, in some configurations, perform the tasks of shut-off valves. This set of functions depends on the design of the pump and how it is placed. By the way, complex systems in which one control unit covers several heating systems (boilers, radiators, hot water supply) contain several circulation pumps to ensure sufficient distribution power in several coolant delivery zones.

Purpose of the device

The thermostat is built into the water heated floor system not only to perform the function of maintaining the specified temperature parameters. Its main purpose is to protect the heat cable from overheating. Having reached the desired temperature in the specified system, the control device automatically disconnects the entire structure from the power supply. This property is inherent in any type of these devices - from very expensive options to budget analogues.

The fundamental advantages of thermostats include the following:

- • individual temperature setting in a separate room or, for example, only a recreation area. This solution provides an optimal thermal comfort level;

- • ease of installation and connection;

- • possibility of complex control from an external timer;

- • low cost when compared with standard forms of heating;

- • a fairly high level of quality of materials;

- • functionality allows you to select an individual system from different types;

- • accurate temperature maintenance allows you to save 30-35% of total energy consumption.

Servo control

Mechanical control infrastructure today is implemented on the basis of a servo drive, which allows you to regulate coolant flows by closing and opening manifold valves. There are two types of these regulators - with a normally closed and a normally open valve. The difference between them lies in the principle of interaction of the device with electrical voltage. In a closed-type system, the valve opens only when voltage is applied, and the normally open control mechanism closes when a similar electrical signal is applied.

The most widely used control systems for water heated floors are a servo drive with a temperature sensor, which make it possible to monitor heating indicators in one mechanical unit. However, the addition of a thermometer option is more of a cosmetic nature, since in automatic thermostats the same sensors are implemented with wider functionality. The concept of a mechanical regulator with integrated measuring instruments is itself outdated.

But is the principle of controlling a water heated floor with a servo drive without a temperature sensor really that good? Although it lacks a temperature indicator function, the drive mechanism may well perform the primary task of receiving temperature readings from the thermostat. The main thing that a servo drive must do is precise mechanical regulation of the state of the valves.

General description of the advantages and possibilities of regulation

Thermostatic blocks are a simple control device equipped with two sensors. The temperature in the room can be changed:

- the method of switching on heating cables or films if an electric heated floor is used;

- the method of starting a circulation pump, if we consider the simplest water floor control system;

- the controller can control three-way valves to add hot coolant into the system or a separate underfloor heating circuit.

The simplest scheme for controlling a water-heated floor is based on shut-off fittings. Taps are installed in the heating circuits. The apartment owner independently regulates the temperature in the rooms by controlling the amount of liquid circulating in the system. We are not talking about precise maintenance of microclimate parameters - everything is controlled according to the principle “it’s still cold - it’s normal - it’s already hot.”

It is not recommended to use heated floor control on taps. According to reviews from owners, the system may become airy and reduce its efficiency. The likelihood of such a process developing cannot be accurately assessed. It all depends on the complexity of the system and the power of the heating equipment.

A more complex floor heating control system necessarily includes automatic controls. If we are talking about electric heating, two-sensor regulators are used that simultaneously determine the temperature of the cable or film heater, as well as the air in the room at a distance from the floor (recommended - at least 120 cm). Control of a water heated floor is based on the use of different techniques, some of which are based on the use of simple switching switches on and off circulation pumps.

In addition to controlling the internal microclimate, the heated floor control unit can adjust the heat transfer parameters according to the outside air temperature. Such a system is expensive and includes groups of sensors located outside the house or apartment. However, after the control unit has been configured, you can enjoy comfort in your rooms in any weather, at any time of the year.

The controller that controls the temperature in the room or regulates the microclimate in the apartment can be programmed. For example, give a command to intensively warm up the premises by the time the owners arrive from work, and at certain hours switch the heated floor to minimum mode.

Control block

Control unit for water floor

A basic electronic control component that provides ergonomic user interaction with the functionality of the water floor. This unit is based on the principle of regulating water temperature, which is implemented through a heating element. In reviews of the control of water heated floors through temperature controllers, many emphasize the ease of working with models equipped with an LCD display and touch buttons. Electronic thermostats are usually criticized for their low control accuracy, even compared to their mechanical counterparts, but modern modifications of the control unit allow adjustments down to 1 degree.

Mixing unit for underfloor heating system

The temperature regime for heating the medium (in this case water is used) for heated floors is much lower than for radiators. The basic principle of operation of mixers is to achieve a decrease in the temperature of the coolant by mixing return water - water that has already given up its heat - with water heated to a high temperature.

To create and maintain stable water circulation in a heated floor system, two-way or three-way valves are mainly used. They can be replaced with thermostatic mixers. If the water speed is insufficient, a circular pump is installed in the system.

The design of the mixing unit for a water floor involves placing the pump between the supply manifold and the supply pipe. Additionally, another outlet is installed to remove water from the outlet collector.

A mixer for a warm water floor significantly improves the operation of the entire system and allows you to automatically adjust the heating temperature of the medium depending on changing weather conditions. To do this, the electric drive, which is installed on the two-way valve, is connected to the temperature controller.

The mixing unit can be operated in manual mode. In this case, the block is operated without installing valves, and the admixture indicators are determined by the selection method

This method must be implemented with caution and is not suitable for high temperature heat sources.

Limiting the maximum temperature can be achieved by installing a thermostatic head placed on the valve and having a remote-type sensor.

Mixers are divided into two groups. The first includes devices equipped with three-way valves with servo drives. With their help, you can configure the control of controllers that respond to weather changes and thermostatic devices. There is the possibility of an unexpected failure in the operation of the unit when, following a signal from the thermostat, the valve can open and hot water reaching a temperature of 90 °C enters the system. This increase in temperature sometimes leads to partial rupture of pipes. Three-way valves have a high water flow rate, which requires special care in setting up the entire underfloor heating system. But still, this group of mixing units is quite in demand for arranging a water floor in very large rooms.

When installing mixers belonging to the second group, two-way valves are used, which are characterized by a low coolant flow rate. The mixing of hot and cold flows is very stable, which allows for smooth adjustment of the process. Such mixers are installed in water floor systems whose area does not exceed 200 sq.m.

Implementation of automation

Automatic control systems are a kind of add-on to electronic thermostats, expanding their basic capabilities. The key difference between automatic regulation is the possibility of autonomous operation of the system. In particular, modern regulators operate on the principle of proportional-integral control, which means independent accounting and decision-making on setting the temperature regime based on current initial data on temperature and pressure. At the same time, a complete set of control functions on the part of the user is preserved. Along with direct mechanical or electronic regulation, the owner can use remote control of the water heated floor from a phone via Wi-Fi or cellular communications. The automatic thermostat itself can keep statistics of indicators by season, making predictions about possible future changes in settings according to given algorithms.

Management in the Fibaro system

Fibaro offers a specialized solution for controlling water floor functions in the form of a Z-Wave kit. The system includes a control panel, a thermostatic unit and a software PID controller, in which you can set the operating schedule of the floor heater by day and week in certain modes. Of course, the function of intelligent temperature control, which is performed based on information from the included sensor on the wire, has not gone away. The operating features of the Fibaro water heated floor control system include expanded cooling capabilities and the “Antifreeze” option, which activates heating automatically, even if it was turned off forcibly. This feature is implemented for safety reasons, since at certain (extremely low) temperatures the coolant circuits may freeze.

Electric heating

Water heated floor under laminate

To control floor heating, mechanical and electronic thermostats are used, which, using a remote probe, take readings and maintain the temperature at a given level, regardless of the environment and time of day.

Programmable thermostats allow you to turn on surface heating at a given time, days and weeks, and thereby obtain significant savings. They are equipped with functions such as getting up in the morning, working day, evening, getting ready for bed. Some models are equipped with an anti-freeze function, maintaining a minimum positive temperature in the room, thereby preventing the room from freezing in the absence of people.

There are paired thermostat controllers that allow you to control electric heated floors in different rooms from one place. These devices allow you to save on the purchase of one controller, instead of several individual copies, which in monetary terms will be much more expensive.

Models of thermal controllers with radio access allow you to work with four separate modules. Readings from the sensors are displayed on a remote control and it is possible to monitor the temperature of the floor and air in the rooms. Electronic multi-zone programmable microcontrollers with radio access are combined into executive modules consisting of underfloor heating heating elements and electric radiators. Such devices are connected to a smart home system and allow you to monitor the modes in each room separately, as well as set days, weeks, and operating hours.

Currently, MCS 300 built-in modules have appeared on the market. This device can be used to control electric heating via a wifi interface. On a home network via a Wi-Fi router, it allows you to connect to such devices through special programs from anywhere in the world. Using the program, you can simultaneously interact with 32 thermostats. Access devices from multiple locations, including over the Internet. Using a mobile phone, tablet or computer, the operating mode, time and degrees are set.

You can learn more about remote control of electric heated floors by watching this video:

In addition to MCS 300, devices are used for control via the GSM network, via SMS commands. This remote control is part of a smart home and allows you to receive operational information about the status of sensors through messages such as intrusion, temperature, lighting, resource consumption (for example, water and light). Also, via SMS commands, you can turn on underfloor heating, a boiler, etc. in advance.

Danfoss control

The manufacturer of heating equipment and components Danfoss also offers special kits for controlling underfloor heating. This family particularly successfully implements the mechanical infrastructure for organizing water heating with a mixing unit and a collector group. This solution is suitable for houses where it is planned to organize complex heating together with radiators. The technical basis for controlling Danfoss water heated floors is the distribution comb, to which the mixing unit is connected. This configuration is advantageous in that during the operation of the floor, the optimal operating temperature of the coolant is 35-40 ˚C. By mixing hot water from the boiler and waste cooled flows from the radiator unit, an optimal heating mode is achieved that does not require adjustment. The user also sets specific parameters using an electronic thermostat, including the one included with the water floor.

A few calculations

How to make a warm floor from heating Warm water floor.

Installation of a heated floor Next, we will tell you how to calculate an electric heated floor. First, you need to calculate the area - to do this, draw out a house plan on paper, mark where the furniture will be (you need to know at least its approximate dimensions). We calculate the area of each room separately, since we recommend making one circuit for each room - this makes it easier to regulate the temperature and easier to save energy (simply turning off unnecessary circuits).

Using a thermostat, you can accurately adjust the temperature to the nearest degree.

At the next stage, we decide on the choice of material and get acquainted with such characteristics as power. For example, when choosing an electric cable, we can purchase a small coil of 2 square meters for heating. m. power 280 W. Coils of other sizes are also available for sale. The same applies to infrared electric heated floors.

Now let's take a look at the power requirements. If electric heated floors work as the main source of heat, the recommended power will be 180 W per 1 sq./m. Similarly, we calculate the power for heating loggias and balconies. If floors will act as an auxiliary heat source, equipment should be selected based on the following requirements:

- Premises located on the first floors of buildings (including private houses) - 130-150 W per 1 sq./m;

- Premises located on the next floors - from 120 to 130 W per 1 sq. m;

- Bathrooms - from 140 to 150 W per 1 sq. m.

If there is a large error in the calculations, then there is nothing to worry about - for these purposes, there will be thermostats in the rooms that will maintain the temperature at a given level. But you shouldn’t make huge reserves, as this is fraught with unnecessary expenses.

To make more accurate calculations, use special calculators that take into account heat losses and other parameters.

Control via Arduino controller

The use of controllers justifies itself in houses where multifunctional control of entire groups of heating systems is provided. The Arduino microcontroller programmer is most suitable for use with household underfloor heating devices. Using special settings, the user creates a control algorithm taking into account the list of input indicators. In modern systems of this type, remote control capabilities are also widely used. Thus, control of an Arduino water heated floor can be organized through the same smartphone by downloading the appropriate Android application with a graphical interface. Among the main tasks that can be solved using such tools are the following:

- Temperature setting and regulation.

- Monitoring data that comes from temperature sensors.

- Informing about the technical condition of the system.

- Activation of emergency modes with alarms when signs of a leak or uncharacteristic change in key operating indicators are detected.

Installation of the control unit

It is advisable to place the control devices as close as possible to the place of operation of the heating pipeline. Fastening operations using a complete set of clamps and mounting panels are easy to perform without the help of specialists, with your own hands. The water heated floor can be controlled from the installation cabinet or remotely. Therefore, it is important to think in advance about the most convenient installation locations in terms of access. It is not recommended to mount the unit with the collector group directly to the supporting structures, since the operation of a heated floor contributes to the spread of vibrations and noise. It is advisable to fasten the system with screws to the installation panel through a damper gasket, which will dampen vibrations and sound effects.

Checking the system for leaks

Before putting the floor heater into operation for the first time, you should test it for leaks, that is, the presence of possible leaks. To do this, it is necessary to hold the system under pressure for about 5-10 minutes, 1.5 times higher than normal operating indicators. In this case, the maximum value should not exceed 3 bar. If during this period of time the pressure does not exceed 0.2 bar, this means that there is no leak in the connections. Depending on the option of a specific water heated floor control system, critical pressure drops can also be reported automatically through special indicators. Moreover, the warning functions also allow the possibility of inclusion in general alarm systems at home.

Is it possible to use heated floors without a thermostat?

Using heated floors without a thermostat is definitely not allowed! Why? Let's figure it out.

What happens if you connect heating elements directly to the electrical network?

If the infrared film is connected directly to a power source, the film will be continuously heated until it reaches the maximum heating temperature. Depending on the model and manufacturer, the maximum heating temperature of a heated film floor can reach 50 °C, 70 °C, 150 °C or another value. If heat dissipation is poor, the heating film will fail and the floor covering will be damaged.

Connecting self-regulating films without a thermostat

When connecting a heating film with a self-regulating effect directly to a power source, as it heats up, its power will decrease due to an increase in resistance. This protects the film from local overheating when heat transfer from the floor surface deteriorates.

By reducing its power by 30% (Marpe Samreg PTC or Marpe Black Heat PTC 30%) or 50% (Marpe Samreg PTC+), the film will continue to heat up. Even though the maximum heating temperature of self-regulating films is limited and is often insufficient to cause them to fail, the floor covering may suffer.

Why do you need a thermostat?

The thermostat for heated floors is designed to turn off the power supplied to the heating elements when the set temperature is reached. The thermostat allows you to control the temperature in the room, and when using thermostats with a floor and air temperature sensor, it prevents overheating of the heating elements of the heated floor and floor coverings.

What happens when it overheats

Let's look at what can happen to various floor coverings when overheated (the indicated temperatures are approximate and depend on the model and manufacturer, the exact values can be found in the product data sheet or by consulting the seller):

- When heated above +30 °C, the laminate may begin to creak, dry out, and release substances harmful to health.

- When heated above +26 °C, the parquet board may begin to creak and deform.

- When heated above +27 °C, natural linoleum can begin to melt and tear, and at +30 °C, PVC linoleum begins to lose color, swell, go in waves, and release phenol that is harmful to health.

- When heated above +27 °C, the carpet may begin to unravel and fade.

Thus, regardless of the type of heated floor and the floor covering used, the use of a thermostat is mandatory!