Products of JSC Plant Eton RF

The weather control unit is a set of equipment that allows you to control the temperature of the coolant in the heating system depending on the air temperature.

Why do you need to install UPR?

At first, the installation of energy-efficient equipment is pushed by tariffs for heat and severe overheating of rooms in the middle of the building, especially in the fall and spring, when you have to open the windows and release the heat to the street, and you have to pay for this heat! The second factor motivating the installation of UPR is the desire to live comfortably with a constant optimal temperature in the apartment.

What do you get after the equipment has been installed:

— Savings on heating costs up to 40%. — You plan to live comfortably and you will no longer have to sleep in a stuffy room. — Your HOA, DUK, etc. They will no longer pay fines for overheated coolant in the return pipeline, and these fines will be borne by the residents! — The temperature in the living areas on all floors of the residential building will be stable and the same, both on the first and on the top floor.

Composition of the weather control unit:

Video review of the working principle of the RG control hydraulic elevator:

A story from the Nizhny Novgorod NNTV channel about weather regulation based on Eton equipment:

Interviews with the heads of management companies that have installed UPR on their own farms:

What components are included in the weather control heating system?

The weather automation uses the following components:

- pump equipment;

- safety valve;

- drive unit;

- a certain type of controller;

- external temperature sensor;

- temperature sensor for heating system;

- check valve;

- shut-off valves;

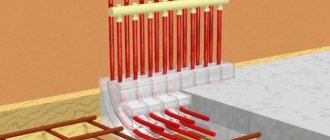

- collector;

- fitting;

- mixing units;

- terminals.

The most important element of the system, which controls the operation of other equipment, is the controller.

The following types of weather-compensated control units exist:

- The main controller has special terminals and can control the operation of one or two boilers at once. There is a built-in timer. The device contains 6 control circuits for heating devices and 2 independent circuits.

- The expansion controller is programmed with 2 hydraulic circuits. It comes without a built-in timer and does not regulate the operation of the boiler. Usually it is used as an additional device if the main one cannot cope with the functions assigned to it.

- The mixing circuit unit is programmed with only one hydraulic circuit that operates autonomously. There is a built-in timer and the ability to organize weather-dependent control with one single circuit.

- The main controller for the buffer tank has terminals for controlling one boiler, which is connected to the heating system via the buffer tank. It is equipped with a timer.

Weather control. Standard heat supply control schemes

Systems for weather control of heat energy (hereinafter referred to as “systems”) are intended for automated temperature control of the coolant, hot water or ambient temperature in the middle of the premises in control systems for heat supply, hot water supply (DHW) or fresh air ventilation.

Heat supply control systems are classified depending on their purpose according to the following thermal schemes:

In standard weather control schemes for heat supply 1, 3-7, pumps are used to overcome the resistance of the supplied equipment, to support circulation in heating systems and hot water supply, and can be turned off by time regulators to reduce the coolant flow rate at night. To save pumps from “dry” running and from water hammer in schemes 1, 3-7, an electrical contact device is used to determine the pressure value.

The systems perform the following functions of heat supply regulation: - control in heating systems according to the heating schedule of the dependence of the coolant temperature on the outside air temperature; - programmatic reduction of coolant consumption for heat supply at night, weekends and holidays (non-working hours); - limitation of the temperature of the return network water according to the schedule its dependence on the outside air temperature in accordance with the requirements of the heat supply organization in heating systems; - maintaining the temperature of hot water in hot water systems with the possibility of reducing the temperature during non-working hours;

— protection against freezing of the heating system;

Based on temperature regulators (see section III) and control and shut-off valves produced by Eton Plant OJSC, as well as other manufacturers, it is possible to complete control and metering systems with up to 2 control loops. They represent a combination of circuits 1 7 with one or more single (2-) circuit temperature controllers. The number of control valves and (or) hydraulic elevators is determined by the number of circuits in the regulator and the control circuit.

To place an order, it is enough to indicate the type of temperature controller, standard sizes and number of valves, respectively, with the real catalog and questionnaire.

MORE DETAILS ABOUT NEWS HOUSING AND UTILITIES IN ZEN

Weather control systems are installed to automatically ensure the required temperature in the premises and reduce heat bills. Our offer for installing modular weather control system SUAPR is very competitive.

Subject of the offer. Supply of Mixing Units for Automatic Weather Control (AWAC) manufactured by Teplotron LLC. Purpose of SUAPR. Reducing payments for consumed thermal energy by residents of apartment buildings (by 18 % - 25 %) and ensuring a constant comfortable temperature in all residential premises.

- Brief description of SUAPR.

Most residential and public buildings are provided with heat from thermal power plants and boiler houses. The temperature of the coolant supplied to consumers is regulated centrally at the heat sources, in accordance with the outside air temperature. Existing heat supply systems are mainly equipped with water-jet elevators, which do not allow regulating the temperature of the coolant supplied to buildings. Reducing the coolant temperature in public buildings during the absence of people in them and in residential buildings during certain transition periods can significantly reduce heating costs.

The use of the SUAPR automatic weather control mixing unit developed by the specialists of Teplotron LLC (registered in the State Register of the Russian Federation under No. 010/019586), which is installed instead of an unregulated water-jet elevator, allows us to achieve comfortable conditions for people to stay and reduce heating costs with minimal time and material costs. Due to the correspondence of the thermal load, overall and connecting dimensions, when implementing a control system, there is no need to design and carry out welding work for the reconstruction of a heating unit. All work on the reconstruction of the ITP consists of dismantling the existing elevator and installing a control system with the appropriate thermal load and standard dimensions in its place. When installing a control system, no design is required (in some cases, heat supply companies approve this technical solution based on the standard design presented), highly qualified personnel, and there is no need for welding work. The SUAPR adjustment is carried out at the factory; no additional settings are required on site. Thus, the use of SUAPR in comparison with traditional automatic weather control systems can significantly reduce the material and time costs of implementation, and therefore reduce the payback period.

According to the letter from the Deputy Head of the North-West Directorate of the Federal Service for Environmental and Nuclear Supervision (ROSTEKHNADZOR), permission to allow SUAPR into operation is not required.

Water jet elevator type 40s10bk SUAPR with similar dimensions and thermal load

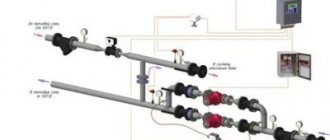

Installation example of SUAPR (heating system for a 5-storey residential building):

Thus, SUAPR is a full-fledged automatic weather control unit of modular design. In all rooms of the building in which the control system is installed, the required (set) temperature is automatically maintained.

2.Selection of control systems for a specific object, installation and commissioning.

The SUAPR model (a total of seven SUAPR models are produced) is selected depending on the heat load (coolant flow) of the building's heat supply system. All required data, including the geometric dimensions of the installed unregulated elevator, are entered into a questionnaire on the SUAPR. Typically, the questionnaire for SUAPR is filled out by the Customer or a specialized organization. A correctly completed questionnaire is the result of an inspection of the facility and guarantees ease of installation and operability of the control system .

The SUAPR, made for a specific object, is supplied assembled, ready for installation, in boxes measuring 1000 mm x 1000 mm x 600 mm. Gross weight no more than 55 kg . When installing SUAPR, no welding work is required. SUAPR is installed in the mounting sockets of a dismantled unregulated elevator. The average duration of work to install the control system by two plumbers is 4-6 hours (including the dismantling of the unregulated elevator). No special knowledge is required to install SUAPR.

After installing the SUAPR, you must:

— place the outside air temperature sensor (part of the SUAPR) on the north wall of the building; — supply 220 V power to the SUAPR. SUAPR is delivered completely ready for work at a specific site and does not require additional settings. If necessary, the SUAPR can be easily reconfigured directly on site to the required temperature schedule. The SUAPR is configured using the RPT-1.2.D keyboard without the use of additional tools and software. It is possible to read information remotely and control the control system by using GSM modems. In the standard version of SUAPR, the RPT-1.2.D controller is located on the SUAPR frame. It is possible to place RPT-1.2.D in a separate automation panel. The required placement of RPT-1.2.D is indicated in the questionnaire. Standard projects for SUAPR, if necessary, will be agreed upon with heat supply organizations of the cities of Taganrog and Rostov-on-Don. Representatives of Teplotron LLC in the Rostov region will be involved for technical support of the implemented equipment.

3.Cost of SUAPR

The tables below (No. 2 and No. 3) show the price prices of SUAPR models (warehouse St. Petersburg) depending on the thermal load of the building. Table No. 2. Cost of SUAPR (Russian rubles including VAT 18%)

| SUAPR modification (one pump) | Water consumption from the network, t/hour | Heat load, Gcal/hour | Price per piece, rubles |

| SUAPR No. 1-102 | 0,5-1 | 0,04-0,08 | 212 400 |

| SUAPR No. 2-102 | 1-2 | 0,08-0,16 | 218 300 |

| SUAPR No. 3-102 | 2-3 | 0,16-0,24 | 285 560 |

| SUAPR №4-102 | 3-5 | 0,24-0,4 | 297 360 |

| SUAPR№5-102 | 5-10 | 0,4-0,8 | 319 780 |

| SUAPR №6-102 | 10-15 | 0,8-1,2 | 339 840 |

| SUAPR No. 7-102 | 15-25 | 1,2-2 | 368 160 |

Table No. 3. Cost of SUAPR (Russian rubles including VAT 18%)

| SUAPR modification (two pumps) | Water consumption from the network, t/hour | Heat load, Gcal/hour | Price per piece, rubles |

| SUAPR No. 1-202 | 0,5-1 | 0,04-0,08 | 271 400 |

| SUAPR No. 2-202 | 1-2 | 0,08-0,16 | 289 100 |

| SUAPR№3-202 | 2-3 | 0,16-0,24 | 368 160 |

| SUAPR №4-202 | 3-5 | 0,24-0,4 | 379 960 |

| SUAPR№5-202 | 5-10 | 0,4-0,8 | 414 180 |

| SUAPR№6-202 | 10-15 | 0,8-1,2 | 446 040 |

| SUAPR№7-202 | 15-25 | 1,2-2 | 486 160 |

When ordering SUAPR from 2 pieces, it is possible to provide discounts of up to 15 % and work under a contract with a partial deferred payment.

The shipment time of the SUAPR is 4 weeks. The approximate cost of delivering one SUAPR to the city of Taganrog is 4,000 rubles. The warranty period for the SUAPR is 18 months from the date of shipment. The economic efficiency of using the SUAPR. The experience of implementing SUAPR in residential and public buildings suggests that heat consumption when installing SUAPR is reduced: - administrative and public buildings by 23 % - 30 %; - residential buildings by 18 % - 25 %.

You can calculate the economic effect of using SUAPR for a specific building using a counter posted on the website www.suapr.rf

- Competitive advantages of SUAPR

— Block design, small size and weight, which ensures ease of installation and maintenance. SUAPR can be easily inserted into any doorway when assembled and can be placed in any basement. — Geometric dimensions and loads coincide with similar parameters of non-adjustable elevators, which allows installation without welding. — When installing a control system, a short-term (no more than 4 hours) disconnection of the building from the heat supply system is required, which allows work to be carried out during the heating season. — SUAPR comes with all the necessary settings for a specific object. If necessary, the SUAPR can be easily adjusted to the required temperature schedule. Highly professional specialists are not required for installation and operation of SUAPR . — The low cost of SUAPR and the minimum costs for its implementation provide this product with the fastest payback period.

Commercial offer

METHODOLOGICAL RECOMMENDATIONS (Principles of design and explanations for operation)

An example of an enlarged calculation for a residential building and an industrial facility. Cost of central heating = 750 Gcal per Year (heating season) Average tariff for the population = 1900 rubles per Gcal 750 * 1900 = 1,425,000 rubles per Year (heating season) Let's accept Savings with SUAPR = 17 % 1,425,000 * 0.17 = RUB 242,250 in year. Fill out the questionnaire and we will select the equipment.

QUESTIONNAIRE FOR THE MIXING UNIT OF AUTOMATIC WEATHER CONTROL (SUAPR)

Manual

Passport for SUAPR

ROSTEKHNADZOR, permission to operate SUAPR

Photos of SUAPR (packaging and installation at sites)

Relevance of automatic control systems for thermal energy consumption

It should be noted that steam-water heat supply is very specific and requires simultaneous solving of hydrodynamics and heat transfer issues; In addition, thermal energy is a special type of energy, its parameters must be controlled in both directions from source to consumer and vice versa, therefore we propose to consider the use of automatic control systems taking into account technical and economic priorities.

The economic sense of installing automatic control systems exists both without installing metering devices and after installing thermal energy metering devices.

In the first case, the regulation system, by regulating the consumption of thermal energy, significantly reduces the costs of heat supply organizations while consumers pay for heat at the approved tariff.

In the second case, consumers pay for the heat actually consumed, taking into account savings, which average from 10% to 30%. Household commercial heat metering devices are being installed everywhere. Installing heat meters alone cannot reduce the total costs of producing and transmitting heat energy. Indeed, if heat meters are installed everywhere, consumers will still pay all costs to the heat supplier.

There are large savings reserves in the social sphere: clinics, schools, public and administrative buildings, primarily because they have periods of absence of people in heated rooms, during which it is possible to set lower parameters for the provision of heat and hot water without disturbing comfort during working hours. time. Those. during commissioning of the control system, for example, at a school, it is possible to immediately establish an economical mode of heat consumption for this facility during the winter holidays.

In residential buildings, programmatic reduction of indoor temperature is not applicable. But it is possible to separately regulate the facades of one building under different conditions of exposure to sunlight and other climatic factors. For this purpose, dual-circuit temperature controllers are used, each circuit of which has the same control program introduced.

An important factor in energy saving for many objects is the elimination of autumn-spring overheating, when, for the purpose of preparing hot water, a coolant with a deliberately high temperature is supplied to the objects at positive outside temperatures, above the so-called “cut-off” point of the temperature graph. In houses where there is a boiler for preparing hot water, since during periods when there is no hot water being drawn, the coolant circulates through the boiler-heat exchanger in vain, also reducing its service life; in addition, changes in the parameters of the heat source propagate very slowly through the heating network, which is corrected by in-house temperature controllers . According to sanitary standards, different temperature conditions in rooms are required, and this is not always realized at the same coolant temperature. Taking into account all these factors, it is necessary to modernize heat consumption systems using modern systems of qualitative and quantitative regulation.

Ideally, there is an effect from the use of automatic control systems down to each heating device, riser, air heater, etc. Our more than many years of experience confirms the effectiveness of their use.

Saving heat, heating, heat supply.

How are savings achieved?

- The consumer himself decides when and how much heat to consume.

- Even distribution of heat throughout the house.

- Prevention of overheating and overheating in residential buildings and enterprises.

- No boiling of plate or shell-and-tube heat exchangers.

- Limiting the flow of excess coolant into the house.

- Increasing the service life of pipelines and heating systems.

- ITP control online, with notification of emergency situations.

- You don't pay for someone else's unused heating during the thaw.

Comfort of living.

- There is no need to use electric heaters.

- Drafts due to wide open windows and balcony doors are a thing of the past.

- The stuffiness in the apartment is not a nuisance.

- You no longer have cold batteries.

Automatic control system for heating and heat supply of the building.

The facility operates without permanent maintenance personnel, and information is displayed on the dispatch control panel or on a cell phone.

The remote control function allows you to change system settings from a distance and adjust its operation manually. See system parameters online.

Central heating points provide residents with heat year-round during the heating season. The main task of the ITP automated control system is round-the-clock monitoring and control of the supply of coolant with constant pressure, maintaining the set temperature in the room. For efficient service, information from actuators and sensors is collected and transmitted to a single dispatch console via wired (cable Internet) and wireless (cellular) communications. This allows you to monitor the operation of the ACS equipment of a heating point in real time and, if necessary, adjust the operating parameters of the equipment.

Heat, heating, heat supply regulators

.

Types of control devices

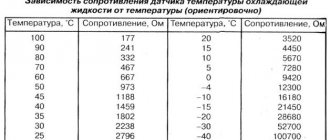

To ensure control of the temperature regime of the heat generator or consumer, the same device equipped with a temperature sensor is used.

These devices are divided into three categories, which can work either individually or in combination:

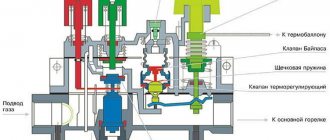

- Thermostat

. This device is the simplest control device in the heating system. Being located in a building, it monitors changes in air temperature. When the required temperature is reached, the thermostat sends a signal to the boiler or radiator tap, as a result of which the heating of the coolant stops or the flow of liquid to the radiator is blocked. Installing a thermostat yourself is not particularly difficult: just look at the photo, which shows the diagram of its connection and operation, to be convinced of the simplicity of this design. - Coolant temperature regulator

. Such a device can work independently or together with a thermostat. The design works due to temperature sensors that are installed inside the heating circuit. They constantly monitor temperature changes in the system and transmit this data to the control module, which controls the circuit's mixing valve. If it is necessary to increase the temperature, the controller can perform this task using a valve. - Weather-compensated automation of heating systems

. This type of device can be classified as the most complex, since such a system has to work not only with the heating circuit, but also with the environment, thereby ensuring the most accurate and rational temperature control.

The basic design of weather-compensated automation includes an outdoor thermometer, a thermal circuit controller and a thermostat located in the room. Despite the high cost, such a system is considered the most popular, since it is capable of providing maximum comfort that can only be squeezed out of heating. Weather-dependent automation of heating systems uses complex software systems that ensure maximum efficiency and cost-effectiveness.

Weather-dependent automation can be controlled either from its own remote control or remotely by installing the necessary software on a smartphone or tablet (more details: “

How to choose remote heating control - characteristics, capabilities

"). In this case, you can regulate the temperature in the house while being away from it.

Conclusion

Automation for heating boilers is expensive, but immediately after installation these devices will begin to save fuel, which will affect the economic situation after some time. In addition, it is the automatic temperature control system that allows you to ensure maximum comfort in the home.

Energy efficiency weather control of heating systems. 11/20/2017 1000

Weather control of heating systems Heating radiators are the most common devices for most Russian cities. They bring warmth into the house. We only notice them when the room is cold or hot. Meanwhile, the operation of the heating system in our homes is connected not only with the temperature and humidity in our living environment, it also affects our budget. Central heating system Fundamentally, central heating of houses is very simple. There is a boiler that heats the coolant circulating through the heating radiators in the house. They heat the air, while the coolant cools and returns to the boiler for heating. The system is divided into several circulation circuits. The movement of the coolant is provided by pumps. The most common coolant is water. The described scheme is simple and understandable to anyone. But for a large number of consumers it may not be effective:

In order to create the required comfortable temperature in the premises, control means are used in urban heating networks and individual circuits. They consist of circulation pumps, water and air heating sensors, adjustable valves and mixers

However, in addition to the listed influences, the operation of heating equipment is significantly influenced by weather conditions: temperature and humidity of the surrounding air, wind load. Stereotypes and misconceptions Without going into detail about the effect of various factors on the quality of solving the problem of providing heat in the human environment, it is difficult to imagine the importance of their influence. Therefore, in a non-professional environment, there are a number of common stereotypes and not entirely correct opinions:

Difficulties of regulation and control The structure of automatic control and regulation of heat flows in modern home heating means is quite complex

Networks are laid taking into account the number and types of consumers; they can be open - with the extraction of hot water from the system or closed - with coolant circulation only for heating devices. There are multi-circuit systems in which a heat carrier with different temperatures transfers energy to another carrier through a heat exchanger. However, even in the simplest system, automation of UTE control is associated with the need to solve a number of technical problems:

Oddly enough, the factor of system inertia with changing heat transfer parameters is the most significant reason for excess consumption of temp energy. At the same time, installing a UTE instead of a conventional meter does not solve the problem of energy-efficient heat management if weather factors are not taken into account. Modern opportunities in energy efficiency Existing technical means allow saving 25-35% of consumed thermal energy due to qualified control of temperature and circulation speed of the working fluid, taking into account weather factors. Basic elements to take into account weather changes:

To control parameters and establish effective modes, a large number of automation elements are required. This amount may seem too expensive. However, modern industry produces all the required devices and mechanisms in the form of serial products. Experience in using heating parameters control elements that take into account weather conditions shows a quick return on investment. The meter readings of the consumed thermal energy will reduce costs immediately after installation. The cost of purchasing the complex will pay off already in the first year of its operation, subject to competent installation and configuration. Some important aspects of the use of UUTE and metering devices A common house metering device installed in the central heating system only registers the amount of energy consumed by a residential building. Metering devices save homeowners' costs only by calculating calories, without reducing the actual volume of resources consumed. For full savings and building energy efficient consumption, one of the most significant aspects is the ability to regulate central heating parameters taking into account environmental weather factors. Such systems are somewhat more expensive than simpler analogues. But they pay for themselves faster, providing higher efficiency in the use of resources. ANK Group has extensive experience in implementing weather control at various facilities, we are confident that we can help you and carry out this work quickly and efficiently.

Heat control system functions

Functions of the heat consumption control system:

1) conversion of coolant parameters (pressure and temperature) coming from the heating network to the values required inside the building;

2) ensuring the circulation of coolant in the heating system (hereinafter referred to as CO);

3) protection of heating and hot water systems from water hammer and from exceeding permissible temperature values;

4) control of the coolant supply temperature taking into account the outside temperature, day and night temperature changes;

5) temperature control in the return pipeline (limiting the temperature of the coolant returned to the heating network);

6) preparation of coolant for the needs of hot water supply, including maintaining the temperature of the hot water supply within sanitary standards;

7) ensuring the circulation of coolant in consumer networks in order to prevent unproductive discharge of insufficiently hot water.

Get full description:

Weather controlled heating

Tired of paying more? There is a way out!

The weather control system for heat supply makes it possible to save up to 35% of heat energy consumption. If we assume that an apartment building (management company, housing cooperative, HOA) pays about 1 million rubles per month for heat supply during the heating period, then the residents will feel the savings in just four weeks!

Call 200-58-78 and in 10 minutes you will know more than in 3 hours of searching on the Internet.