Accompanying work when starting a gas boiler

Power is supplied, the heating regulator is set to the desired position.

The appearance of a hum indicates that the pump is starting to operate. Using a screwdriver, slightly unscrew the cap before water begins to leak out, then return the cap to its original position. This is done several times until the gurgling sounds disappear. The electric ignition of the boiler is triggered and it turns on. The pressure in the system is regulated by adding coolant. The system with circuits gradually heats up and enters operating mode. The effectiveness of the work depends on the accuracy of the preparatory stages.

Crimping

Pressure testing of heating pipes is carried out to identify possible leaks.

The procedure is carried out to detect leaks. Liquid or air is pumped into the system and a ten-minute break is taken, then the pressure gauge readings are checked. Constant values indicate the tightness of the circuits and connections.

Sometimes pressure testing is neglected, for example, due to the lack of a pump, but carelessness threatens to cut off the heat supply in the dead of winter. The procedure is repeated after the end of the heating season in preparation for the next one.

Washing

The process is intended to clean the system of debris. The taps on all radiators are opened, and containers are placed under them to collect water. A pressure of 4 bar is established in the system, the flow of liquid flushes the pipes and batteries from contaminants. In advanced cases, the procedure is performed several times.

There are 3 cleaning methods:

- Mechanical. Scale from the radiator is removed with a vacuum cleaner, scraper, or brush after soaking the elements in cleaning solutions.

- Chemical. Acidic solutions are pumped into the booster and driven for several hours. The method removes carbonate and ferrous deposits well.

- Hydrodynamic. Injecting liquid under pressure.

Flushing

How to clean the heat exchanger of a gas boiler from scale with your own hands? If there is a small amount of plaque inside, you can get by with manual washing using a citric acid solution.

If there is a thick layer of scale, you will need a washing unit that will circulate the detergent for several hours. A 10-liter tank with a pump is suitable for this purpose (you can use a circulation pump from the circuit). Two hoses from the pump are connected to two heat exchanger pipes.

There are three cleaning methods:

- mechanical;

- chemical;

- hydrodynamic.

In the first case, you can use a brush, scraper, or vacuum cleaner to remove plaque. Heat exchanger parts are pre-soaked in cleaning solutions.

During chemical treatment, an acid wash solution is pumped into the system using a booster and driven through a heat exchanger for several hours. Acidic solutions are good at removing ferrous and carbonate sediment. At the end of cleaning, the product is drained and a neutralizing agent is added.

The hydrodynamic method is the injection of water with abrasives into the system under pressure. In this way, the internal surfaces are cleaned mechanically, but the cleaning efficiency is higher than when processed manually. Flushing can be done without dismantling the system, but it is quite expensive. When cleaning yourself, you need to monitor the pressure in the circuits to avoid rupture of the heat exchanger.

Types and design of a gas boiler

The classification of boilers operating with gas is as follows:

- samples of floor and wall type. If we talk about convenience, then wall-mounted equipment, which is more typical for private buildings, would be more acceptable. The main advantage of a floor-standing unit is its much greater power, as a result of which it can be used to heat a room with a very significant area. Such models are very often used in production;

- gas boilers of atmospheric and turbocharged type. To understand how gas heating with an atmospheric boiler works, you can recall the principle of operation of a standard stove, where air from the room enters a specially designed chimney due to natural draft. Turbocharged devices are equipped with a fan, which is included in the design, and the fuel combustion chamber is completely closed, so all the required amount of air comes from the street (more: “How does a turbocharged gas boiler work - principle of operation, advantages and disadvantages”);

- mechanisms with one and two circuits. The design of a gas boiler with one circuit is designed so that this equipment is used exclusively for heating rooms, while devices with two circuits can also play an important role in the water supply system, providing the room with hot water;

- boilers equipped with a conventional burner or a modulating burner (for more details: “What are the types of gas burners for heating boilers - types, differences, rules of use”). In the second case, the power of the operating equipment is automatically regulated, due to which fuel costs can be significantly reduced;

Combustion products and the cause of their occurrence

- soot;

- resin;

- tar.

The reasons for the appearance of these substances are the following important points:

- Causes of soot:

- there is not enough oxygen for the combustion process;

- Fuel combustion temperature is too low.

- Factors influencing the appearance of resin:

- low-quality fuel is used;

- the fuel material has a high degree of humidity;

- the boiler operates at low temperature;

- Too much fuel is loaded into the firebox.

- Tar appears in the following cases:

- weak air flow into the combustion chamber of the pyrolysis boiler;

- incorrect design of the unit;

- low height chimney.

As we can see, the main reasons for the appearance of harmful substances are poor fuel and the technical aspects of organizing the combustion process.

Experts advise: use only high quality fuel - otherwise the wear and tear on the boiler will rapidly increase.

Starting the floor-standing unit

Preparations for starting a floor-standing boiler are carried out in the same way. The startup process itself goes like this:

- make sure that the power knob and temperature regulator are in the “Off” position;

- open the gas supply valve;

- turn the power knob to the “Ignition” position and press it. Hold the pressed position for several seconds (this is necessary so that the gas has time to displace the air accumulated in the tube), then press the “Piezo Ignition” button;

- release the control knob and make sure there is a torch on the pilot burner. If there is no torch, you need to try again, slightly increasing the holding time of the control knob in the pressed position;

- Set the coolant temperature adjustment knob to the desired position, after which the main burner will automatically start.

The first start-up of the gas boiler after installation must be carried out by service center specialists. If the consumer performs this procedure independently, he will not be able to obtain a warranty for the heating unit. However, the owners need to know how the boiler will start up, since shutdowns of the unit are possible during operation.

Possible problems

It happens that the boiler lights up, but quickly goes out. Before proceeding with the repeated ignition procedure, it is necessary to find out the reason that leads to the extinguishing of the burner. Most often, this happens:

- in the absence of normal draft in the chimney;

- insufficient gas supply pressure;

Modern boilers are equipped with a complex automation system, so the reason that the boiler lights up and then goes out is a malfunction of the automatic systems. So:

- If the burner goes out almost immediately after ignition, then you need to check whether the photocell installed on the flame sensor is covered with soot. To eliminate the malfunction, it is necessary to clean the sensor;

- if the sensor that controls the gas draft in the chimney fails, the boiler cannot be started, the automation will block the gas supply;

- The reason for shutting off the gas supply may be a faulty thermocouple or a failed sensor that controls the coolant pressure.

Modern heating units are equipped with a liquid crystal display, which displays an error code when a malfunction occurs. Explanation of error codes can be found in the technical data sheet of the equipment.

If no information is displayed on the display, then the cause of this malfunction is most likely a blown fuse or an incorrect connection to the electrical part of the boiler.

The first start-up of a newly installed gas boiler should be carried out by a specialist performing commissioning work. If the first start-up is carried out by the consumer independently, then it will not be possible to issue a warranty for the heating equipment, so you should not neglect the need to call a specialist from the service center. In the future, it will be possible to ignite the unit after stops without the involvement of professionals. But first you need to study the instructions and strictly follow the instructions given in it.

If there is no result, do not go into the transformer

If there is no ignition in a gas boiler, the reason may be in the system itself or in the gas supply being cut off or the filter being clogged . If the equipment runs on electricity, there may be no voltage in the network. It is not recommended to repair breakdowns on your own without the appropriate skills. It's better to consult a specialist.

After purchasing and installing a new gas unit, inexperienced users may have a question about how to light a gas boiler. Please note that the first start-up should only be carried out by a gas service specialist. He can also give some recommendations on how to turn on and subsequently operate the unit.

Features of turning on a gas boiler

How to turn on a gas boiler? When starting, follow the rules specified in the passport and take into account the operating features listed below.

How to start a gas boiler? We list the main most important features:

Particular attention should be paid to the fact that it is recommended to fill the coolant at positive room temperatures. Otherwise, traffic jams may form.

Therefore, carefully check what the temperature is in the rooms and house, whether there are frozen sections of pipelines in winter. We start the boiler itself strictly according to the instructions, maintaining the required amount of time while holding the start button, otherwise it may not start. For different models, the passports always describe in detail the startup procedure. Be especially careful when working with gas equipment, as this is a very dangerous type of fuel, characterized by a low odor and a high explosion hazard. Do not neglect safety measures when working with the device, do not violate the procedure for working with it. At the slightest deviation from normal operation, immediately carry out measures to repair and adjust the equipment, including calling a specialized technician. Observe the requirements for the installation of the boiler room and ventilation. Your safety in the house directly depends on this.

To summarize, we can say that a gas heating system is currently one of the most popular devices from autonomous heating sources. The economic component is always of interest to the common man. Utility costs take up a significant part of the family budget. The growth of tariffs, with annual indexation, leads to a gradual increase in the level of prices for services to the population.

The consumer tries to find any opportunity to reduce these costs. The cost of natural gas is currently low compared to other energy resources. Therefore, it is profitable to gasify houses and install a heating system that runs on gas. Even if you have to spend a lot of money on it during construction, installation and commissioning, it always pays off later.

Is it legal to turn off heating in winter for scheduled work?

Debt to the supplier. In other words, power cuts for non-payment. This reason worries consumers the most, since there are many nuances with turning off debtors’ electricity.

The Investigative Committee of the Russian Federation knows of several dozen cases where, under the guise of employees of a management company, fraudsters tried to “strip” money from citizens. One of the cases occurred in Moscow, when two men went to apartments in residential buildings and informed citizens about their debt. If the residents themselves were sure that they did not have any debts, they showed the receipts, after which the “employees of the management company” apologized and referred to the fact that the payment apparently had not yet reached them. For the rest, who doubted the existence of a debt trap, the men offered to pay on the spot or they would immediately turn off the power.

Dear readers! Our articles talk about typical ways to resolve legal issues, but each case is unique.

In this article we will try to answer these questions. This article will also discuss the reasons for power outages, rules for power outages, legal or illegal power outages in various situations, the procedure for turning off electricity for debts and many other issues.

Exceptions to this rule are established by the above laws and government regulations. All other cases of turning off electricity, except those given in the listed documents, are illegal.

The electricity went out, the boiler automation stopped working, the fuel pump stopped circulation. In this case, the liquid in the heat exchanger continues to be heated by the remaining fuel in the burner and the temperature of the heat exchanger itself. Boiling of the liquid causes damage to the heat exchanger itself or the heating pipes.

Today it is impossible to imagine our life without electricity, but this remains only loud words until the light in the apartment goes out at the most inopportune moment. To prepare for power outages, you need to know why they happen and what to do in such situations.

How to remove air locks

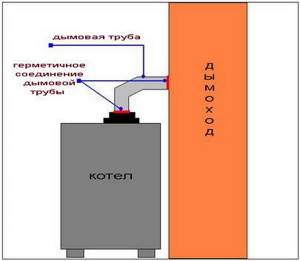

Diagram of the correct location of the boiler and chimney.

Simply connecting the system by filling it with water is not enough. It will not work or its effectiveness will become extremely low. To carry out a full first start-up of the equipment, it is necessary to bleed all the air that has accumulated in it from the system. A modern gas boiler may have a special system for automatically releasing air when filling, but the efficiency of such systems is low. This means that manual bleeding of the main and other systems is required during connection. Only after this can you start.

Removing air pockets during connection is carried out not only in the circulation pump, boiler, but also in all heating radiators. In this case, it is recommended to start the process with radiators. Especially for this purpose, they are equipped with so-called Mayevsky taps, which you simply need to open by placing a basin under them. At first, a slight whistle will be heard - this is the air gradually leaving the system. If the plugs are removed, water begins to flow. If the batteries are free of air masses, then the taps must be closed. This simple procedure is carried out with each radiator; it must be checked and cleared of plugs. When air has been removed from all radiators, the pressure gauge needle will be set to the desired value. Before turning on the gas boiler, you need to add coolant to the system, that is, feed it with liquid.

Next, you need to completely remove all air pockets from the circulation pump, which requires disassembling some parts of the boiler. This work is simple, you just need to remove the front panel of the boiler, and then find a cylindrical part that has a lid in the middle of the body, it has a slot for a screwdriver. The boiler must be started, that is, power must be supplied, and the heating regulator must be set to the required operating position. After this, a faint hum will be heard - this will start the circulation pump. You can hear gurgling and other sounds. Using a screwdriver, you need to slightly unscrew the lid of the found part; this should be done until water flows out. As soon as the liquid begins to seep out, the lid must be screwed back on. This procedure needs to be carried out 2-3 times, after which the air pockets will completely leave the system, the sounds and gurgling will disappear, and the pump will begin to operate quietly. Immediately after this, the electrical ignition of the equipment will work, and the gas boiler will begin to operate independently.

The pressure in the heating system must be equalized by adding water to the required level. The system gradually warms up and begins to enter normal operating mode. Connection and first start-up for any heating equipment is a complex and demanding process. How effective the heating will be depends on proper preparation, startup, and adjustment of the system.

Working with AOGV

It begins when the gas supply is blocked - the corresponding valve closes. And this is a general principle for similar work with any boilers and columns.

How to clean the burner of an AOGV gas boiler? After shutting off the gas, this element is removed from its position. The burner has a nozzle

It is carefully unscrewed and carefully cleaned with a brush. The burner itself is cleaned by blowing using a special pump

Then the nozzle and burner are returned to their place.

These are general criteria. And the details are presented on the next two models.

First. AOGV 11.6-3. This is a reliable and practical device.

But after a certain period of operation, it is thoroughly cleaned. The process goes like this:

The burner block is removed

To do this, the pan of the apparatus is rotated, and three tubes are disconnected from the automation unit: contact, gas and thermocouples. Carefully unscrew the nuts located on the fittings of the automation mechanism. The paronite gasket on the main gas pipe is removed and its conditions are studied. If it is damaged, it needs to be replaced. The marked pallet is taken out through the groove, which is as close as possible to the tubes

The casing is also pulled out along with it. When fixing the lower part of the tray, point it towards you and remove the remaining holders (two pieces) from the engagement. This entire assembly falls to the floor. The main burner is examined and cleaned. The igniter nozzle is inspected. The wick and thermocouple are unscrewed. The box-shaped casing is separated from the pilot burner. This clears the way to the nozzle. If it is brass and there is plaque on it, it can be removed with fine-grained sandpaper. Cleaning the nozzle. To do this, thin copper wire and a blowing method under high pressure are used. The second action is carried out by a special pump on the side where the tube is connected to the tee. The same sandpaper is used to very carefully clean the bend of the thermocouple tube.

After this work, all the parts are assembled using the reverse algorithm. Smoothly, avoiding distortions, lift the entire block. The burner should be inside the housing, and the igniter and thermocouple should not touch the casing flange.

From the side of the tubes, the entire assembly should be tilted towards itself with a slight downward slope. The opposite side of the tray should rise.

Then feed it forward and simultaneously put on a pair of distant holds. They should be on the casing flange. The nearest hook goes to a cut groove. After it enters there, the entire pallet rotates in the opposite direction to the clockwise direction. The gas pipe should be positioned only under its branch pipe of the automation unit.

Next, it is tested how correctly the gaskets fit, and all the tubes are returned to their places. The wrench tightens the nuts on two tubes: the igniter and the gas tube.

Before reassembling the thermocouple tube, its contact areas are carefully but carefully cleaned. The nut here is tightened with your fingers.

The final stage is to check the tightness of all connections for potential leaks. If they are absent, the boiler turns on. If available, these places are covered with sealant, the nuts are tightened.

The second model is AOGV-23.2-1 Zhukovsky.

It works like this:

- The nut is unscrewed so that the gas pipe passes through.

- The angle, igniter and thermocouple are unscrewed.

- All burners in the set stretch outward and extend to the side towards the user. If there are difficulties with their movement, loosen and unscrew the studs with pliers. Clean all jets and other components.

- Disassembly of burners. To do this, unscrew 4 pins on both sides.

- The plates with slots are removed from the top of the burners, then the springs. All parts are thoroughly cleaned.

- Reassemble all elements in reverse order.

After reassembly, a leak test is carried out to examine how tightly the burners adhere to the body.

Removing air pockets

Boilers may have an automated air removal system, but often it does not work fully. Therefore, it is better to bleed the air manually. This is necessary for the boiler to operate smoothly.

Air must be bleed from the circulation pump, the equipment itself and from all radiators of the heating system. Start with the last one. Drain the water from them into a basin by opening the Mayevsky taps. The release of air from the system will be accompanied by a slight whistle. As soon as water flows, the plugs are removed. You can close the taps.

Mayevsky's tap prevents water from leaving the heating system

After cleaning all radiators, the pressure will drop. It needs to be raised to normal.

The next step is to remove air from the circulation pump. To do this, you need to disassemble several parts of the boiler.

- Remove the front panel of the boiler.

- Inside, find a cylindrical part with a cover with a slot for a screwdriver.

- Start the boiler and set the heating regulator to the desired operating position. You will hear a faint hum - the circulation pump has started working. Sometimes this process is accompanied by gurgling and other sounds.

- Remove the cover from the cylindrical part using a screwdriver.

- As soon as water starts leaking, screw the lid back into place.

- Repeat this 2-3 times. After this, extraneous sounds should disappear and the pump will function silently.

After all the procedures have been correctly completed, you can light the boiler and it will start operating in normal mode. Equalize the pressure to the desired level again to ensure the boiler operates correctly.

The first start-up of heating equipment is a simple process, but it must be taken seriously and responsibly. Don't ignore the rules. The entire operation of the heating system will depend on their exact execution.

Peculiarities

In order to turn on a gas boiler, you need to know its structure well, as well as its system features.

The first step is to consider the design of a standard AGV.

- Boiler equipped with an autonomous gas heater. This is a tank that is located in a casing.

- The pipe that is inside this tank. Gas combustion occurs in it, due to which the water is heated. The combustion products that are formed inside come out through the chimney.

- Heating devices. For example, hot water flows into the heating circuit. Then it circulates through all the pipes. When the water cools, it is sent back to be warmed up. All this is a closed gravity heating system.

- An expansion tank that is installed on top, above the gas boiler. It allows water, which expands when heated, to rise to the top.

- Pump. It is located behind the gas boiler, which allows you to efficiently pump water through the entire system. The speed of coolant movement throughout the system can be increased or decreased. All these processes are controlled using automation.

Such heating devices have both disadvantages and advantages.

Among the advantages, the following points can be noted.

- AGVs are safe and reliable in operation, completely independent of electricity, and have the ability to install automatic locking.

- They consist of different types of water heaters. This includes both floor and wall structures.

- Such units are quite simple, easy to repair and maintain.

- They are not very expensive, and besides, such models are very economical.

Installation

The outer part of the chimney and the part located in the attic must be thermally and waterproofed. It is necessary to install an inspection in the chimney designed to collect debris that has entered the chimney.

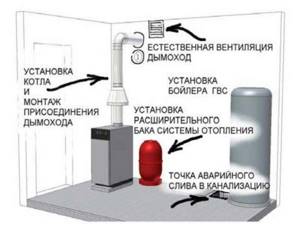

Modern gas water heating installation.

Gas heaters can be connected to the gas pipeline and registered only by representatives of the regional gas industry. It is imperative to thermally insulate the pipeline through which the coolant will flow to the radiators. But it is not necessary to subject the return circuit to this procedure. If the house uses a heating circuit with natural circulation of coolant, the device should be mounted below the place where the radiators are installed. It is recommended to install it in the basement.

Installation of harness

In the process of installing gas heating, it is important to correctly set the angle of inclination of horizontal sections of the pipeline. The requirements include 1 cm of slope per 1 m of pipeline length

This allows for more efficient fluid circulation, reducing the likelihood of air locks. Providing the required slope will help drain water from the system if it is intended to preserve or repair individual elements.

AGV installation process.

The heating system will have a shorter service life if the temperature exceeds +50 °C, as this will cause condensation to form on the walls of the pipes and boiler. To improve the performance of systems using gas heat sources, heating can be supplemented with a circulation pump.

Related Posts

- Connecting and calculating a buffer tank to a solid fuel boiler

- Gas boiler aogv

- Turbocharged or atmospheric gas boiler? which one should I take?

- The operating principle of a double-circuit gas boiler. classification and advantages

- Types and principle of operation of a gas boiler for heating a private house

- How to make steam heating

- Hydroarrow: principle of operation, purpose and calculations

- Why does a gas boiler go out: what could be the reasons and what to do if it turns off

- How to reduce the power of a gas boiler: the best options to reduce gas consumption by the boiler

- Combined heating boilers with wood and gas

- How to correctly calculate the power of a gas boiler

- A supply of hot water that is always at hand: how does an electric water heater for heating work?

- Characteristics and principle of operation of an induction heating boiler

- Ariston double-circuit gas heating boilers

- How to choose and install an air valve for heating

- The best electric boiler for heating a home according to customer reviews

- Thermal accumulators for autonomous heating systems

- How to choose a wood-electricity combi boiler

- Installation and installation of a solid fuel heating boiler

- Connection diagram for double-circuit gas boilers to the heating system

- Remote control of the boiler: gsm, internet and other automation options

- Thermal relay with remote temperature sensor: operating principle

- Economical heating of a private house and apartment

- Leningrad heating system for a private house

- Uninterruptible power supplies for heating boilers of any type

Read with this

- Connecting and calculating a buffer tank to a solid fuel boiler

- Gas boiler aogv

- Turbocharged or atmospheric gas boiler? which one should I take?

- The operating principle of a double-circuit gas boiler. classification and advantages

- Types and principle of operation of a gas boiler for heating a private house

- How to make steam heating

- Hydroarrow: principle of operation, purpose and calculations

- Why does a gas boiler go out: what could be the reasons and what to do if it turns off

- How to reduce the power of a gas boiler: the best options to reduce gas consumption by the boiler

- Combined heating boilers with wood and gas

Pressure testing and washing

Pressure testing is not always done due to the lack of a special pump and the reluctance to call a team, but if the heating fails in the midst of cold weather, the costs can be much higher!

It is especially important to check a new system and one that, on the contrary, has been in use for several years. The cost of crimping in construction companies is from 3000 rubles

Additionally, they may charge a fee for visiting the site (about 2 thousand rubles). By the way, a manual pressure testing pump will cost 4.5 – 6 thousand rubles

The cost of crimping in construction companies is from 3,000 rubles. Additionally, they may charge a fee for visiting the site (about 2 thousand rubles). By the way, a manual pressure testing pump will cost 4.5 – 6 thousand rubles.

Causes and consequences of clogging

Energy-dependent ones are in turn divided into:

- gas processing;

- electrical installations;

- solid fuel and liquid fuel equipment;

- combined models.

Volatile boilers may turn off for a number of reasons:

- voltage drops and surges in power lines

- lack of electricity

- factory settings failure.

Often used in homes: AOGV, Zhukovsky boiler, gas “Ochag”, Lemax, Signal, Conord.

Do-it-yourself furnace: drawing, operation diagram. Read here.

Connection to the city water supply network: documents, prices:

Mechanical ones may work intermittently due to wind flow entering the chimney. In addition, due to insufficient oxygen, the flame may go out

You should pay attention to the hood (cheaper models do not always have it)

If the chimney becomes dirty, modern devices have a warning system that will notify you of problems and the need for cleaning.

Classification

There are a huge number of types of this equipment, which allows you to choose the one that suits you in all respects.

Table: types of gas boilers

| Number of circuits | By traction method | By ignition type | By installation method | By power modulation | |||||

| Single circuit: heating only | Double-circuit: heating and hot water supply | Natural traction | Ventilation draft | Electronic ignition | Piezo ignition | Floor-standing | Wall mounted | Single stage | Two-stage |

The gas boiler can be located on the floor and wall

Floor-standing boilers differ from wall-mounted boilers in a wide range of power adjustments. With this equipment you can heat a room of 200 m2. If you connect a boiler to it, you can also provide yourself with hot water.

A wall-mounted gas boiler will fit perfectly into any interior

A single-circuit boiler can heat one thing: either the coolant, or the heating system, or the hot water supply. When using a dual-circuit system, you can simultaneously connect space heating and hot water supply.

Boilers with natural draft are distinguished by the fact that combustion products are removed using constant inflows of street air. They are often used to heat non-residential premises and small houses. In boilers with ventilation draft it is forced. In them, combustion occurs in a closed chamber. The special chimney is equipped with external and internal pipes through which air is drawn in. They do not burn room oxygen and do not require additional air flow to support combustion.

In the room where the gas boiler is located, the ventilation system should be well thought out

For equipment with an electronic igniter, the switching process is automated. Such models are more economical than boilers with piezo ignition, since they do not have a special part with a constantly burning flame. If the power supply is interrupted, the equipment stops functioning, but automatically resumes operation when power returns.

Boilers are also classified according to energy efficiency:

- condensation;

- convection

The latter do not form condensate, which can dissolve acids located on the walls of the device. But the heat transfer in it is lower.

How do condensing devices work?

In conventional appliances, combustion products bypass the heat exchange surfaces and release part of the energy to the working environment of the heating system. Exhaust gases are discharged through a conventional chimney. In this case, a certain part of the heat is lost in the form of water vapor that appears during fuel combustion.

The operating principle of condensing gas boilers is somewhat different. The devices are capable of using the latent energy of water vapor. They are equipped with a blower fan that has a variable speed. In this regard, the combustion chamber is closed. Exhaust gases are discharged using a coaxial chimney.

Variable fan speed allows you to adjust the ratio of gas and supplied air. The condensing boiler does not function at its maximum efficiency in all cases. In order for the device to operate in economical mode, it is necessary to maintain the temperature of the coolant in the return pipeline less than 57 degrees.

The efficiency of the condensing device increases with decreasing operating temperature of the heating system. In other situations, the effectiveness is slightly reduced. Therefore, such a device is appropriate when used with heated floors, where the operating temperature range ranges from 40-45 degrees.

Unlike a conventional boiler, the condensing analogue has a larger heat exchanger area. In it, exhaust gases are cooled to a temperature below 40 degrees. The condensation process occurs directly in the heat exchanger, so it is made of corrosion-resistant materials.

Accompanying work when starting a gas boiler

The first start involves pressure testing and flushing the system. Many specialists bypass this stage, but it is still recommended not to abandon it. In order to carry out all further operations, it will be necessary to use a pressure pump. The system is tested to determine the strength and tightness of all components and connections of the system. During pressure testing, the system is checked for leaks. Pressure testing can be done with a water column or compressed air. To do this, pump water under pressure equal to one and a half times the operating pressure, after which the system must remain at rest for 15 minutes. Then the operating pressure should be restored. If the pressure gauge shows a decrease in pressure during pressure testing, this means that a leak has formed somewhere. Defects should be eliminated by repeating the crimping process.

Next, you should start flushing the system; this is considered an indispensable process that should accompany the first start-up of the unit. Initially, a rough flush should be performed, which will remove light suspended matter. The washing process must be carried out at a pressure of 4 bar. Finish washing will be the second stage, for which injection pumps should be used. There is a possibility that the filters, which are installed directly in front of the boiler, will become clogged. If this happens, you should close the shut-off valve and clean the filter after disassembling it.

Possible breakdowns of a gas boiler

There is such a problem: after you release the start button, the igniter goes out. This malfunction is associated with a breakdown of the gas boiler automation system. But under no circumstances should you use the boiler with the automation switched off. This is due to the fact that if the flame goes out due to a strong air flow or if the gas supply is unexpectedly stopped, the gas supply may begin to flow into the room.

Thus, the igniter flame begins to come into contact with the thermocouple. The thermocouple heats up in 30-40 s, and an emf appears at its terminals. It is enough to trigger the electromagnet. Thus, the rod is fixed in the lower position. After this, you can release the start button.

The draft sensor is located in the upper part of the gas boiler, next to the pipe for discharging combustion products into the environment. Such a device consists of a contact and a bimetallic plate.

If a pipe becomes clogged, its temperature rises sharply. The bimetallic plate begins to heat up and the voltage supply circuit to the electromagnet breaks. Thus, the stem cannot be held by the electromagnet and the valve closes. This means the gas supply will stop.

Commissioning of a floor-standing boiler

Introductory information

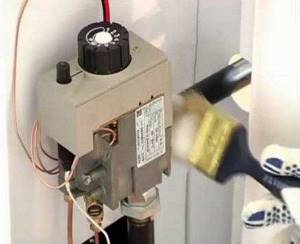

Automation EuroSit 630 is a multifunctional device that regulates the gas supply. It provides the ability to regulate the temperature and completely turn off the main burner.

Purpose:

- automatic adjustment of gas supply;

- control of the safety of gas equipment.

It is worth noting the difficult method of turning on the device. In his defense, we can say that in this way the manufacturer was concerned about the safety of its consumer and the safety of gas equipment.

Start of a gas boiler

The operation of a gas boiler begins with the start of the automation. In the situation of using the 630 EuroSit valve, the startup process will consist of several stages. They should be performed in accordance with the established order:

- turning on the tap on the riser;

- turning on the pilot burner;

- turning on the main burner;

- temperature adjustment and setting.

Step-by-step description of the startup procedure

The first step is to turn on the gas supply to the system. To do this, you need to open the tap on the riser.

Now you can start working on the gas valve. To do this, you need to concentrate on the control handle of the device. Initially, it is located in the “off” position. It must be moved to the “ignition” position (image of fire on the regulator). After this, you need to press the handle so that the forced supply of gas to the pilot (ignition) burner begins. Now you should press the piezo ignition button while continuing to hold the handle pressed. The presence of a flame on the pilot burner indicates that everything was done correctly. The handle should be kept pressed for the next ten seconds after pressing and while checking for the presence of flame. This must be done to start the gas boiler mechanism.

After ten seconds, you need to release the control handle and check again for the presence of a flame on the pilot burner. If there is no flame on the burner, then all the operations described above should be repeated. In this case, you will have to increase the time you press the control handle.

If there is a flame on the pilot burner, then you can proceed to ignite the main burner. To do this, the control handle must be moved to position from “1” to “2”, turning it counterclockwise. The correctness of the actions will be indicated by the appearance of a flame from the main burner. After making sure that it is present, the control handle can be moved to positions from “1” to “7”. The position must be selected based on the coolant temperature needed to be obtained. In the situation with the EuroSit 630 model, the number 7 on the handle corresponds to a temperature of 90 degrees. This is the maximum possible value for the model. By following all these steps, starting the gas boiler will go without problems.

Disabling a device

To turn off the gas boiler, you must turn off the gas valve. There are two shutdown options:

- turning off the main burner;

- turning off the main and pilot burners.

In the first case, the control handle must be turned clockwise and set in the “ignition” position. The main burner will then be switched off, but the pilot burner will continue to operate.

In the second case, the same control knob must be turned clockwise until the “off” position is reached. These actions will stop supplying gas to all burners. A click will sound to confirm that the device is turned off. The flame will also disappear. The gas supply has now been stopped.

Review of popular models and manufacturers

The market for advanced gas equipment and related elements includes automation from both domestic and foreign manufacturers. According to the principle of operation, all devices are absolutely identical, but in terms of design there are significant differences between them.

The presence of automatic control in the gas heating system makes it possible to comfortably heat the room and rationally use energy resources. With a reasonable approach, savings can range from 30 to 43%

The cost of modules varies over a wide range. Simple mechanical products with a minimum of functions belong to the budget class and are sold at the lowest price. Advanced electronic panels are valued much higher, but provide the user with more extensive options for individual settings and control of operation.

Some devices, such as SABC automation, in addition to basic functions, are equipped with a built-in pressure stabilizer. This allows for more precise adjustment of the operation of gas equipment

Programmable electronic devices are considered luxury. They enable the owner to set an operating plan for the equipment for a long period of time, taking into account seasonal weather conditions and the current outside air temperature.

No. 1 - automatic EUROSIT 630

The automatic non-volatile unit EUROSIT 630 produced by the Italian company Sit Group (Eurosit) occupies a leading position in the market in terms of sales.

It is considered universal and works effectively with parapet and floor-standing boilers with a power from 7 to 24 kW. Switching on/off, igniting the pilot burner and setting the desired temperature are carried out using one handle with a button.

The Eurosit 630 module is a modern unit for controlling gas equipment. Fully complies with international standards and safety requirements for such devices. Has a European quality certificate and a guarantee from the manufacturer

The product is characterized by a high level of reliability, can withstand significant operating loads and has extensive functionality. The structural elements are “hidden” in the housing, to which sensor cables and other connecting tubes are routed.

The ignition time of the heating boiler using the Eurosit 630 automatic system is 10 seconds. Gas is immediately supplied to the system and very soon the room warms up to the set temperature

Inside the unit there is a cut-off valve, a spring valve and a pressure regulator. The gas supply is carried out from below or from the side according to the user’s wishes. In terms of cost, the unit is included in the budget category.

No. 2 - Honeywell 5474 module

The Honeywell 5474 device is manufactured by the German concern Honeywell , which has been specializing in the development and sale of various types of automation for more than a hundred years. Works correctly with domestic gas boilers with a power of up to 32 kW.

Honeywell 5474 is a non-volatile device for controlling the heating system. Equipped with micro-torch burners made of heat-resistant stainless steel. They ensure better gas combustion, reduce the emission of harmful substances into the atmosphere and prevent excess soot from depositing in the chimney

The Honeywell 5474 automatic system is equipped with a basic set of control functions that guarantee efficient operation of the boiler with absolute safety for users.

In automatic mode, the product maintains the specified coolant temperature (from 40 to 90 degrees), turns off the boiler in the event of a fuel supply cutoff, lack of draft at the required level in the chimney, reverse draft occurs, or burner extinguishment.

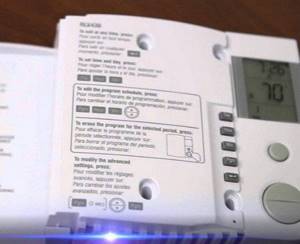

No. 3 - premium automation from Honeywell

In addition to inexpensive budget models, Honeywell also produces other types of automatic equipment, for example, luxury chronothermostats of the premium ST series or programmed thermostats Honeywell YRLV430A1005/U.

The YRLV430A1005/U device, with the widest possible functionality, has a user-friendly interface and does not cause any difficulties for customers during use. The cost of the product is quite high, but still lower than that of competitors offering models with similar characteristics

These electronic panels allow you to set the heating equipment the most detailed and precise settings, up to changing the temperature several times a day depending on the time of day, weather conditions and personal wishes.

No. 4 - Orion device

The Orion automatic device is manufactured in Russia. The device includes a piezoelectric ignition and a draft sensor.

The Orion device looks simple and has a minimal set of functions. Its capabilities are not too great, but, thanks to its reasonable price and basic control method, the unit is in demand

The device turns off the gas in case of random extinguishing of the burner or lack of the required draft. When the room temperature drops, the thermostat activates the fuel supply and the boiler resumes operation.

The transition to the flame reduction mode when a certain (user-specified) temperature is reached occurs automatically and allows you to save fuel resources.

Preparatory stage

Before starting the heating unit, it is necessary to carry out a number of preparatory work, including:

- filling the heating circuit;

- eliminating air jams;

- additional check of equipment serviceability.

Filling the system

If a modern gas boiler is installed, then the process of filling the heating system circuits is not particularly difficult. For this purpose, a special pipe is used, to which the coolant supply is supplied. After opening the tap, the circuits will begin to fill with water.

The condition of the heating system is monitored by special devices - pressure gauges. The readings of these devices allow you to monitor the operating pressure in the system. After the pressure gauge shows a pressure value of 1.5-2.0 atmospheres, you will need to stop the coolant supply.

Removing air

The presence of air pockets does not allow the coolant to circulate freely in the system. Many models of modern boilers are equipped with a device that allows you to automatically release air trapped in the system.

But often the operation of such devices is not efficient enough. Therefore, experts recommend venting air from radiators and the circulation pump. To remove air pockets from radiators, the latter are equipped with Mayevsky taps. To remove the blockage, you must:

- place any container under the tap;

- open the tap;

- bleed the air until water begins to flow;

- Close the tap.

This procedure must be done with each heating radiator.

A more complex operation is to bleed air from the circulation pump; for this you need to:

- remove the lid from the boiler;

- find where the pump is installed, it looks like a cylinder with a cover with a slot;

- put the boiler into operation (how to do this will be described below);

- when the unit is turned on, the circulation pump will also begin to operate;

- if this unit is air-filled (and this usually happens if the first start-up is carried out after filling the system with water), it will make gurgling sounds during operation;

- Using a screwdriver, you need to carefully begin to unscrew the lid with the slot;

- first, air will begin to come out from under the lid, and after the water flows, you need to screw the lid back;

- if the gurgling sounds do not stop, then you need to repeat the operation;

- after the air lock is eliminated, the pump will operate quietly and the boiler will go into operating mode.

additional verification

Before starting the unit, you must:

- make sure that the gas pipeline is sealed, that is, the meter does not record gas consumption when the gas valve on the unit is closed;

- check whether the automation system works, turning off the boiler in the event of an emergency;

- check for traction.

If at least one of the above conditions is not met, the launch cannot be performed.

Briefly about the operating instructions and setup

The operation of Conord gas boilers is not particularly difficult, since the units have a durable and reliable design and are resistant to loads and external influences.

However, to improve working conditions, several simple procedures should be followed:

Install a strainer in the gas line to prevent fine metal dust and scale from entering the burner. Use water softeners or filters

This is especially important for residents of regions with hard water. On the return line of the heating system, it is necessary to install a filter that retains scale, slag and other debris that is present in the system. This will protect the heat exchanger from clogging and increase the service life of the boiler.

Compliance with these simple requirements will save the user from having to clean and repair the boiler once again.

Setting up the unit is not difficult - all communications are connected, the strength and tightness of the connections are checked.

Then the operating mode is set and the burner is ignited using a piezo ignition system or a regular match.

Preparatory stage

As a rule, in warm weather the heat supply structure is not used. Therefore, before starting heating in a private house, it is necessary to ensure the integrity and reliability of its elements and carry out a number of preparatory work. Before using a closed heating system, you need to determine the amount of deviation of its actual indicators from the calculated parameters.

According to the rules, preparation for the heating season is carried out in a certain sequence. First of all, a visual inspection of communications and heating equipment is carried out. For the property owner, the first question should not be how to put the radiator into operation. First of all, he needs to make sure that there is no mechanical damage to the device body and check the reliability of its connection to the pipeline.

Also, before starting the heating system, a number of preventive measures are carried out:

- Checking the condition of the smoke exhaust system. To start a boiler, there must be sufficient draft force in the chimney to maintain combustion. For this reason, the internal cavities are cleaned of soot and the integrity of the pipe is inspected. In a brick structure, if necessary, replace damaged elements. Rust, if any, is removed from galvanized pipes.

- Visual inspection of pipes. Without this, running the heating system is dangerous. You need to find out how tight the pipes are and whether there are any cracks or noticeable defects.

- Battery condition monitoring. Before starting heating in an apartment building, the management company must warn residents about this, and they must check the integrity of the radiators. You cannot disconnect individual devices from the heating network. When filling the pipelines, make sure there are no coolant leaks.

This is a list of rules without which the first start-up of the system should not be done. In order for the heating season to start correctly, a number of measures must be taken. A test run of the heating system in an apartment building is carried out 1–2 months before heating starts. It is best for property owners to stay home during this time to ensure there are no leaks.

What type of burner do you prefer?

Some types of devices were developed specifically to solve such a complex problem as quickly boiling water in difficult weather conditions. These burners are ideal for cooking freeze-dried food. The special design of these systems minimizes fuel consumption, which makes them very profitable. The special manufacturing technique of these devices determines their focus on maximizing the acceleration of the process of boiling water.

Integrated cooking systems are ideal for quickly boiling water. However, their main disadvantage is that it is extremely difficult to prepare any dish with their help.

To prepare complex foods, you should choose burners with precise flame control. This is due to the fact that for high-quality cooking of different types of products, different flame strengths are needed. Such devices also boil water very well, however, the boiling time is significantly influenced by the dishes. The quality of flame control is largely determined by the product model.

How the Lemax boiler works and how it works

The location of Lemax's enterprises is the Russian city of Taganrog. The supply of main components for boiler equipment assembled at our own facilities is carried out by both Western and domestic partners. The production of the heat exchanger and housing is mainly carried out by Russian enterprises, while control units, automation and burners come from abroad.

Boilers of this type can be equipped with both open and closed combustion chambers. There are always pressure and temperature regulators on the body of the units. As a rule, you can turn on a Lemax boiler not only from the mains: some models do not depend on electrical energy at all. According to safety regulations, a Lemax device must always be connected to a chimney. Only rooms with good ventilation are suitable for installing the equipment.

A characteristic feature of Taganrog devices is the simplicity of the procedure for lighting a Lemax boiler. Regardless of how many circuits this equipment serves, and what kind of material was used for its manufacture, connecting it to the electrical network usually does not cause any particular difficulties. A prerequisite is the use in the circuit of how to turn on a Lemax gas boiler, a voltage stabilizer (any surge can cause a breakdown of the device).

The Lemax boiler consists of the following components:

- Gas burner.

- valves.

- Control boards.

- Expansion tank.

- Circulation pump.

Connection nuances and verification

Connect the thermoelectric converter to the measuring device using a compensation cable. In order to minimize the measurement error as much as possible, the cores of this wire are made of the same material as the sensor itself.

Check the functionality of the thermocouple as follows:

- one end of the device is connected to a multimeter;

- the other end is manually heated using a lighter or gas torch.

If the device is in good condition, this is indicated by the presence of a voltage in the region of 50 mV.