The most effective way to heat your home is to install a gas boiler. A large number of models on the market can satisfy the needs of all categories of users. Choosing a gas boiler based on its technical parameters will help determine a product that will operate effectively for a long time without failures or extra costs.

Types and design of gas boilers

The device is an installation for creating thermal energy by burning fuel. A gas boiler is the most common type of heat generator, due to the cost-effectiveness of the substance and the reliability of the equipment.

Domestic and foreign industry produces a wide range of installations with very different characteristics.

Gas heating appliances are technological equipment that is made from durable materials. To ensure reliability, diagnostic sensors are provided, as well as a security system that blocks the operation of the boiler if a malfunction is detected.

According to design features, equipment can be divided into several groups.

For installation:

- floor;

- wall-mounted

By number of circuits:

- single-circuit;

- double-circuit.

By burner type:

- atmospheric;

- closed.

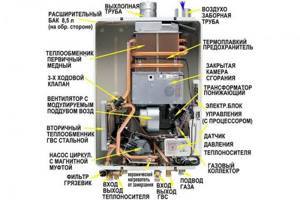

The main structural elements of the boiler are:

- gas burner - fuel releases energy in it;

- heat exchanger - energy heats circulating water;

- flue gas removal system;

- expansion tank - to compensate for fluctuations in coolant volume due to heating;

- complex with a self-diagnosis sensor;

- Control block.

In addition, many models use a circulation pump to pump coolant. Air supply and smoke removal are carried out by a fan.

Principle of operation

Regardless of the type, the functioning scheme of all boilers is the same.

The smooth operation of the equipment is carried out according to the following algorithm:

- The sensor system measures the temperature - if it is below the set value, the thermostat controller opens the gas valve. Fuel enters the combustion chamber.

- Next, the electric or piezo ignition is triggered.

- As a result of the combustion reaction, the water circulating in the heating circuit begins to heat up in the heat exchanger.

- Having reached the temperature set by the thermostat, the automation turns off the burner.

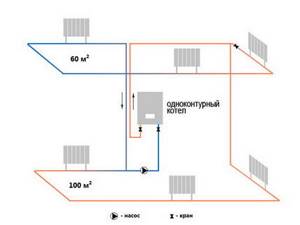

This is how a single-circuit boiler works. To provide the house with not only heating, but also hot water, in addition to such an installation, you can connect an electric boiler or gas water heater.

Double-circuit boilers are capable of not only raising the temperature in the room, but also heating water.

But such installations cannot work simultaneously to generate heat and supply hot water. For a small private house or apartment, stopping the heating circuit for a short time is almost imperceptible.

If we are talking about a room of considerable area, the best solution would be to install equipment for heating and hot water supply, operating independently of each other.

How do such devices work?

All wall-mounted gas boilers can be divided into two large groups - single-circuit and double-circuit. The former are used for the installation of autonomous heating systems, and the latter are purchased if, in addition to heating, it is necessary to provide hot water for technical needs.

All wall-mounted double-circuit boilers are designed quite simply. There are two circuits inside them. The first provides heating radiators with coolant, and the second plays the role of a water supply system. Moreover, the technical characteristics of some models allow the use of the secondary circuit in two operating modes. It can function together with the heating circuit and separately from it. This function is very convenient in the summer, when you need to use hot water without heating the house.

When studying the technical parameters of the device, you must also pay attention to the operating principle of the installation. Some manufacturers produce gas boilers that heat water only after the cold water supply tap is opened. Other manufacturers offer samples operating in boiler mode. In them, water is supplied to a separate tank, and only there is it heated to a certain temperature.

Note! Practice shows that the boiler mode is more economical, but only if there is a large tank available.

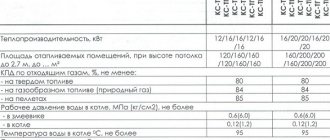

Specifications

Depending on the type of equipment, a different set of parameters is taken into account when selecting a model.

Wall-mounted devices are a ready-made heating system that is easy to install. They are economical, but sensitive to voltage changes in the electrical network. When installing a boiler in a private house, it is wise to install a good voltage stabilizer and an uninterruptible power supply.

When selecting a model for a wall-mounted unit, the most important technical characteristics are:

- installation power - selected based on the area of the room;

- efficiency - fuel consumption depends on the parameter; for most wall-mounted models this indicator changes slightly;

- noise - important when installing equipment in a residential area;

- heat exchanger material - most models are equipped with a copper or steel coil, some use aluminum, which is cheaper but has lower thermal conductivity and corrosion resistance;

- the presence of additional functions - different devices are equipped with their own list of capabilities;

- the material from which the internal parts of the boiler are made - plastic is used in cheap models, brass is used in expensive boilers.

Floor heating devices are difficult to install. Incorrect installation may cause service problems. However, this technique is insensitive to voltage surges, durable, and reliable.

For floor structure equipment, it is worth considering the following characteristics:

- power - it is recommended to take a boiler with a reserve, since in the cold season the indicator decreases;

- heat exchanger material - in stationary models steel or cast iron is used;

- Dimensions - floor units may differ in height and width;

- energy dependence - complex expensive devices are equipped with automation powered by electricity; simple devices do not require a network connection;

- Efficiency - the spread of this parameter for floor-standing installations varies over a wide range.

What is the difference between a floor-standing gas boiler and a wall-mounted one?

In the first case, the units have medium or high power. They differ in greater mass. The power of such a device can exceed 300 kW. The installation is capable of effectively heating residential, domestic and commercial premises of considerable area.

The main design difference between a floor-mounted heating device and a wall-mounted one is the heat exchanger. In the first case, it is larger and more massive. Material: alloy steel or cast iron. The latter has increased fragility, but is resistant to corrosion, has high thermal conductivity, and is durable. At the same time, floor-standing devices can be either completely energy-independent or operate when connected to the mains.

Wall-mounted boilers are equipped with heat exchangers made of steel or copper. The service life of such installations is shorter. They are convenient to use for heating residential premises. They operate quietly, have small dimensions and weight. All wall-mounted units are energy-dependent. For the operation of the pump and fan, which ensure the movement of the coolant, as well as the removal of flue gases, a connection to the electrical network is required.

Useful recommendations for choosing a quality device

Modern heating equipment has a beautiful design with all kinds of sensors and operating modes. However, you should choose not by the appearance of the boiler, but by its functionality. Some tips for choosing the optimal model:

- Material. Must be durable and thermally conductive. It is preferable to choose copper, it is more resistant to corrosion, is lightweight and has better heat transfer characteristics.

The efficiency of the unit depends on the conductivity of heat.

- Energy dependence. All mounted equipment operates on electricity. If it is turned off, the unit stops working. It is recommended to take care of a backup power generator in advance.

Do not forget to take into account such nuances as interruptions and surges in the electrical network.

- To organize individual heating in an apartment, it is better to install a boiler with an air blower and a coaxial pipe for exhaust gas outlet. It has simple installation and high efficiency.

These heating units are considered more practical and less troublesome. Air enters these units from the street using a turbine and a coaxial pipe.

For reference! It is not advisable to install heating equipment with an open chamber in living rooms.

How to choose boiler power

The decisive factor in calculating this equipment indicator is the area of the heated room. There must be at least 1 kW per 10 m². This principle makes it possible to estimate the required power of the installation as a first approximation. Moreover, this calculation is correct for a building with an insulated attic, good thermal insulation, and double-glazed windows. The climatic conditions correspond to central Russia.

More accurate power calculations should include the following parameters:

- room dimensions;

- heat loss of the building;

- temperature fluctuations indoors and outdoors;

- energy consumption for hot water supply;

- insulation of the room.

It is most convenient to select an installation using specialized software.

The calculations must take into account that the actual power of the device may be less due to ventilation.

To compensate for losses, it is recommended to increase the obtained value by 10-20%. When using a boiler for hot water supply, it is advisable to add an additional 20-25%.

Choosing a unit with excess power is undesirable - this leads to higher prices for heating equipment, increased fuel costs, and increased wear and tear on equipment components.

Types of heat exchangers

When choosing heating equipment, the material used plays an important role. The energy efficiency and reliability of the system depend on it.

The efficiency of a device with a copper heat exchanger is higher and the size is smaller, so this metal is used in wall-mounted models.

Cast iron is used for stationary floor-mounted installations of high power. The density of the material makes it unsuitable for use in compact boilers. Cast iron is durable.

The disadvantage of the material is the likelihood of condensation forming on the surface of the heat exchanger when the temperature drops to 60 °C. This can cause erosion of the metal and then lead to microcracks. Copper has no such drawback, so the operation of equipment made from this material does not depend on temperature changes.

Many models of gas boilers are equipped with steel heat exchangers. The material occupies an intermediate position between cast iron and copper. Metal is used in both floor-standing and wall-mounted devices. It is stronger than cast iron, but has lower thermal conductivity than copper. Steel appliances are susceptible to temperature changes, and the material is sensitive to corrosion due to condensation of water vapor.

If your budget allows, it is wise to opt for a model with a copper heat exchanger. However, the material is used mainly in wall-mounted appliances.

Criteria for choosing a mounted boiler

Having decided on the required type of heating device, you can begin to select a specific model. It is worth considering the main criteria.

Device operating power

You can determine the required power of a mounted gas boiler based on the volume of the heated room and the required amount of heated water if you plan to purchase a double-circuit model.

It is very good if all the calculations are carried out by a specialist who can take into account all the heat loss of the building, its volume and many other factors. The calculated power in this case will be as accurate as possible. If this is not possible, the device is selected at the rate of 1 kW of generated power per 10 sq. m area.

Since these are very approximate figures, it is recommended to add 15-20% to the resulting value as a “margin”. It should not be too large, otherwise the boiler will not work efficiently and will quickly fail.

A good choice is equipment with a modulating or at least two-stage burner. They allow you to regulate the power of the device, which makes it possible to significantly save fuel.

Material for the manufacture of heat exchanger

In terms of performance characteristics, the best material for heat exchangers is copper. It is not subject to corrosion, conducts heat well, and is lightweight. Copper components can fail quite quickly when working in powerful boilers, but they serve well in wall-mounted models. Stainless steel is another material from which heat exchangers are made.

A stainless steel heat exchanger is the most popular solution for wall-mounted boilers. It fails quite quickly, but if necessary the unit can be replaced

Such parts are low cost, light weight and have good thermal conductivity. But at the same time they are prone to corrosion and can burn out. As a result, they last relatively short time. Cast iron parts are practically not used in wall-mounted boilers because they weigh so much. It would be a good choice though. Considering the corrosion resistance and durability of the material.

Boiler control system

The most convenient equipment to use with automatic control. Such devices require initial setup, after which they do not require human control. Automation independently monitors all possible changes in the environment and makes adjustments to the functioning of the boiler. It would be very good if the device had an increased degree of protection.

Gas equipment is potentially dangerous, so this will not be unnecessary. Automatic control is only possible for volatile boilers. For devices not connected to electricity, only manual control remains. If this is the case, it is important to understand the boiler operation scheme and determine in which case and what kind of human intervention will be necessary. It's better to check this before purchasing.

To use the boiler as efficiently as possible, it is worth purchasing a model with a modulating burner. It allows you to regulate the power of the heating device

In addition, it is worth paying attention to the method of igniting the boiler. The more common and inexpensive piezo ignition has a significant drawback. Its presence leads to excessive fuel consumption, since the pilot burner must be constantly burning. Electronic ignition is more economical, but depends on the availability of electricity.

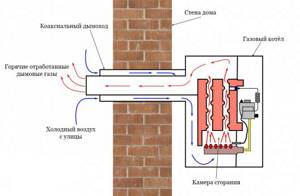

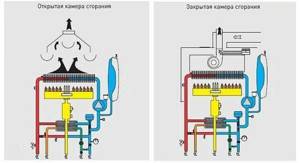

Selection based on combustion chamber

Boilers can be open or closed. The first uses air directly from the room. In this case, it is necessary to install a chimney. Boilers with an open or atmospheric combustion chamber are mainly installed in separate rooms. A similar type is used in floor-standing installations with a power of more than 35 kW.

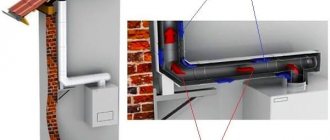

In a closed combustion chamber, a coaxial chimney is used to supply air and remove flue gases. This device consists of two pipes of different diameters, the first is inserted into the second. Air is supplied to the burner through one channel, and the combustion product is discharged through the other. The closed type is used mainly in wall-mounted units.

Types of heating devices

The store variety is a little scary and disorienting. It is difficult to immediately decide on the right model. To make this easier, let’s get acquainted with the main features of devices that determine their performance characteristics.

Gas burner type

Two types of burners can be installed in attachments. The simplest one is the so-called atmospheric one. The principle of its operation is very simple: gas fuel burns inside the unit. This requires air that enters the device from the room where the boiler is located. To ensure a continuous flow of air masses and at the same time get rid of toxic flue gases, it is necessary to install a chimney.

In this case, only a traditional vertical high chimney, correctly designed and correctly installed, can be used. The draft is provided by the temperature difference between the room and the street. As a rule, with proper calculation, it is quite sufficient for normal operation of the boiler. An atmospheric burner has significant advantages.

A boiler with a closed burner is more efficient and economical, but equipment with an atmospheric burner can operate in conditions of lack of electricity

First of all, it does not require electricity to use. The boiler can be operated in the complete absence of power supply, which is very important for places where electricity is not always available. In addition, the cost of boilers equipped with such a burner is significantly lower than their analogues. However, you need to understand that for the safe use of such equipment, you will need to install effective ventilation in the room where it is installed.

It is advisable that such devices be installed in a separate room. A prerequisite for operating the device is the presence of a smoke exhaust. And another minus is the relatively low efficiency.

The presence of a closed burner implies that air is forced into it. For this purpose, an additional system equipped with a pump is installed. It takes outside air and supplies it to the combustion chamber and at the same time removes flue gases.

Such equipment is equipped with a coaxial type chimney. These are compact structures consisting of pipes nested inside each other. Smoke is removed through the inner part, and air is drawn in through the outer part.

This chimney is very effective, takes up little space and is quite easy to install. It can be installed not only vertically, but also horizontally at a slight angle. In the latter case, the passage to the street is made directly in the wall.

A boiler with a closed burner has a higher efficiency, which allows its owner to save fuel

The advantages of closed burners include high efficiency and complete safety during operation. They do not take air from the room, so they can be installed in bathrooms or kitchens. However, they require electricity to operate, otherwise the boiler will simply stop. The cost of devices with closed burners is much higher than that of equipment with atmospheric ones.

Number of device circuits

Mounted boilers can have one or two heating circuits. In the first option, the equipment is equipped with one heat exchanger, which is used only to heat the coolant fluid. Thus, the device is intended exclusively for heating. If hot water supply is also required, additional equipment is installed, which will certainly take up some free space.

The main advantage of single-circuit models is their simplicity of design, which simplifies their installation and operation, as well as greater power compared to double-circuit analogues. The latter have two built-in thermal circuits. In one the coolant is heated, in the second - water for hot water supply. This makes their design more complex and vulnerable. Boilers with a so-called bithermic heat exchanger are produced.

A single-circuit mounted boiler provides only heating of the coolant. The number of radiators it serves is determined by the power of the device

It is divided into two segments, one for coolant, the second for hot water. Thus, a dual-circuit device works with only one heat exchanger. As practice shows, bithermal devices are not reliable enough and are not very convenient to use.

If necessary, it is optimal to purchase a unit with two separate heat exchangers. Double-circuit boilers spend their power not only on heating, but also on hot water supply, so it is somewhat lower.

Such devices are ideal for small apartments or houses. You need to understand that double-circuit equipment is most often not capable of providing a large amount of hot water. If your DHW needs exceed 15 liters per minute, it is worth purchasing a single-circuit model and additional heating equipment.

You should do the same if you have too hard water. In this case, the secondary heat exchanger will very quickly become covered with deposits and fail.

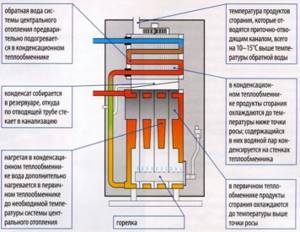

Use of condensate heat

Condensing units appeared on the domestic market not very long ago, while they are used very widely throughout the world. Their distinctive feature is the ability to use heat from water vapor generated during the combustion of a gas mixture. The latter is collected in the form of condensate in an additional heat exchanger. Here it gives off its heat to the coolant liquid.

A condensing type gas boiler has an efficiency of more than 100% due to the use of heat obtained from exhaust flue gases

In this way, it is possible to obtain additional thermal energy, which makes the use of a condensing boiler as efficient as possible. According to experts, the efficiency of such devices is above 100%, which may seem fantastic. However, this is reality. The device gains an additional 9-11% efficiency by using the heat of the exhaust flue gases. The average efficiency of such boilers reaches 105-111%.

The advantages of condensing equipment include economical fuel consumption. Compared to traditional convection appliances, it is about a third smaller. The gases discharged from the boiler have a low temperature, which makes it possible to install cheaper and easier-to-install plastic chimneys. The amount of toxic emissions from a condensing boiler is minimal, and the noise level during operation is also low.

The disadvantages of such equipment include a small temperature difference between return and supply. For traditional convection devices it averages 55° to 75°, for condensing devices it is 35° to 55°. Thus, to warm the room, you will need to install additional radiators or install a heated floor system. In addition, the condensate formed in the boiler must be disposed of.

Externally, condensing boilers do not differ from their convection counterparts. They are only slightly larger due to the fact that an additional heat exchanger is installed in the housing

This is quite problematic because it contains acid. It is unacceptable for it to end up, for example, in a septic tank. It is advisable to install a special system to collect condensate. However, for low-power boilers located in houses with centralized sewerage, this is not necessary.

Another significant disadvantage of condensing equipment is its high cost. Compared to traditional analogues, it is 20-35% higher.

Rating of the best gas boiler manufacturers

The reliability and stability of heating a private house or apartment depends on the operation of thermal equipment. Saving in its selection is impractical.

Among manufacturers producing boilers, the following brands are popular with consumers:

- Buderus is a company of German origin that produces reliable wall and floor models. There are devices with cast iron heat exchangers. The product line includes devices with open and closed burner.

- Navien is a Korean manufacturer with official representative offices in Russia, the USA and other countries. The products are famous for their unpretentiousness, low noise level, and reliability in operation. Navien boilers are distinguished by their low gas pressure requirements.

- Bosch - a company from Germany is famous for the reliability of its equipment. The manufacturer produces a full range of gas equipment for domestic use. The boilers are distinguished by increased operational safety and convenient control.

- Vaillant is a German brand popular in the gas equipment market. The company produces boilers with a closed and open combustion chamber with a power from 4 to 240 kW. The products are equipped with a reliable safety system, including protection against freezing, overheating and pump blocking. There is a wide network of service centers throughout Russia.

- Viessmann is a manufacturer that produces reliable heating and water heating equipment. The line of gas boilers includes single- and double-circuit models for floor and wall installation. The devices are environmentally friendly and have low noise levels. There is built-in protection against power surges. Many models can use both natural and liquefied gas as fuel.

- Ariston is an Italian brand, along with household appliances, offering gas equipment for heating and hot water supply. The boilers are famous for their high efficiency and low energy consumption. The devices are equipped with pump stop protection, flame modulation, and a semi-automatic ignition system. Thanks to the stylish design, the equipment looks good in the interior.

- Baxi is a company from Italy that produces water heating and heating equipment. The product line includes convection and condensing boilers of different capacities and designs. They are equipped with a good system for ensuring safe operation. There is a flame modulation mode that helps reduce fuel consumption. Built-in automation responds to changing weather conditions.

- Lemax is a Russian brand that produces reliable, inexpensive installations using components from foreign manufacturers. Models available for floor and wall installation. The devices are adapted for Russian conditions: they can be operated at low gas pressure, and the voltage range has been expanded. Composite materials are used in manufacturing. A wide network of service centers allows you to quickly resolve any problems that arise.

- ZhMZ - products of the Zhukovsky Machine-Building Plant are popular in the budget segment of the market. The devices have a full range of basic functions and are well adapted to work in Russian conditions. There is gas pressure control, non-volatile ignition, and overheating protection. German-made automation is used. The devices are designed to operate on natural and liquefied gas.

- Neva is a Russian company from St. Petersburg that produces heating equipment of several modifications. Boilers with one and two circuits are available. The copper heat exchanger is highly efficient and resistant to temperature changes. The safety system includes protection against freezing, overheating, and pump blocking. The auto-diagnosis function allows you to quickly identify malfunctions in the installation.

By choosing a boiler manufactured by one of the manufacturers listed above, you can be sure of its long-term reliable operation.